355MPa thick steel plate with low-temperature toughness and preparation method thereof

A low-temperature toughness, thick steel plate technology, applied in the field of steel material production, can solve the problems of prolonging the production cycle and improving, and achieve the effects of reducing the rolling temperature, optimizing the cooling process, and high-toughness welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The 355MPa grade low temperature toughness thick steel plate is composed of the following components by weight percentage: C: 0.09%, Si: 0.22%,

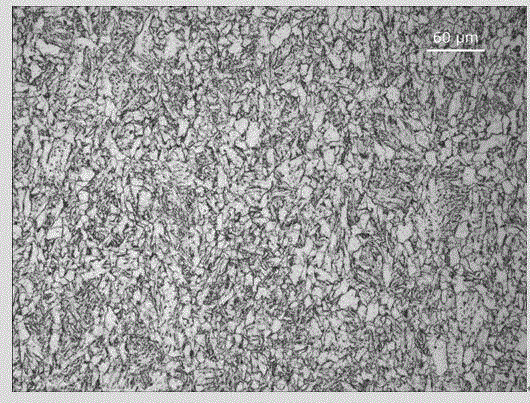

[0021] Mn: 1.47%, P0.012%, S0.003%, Nb: 0.041%, V: 0.042%, Ti: 0.016%, the balance Fe and unavoidable impurities. The final structure of the thick steel plate is characterized by quasi-polygonal ferrite and a small amount of pearlite.

[0022] The thickness of the steel plate is 55mm.

[0023] The preparation method of the 355MPa grade low temperature toughness thick steel plate comprises the following steps:

[0024] (1) Smelting process: Top-bottom combined blowing converter smelting, molten iron desulfurization ≤ 0.003%; strictly control the P content of molten iron, use high-quality scrap steel, LF refining adopts white slag operation, the chemical composition of molten steel is controlled according to the target value, ferro-titanium in LF Join later. RH refining pure degassing time ≥ 6 minutes; soft blowing after 250R...

Embodiment 2

[0028] The 355MPa low temperature toughness thick steel plate is composed of the following components by weight percentage: C: 0.10%, Si: 0.34%,

[0029] Mn: 1.42%, P0.013%, S0.002%, Nb0.031%, V: 0.039%, Ti: 0.013%, the balance Fe and unavoidable impurities. The final structure of the thick steel plate is characterized by quasi-polygonal ferrite and a small amount of pearlite.

[0030] The thickness of the steel plate is 40mm.

[0031] The preparation method of the 355MPa grade low temperature toughness thick steel plate comprises the following steps:

[0032] (1) Smelting process: Top-bottom combined blowing converter smelting, molten iron desulfurization ≤ 0.003%; strictly control the P content of molten iron, use high-quality scrap steel, LF refining adopts white slag operation, the chemical composition of molten steel is controlled according to the target value, ferro-titanium in LF Join later. RH refining pure degassing time ≥ 6 minutes; soft blowing after 250RH degass...

Embodiment 3

[0036] The 355MPa low temperature toughness thick steel plate is composed of the following components by weight percentage: C: 0.08%, Si: 0.41%,

[0037] Mn: 1.49%, P0.014%, S0.003%, Nb0.043%, V: 0.041%, Ti: 0.014%, the balance Fe and unavoidable impurities. The final structure of the thick steel plate is characterized by quasi-polygonal ferrite and a small amount of pearlite.

[0038] The thickness of the steel plate is 60mm.

[0039] The preparation method of the 355MPa grade low temperature toughness thick steel plate comprises the following steps:

[0040] (1) Smelting process: Top-bottom combined blowing converter smelting, molten iron desulfurization ≤ 0.003%; strictly control the P content of molten iron, use high-quality scrap steel, LF refining adopts white slag operation, the chemical composition of molten steel is controlled according to the target value, ferro-titanium in LF Join later. RH refining pure degassing time ≥ 6 minutes; soft blowing after 250RH degass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com