Application of steel-titanium-aluminum composite joint to refrigerating system of fishing boat

A refrigeration system and composite joint technology, applied in the application field, can solve problems such as leakage of refrigerant in the pipeline, affecting the quality of fishery products, failure of the refrigeration system, etc., to achieve the effects of protecting the environment, ensuring quality, and eliminating leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

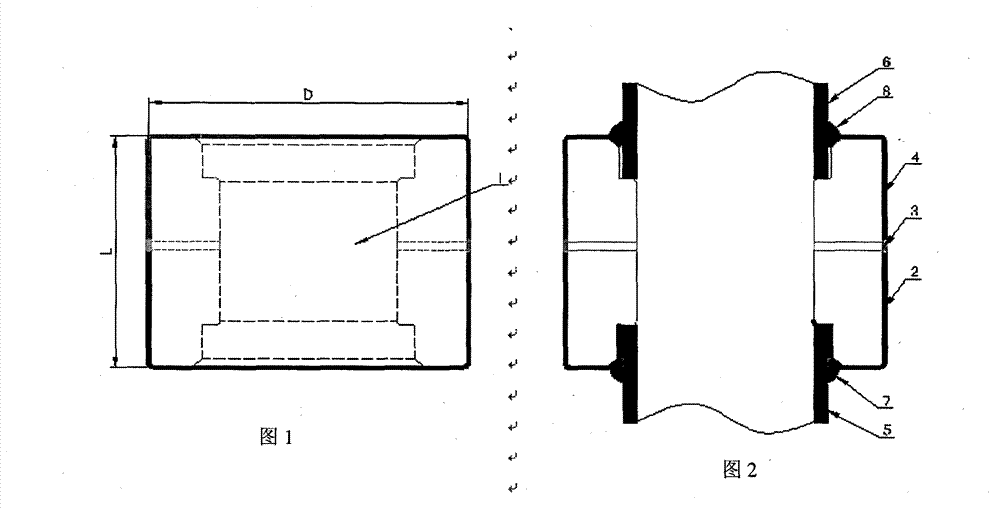

[0020] The invention relates to a connection method, which is mainly used for connecting two pipes of different materials in a refrigeration system, that is, steel pipes and aluminum pipes.

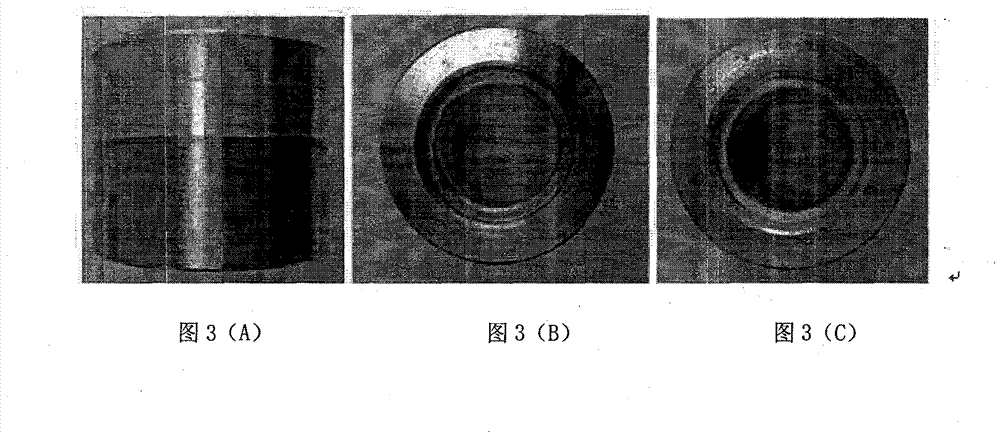

[0021] In the refrigeration system, the aluminum pipe (6) is welded to the aluminum end (4) of the steel-titanium-aluminum composite joint (1) to form a welding joint (8), and the steel pipe (5) is connected to the steel-titanium-aluminum composite joint (1). The steel end (2) of the compound joint (1) is welded and connected to form a weld joint (7). Through the steel-titanium-aluminum composite joint (1), the steel pipe (5) and the aluminum pipe (6) form an effective connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com