Intelligent preparation method for vermicular graphite cast iron brake drum

A technology of intelligent preparation and vermicular graphite cast iron, which is applied in casting molding equipment, casting molds, casting mold components, etc., can solve the problems of large volume of brake drums, low efficiency, and difficulty in grinding, and achieves good electromagnetic stirring effect. It is convenient to change the steel grade and reduce the life of the crucible

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

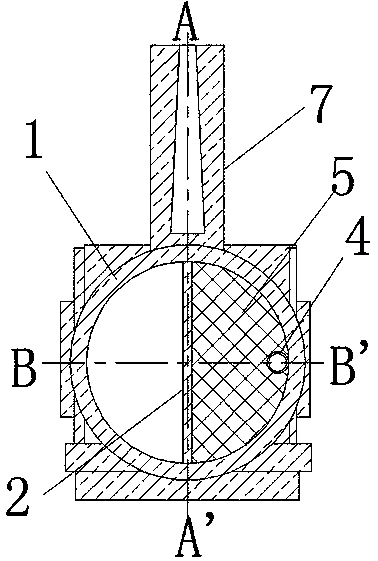

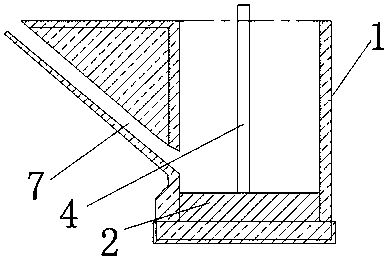

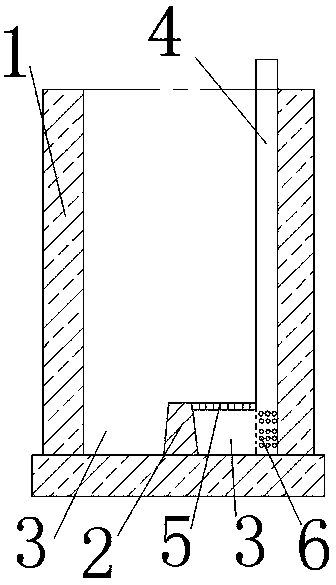

Image

Examples

Embodiment 1

[0051] Example 1. An intelligent preparation method for a vermicular graphite cast iron brake drum, comprising the steps of:

[0052] Step 1: Prepare 30kg of steel scrap and 50kg of recycled material for every 100kg of pig iron according to the weight ratio, and put part of the pig iron, all of the scrap steel, and all of the recycled material into a low-frequency induction furnace for melting.

[0053] Step 2: Add carburant, control the amount of carburant added, so that the carbon content of the solution is: 3.6%; wherein the carbon equivalent needs to be kept at 4.07%, and the carbon equivalent=mass percentage of carbon+(mass percentage of silicon / 3); remove the slag, spare.

[0054] Step 3: Lay a layer of ferrosilicon on the bottom of the intermediate frequency induction furnace to form a ferrosilicon layer, then add some pig iron to form a pig iron layer, raise the temperature, add a part of electrolytic copper and ferromanganese before the added ferrosilicon and pig ir...

Embodiment 2

[0068] Example 2. The difference between this embodiment and Embodiment 1 is that an intelligent preparation method of a vermicular graphite cast iron brake drum includes the following steps:

[0069] Step 1: Prepare 25kg of steel scrap and 45kg of recycled material for every 100kg of pig iron according to the weight ratio, and put part of the pig iron, all of the scrap steel, and all of the recycled material into a low-frequency induction furnace to melt.

[0070] Step 2: add carburant, control the amount of carburant added, so that the carbon content of the solution is: 3.7%; wherein the carbon equivalent needs to be kept at 4.2%, and the carbon equivalent=mass percentage of carbon+(mass percentage of silicon / 3); remove the slag, spare.

[0071] Step 3: Lay a layer of ferrosilicon on the bottom of the intermediate frequency induction furnace to form a ferrosilicon layer, then add some pig iron to form a pig iron layer, raise the temperature, add a part of electrolytic copp...

Embodiment 3

[0087] Example 3. The difference between this embodiment and Embodiment 1 is that an intelligent preparation method of a vermicular graphite cast iron brake drum comprises the following steps:

[0088] Step 1: Prepare 25kg of steel scrap and 40kg of recycled materials for every 100kg of pig iron according to the weight ratio, and put part of the pig iron, all of the scrap steel, and all of the recycled materials into a low-frequency induction furnace for melting.

[0089] Step 2: Add carburant, control the amount of carburant added, so that the carbon content of the solution is: 3.71%; wherein the carbon equivalent needs to be kept at 4.28%, and the carbon equivalent=mass percentage of carbon+(mass percentage of silicon / 3); remove the slag, spare.

[0090] Step 3: Lay a layer of ferrosilicon on the bottom of the intermediate frequency induction furnace to form a ferrosilicon layer, then add some pig iron to form a pig iron layer, raise the temperature, add a part of electrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com