Patents

Literature

74results about How to "Little increase in cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enamel steel for cold rolling water heater and manufacturing method thereof

InactiveCN101684532AGood explosivenessGood formabilityTemperature control deviceMetal rolling arrangementsEconomic benefitsSurface roughness

The invention discloses enamel steel for a cold rolling water heater and a manufacturing process thereof. The enamel steel for cold rolling water heater comprises components as follows in percentage by weight: C: 0.01%-0.08%. Si: less than or equal to 0.03%, Mn: 0.10%-0.60%, P: less than or equal to 0.02%, S: 0.003%-0.02%, N: 0.001%-0.006%, AIs: less than or equal to 0.04%, Ti: 0.02%-0.12%, and the balance of ferrum and unavoidable impurities, wherein excess Ti content in steel is equal to Ti-(4*C+3.43*N=1.5S) which is less than or equal to 0. The manufacturing process is characterized in that the heating temperature of billet steel is 1160-1300 DEG C; the hot rolling finish rolling temperature is 850-950 DEG C; the coiling temperature of steel plates is 660-760 DEG C; the cold rolling draft is 60%-80%; the annealing temperature is 760-880 DEG C; the temperature preservation time is 60-200s; rapid cooling speed rate is 15-45 DEG C / s, planishing elongation is 0.7%-1.8%; and surface roughness is 0.7-1.9 micrometres. The invention has the advantages of excellent formability, enamel-spreadable property, pressing resistance, weldability and fish-scaling resistance, stable yield strength after enamelfiring, less cost increase, stable effect and significant economic benefits.

Owner:ANGANG STEEL CO LTD

Heat-resistant stainless steel with high-lasting strength and manufacturing method thereof

ActiveCN101705437ASimple structureMeet the requirements of the use environmentTemperature control deviceFurnace typesPower stationSuperheater

The invention discloses a heat-resistant stainless steel with high-lasting strength and a manufacturing method thereof. The heat-resistant stainless steel includes the following components by percentage: 24.00-26.00 of Cr, 17.00-23.00 of Ni, 0.05-0.75 of Si, 0.15-2.00 of Mn, less than or equal to 0.030 of P, less than or equal to 0.030 of S, 0.04-0.10 of C, 0.15-0.35 of N, 0.01-5.00 of RE, and 0.20-0.60 of M, wherein M is Nb and Ta. The manufacturing method comprises the following steps: 1. smelting: smelting molten steel in accordance with component requirements of the stainless steel; 2. pouring billet steel; 3. hot-rolling the billet steel: a. heating, the temperature of a uniform temperature section in a furnace is at the temperature of 1130 DEG C plus or minus 50 DEG C, and the soaking time is 80 minutes plus or minus 10 minutes; and b. rolling or forging, the initial rolling / initial forging temperature is at the temperature of 1100 DEG C plus or minus 50 DEG C, and the finishing rolling / finishing forging temperature is at the temperature of 860 DEG C plus or minus 50 DEG C; and 4. heat treatment, the solid solution temperature is at the temperature of 1175 DEG C plus or minus 75 DEG C, and water quenching after heat preservation. Through deduction by tests after sampling the stainless steel manufactured by the method, manufactured seamless tubes can satisfy the use requirements of superheaters and reheaters of ultra-supercritical power station boilers.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

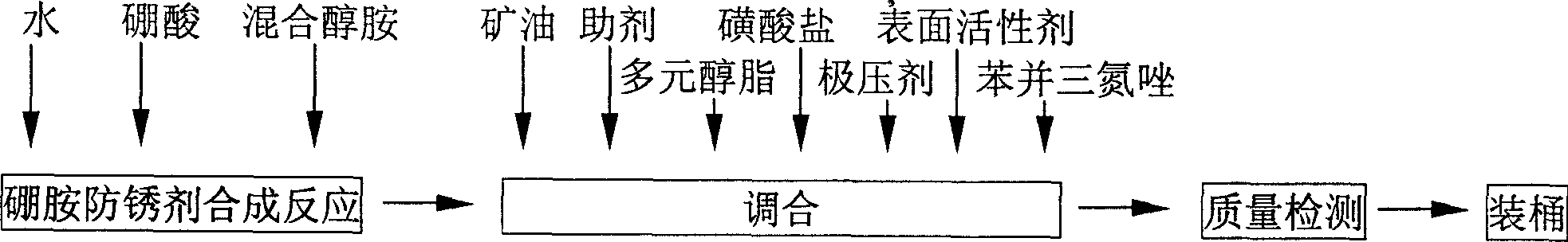

Extreme pressure cutting fuild microemulsion free of chlorine and its preparation method and uses

InactiveCN1730634AReduce emulsificationExtended service lifeLubricant compositionActive agentSurface-active agents

The invention provides a fluoro-free extreme-pressure microemulsion cutting liquid, whose constituents by weight percentage include water 20-40, mixed alkylolamide 6-12, boracic acid 2-6, sulfonates rust-preventing agent 8-12, auxiliary agent 1-5%, anionic surface active agent 8-12, polybasic alcohol 2-6, sulfurized grease 4-10, mineral oil 15-30, benzotrizaole 0.1-0.3. The invention also provides a process for preparing the liquid.

Owner:GUANGZHOU MECHANICAL ENG RES INST

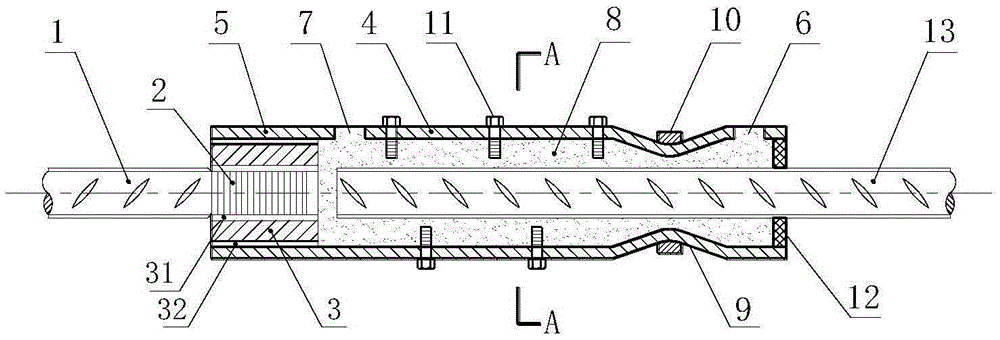

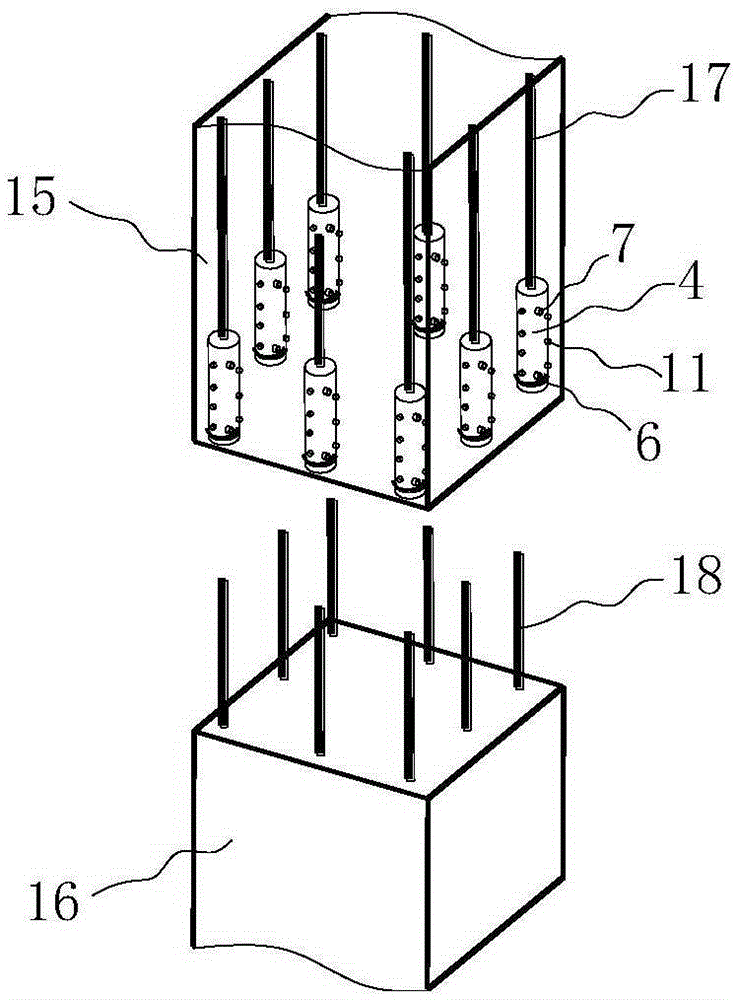

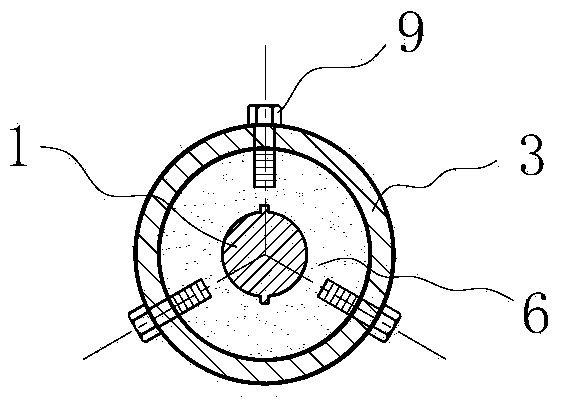

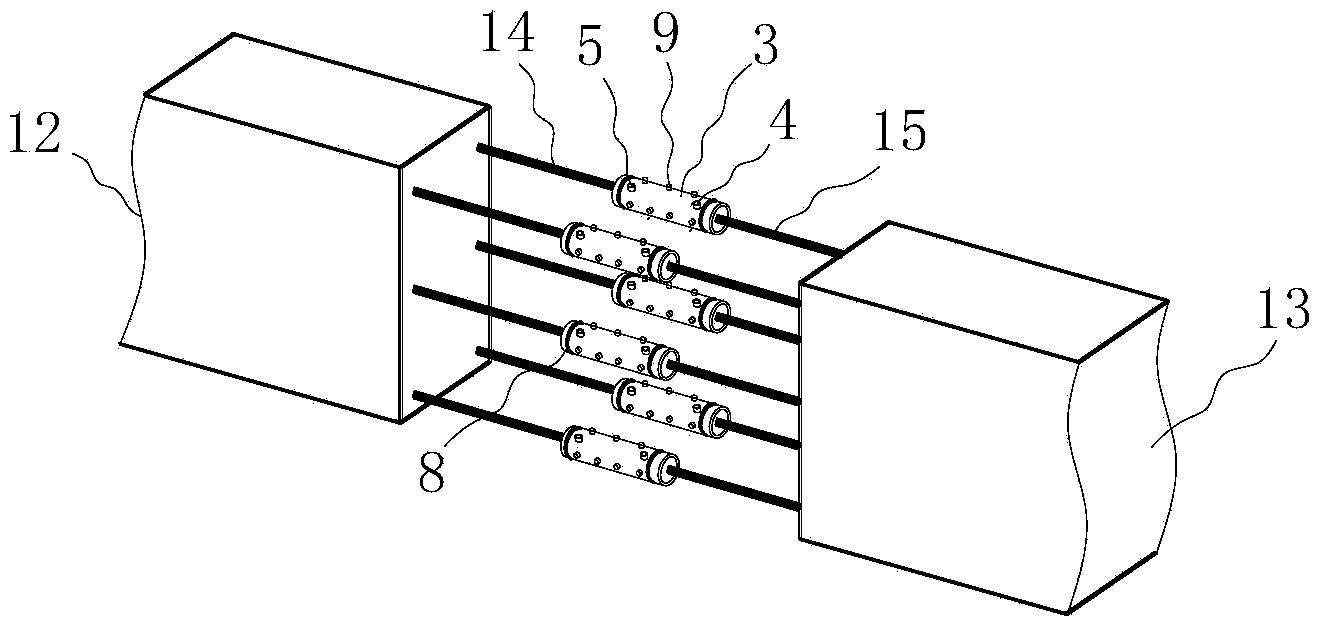

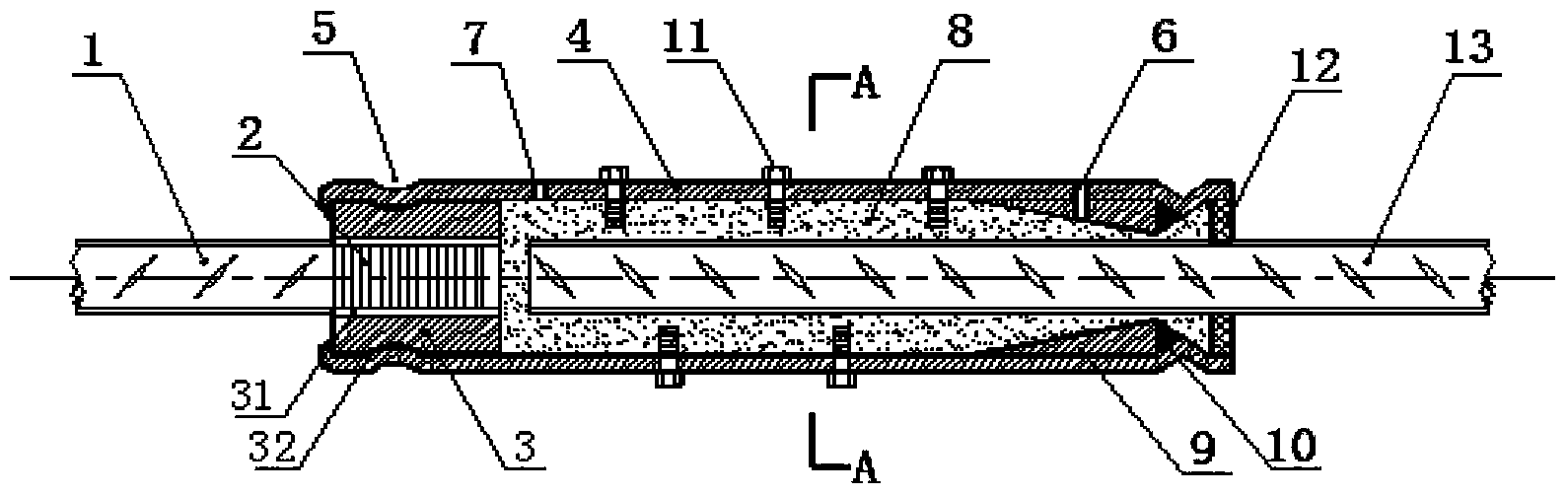

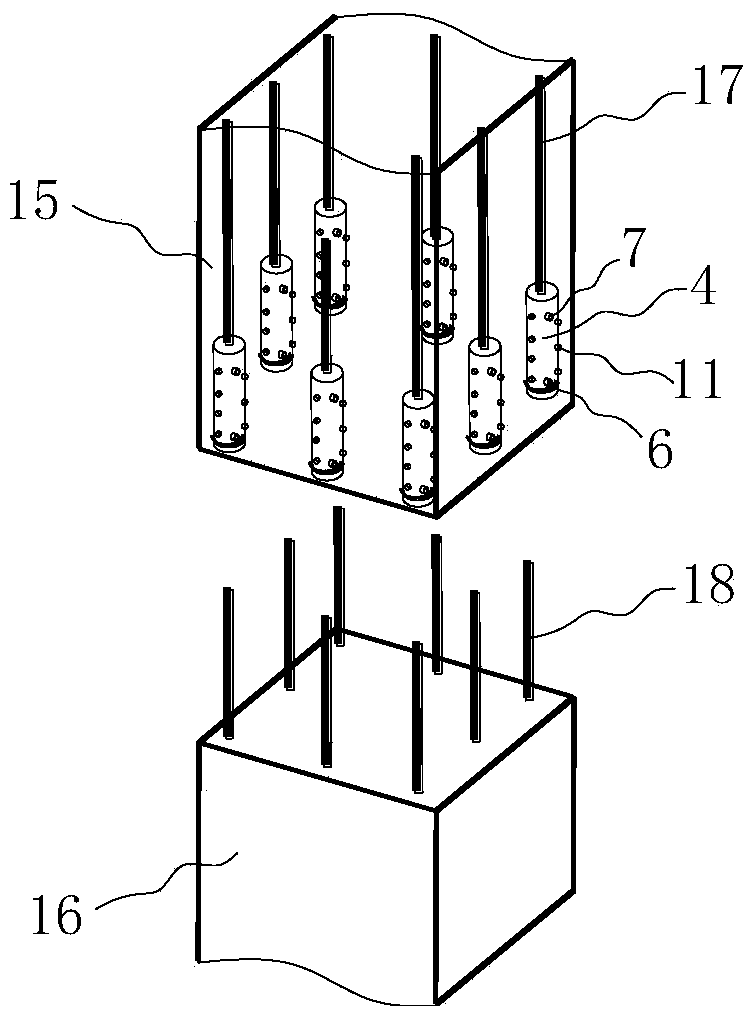

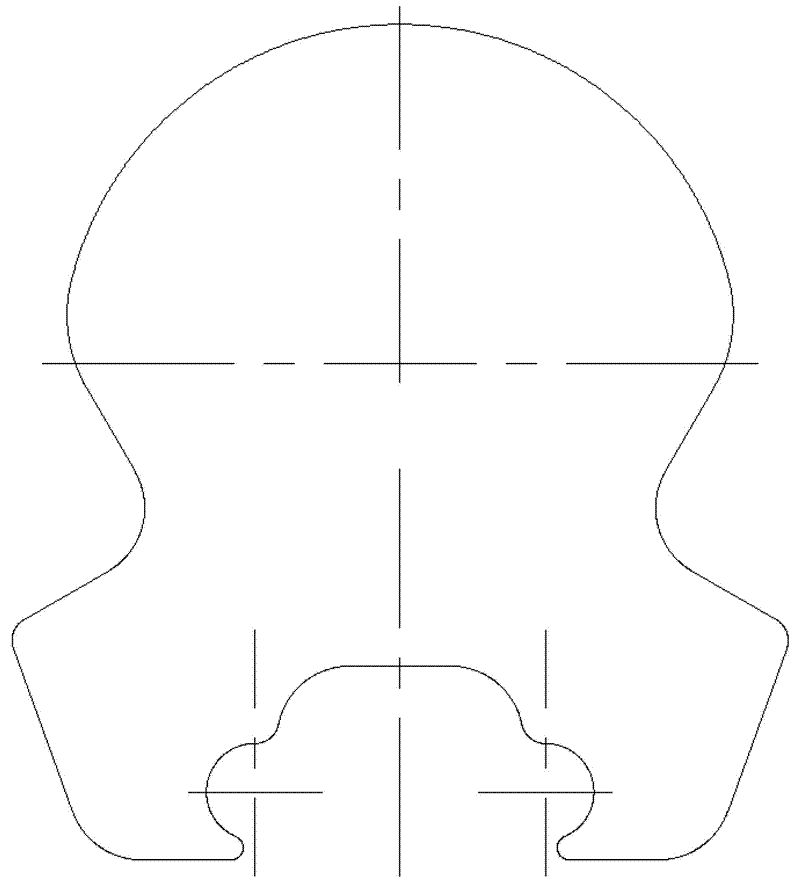

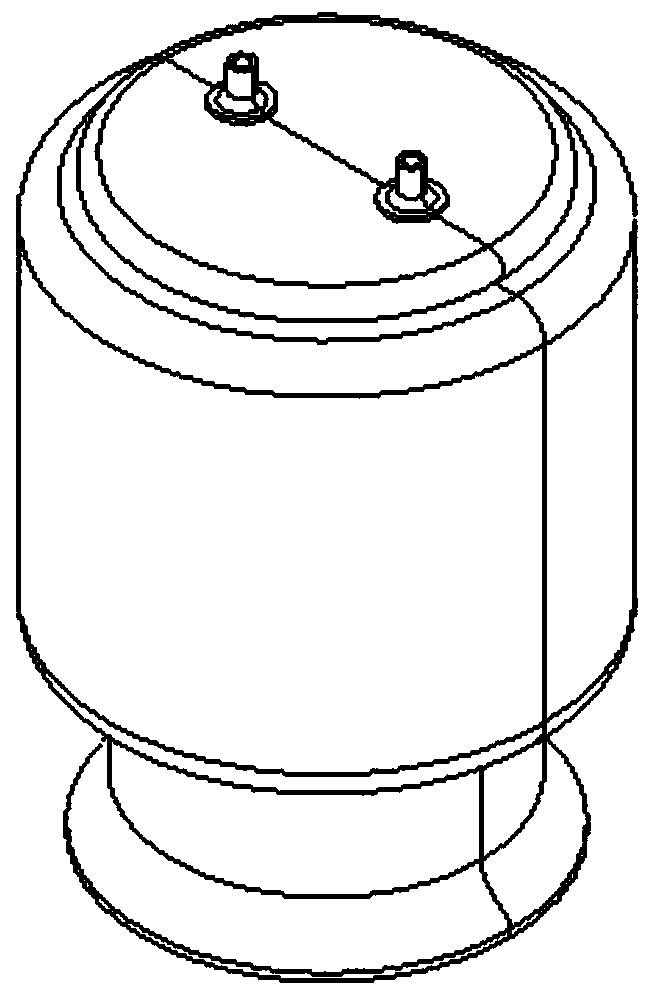

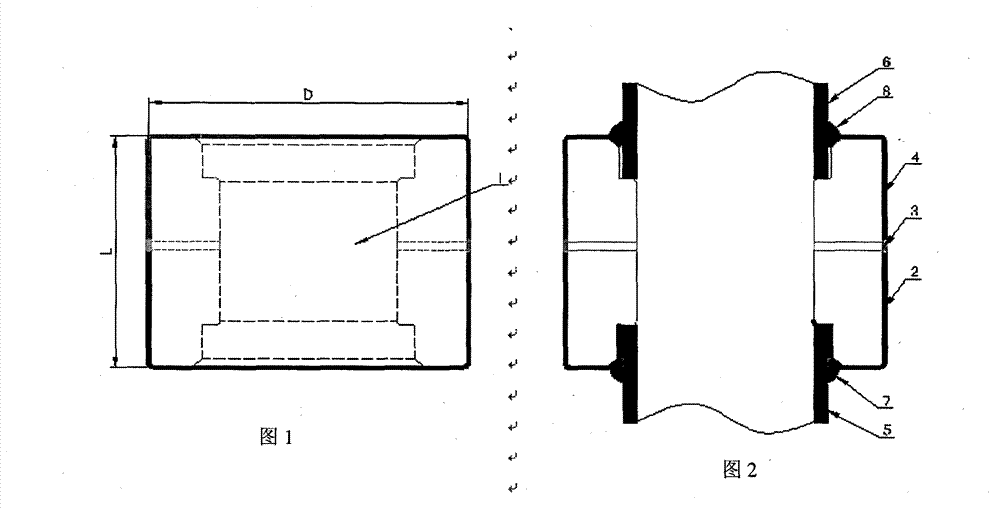

A Shear Enhanced Semi-grouting Sleeve

ActiveCN103758291BReduce manufacturing costWide variety of sourcesBuilding reinforcementsMechanical millingEngineering

The invention discloses a shearing reinforcing type semi-grouting sleeve which comprises a sleeve body, wherein the sleeve body is of a tubular structure; an elastic rubber sealing ring is arranged at the opening of one end of the sleeve body; a threaded connecting piece is arranged at the opening of the other end of the sleeve body; a grouting hole and a discharge hole are formed in side walls close to the end parts of the sleeve body; bolt holes are formed in the side wall along the sleeve body; anti-shearing bolts are arranged inside the bolt holes. The shearing reinforcing type semi-grouting sleeve has the advantages of wide material resource, simplicity in machining and manufacturing, reliability in property and the like, can greatly overcome the defects that the conventional cast iron or cast iron steel sleeve is complex to manufacture and high in cost, a mechanical milling sleeve is labor and time waste, and the like, can be widely applied to assembled type concrete structures, and has wide engineering application prospects.

Owner:SOUTHEAST UNIV

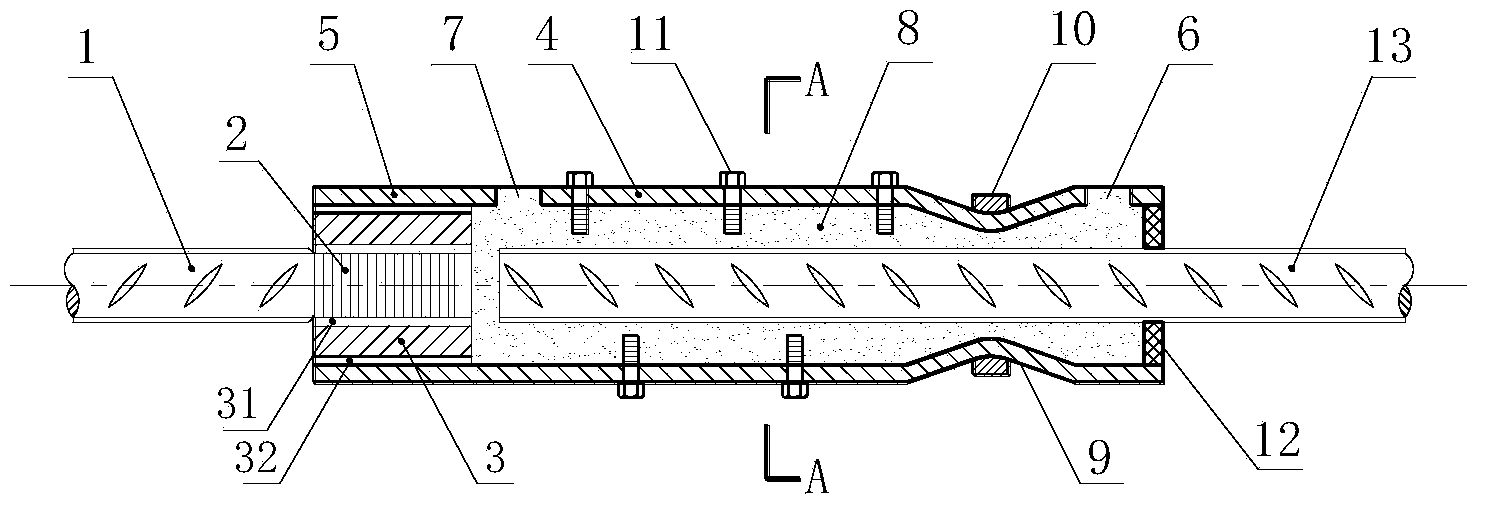

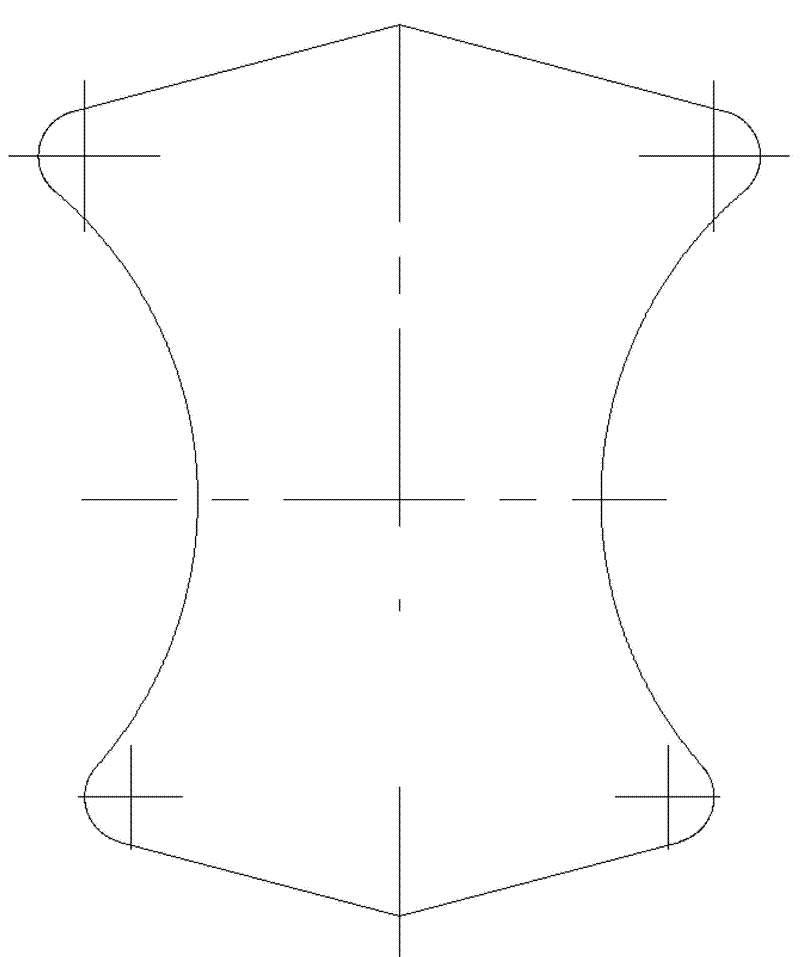

Shearing reinforcing type full-grouting sleeve

ActiveCN103758292AReduce manufacturing costWide variety of sourcesBuilding reinforcementsMechanical millingEngineering

The invention discloses a shearing reinforcing type full-grouting sleeve which comprises a sleeve body, wherein the sleeve body is of a tubular structure; elastic rubber sealing rings are arranged at the openings of two ends of the sleeve body; a grouting hole is formed in the side wall close to the opening of one end; a discharge hole is formed in the side wall close to the opening of the other end; bolt holes are formed in the side wall along the sleeve body; anti-shearing bolts are arranged inside the bolt holes. The shearing reinforcing type full-grouting sleeve is wide in material resource, simple to machine and manufacture and reliable in property, greatly overcomes the defects that the conventional cast iron or cast iron steel sleeve is complex to manufacture and high in cost, a mechanical milling sleeve is labor and time waste, and the like, can be widely applied to assembled type concrete structures, and has wide engineering application prospects.

Owner:SOUTHEAST UNIV

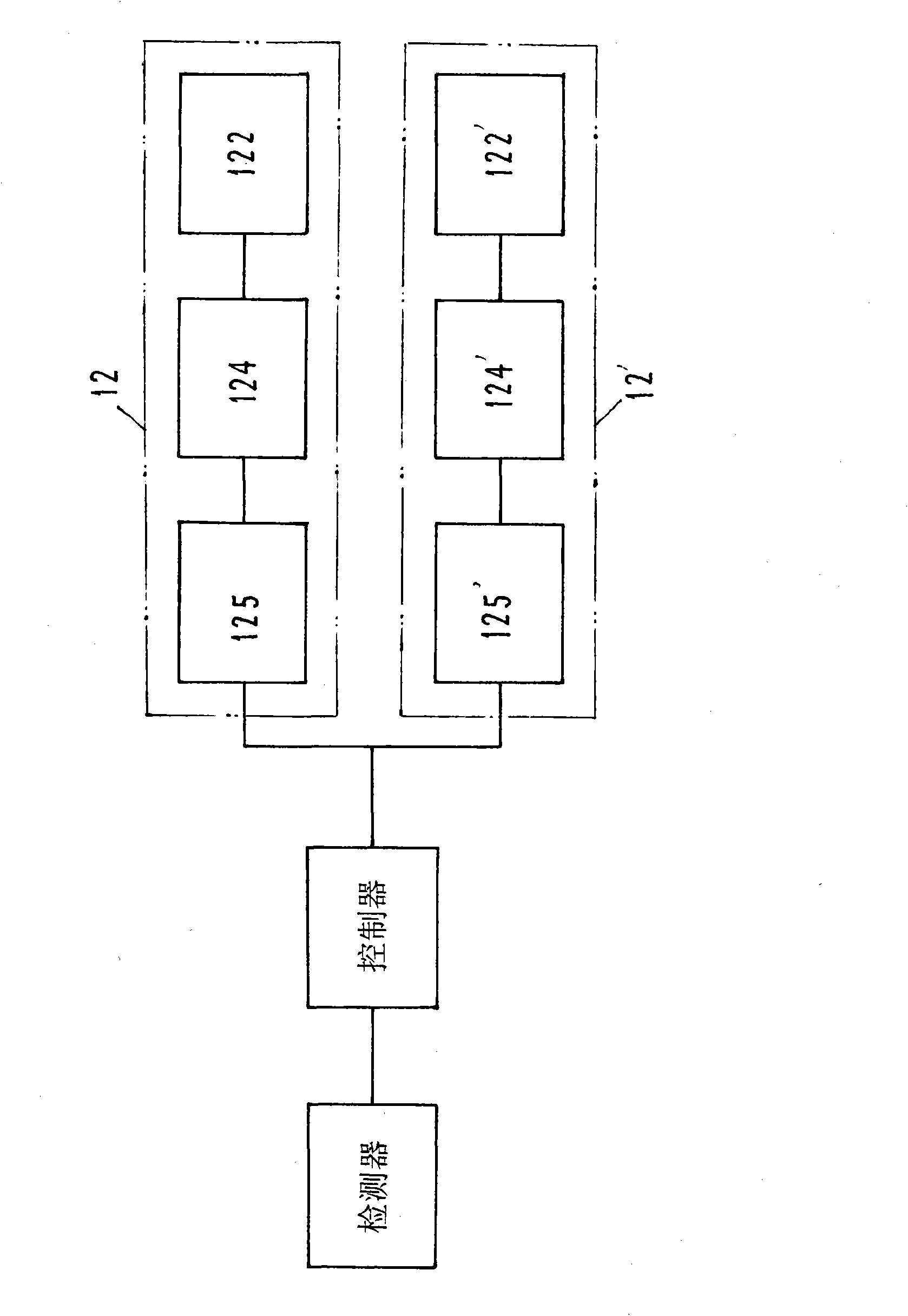

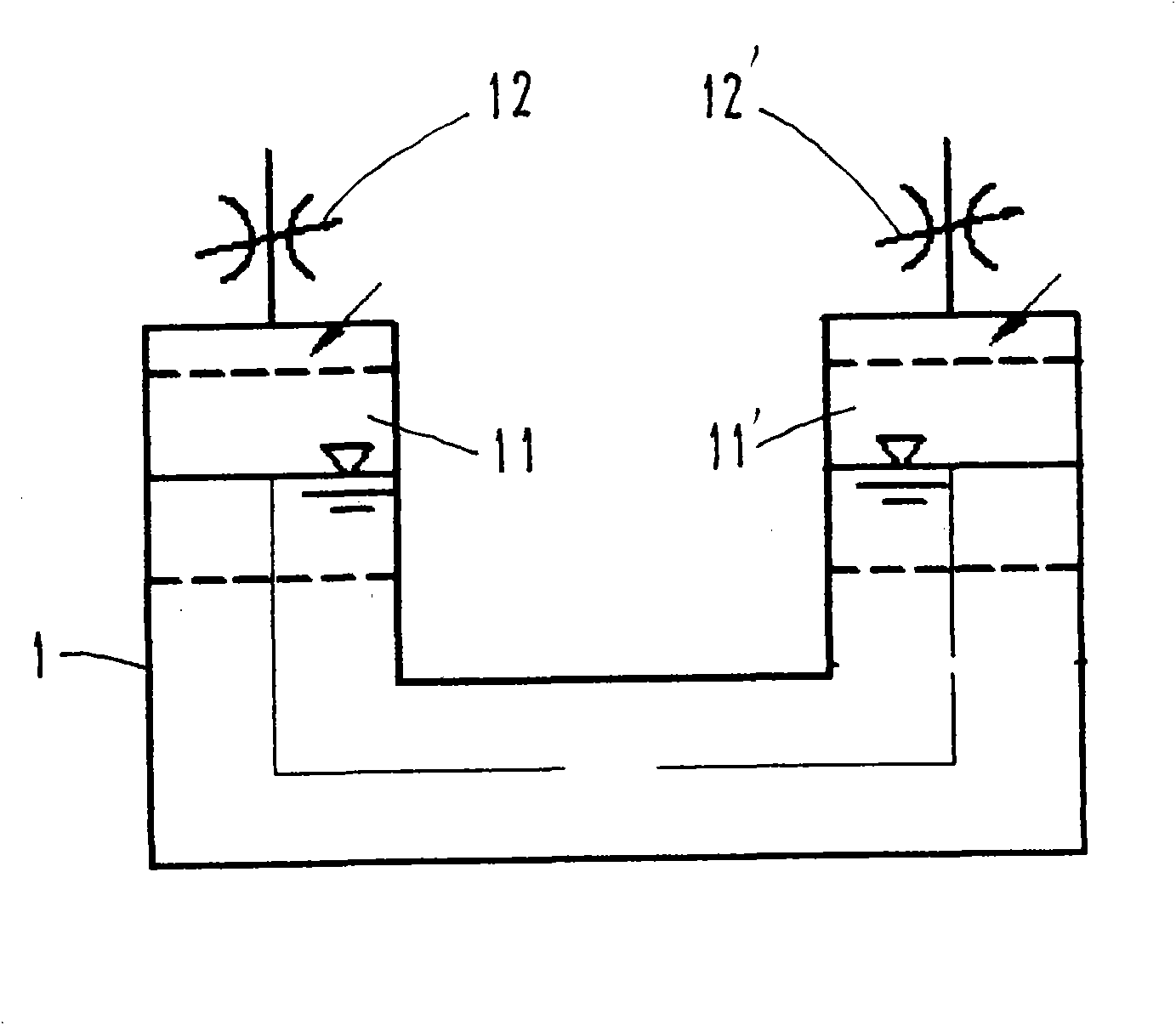

Tank stabilizer control device

ActiveCN101624087AImprove sailing performanceIncrease the effective cross-sectional areaVessel movement reduction by mass displacementEngineeringWater level

The invention discloses a tank stabilizer control device, which mainly solves the technical problems of improving the pitch damping effects of ships and the like, and adopts the technical scheme that: a left throttling passage and a right throttling passage are arranged at the top parts of a larboard air chamber and a starboard air chamber of a U-shaped tank stabilizer, throttling components are arranged on the two passages, the two components are connected with a controller which is connected with a detector, detected ship swinging period signals are input to the controller, control signals are output to the two throttling components according to set rules, and the throttling components adjust effective sectional areas of the two throttling passages so as to realize the water level alternation period of the U-shaped tank stabilizer the same as the ship swinging period. The tank stabilizer control device is applied to various U-shaped tank stabilizers.

Owner:SHANGHAI HUNTER MARINE EQUIP CO LTD

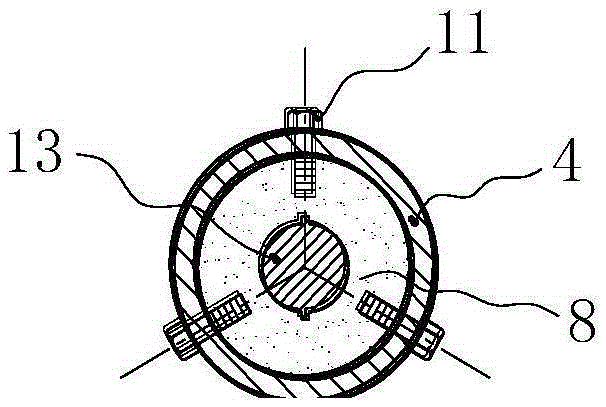

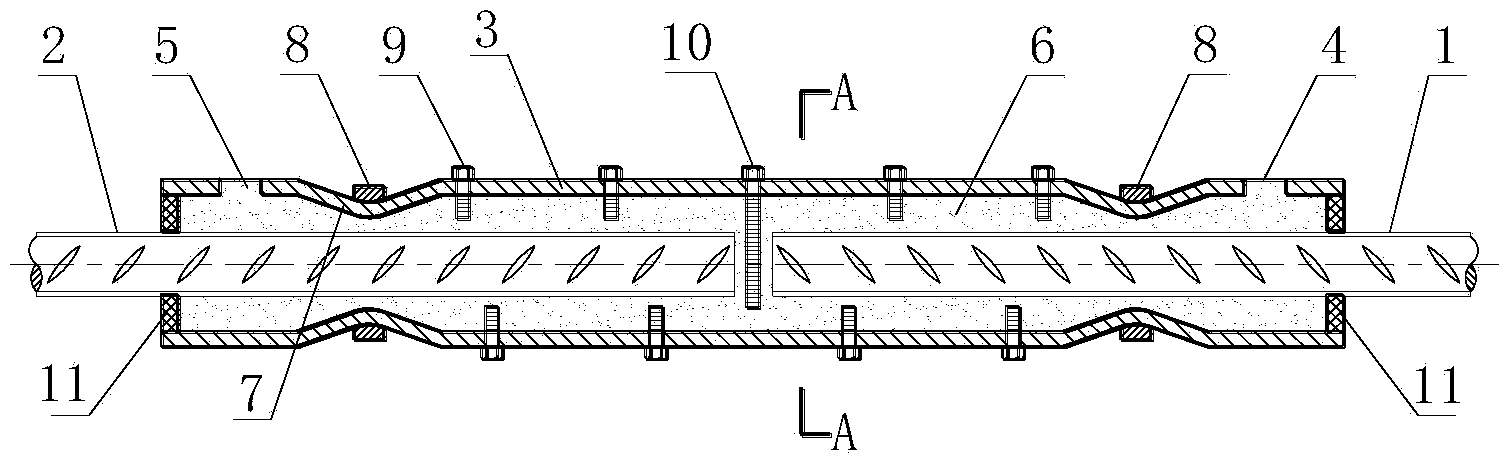

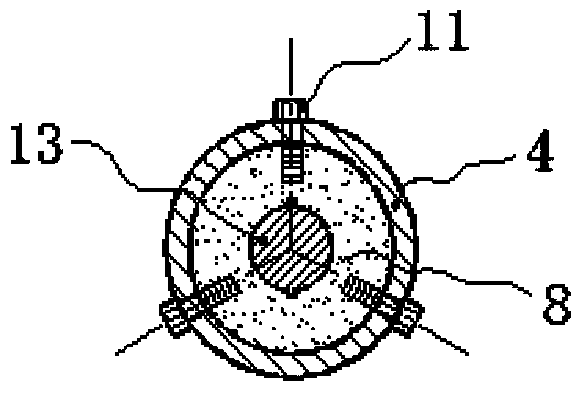

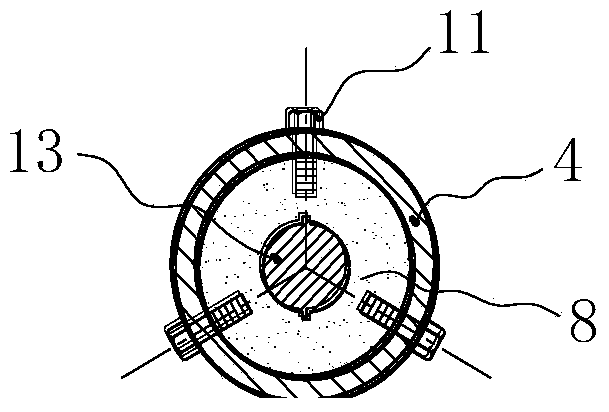

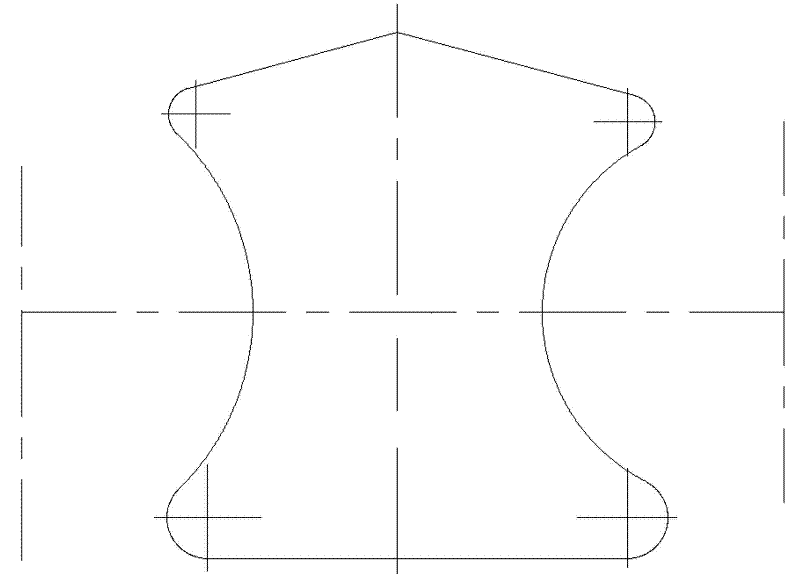

Half-grouting sleeve embedded with cone

ActiveCN103899043AReduce manufacturing costWide variety of sourcesBuilding reinforcementsRebarMechanical engineering

The invention discloses a half-grouting sleeve embedded with a cone. The half-grouting sleeve comprises a connecting piece (3), a sleeve body (4), a grouting port (6), a grout outlet (7), a cone (9), a shearing bolt (11) and an elastic rubber sealing ring (12), wherein the connecting piece (3) is arranged at one end in the sleeve body (4), and the elastic rubber sealing ring (12) is arranged at the other end of the sleeve body (4); the cone (9) is embedded at one end, which is provided with the elastic rubber sealing ring (12), of the sleeve body (4); the grouting port (6) and the grout outlet (7) are formed in an outer wall on the side face of the sleeve body (4); the shearing bolt (11) is arranged on a middle part of the sleeve body (4); one end of a fixing side thread steel bar (1) is connected with the connecting piece (3); one end of an insertion side thread steel bar (13) penetrates through the elastic rubber sealing ring (12); the cone (9) is positioned in the sleeve body (4). The half-grouting sleeve has the advantages of simplicity in manufacturing, low cost and the like, is particularly applied to connection of longitudinal steel bars of beams, posts and shear wall members, can be widely applied to an assembled concrete structure and has wide engineering application prospects.

Owner:SOUTHEAST UNIV

Shearing reinforcing type semi-grouting sleeve

ActiveCN103758291AExtensive sources of materialsEasy to processBuilding reinforcementsMechanical millingMaterial resources

The invention discloses a shearing reinforcing type semi-grouting sleeve which comprises a sleeve body, wherein the sleeve body is of a tubular structure; an elastic rubber sealing ring is arranged at the opening of one end of the sleeve body; a threaded connecting piece is arranged at the opening of the other end of the sleeve body; a grouting hole and a discharge hole are formed in side walls close to the end parts of the sleeve body; bolt holes are formed in the side wall along the sleeve body; anti-shearing bolts are arranged inside the bolt holes. The shearing reinforcing type semi-grouting sleeve has the advantages of wide material resource, simplicity in machining and manufacturing, reliability in property and the like, can greatly overcome the defects that the conventional cast iron or cast iron steel sleeve is complex to manufacture and high in cost, a mechanical milling sleeve is labor and time waste, and the like, can be widely applied to assembled type concrete structures, and has wide engineering application prospects.

Owner:SOUTHEAST UNIV

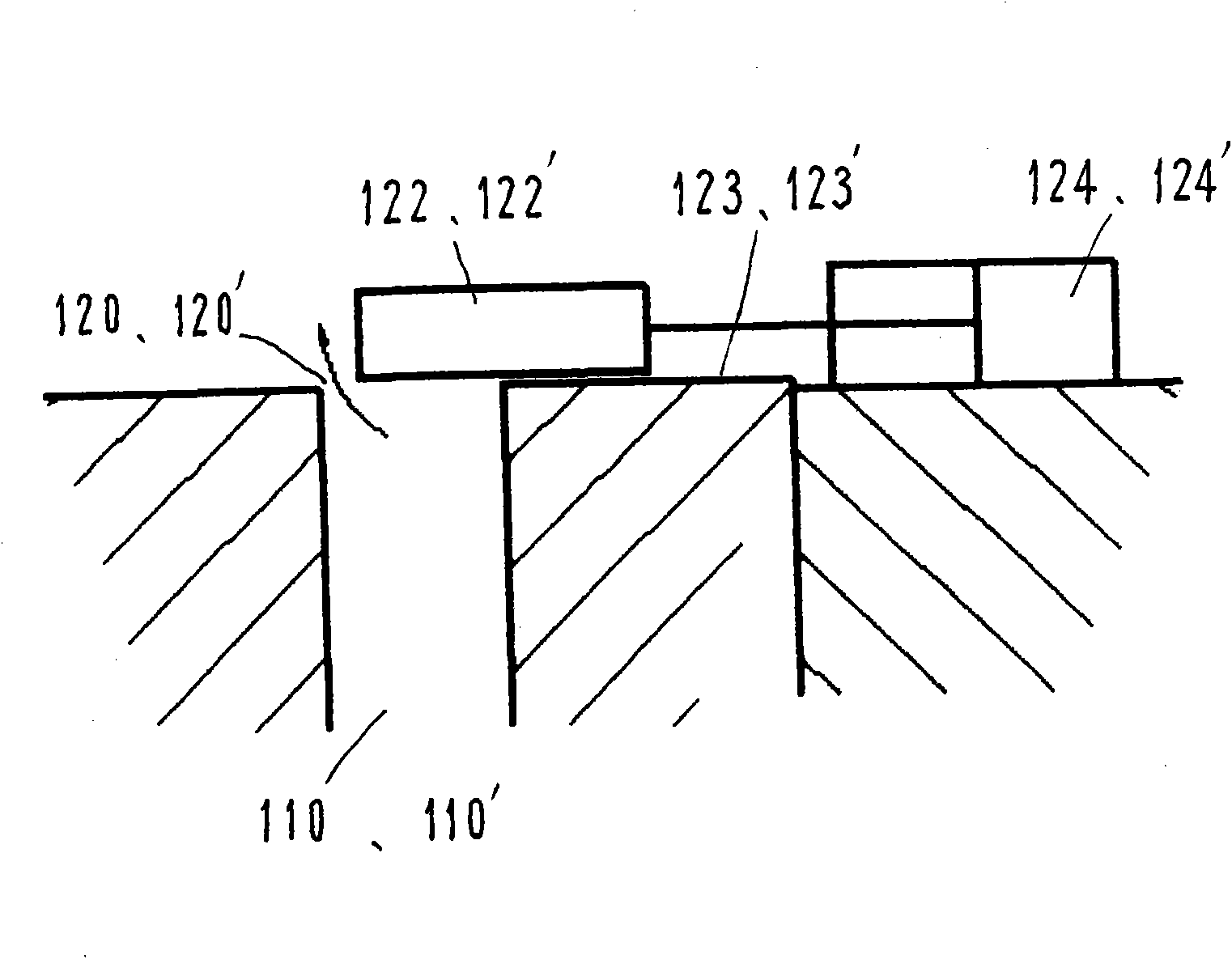

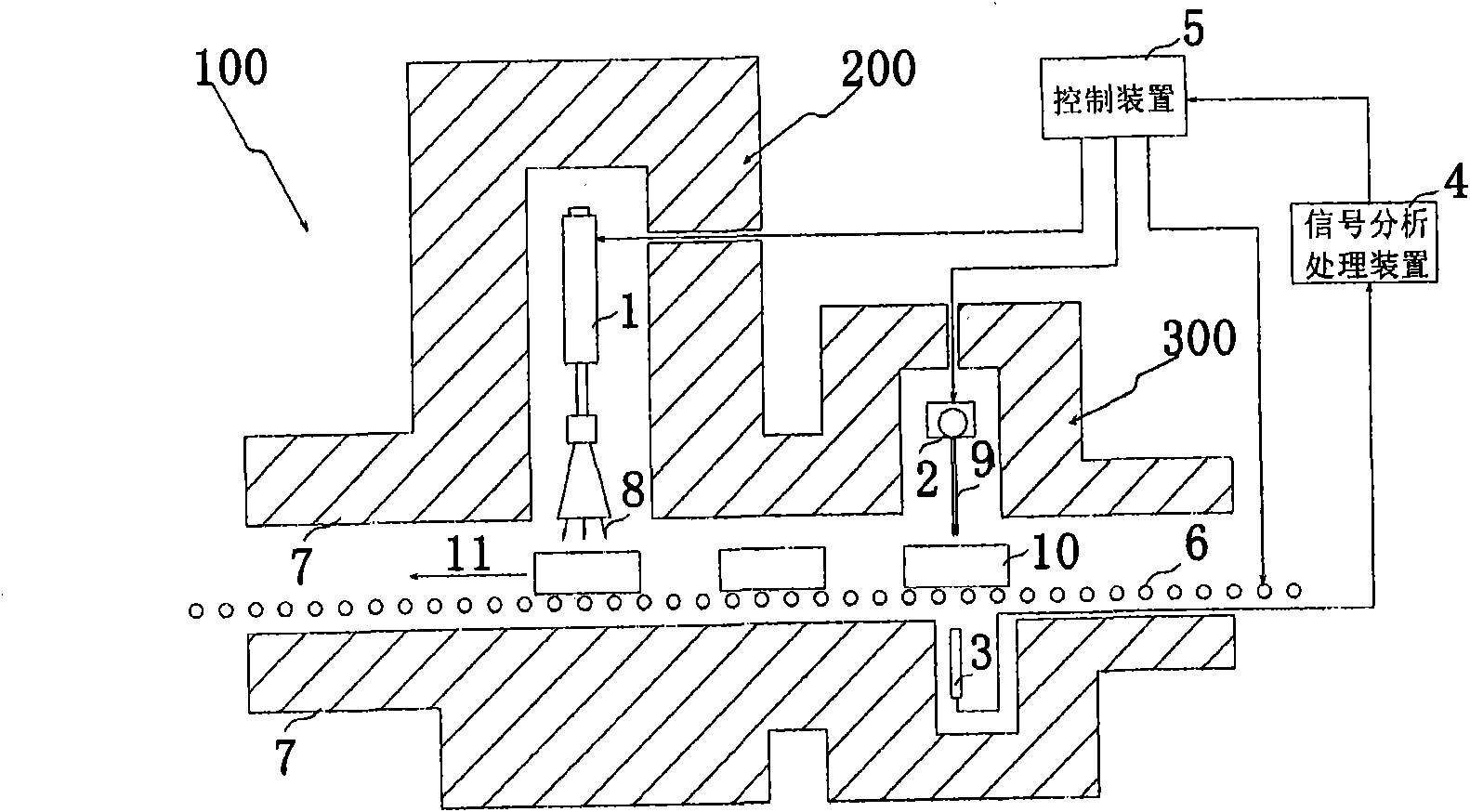

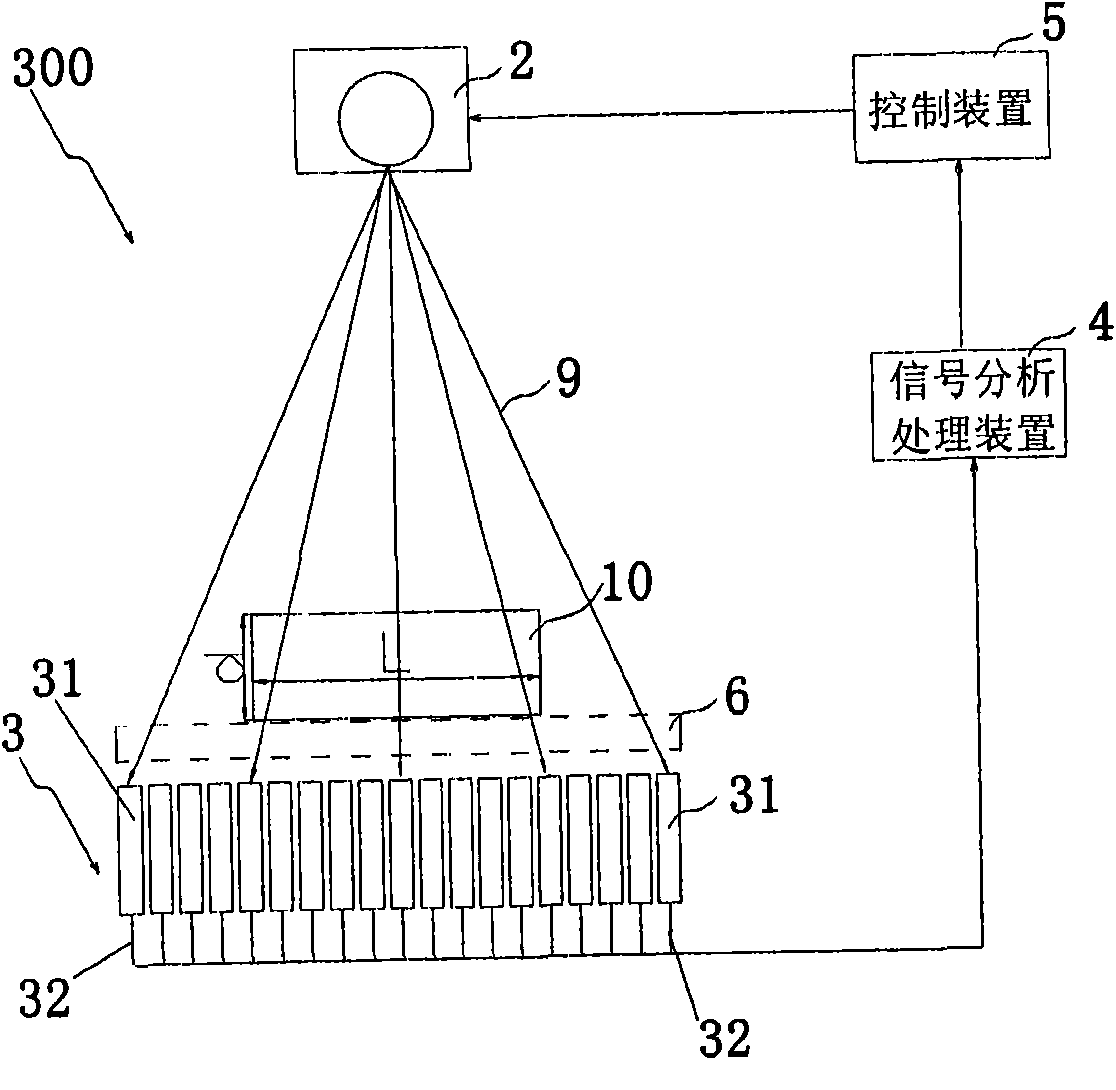

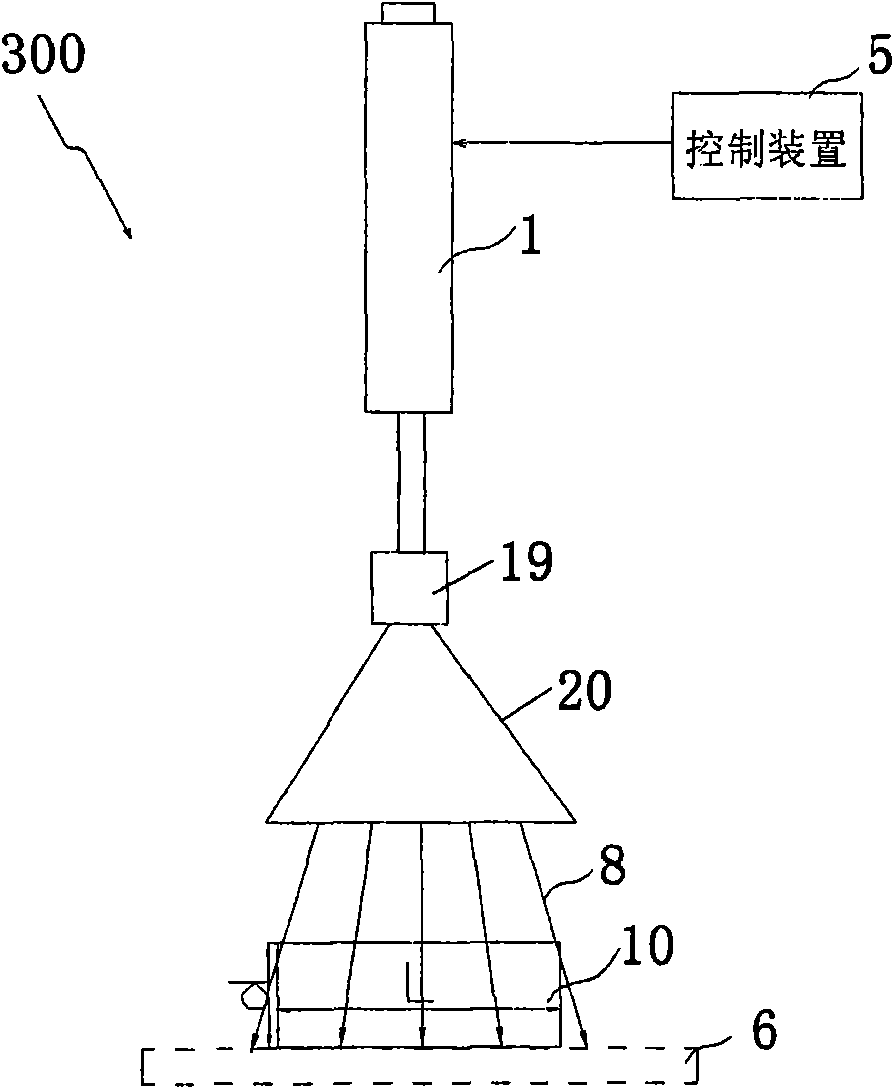

Irradiation processing method and device of electron beam

ActiveCN101937729AImprove utilization efficiencyGuarantee the effect of irradiation processingRadiation applicationsPretreated surfacesIrradiationElectron

The invention discloses an irradiation processing method of an electron beam, which comprises the following steps of (a) providing a radiation perspective detecting device; (b) detecting by utilizing the radiation perspective detecting device to obtain the information of the quality thickness (dp) of an object to be subjected to irradiation processing; (c) providing an electron beam irradiation processing device; (d) regulating the energy (E) of the electron beam of the electron beam irradiation processing device by using a control device to ensure that the energy (E) of the electron beam is matched with the quality thickness (dp) of the object to be subjected to the irradiation processing; and (e) executing electron beam irradiation processing by utilizing the regulated electron beam irradiation processing device. According to the technical scheme, during the detecting step (b), the information of the object length (L) of an object to be subjected to irradiation processing is obtained at the same time by utilizing the radiation perspective detecting device. During the regulating detection step (d), the scanning width (W) of an electron beam subjected to the electron beam irradiation processing device is adjusted by means of the control device, so that the scanning width (W) of the electron beam is matched with the object length (L) of the object to be subjected to irradiation processing.

Owner:NUCTECH CO LTD

High-zinc feed for laying duck

InactiveCN101971929AHigh health valueLittle increase in costFood processingAnimal feeding stuffHigh absorptionSulfate

The invention relates to laying duck feed, in particular to laying duck compound feed, by which the laying duck can lay eggs with high zinc content. The high-zinc feed for laying duck is prepared from energy feed, an animal protein source, a plant protein source, a fat source, a calcium source, a phosphor source, an additive, zinc sulfate and zinc methionine. The invention adds the zinc sulfate and the zinc methionine in the feed and adopts the way of combined addition of inorganic zinc and organic zinc, so the increment of the feed cost is small, the influence on other metal element absorption is also prevented, and the regular egg laying property of the laying duck is guaranteed; in addition, the high absorption and utilization rate of the organic zinc has remarkable effect on the improvement of the zinc content of the duck egg.

Owner:JIANGMEN HAID FEED

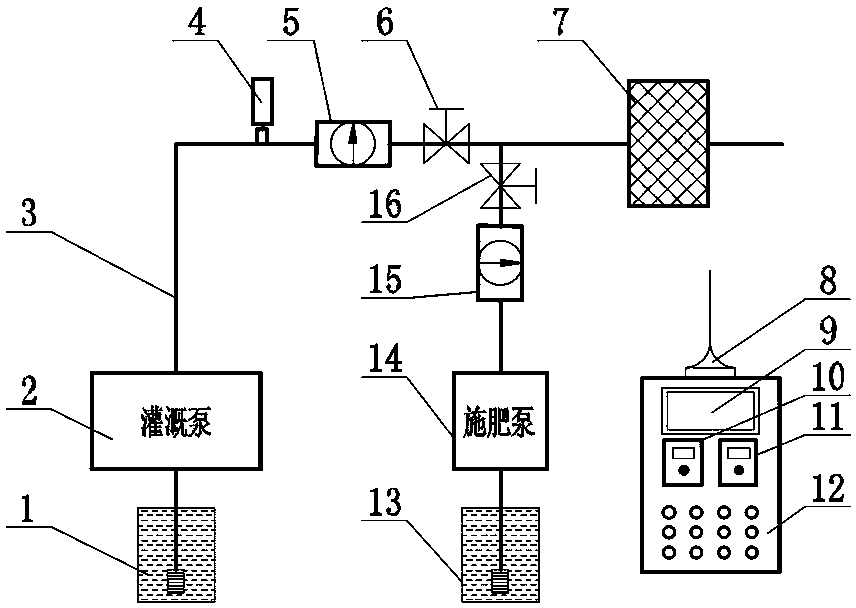

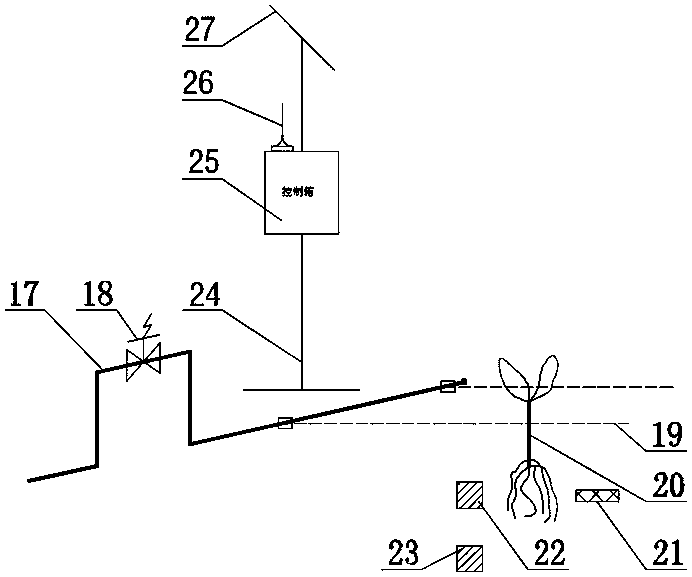

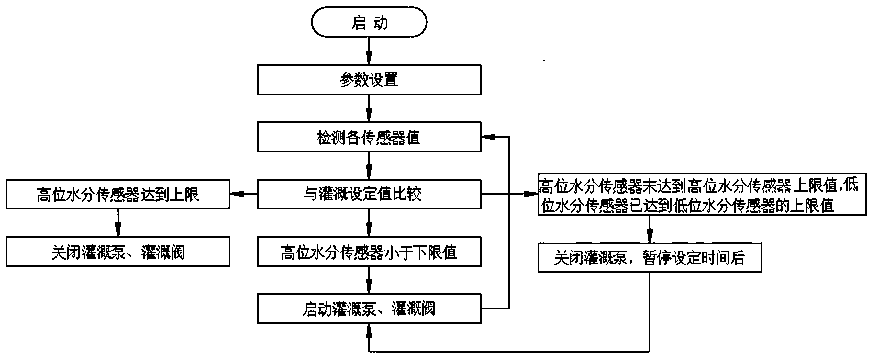

Water and fertilizer integrated precision management and control system and control method

ActiveCN108541439APromote growthAvoid wastingClimate change adaptationWatering devicesControl systemFiltration

The invention discloses a water and fertilizer integrated precision management and control system and a control method. The water and fertilizer integrated precision management and control system comprises a head device and a field tail device, wherein the head device comprises an irrigation system, a fertilization system and a head control system, and the irrigation system comprises an irrigationpump, an irrigation pipeline, a pressure sensor, an irrigation flow meter, a filtration system and an irrigation valve; the fertilization system comprises a fertilization pump, a fertilization pipeline, a fertilization flow meter and a fertilization valve, and the field tail device comprises a tail irrigation system and a field control system; the tail irrigation system comprises a field pipeline, a solenoid valve and a drip irrigation pipe, and the field control system comprises a field control box, a field power module, an EC sensor and a moisture sensor. According to the water and fertilizer integrated precision management and control system disclosed by the invention, the moisture sensor and the EC sensor are arranged according to the optimal water and fertilizer absorption position at the root of the crop, and the applying amount and reaching position of water and fertilizer in the actual irrigation and fertilization are detected, so that the water and fertilizer waste are effectively avoided, and thus the water and fertilizer content in the root of the crop is not too high or too low, which promotes crop growth.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

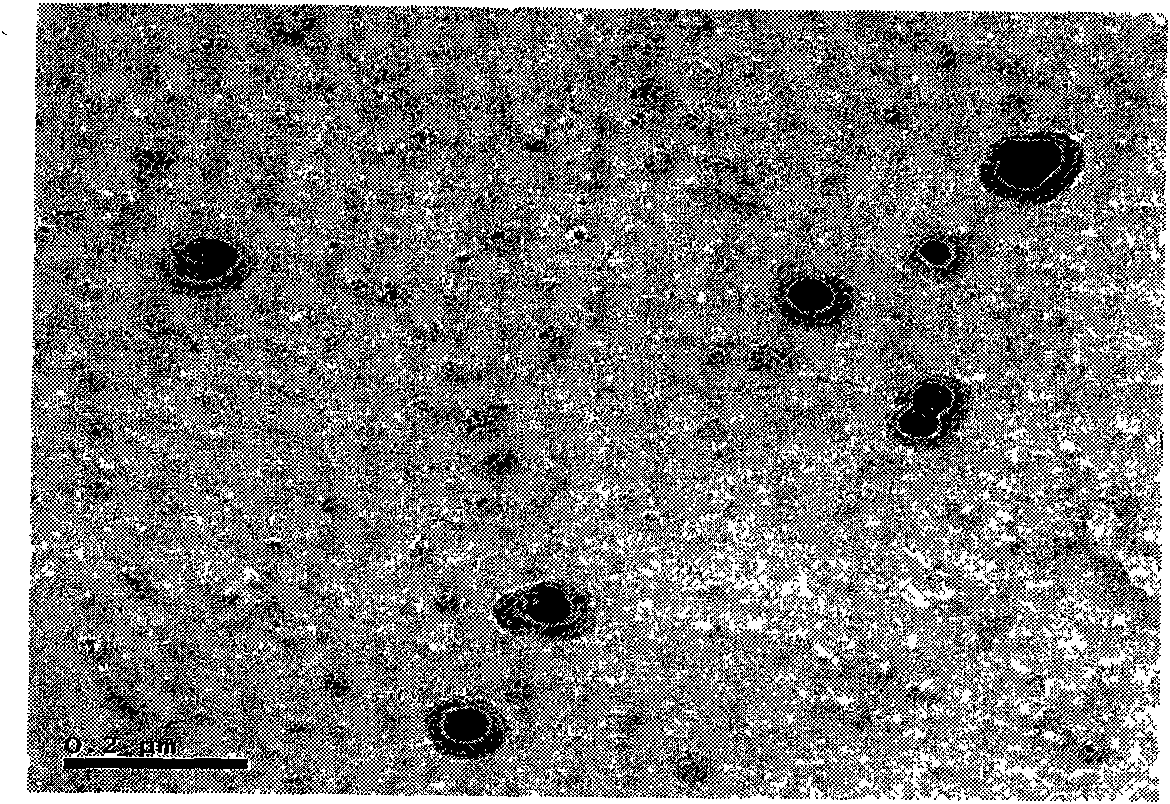

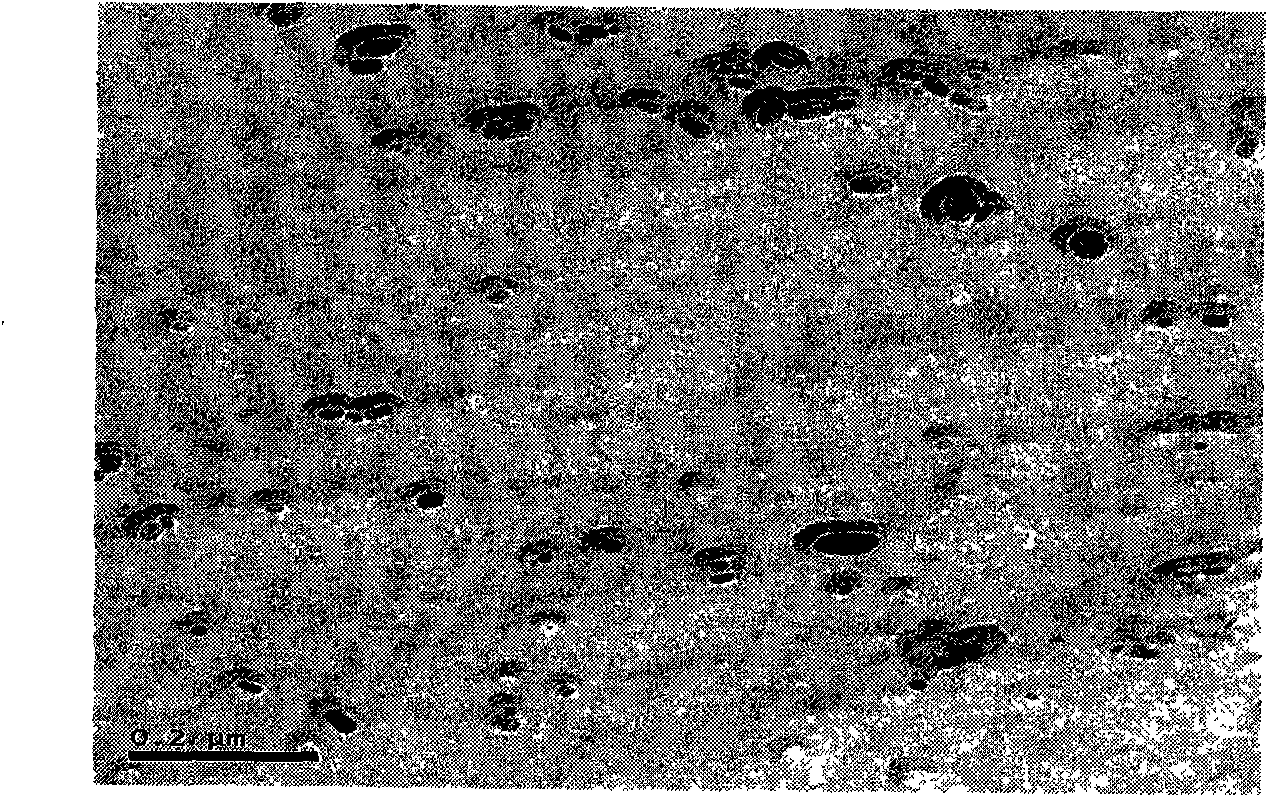

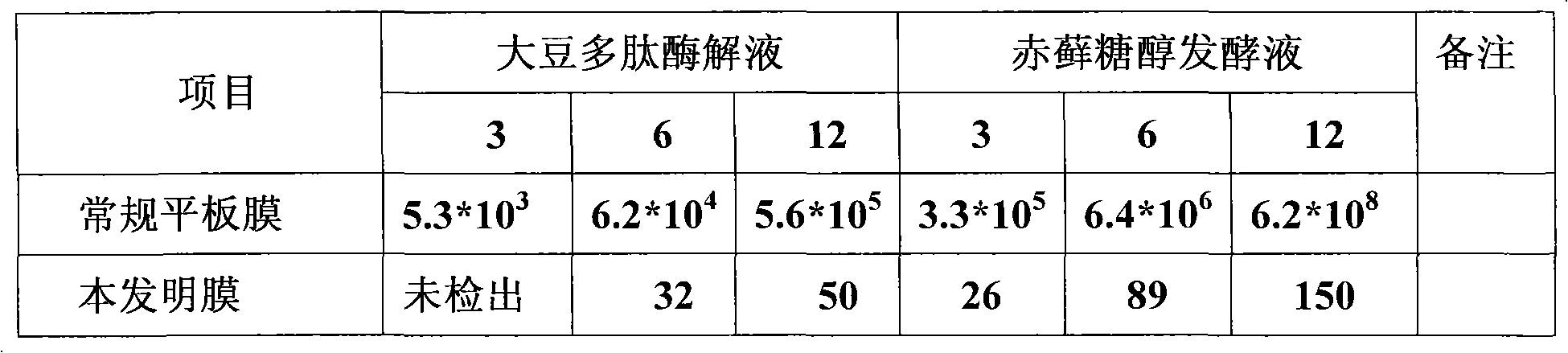

Anti-microbial contamination hollow fiber membrane and preparation method thereof

ActiveCN102091537ALittle increase in costGood adhesion inhibitionSemi-permeable membranesFiberHollow fibre membrane

The invention discloses an anti-microbial contamination hollow fiber membrane and a preparation method thereof, belongs to the technical field of membranes, and particularly relates to an anti-contamination polymeric membrane technique. The anti-microbial contamination hollow fiber membrane contains carbon nanotubes; and the mass ratio of polyvinylidene fluorid (PVDF) to carbon nanotubes is 1:0.001 to 1:0.01. Compared with the conventional PVDF hollow fiber separation membrane preparation, the product disclosed by the invention can be produced without special equipment and the industrial implementation is easy; in a word, the process is simple and the increase in the cost of the membrane is low. The hollow fiber separation membrane product has high attachment inhibition effect on microbesin separation media, and has high microbial contamination resistance.

Owner:TIANJIN POLYTECHNIC UNIV

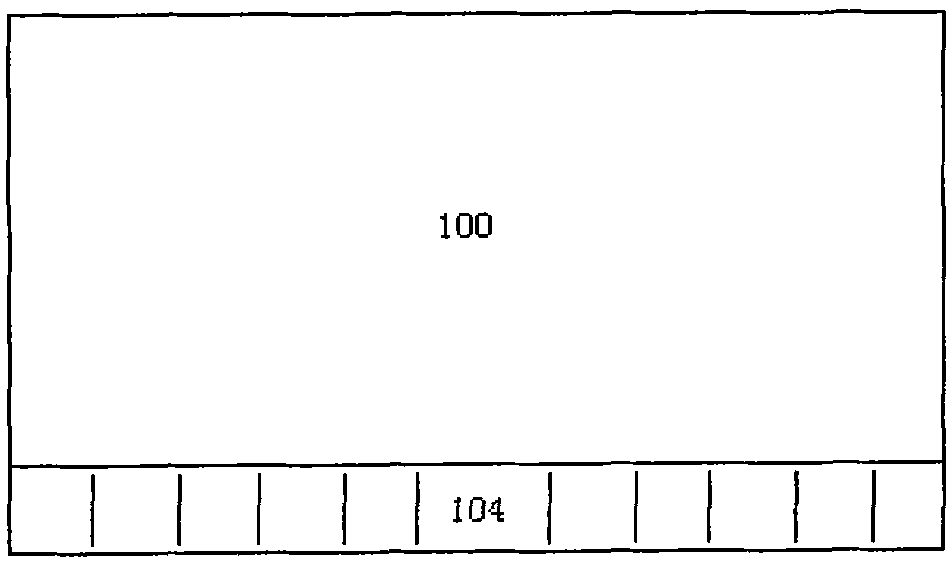

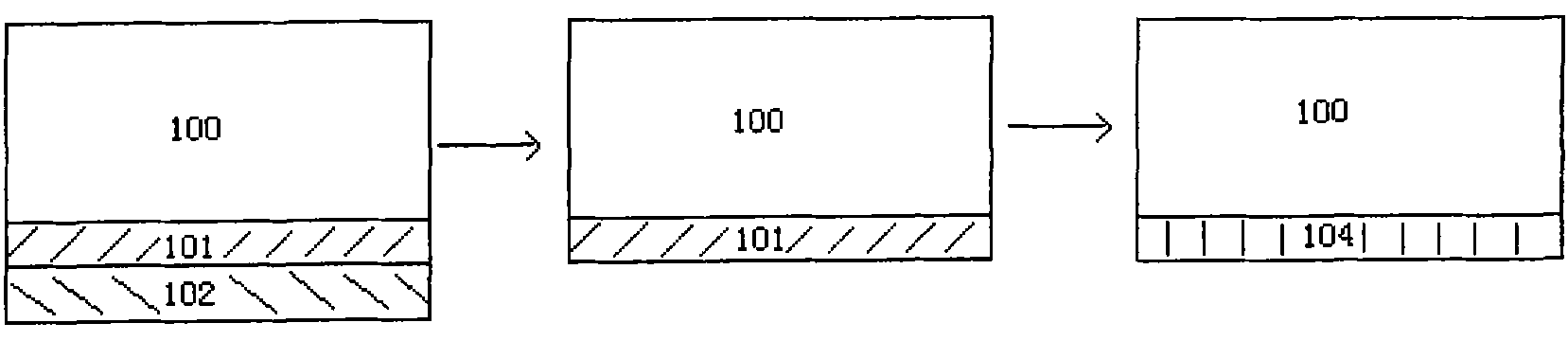

Preparation method of silicon-based dielectric film

InactiveCN102080244AImprove efficiencyGood interface consistencyFinal product manufactureSurface reaction electrolytic coatingDielectricGroup element

The invention provides a preparation method of a silicon-based dielectric film used for a photovoltaic cell. The preparation method is characterized by comprising the following steps: firstly, doping a silicon-based substrate (100) with III group elements or metal elements; then, preparing an SiN film (104) containing III group nitrides or metal nitrides by adopting an anode nitridation method; and then, carrying out annealing treatment, thus obtaining the needed film. The silicon-based dielectric film prepared by the method can be used as the anti-reflection passivating film or back reflection passivating film of the photovoltaic cell.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Hot extrusion mold for producing profile for electrified high-speed railway feedback line clamps

InactiveCN102366766ARealize continuous mass productionIncrease productivityExtrusion diesThermodynamicsEngineering

The invention provides a hot extrusion mold for producing a profile for electrified high-speed railway feedback line clamps. The mold core of the hot extrusion mold is of a single-cone integral type, and the inner cavity structure of the hot extrusion mold comprises an inlet region, a sizing region, a cone angle transition region and an outlet region, wherein the sizing region is enlarged conically toward the front face of the mold core to form the inlet region; the cone angle transition region is enlarged transitionally between the sizing region and the outlet region; and the cross-sectional shape and size of the sizing region are uniformly enlarged for 0.3-0.8mm on a single side compared with the shape and size of the profile. The hot extrusion mold provided by the invention is suitable for producing a profile copper product with a complex shape, and is especially suitable for producing various special profiles for electrified high-speed railway feedback line clamps, thereby laying a foundation for the subsequent drawing process, realizing continuous volume production of such products, improving production efficiency, reducing cost and shortening production cycle.

Owner:BAIYIN NONFERROUS GROUP

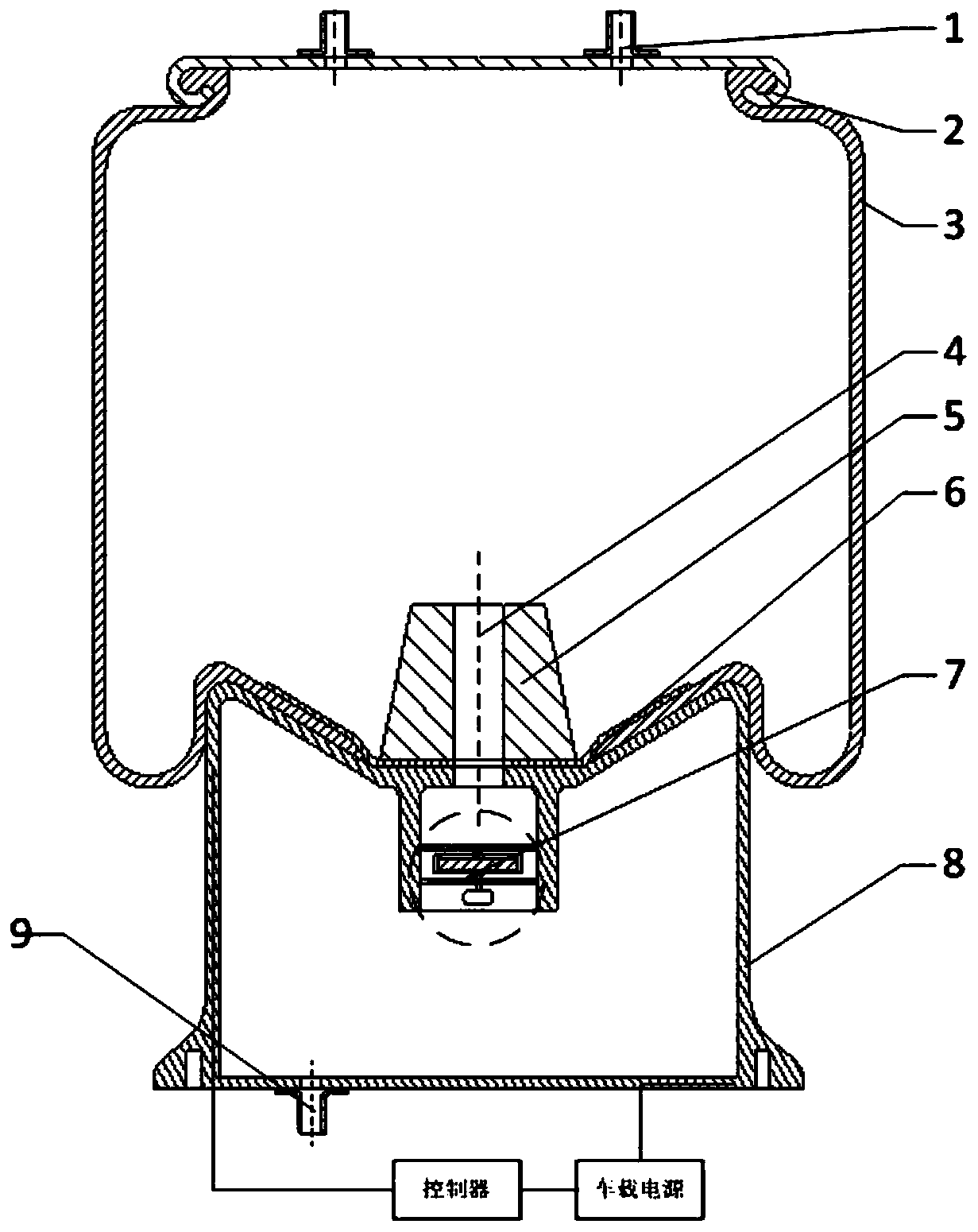

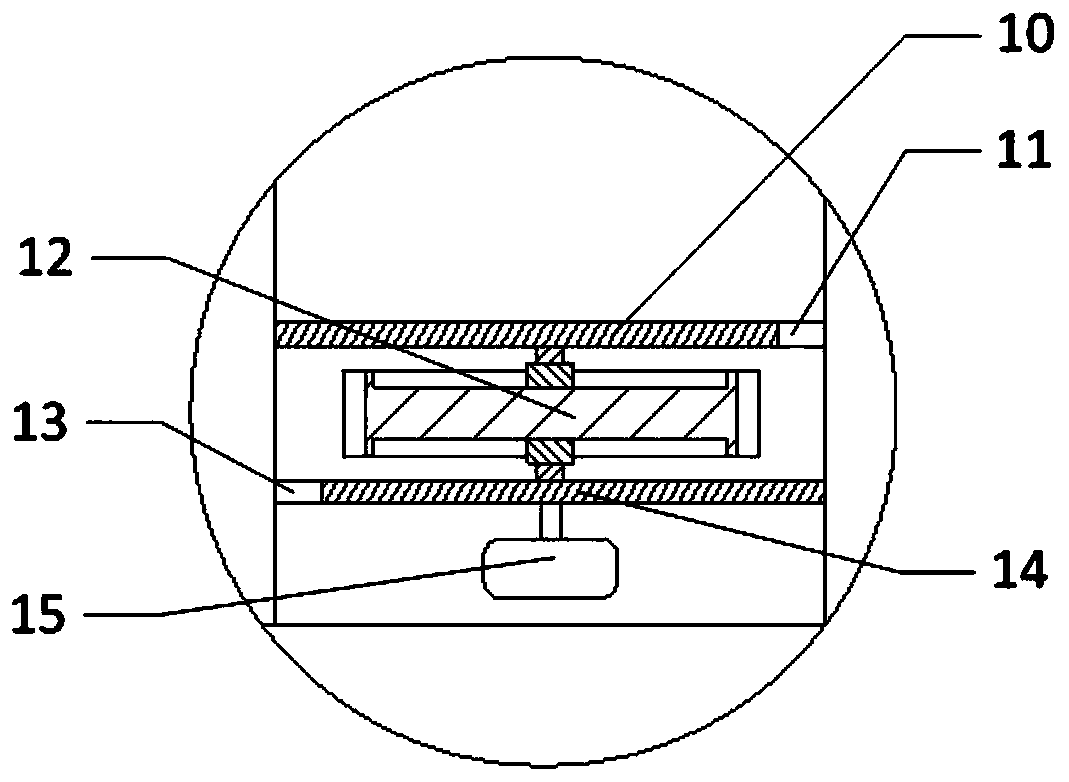

Air suspension system and control method for vehicle under rushing working condition

PendingCN110901329AQuick responseIncrease stiffnessResilient suspensionsVehicle springsAir compressionAir spring

The invention discloses an air suspension system and a control method for a vehicle under a rushing working condition. The vehicle air suspension system comprises an air spring and an air compressiondevice. The two ends of an air bag are sealed through an upper cover plate and a lower pressing plate, and the air bag is communicated with an additional air chamber through an air inlet pipeline andan air outlet pipeline; a buffer pad is mounted on the lower pressing plate; the whole base is in a hollow ring shape, an inner ring wall which extends downwards but does not make contact with the bottom is arranged at the top in the base, and an inflation pipe is arranged at the bottom of the base. And an air compression device is arranged on the inner ring wall. The vehicle can trigger the air compression device to work under the urgent running working condition, and the working rule of the air compression device is determined by the control method.

Owner:JIANGSU UNIV OF SCI & TECH

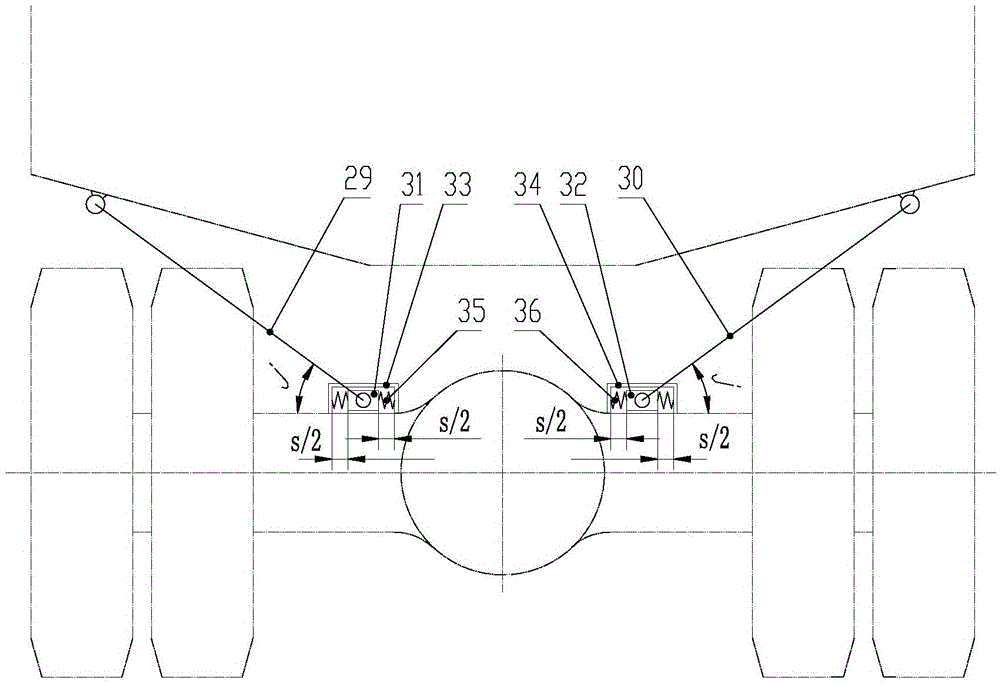

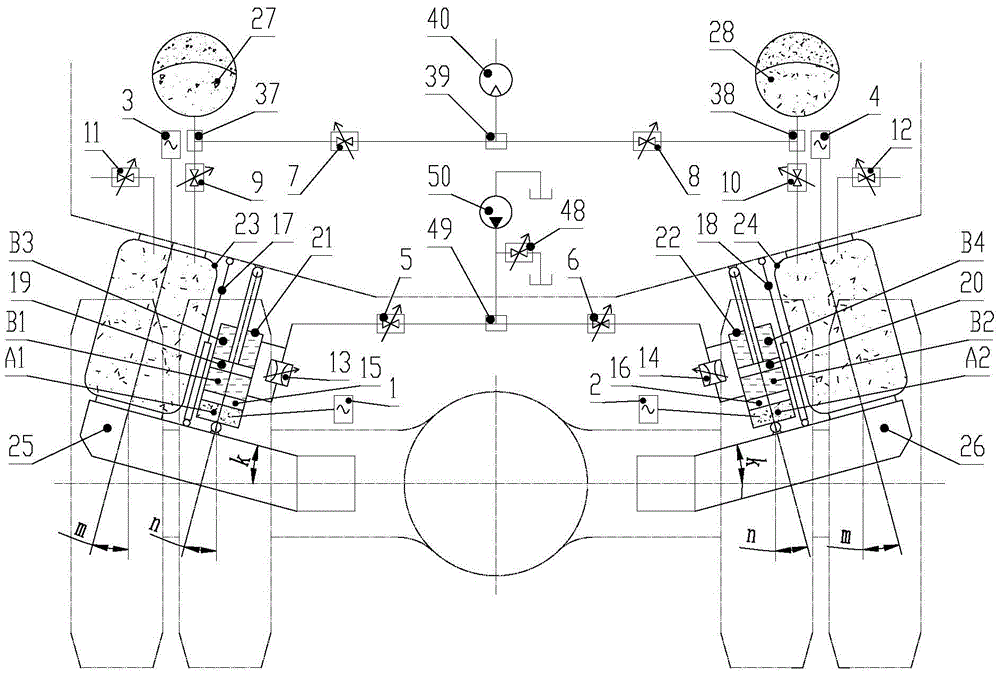

Commercial vehicle electronic control suspension and inclination correcting system

ActiveCN105620220AMinor changesLower transient rollover thresholdResilient suspensionsElectric controlCommercial vehicle

A commercial vehicle electronic control suspension and inclination correcting system comprises a vehicle body, a vehicle axle and vehicle wheels and further comprises an electronic control suspension, the electronic control suspension comprises suspension springs, damping-tensioning combiners and a transversely-arranged connecting rod slider mechanism, the suspension springs and the damping-tensioning combiners are arranged in a left-right symmetry manner, and the transversely-arranged connecting rod slider mechanism comprises connecting rods, sliders and sliding grooves which are arranged symmetrically.When a vehicle is in a design posture, and the central lines of the connecting rods positioned on the left and right sides outwards inclines by an angle j and are in a symmetrically-arranged form; one ends of the connecting rods are in hinged connection with the vehicle body while the other ends of the same are in hinged connection with the slider, the sliding grooves are fixedly connected with a shell of the vehicle axle, the sliders can linearly move in the sliding groove, and the moving stroke is s.The commercial vehicle electronic control suspension and inclination correcting system is little in modification on a chassis of an original vehicle, low in cost and high in effectiveness.

Owner:ZHEJIANG UNIV OF TECH

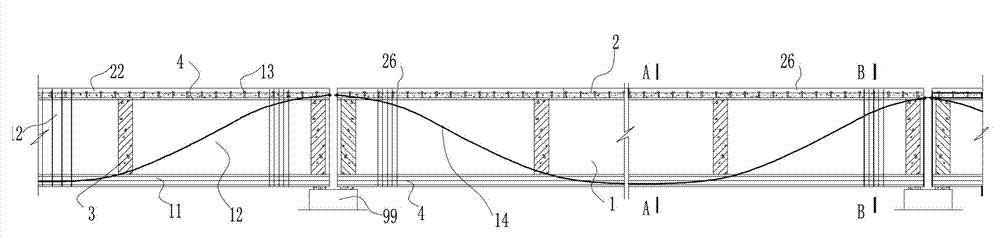

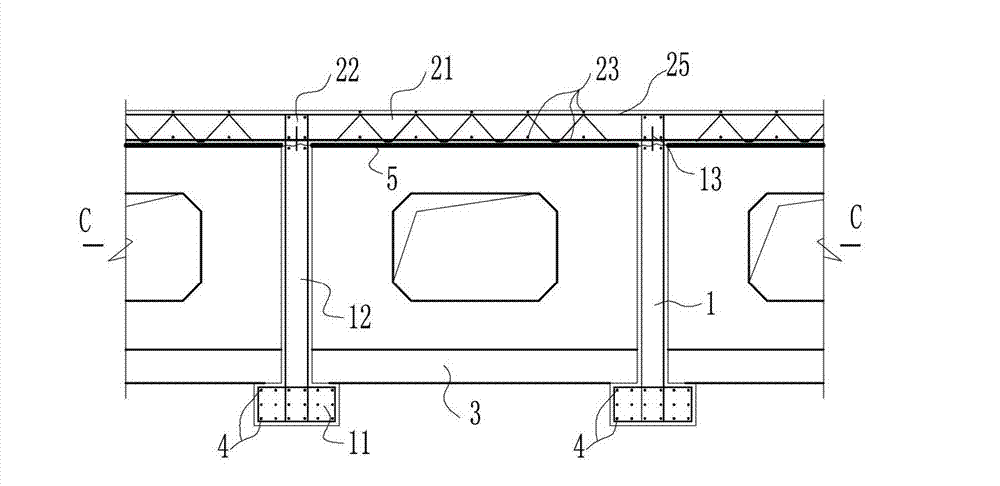

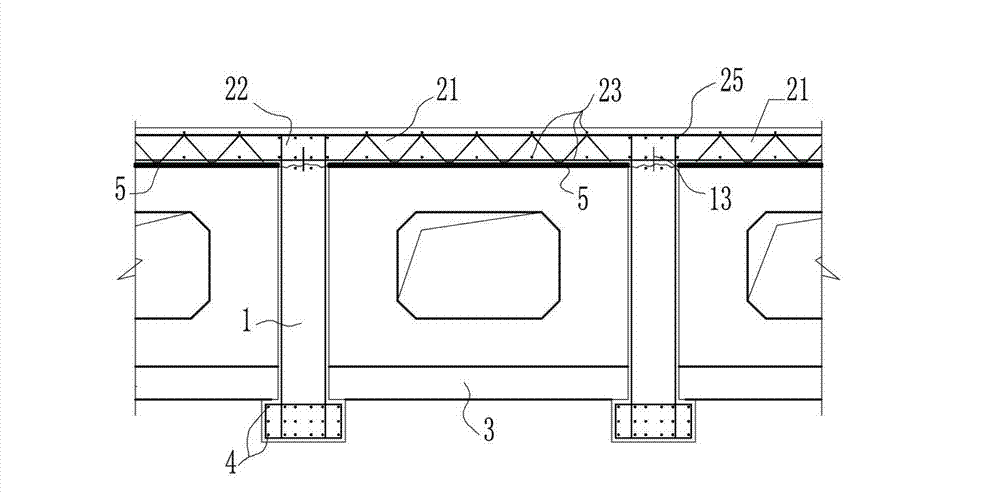

Simply supported prefabricated integrally-cast superposed bridge and construction method thereof

ActiveCN102808372ALight weightEasy to transport and installBridge erection/assemblyPre stressInverted t

The invention discloses a simply supported prefabricated integrally-cast superposed bridge. The prefabricated integrally-cast superposed bridge comprises inverted T-shaped prestressed prefabricated beam parts, cast-in-situ parts and horizontal baffles, and is characterized in that each cast-in-situ part comprises a cast-in-situ plate and a cast-in-situ superposed part at the upper part of the beam part; pretensioned prestressed steel strands are embedded in the upper parts of a web plate and a lower flange of each inverted T-shaped prestressed prefabricated beam part; the horizontal baffles adopt prefabricated plates, and are longitudinally arranged at intervals between the web plates of the adjacent prefabricated beam parts at the two ends of each beam part and positioned above the flanges of the prefabricated beam parts; and the inverted T-shaped prestressed prefabricated beam parts adopt manufacturing moulds commonly used with buildings, and mould plates are good in commonality, convenient to mount and dismount, high in working efficiency and low in amortized cost.

Owner:杨众 +1

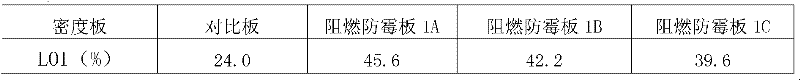

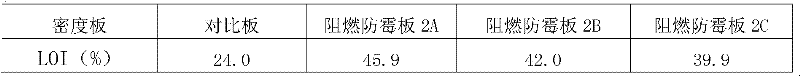

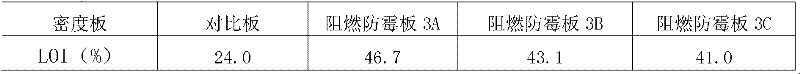

B-P-Mg-Si series density fiber board inflaming-retarding mildewproof agent and preparation and application thereof

The invention relates to a B-P-Mg-Si series density fiber board inflaming-retarding mildewproof agent and a preparation method and application thereof. The density fiber board inflaming-retarding mildewproof agent comprises the raw materials in parts by weight: 30-100 parts of sodium borate, 20-90 parts of polyammonium phosphate, 40-60 parts of magnesium hydroxide and 6-20 parts of organosilicon quaternary ammonium salt. When used for preparing a density fiber board, the B-P-Mg-Si series density fiber board inflaming-retarding mildewproof agent has the addition amount of 4-6 percent of the mass of oven-dry wood as the density fiber board. An inflaming-retarding mildewproof density fiber board prepared by adopting the B-P-Mg-Si series density fiber board inflaming-retarding mildewproof agent has combustion oxygen indexes of exceeding 39.0 percent, can reach the B1-level standard of the combustion performance of building finishing materials, and accords with the requirement of fire service law.

Owner:SHANDONG UNIV

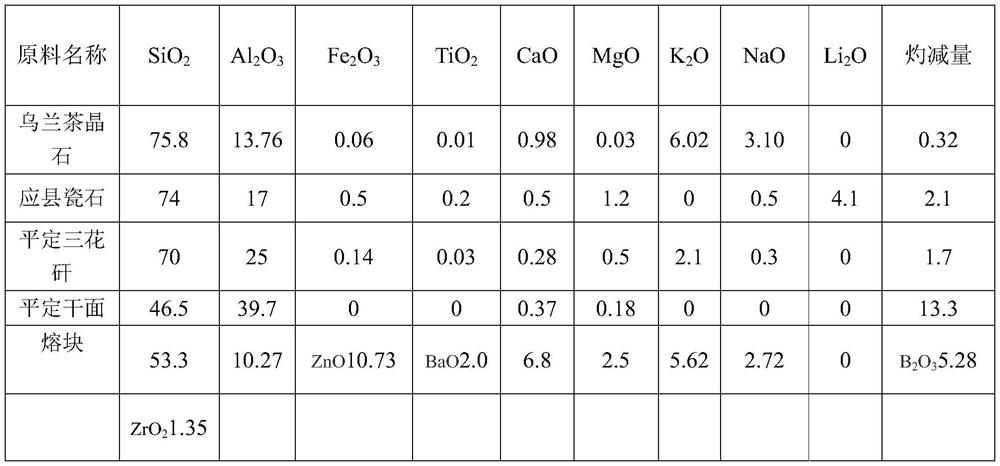

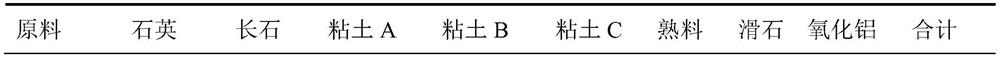

Antibacterial fantasy ceramic

ActiveCN112194476ALittle increase in costImprove antibacterial propertiesCeramic materials productionCelluloseFrit

The invention relates to ceramic production, in particular to antibacterial fantasy ceramic. The ceramic is made of blank and glaze, and is prepared from 18-28 parts of Wulan tea-coloured crystal, 20-30 parts of Jiangxian chinastone, 21-33 parts of Pingding three-flower gangue and 16-29 parts of Pingding dry surface. The glaze comprises the following components in parts by weight: 95 parts of frit, 3 parts of Pingding dry surface and 2 parts of cellulose. Wulan tea-coloured crystal is adopted as a main raw material of a ceramic body and glaze for formula design, special additives do not need to be added, domestic or imported antibacterial agents in the current market are basically 400,000-1,200,000 / ton, the cost is extremely high, the cost of ceramic ingredients is basically not increasedby the Wulan tea-coloured crystal, and a test result shows that the antibacterial effect is extremely good; the antibacterial fantasy ceramic has the function of emitting far infrared rays, and has the advantages of being easy to clean, bright in color, good in light transmittance and the like.

Owner:PINGDING YINGYU PORCELAIN

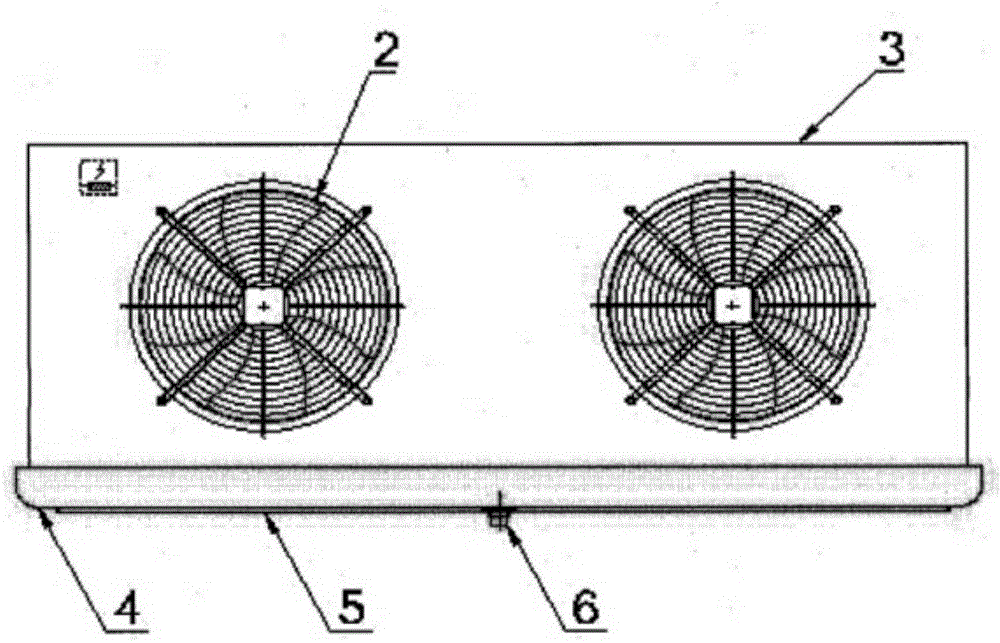

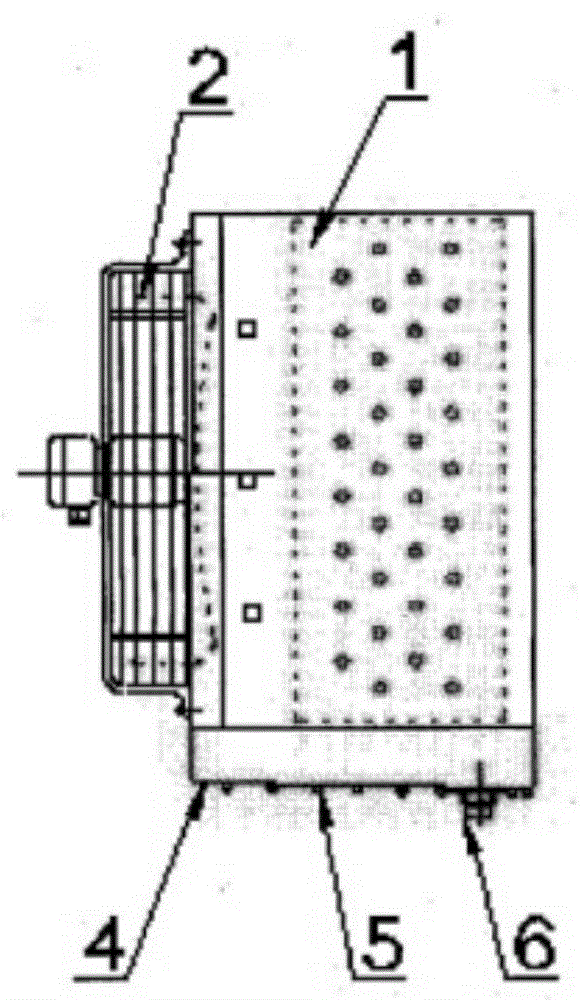

Ship fan evaporator using hot air to melt frost

At present, the conventional ship fan evaporators use hot air to melt frost, a ship keeps inclination sailing during a period due to waves, and then water gathered in a water holding disc cannot be drained completely, an ice layer will cover the water holding disc after a few of frost melting cycles, the drainage opening will be blocked, and a frost melting system will fail. The ship fan evaporator is different from the conventional an evaporators using hot air to melt frost, and is characterized in that a plurality of seamless tubes as heating coils are arranged under a water holding disc according to the area of the water holding disc, the heating coils heat the water holding disc during a frost melting process all the time so as to prevent frost molten water from freezing, and the frost molten water can be smoothly drained out from a drainage opening.

Owner:广州中臣碧阳科技集团有限公司

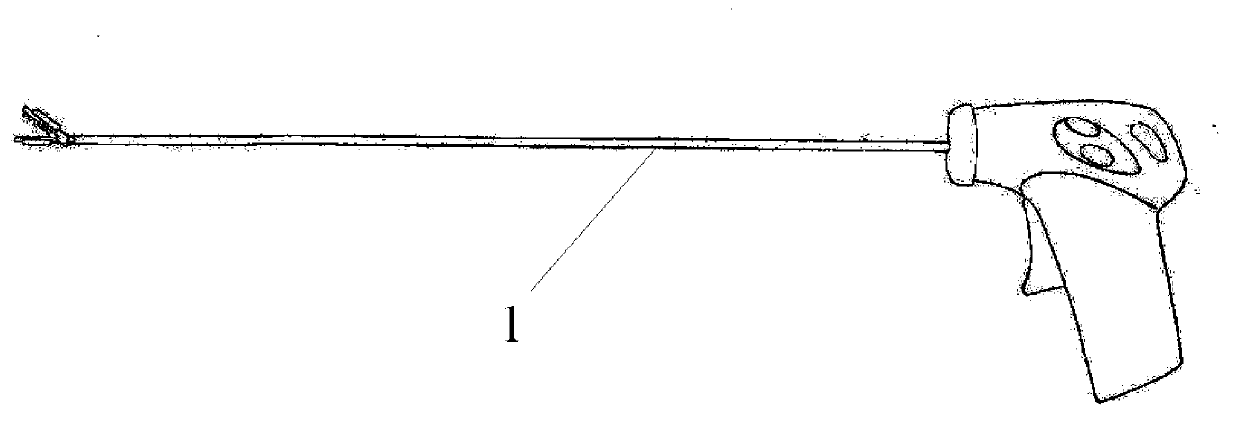

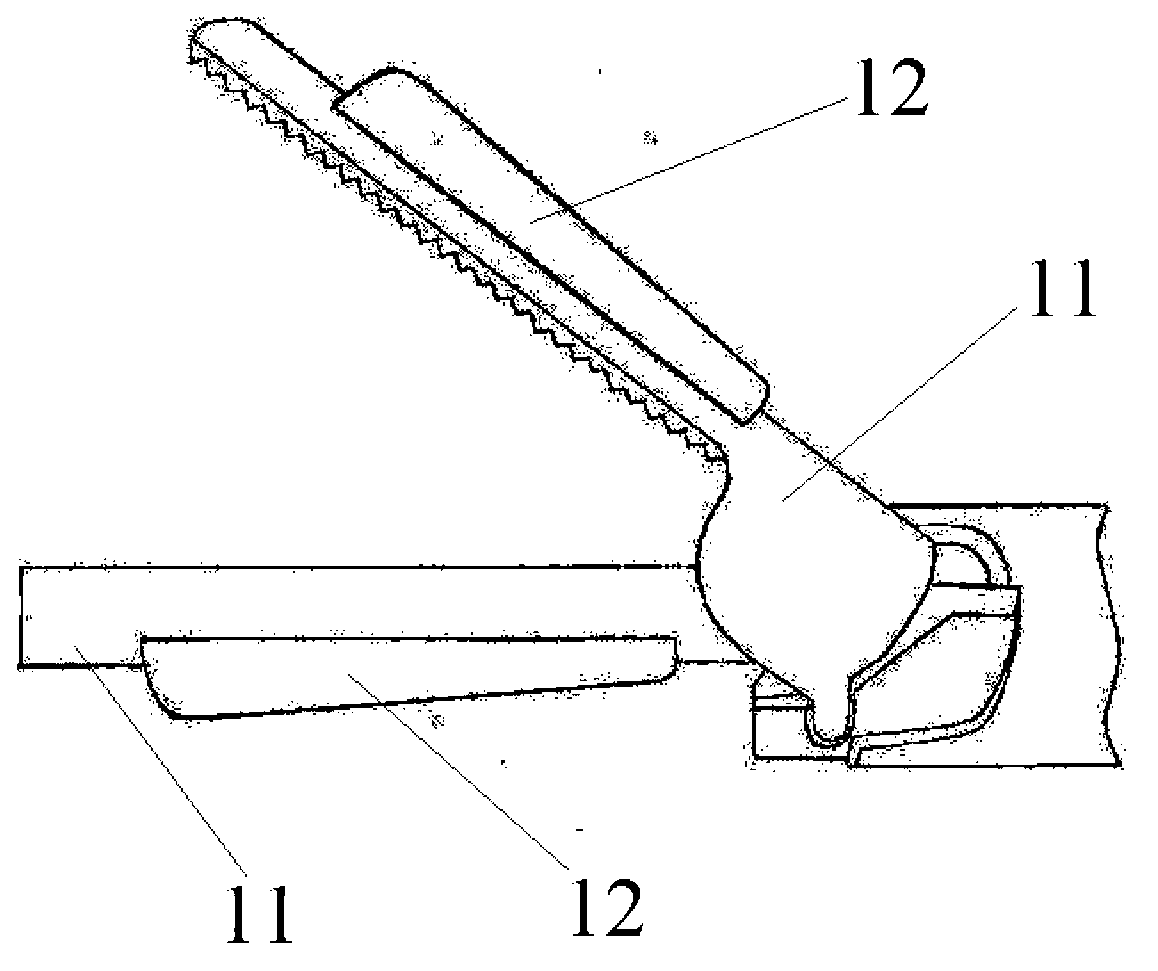

Split type multifunctional divider

InactiveCN103099672AReduce bleedingShorten operation timeSurgical instruments for heatingManufacturing technologyElectro coagulation

The invention discloses a split type multifunctional divider which is characterized by comprising a split type surgical cutter. Electrotome electro-coagulation blades are arranged on two side faces of a head of the split type surgical cutter. The split type multifunctional divider is further characterized in that the split type surgical cutter is an ultrasound cutter or a force-confirming cutter. The split type multifunctional divider is not only a simple combination of the ultrasound cutter or the force-confirming cutter and an electrotome, but also an innovation on bleeding stopping schemes. The split type multifunctional divider has the same advantage of directly separating a ductule structure as the ultrasound cutter or the force-confirming cutter, stops bleeding of liver essence sections thoroughly through electrotome electro-coagulation, reduces bleeding in surgery, and shortens surgery operation time. Simultaneously, manufacture technology is mature, less cost is increased, and comprehensive benefits are evident compared with benefits brought for patients.

Owner:张勇

Process control technology for vacuum brazing aluminum alloy composite board belt foil

InactiveCN101270421AReduce the amount addedSimple production processMetal rolling arrangementsChemical compositionAlloy composite

The invention discloses a processing control technology of vacuum brazing aluminum alloy composite plate strip and foil. During melting the aluminum alloy, various metal or additive including Aluminum-Bismith master alloy with the Bismith content of 3 percent are added successively according to the chemical components requirement of ingot, and the Bismith content is controlled at 0.05 to 0.15 percent for controlling the whole components of ingot at the standard requirement scope; when rolling the brazing composite plate blank, the Aluminum-Bismith master alloy is fabricated into the thickness of 40, 50 and 60 milimeter and combined on a core material of 265, 265 and 240 milimeter, and the composite plate strips of the clad ratio of 12, 14 and 16 percent are obtained after rolling. By adopting a solder layer with new chemical composition, the invention controls the different clad ratio according to different thickness of material, thereby meeting and adapting the new requirement and new standard from the manufacture industry of heat exchanger, thus solving the leakage and cracking problem occurred in the vacuum brazing process of the aluminum heat exchanger.

Owner:无锡冠云铝业有限公司 +1

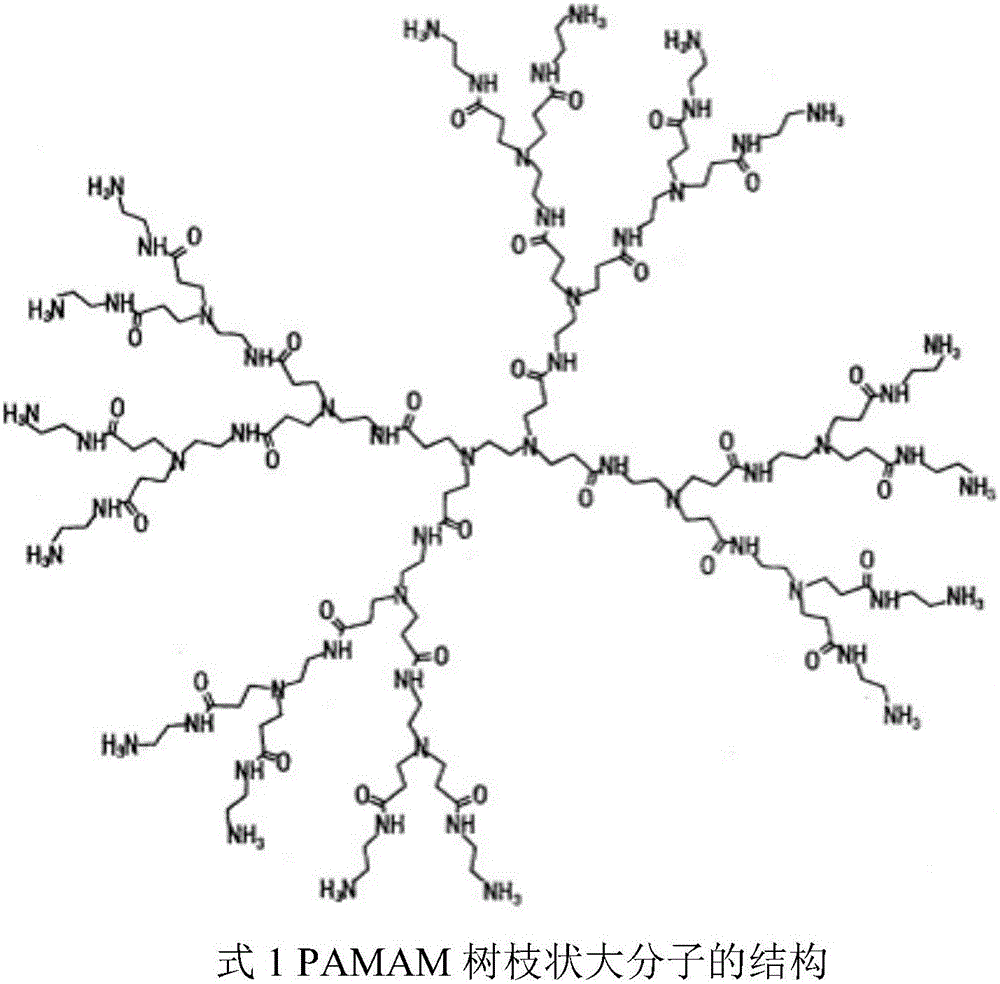

Preparation method of modified PVDF for heavy metal ion adsorption type separation films

InactiveCN106582335AImprove adsorption capacityGood adsorption of heavy metal ionsSemi-permeable membranesOther chemical processesHollow fibreFiber

The invention discloses a preparation method of modified PVDF for heavy metal ion adsorption type separation films, belongs to the field of functional high polymer materials and particularly relates to a preparation technique used for preparation of the raw material PVDF for the heavy metal ion adsorption type separation films. The preparation method of the modified PVDF for the heavy metal ion adsorption type separation films has the characteristics that the modified PVDF is prepared by the means of the method that PVDF power is subjected to modifying through polyamide-amine (PAMAM) and can be applicable to preparing the flat sheet separation films or the hollow fiber separation films which have an adsorption effect on heavy metal ions. The heavy metal ion adsorption capacity of the separation films prepared from the modified PVDF is increased with augment of PAMAM hyperbranched modified algebra, the adsorbed heavy metal ions can be efficiently recycled through cleaning after the heavy metal ions are adsorbed by the separation films, and the separation films can be repeatedly used. The pure water influx of the separation films prepared from the modified PVDF is improved compared with pure PVDF films, and the physical property of the separation films is stable. Special equipment is not required for production of the modified PVDF for the heavy metal ion adsorption type separation films, industrial implementation is easy, and the cost of the prepared modified PVDF is small in increased amplitude.

Owner:TIANJIN CNCLEAR ENVIRONMENTAL PROTECTION SCI & TECH CO LTD

High-performance volcanic ash concrete and production process thereof

The invention discloses high-performance volcanic ash concrete and a production process thereof and belongs to the field of non-metallic mine deep processing. The high-performance volcanic ash concrete comprises a gelling material, sand, stones, water and an additive, wherein the gelling material comprises cement, high-quality volcanic ash and silicon ash; the additive is an efficient water reducer; the constitution of each raw material is as follows: the using amount of the water is less than or equal to 150kg; the total amount of the gelling material is 300kg / m<3> to 350kg / m<3>; the using amount of the cement is 50 to 60 percent of the total amount of the gelling material; the using amount of the high-quality volcanic ash is 30 to 40 percent of the total amount of the gelling material; the using amount of the silicon ash is 2 to 5 percent of the total amount of the gelling material; and the using amount of the efficient water reducer is 0.5 to 1.0 percent of the total amount of the gelling material. The high-performance volcanic ash concrete prepared by the production process disclosed by the invention has better anti-permeability, chemical corrosion resistance and durability, and good falling-keeping effect; the used raw materials are low in cost and high in cost performance.

Owner:山东森森矿业新材料有限公司

Application of steel-titanium-aluminum composite joint to refrigerating system of fishing boat

InactiveCN103195990AEasy to connectIncrease costNon-disconnectible pipe-jointsTitaniumSteel pipeline

The invention discloses application of a steel-titanium-aluminum composite joint to a refrigerating system of a fishing boat. A mature steel-titanium-aluminum composite board in the market is used, and according to the specification of a refrigerating system pipeline, the steel-titanium-aluminum composite board is processed into a special composite joint; an aluminum evaporator and a steel pipeline are connected by the steel-titanium-aluminum composite joint, the steel pipeline is welded with a steel end of the composite joint, and the aluminum evaporator is welded with an aluminum end of the composite joint; and the connection way of the refrigerating system pipeline is a welding way which replaces the conventional flange connection, so that leakage in an interface position is avoided. Through the application, the leakage of a refrigerating agent at the interface position of the refrigerating system pipeline of the fishing boat is effectively avoided, the running stability of the whole refrigerating system is ensured, and thus the quality of fishes is ensured; and the steel-titanium-aluminum composite joint is applicable to the refrigerating system of the fishing boat, as well as a refrigerating system on land.

Owner:广州中臣碧阳科技集团有限公司

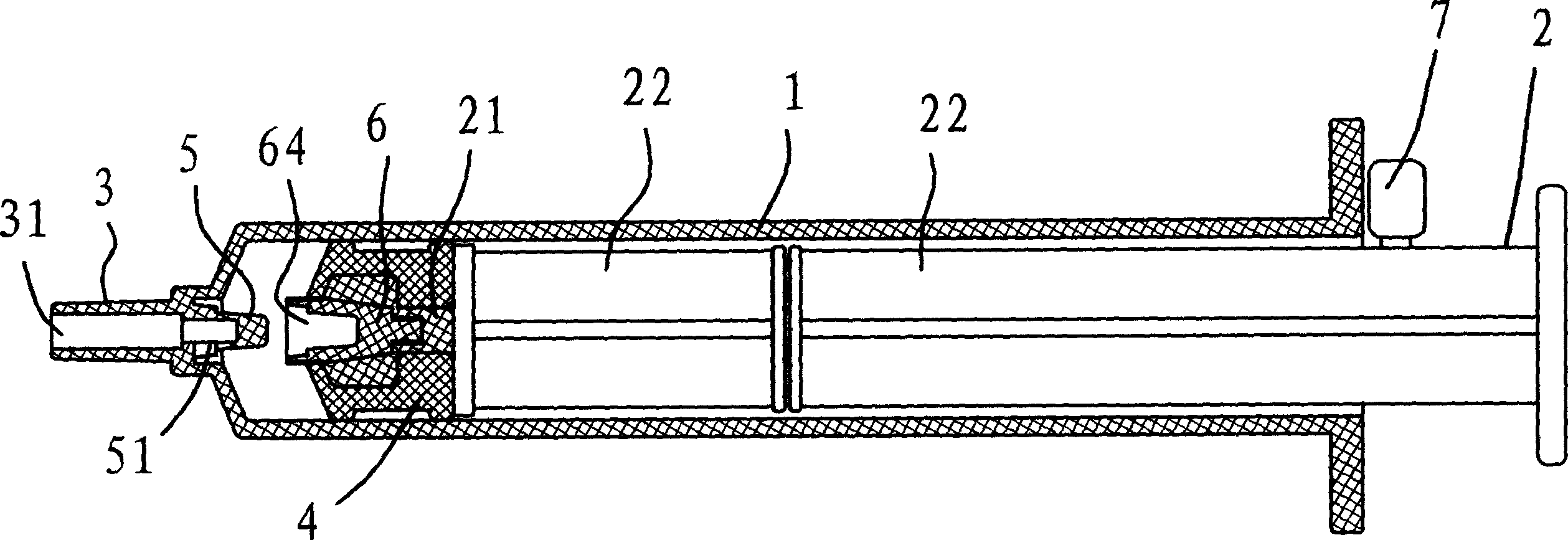

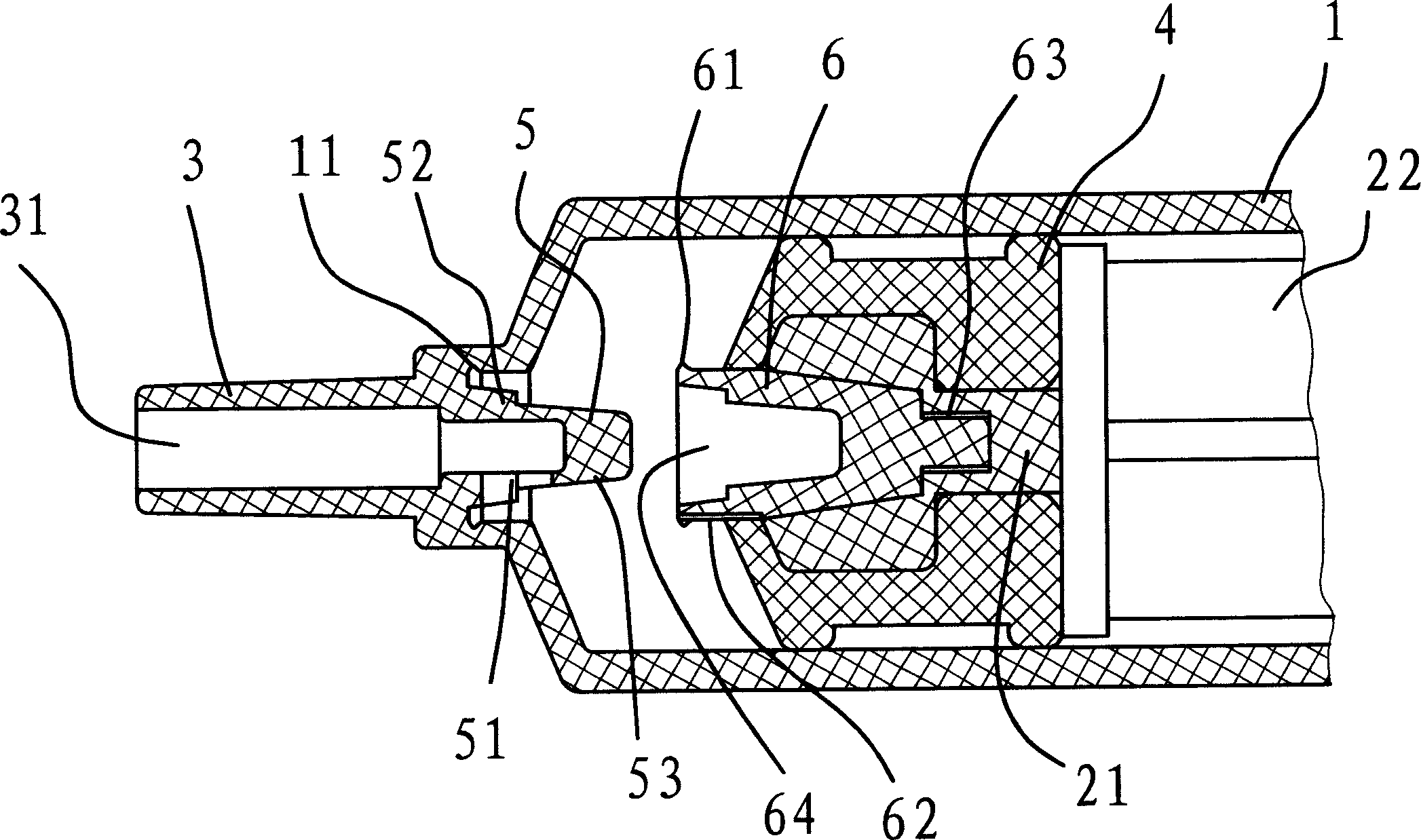

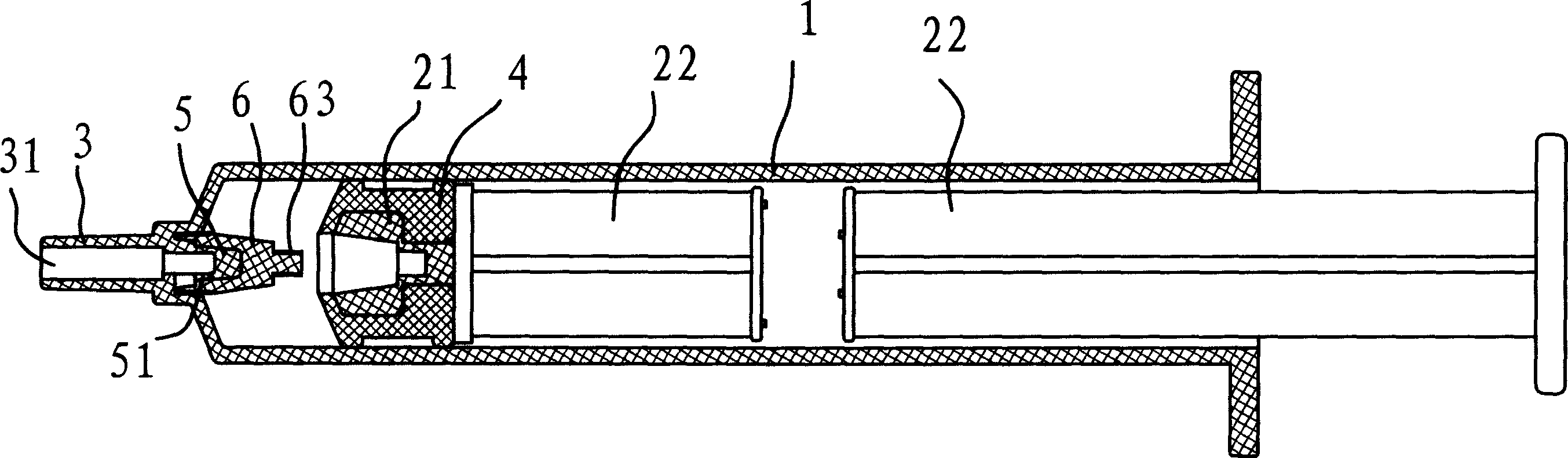

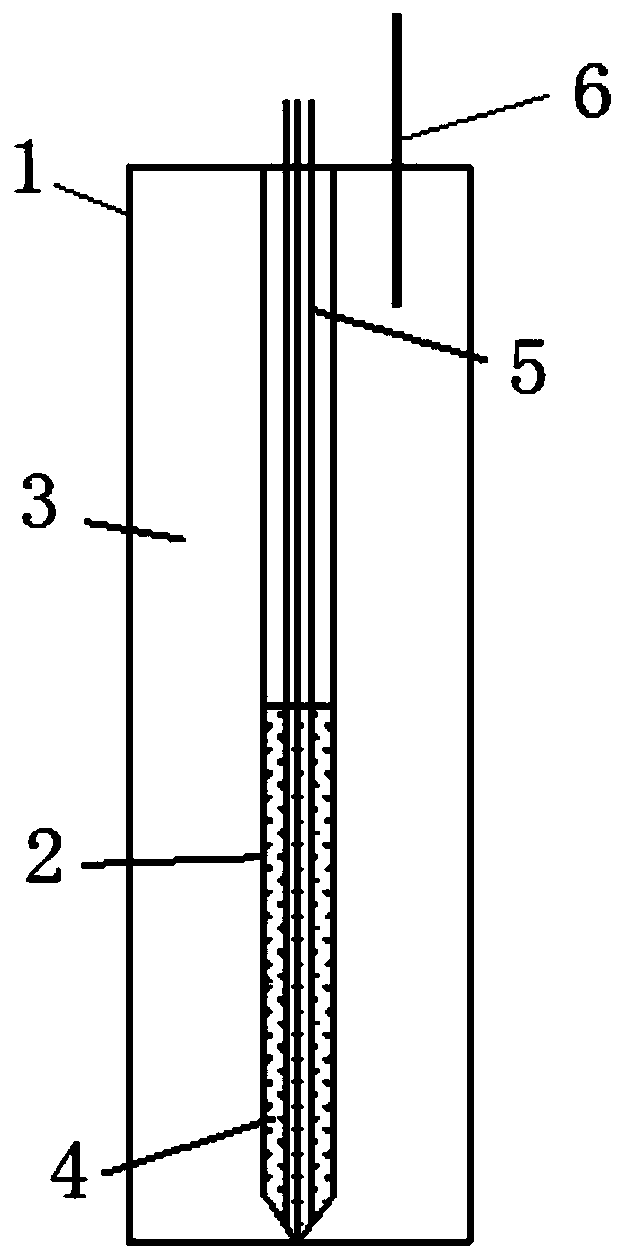

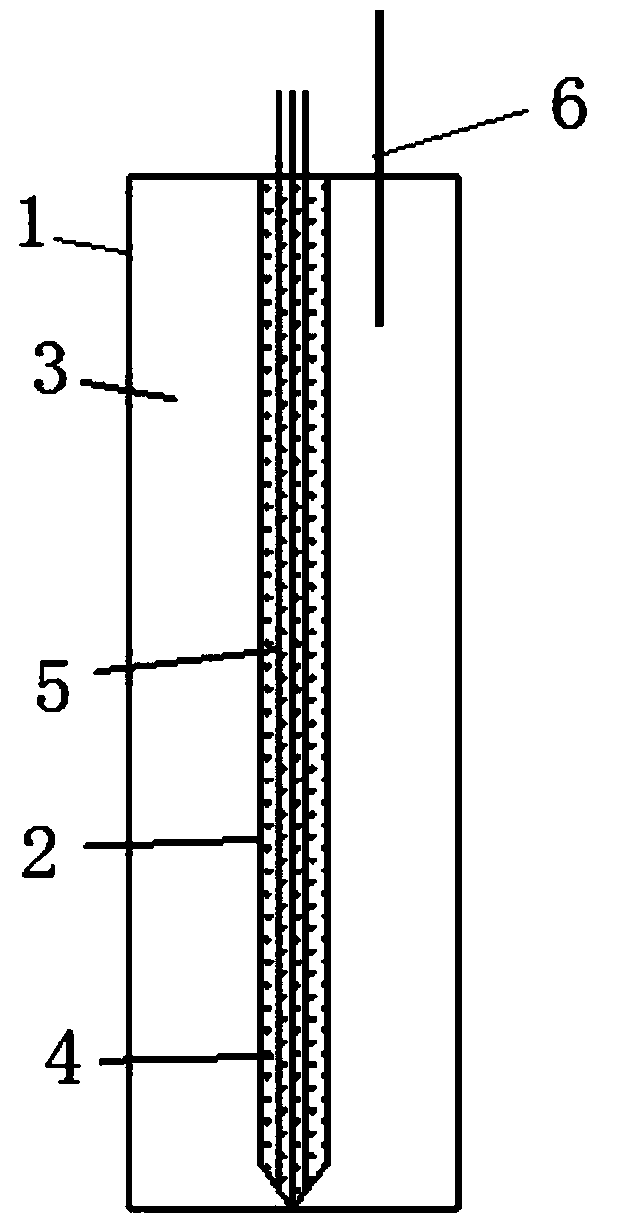

Self-destructted type injector

InactiveCN1539519AIngenious structureLittle increase in costInfusion syringesIntravenous devicesEngineeringNeedle holder

A self-destroyed injector is composed of an injection tube with needle holder and an injection rod with a rubber plug on its head. A plug with a central through hole is arranged in the internal through hole of needle holder and can be sleeved by a blocking sleeve on the front end of injection rod, so it can not be used again. Its advantage is simple structure.

Owner:颜智远

Preparation method of post-grouting reinforced CFG pile with anti-break pile head

ActiveCN110359449AReduce settlement deformation and uneven deformationImprove bearing capacityBulkheads/pilesSteel tubePressure grouting

The invention belongs to the field of piling and specifically relates to a preparation method of a post-grouting reinforced CFG pile with an anti-break pile head. The method is characterized by comprising the steps that firstly, drilling is carried out with a spiral drilling machine; secondly, after drilling construction to a hole bottom and pressure grouting of concrete to a pile top, a first reinforcing bar (6) is inserted into the pipe top with a depth of 0.5m-1m, so a precast CFG pile is formed; thirdly, a back insertion steel tube (2) with a grouting head is inserted to a pile end from the center of the pile top of the precast CFG pile, and a steel strand (5) extends to the front end of the back insertion steel tube (2) from the rear end of the rear insertion steel tube (2); fourthly,after shaping of the precast CFG pile for 24h-48h, gradually grouting is conducted in the back insertion steel tube(2) by the grouting head, and the pile end is reinforced; fifthly, lengths of the first reinforcing bar (6) and the steel strand (5) exposed above the pile top are trimmed; sixthly, a sandy stone filling layer is poured on the first reinforcing bar (6) and the steel strand (5) abovethe pile top; and seventhly, roadbed building stones are disposed on the sandy stone filling layer and then compacted. The preparation method provided by the invention has the beneficial effects thatthe pile end is firm, and the pipe top is firm and free of getting broken.

Owner:CHINA BUILDING TECHN GROUP

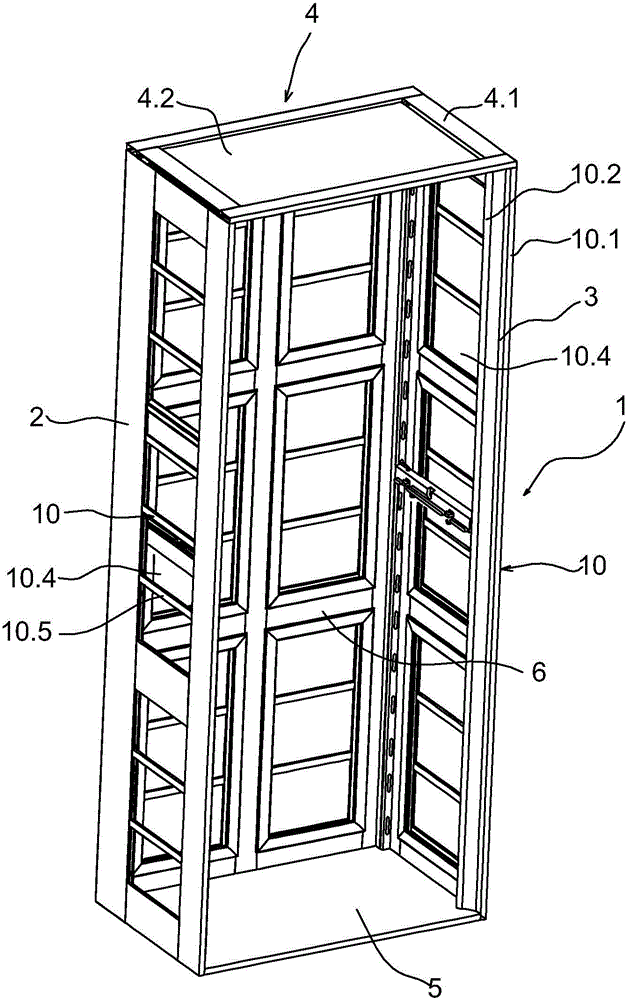

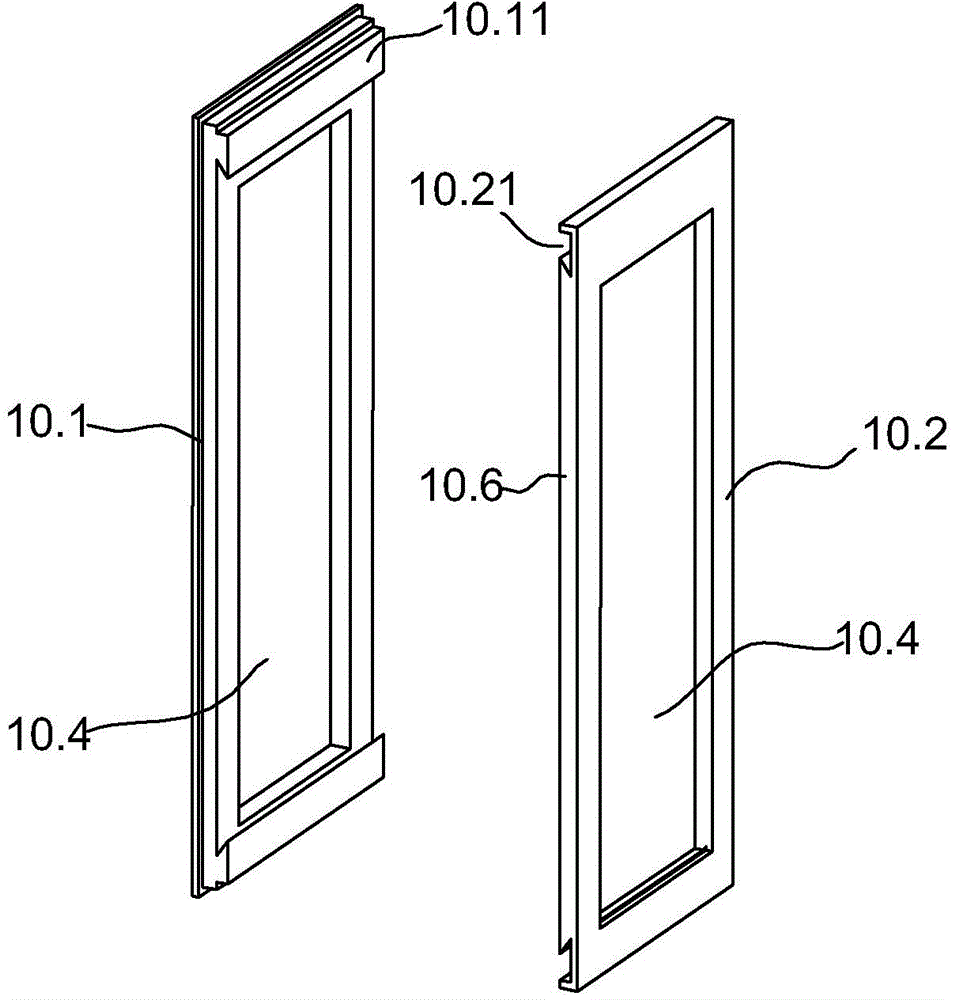

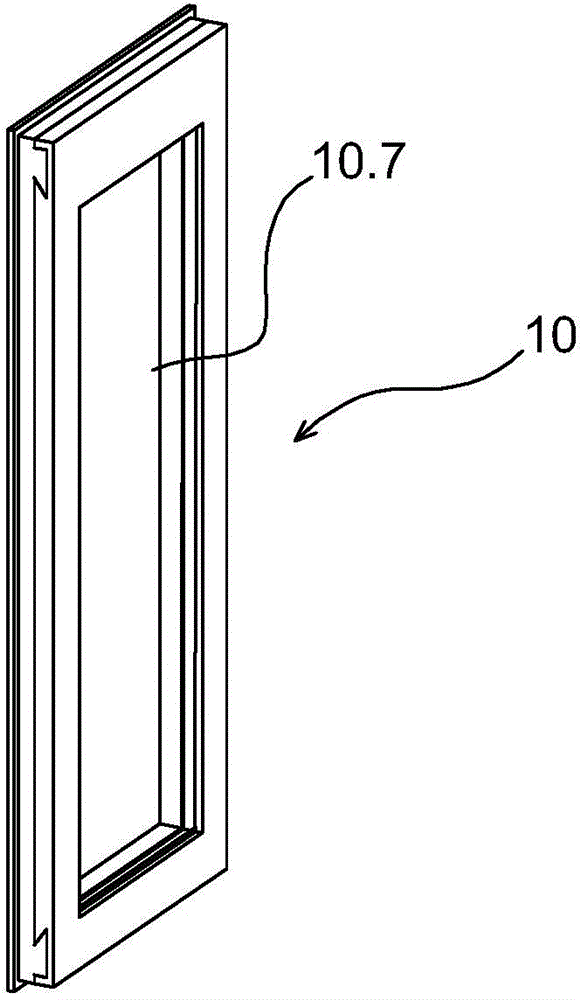

Cabinet

InactiveCN105310319AAvoid Stylized FlawsSatisfy the aesthetic point of viewDismountable cabinetsFittingEngineeringSurface plate

A cabinet comprises a left side plate, a right side plate, a top plate, a bottom plate and a back plate which form a cabinet body as well as partition boards dividing space in the cabinet body. The cabinet is characterized in that at least one of the left side plate, the right side plate, the top plate, the bottom plate, the back plate and the partition boards adopts a detachable decorating plate; the decorating plate comprises an outer surface plate and an inner surface plate, the outer surface plate and the inner surface plate are detachably connected together after being buckled, and filling space allowing decorating sheets or decorating soft rolls to be arranged is formed between the outer surface plate and the inner surface plate, and at least one of the outer surface plate and the inner surface plate has a gap part allowing the decorating sheets or decorating soft rolls to be exposed. Accordingly, the cabinet can reflect clothes placed inside, and the beautiful characteristic of the clothes is set off; the decorating sheets or the decorating soft rolls in the decorating plate can be taken out to be replaced, so that decoration in the cabinet body changes continuously and coordinates and matches with new clothes, and the continuously improving aesthetic view of consumers can be met.

Owner:应孝华

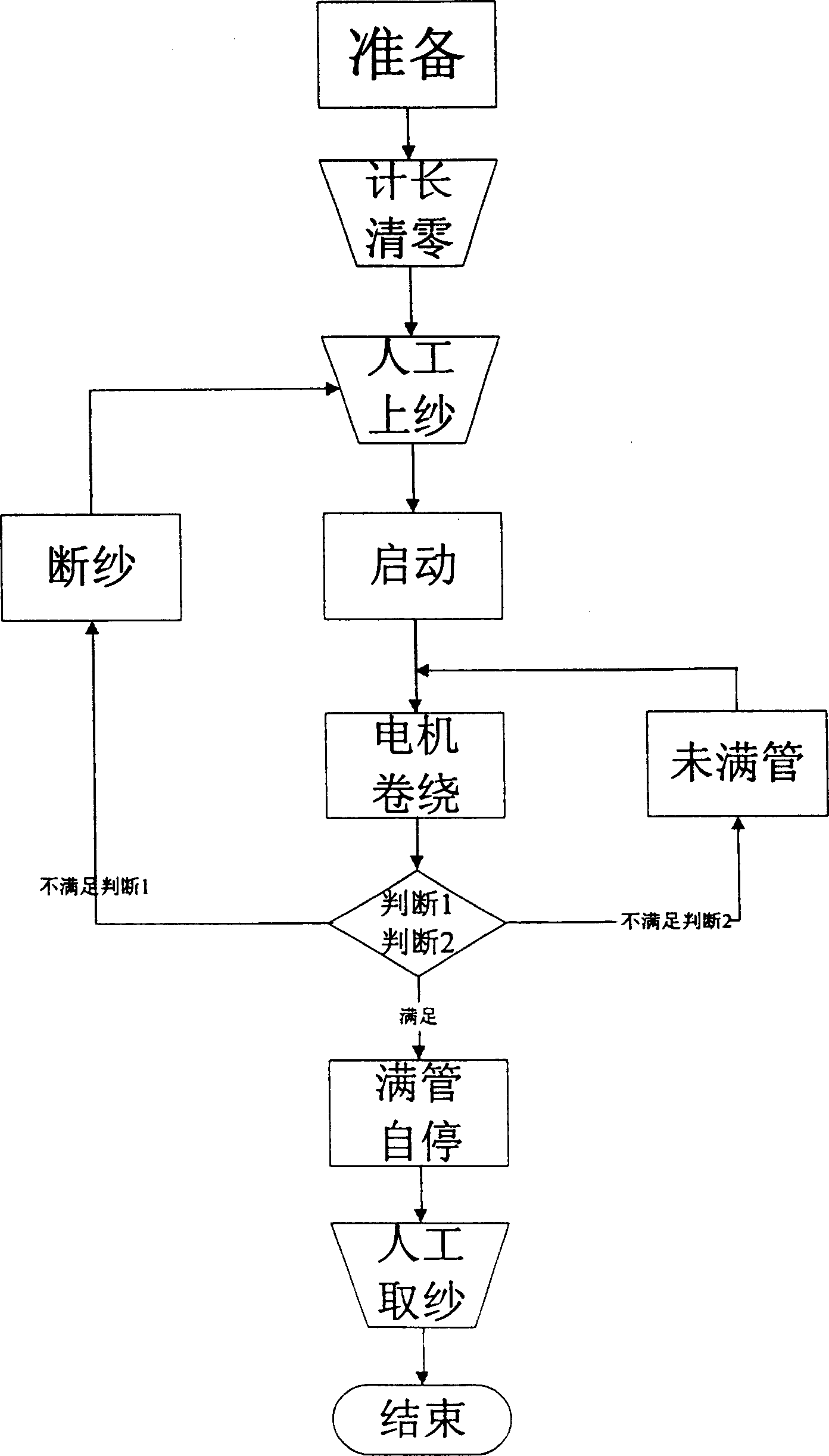

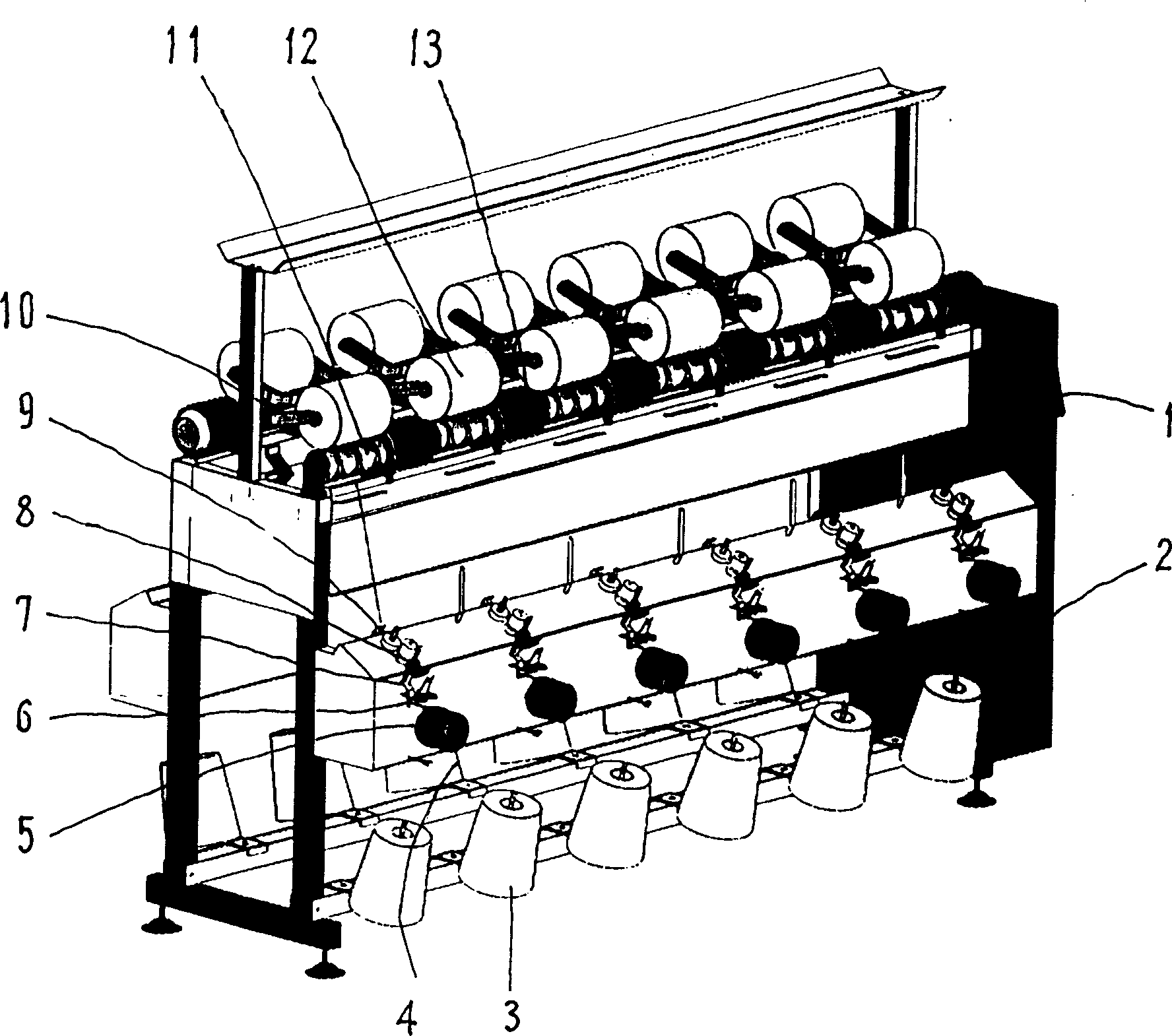

Loose type coning control method

InactiveCN1769154AUniform winding densityMeeting demands for ever-increasing technical requirementsFilament handlingYarnBobbin

The invention relates to a method for controlling the loose bobbin winder, which can improve the winding quality when winding yarn. The inventive method comprises: preparation, calculating length and clear, hand-operated yarn up, starting, motor winding, automation, judgment, calculating the length and stopping when the tube is full, hand-operated get yarn, and finish. The invention can apply variable semi-automatic bobbin winder control.

Owner:SHANGHAI CORAL TEXTILE MACHINERY

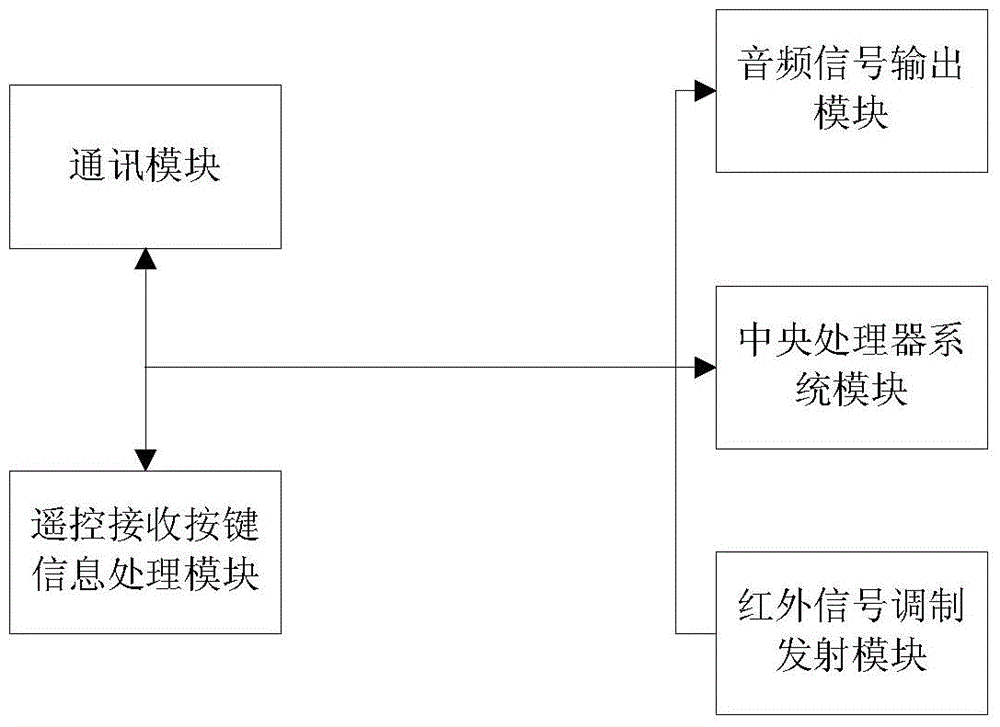

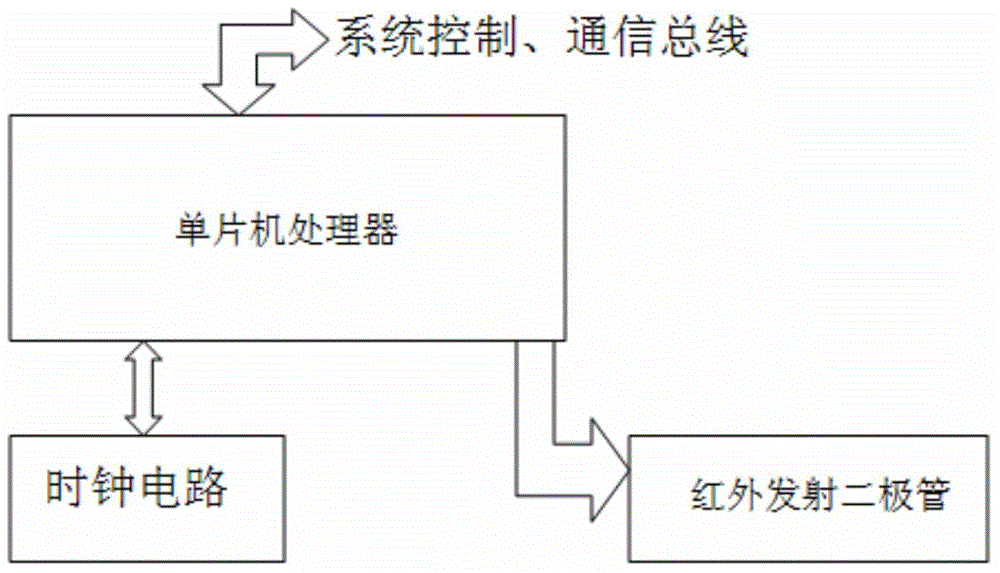

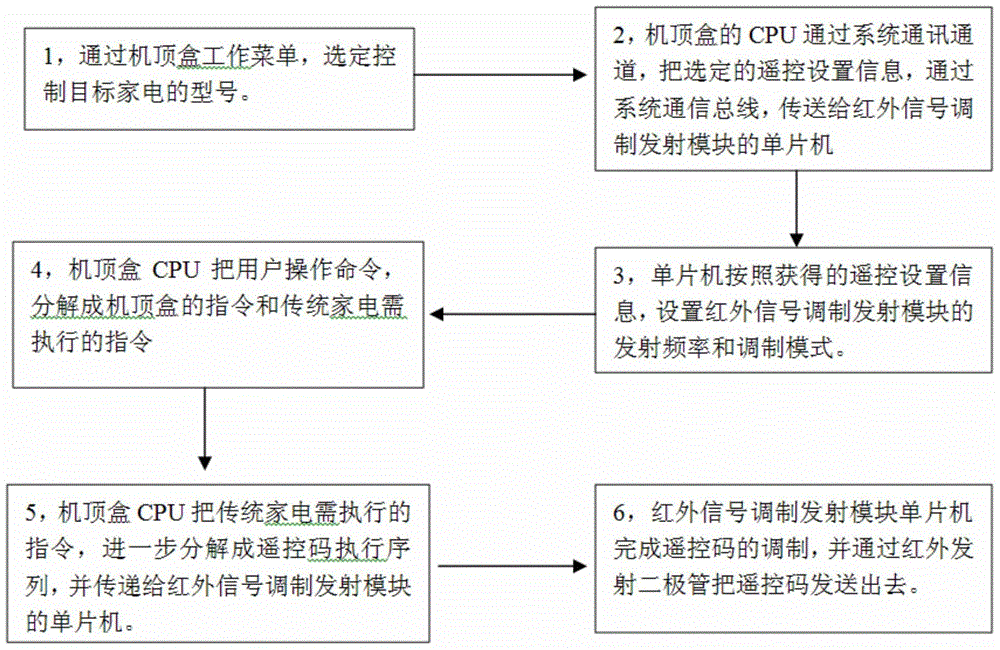

Set top box capable of controlling traditional household appliance and control method

InactiveCN104469458AAchieve intelligenceFlexible and diverse controlNon-electrical signal transmission systemsSelective content distributionInformation processingRemote control

The invention provides a set top box capable of controlling a traditional household appliance and a control method. The set top box comprises a remote control received key information processing module, an infrared signal modulating and transmitting module and a central processor system module, the remote control received key information processing module is used for receiving and processing a selecting control instruction of a user on the type of a target household appliance and an instruction of the user for operating the traditional household appliance, and the infrared signal modulating and transmitting module is used for carrying out remote control code coding and signal modulation according to the instruction of the user for operating the traditional household appliance, and then sending signals to the target household appliance. The central processor system module is used for calling corresponding remote control setting information in a remote control code database according to the selecting control instruction of the user for the type of the target household appliance and setting the sending frequency and the modulating mode of the infrared signal modulating and transmitting module according to the remote control setting information. The instructions sent by the user are analyzed, the control instruction on the traditional household appliance is formed intelligently, intelligent, flexible and multiple control and remote operations on the traditional household appliance are achieved, and the set top box is wide in application range, few in cost increase and very obvious in benefit.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com