Ship fan evaporator using hot air to melt frost

A marine fan and evaporator technology, which is applied to evaporators/condensers, refrigerators, lighting and heating equipment, etc., can solve the problems of defrosting system failure, icing, and dirty water drainage, and achieve a simple structure Effect

Inactive Publication Date: 2017-02-15

广州中臣碧阳科技集团有限公司

View PDF8 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] If the fan evaporator used on the ship is defrosted by hot steam defrosting, the ship will maintain an inclination angle for a period of time due to the action of the waves, which will cause the accumulated water in the water receiving tray to be unclean and freeze. After several defrost cycles, the ice layer will cover the drip pan and block the drain, so the defrost system will fail

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

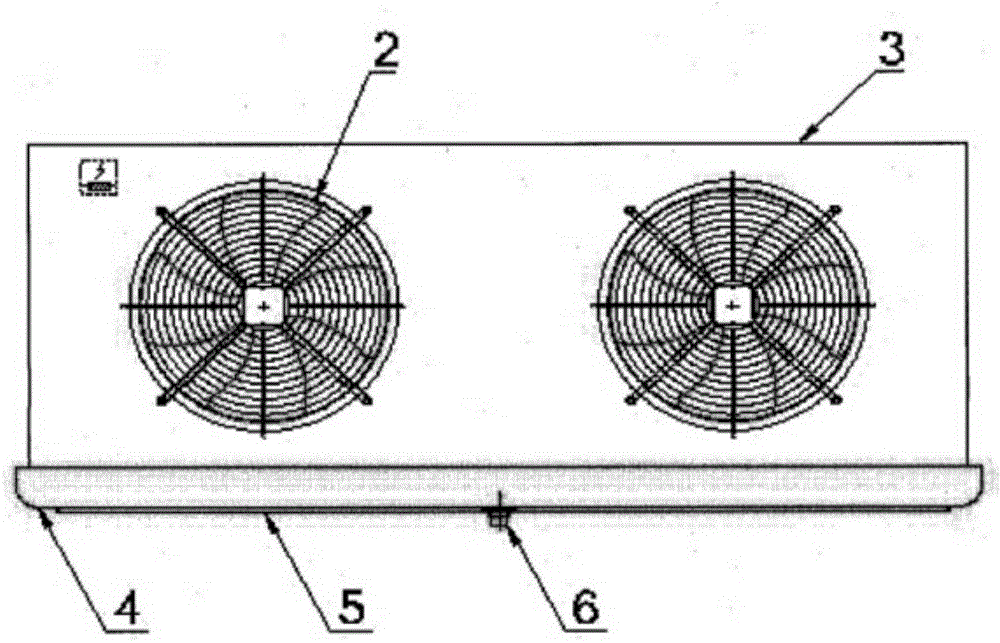

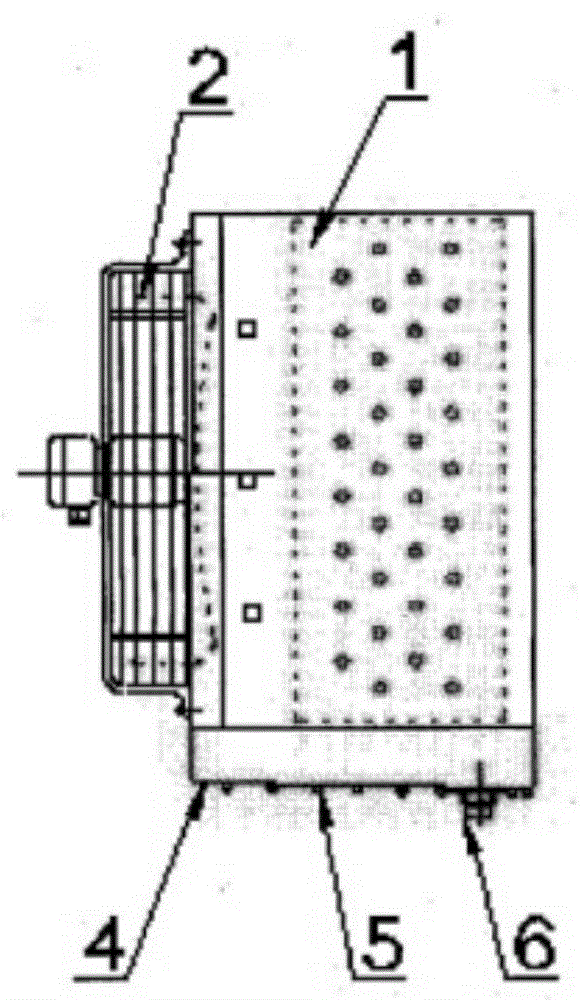

[0010] When the fan evaporator is in the defrosting process, the high-temperature refrigerant gas first passes through (5) the heating coil, and then enters (1) the coil finned coil, and the frost layer on the outer surface of the evaporator melts into water when heated, drip into (4) water receiving tray, and the water in (4) water receiving tray is drained from (6) drain outlet under the influence of temperature of (5) heating coil.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

At present, the conventional ship fan evaporators use hot air to melt frost, a ship keeps inclination sailing during a period due to waves, and then water gathered in a water holding disc cannot be drained completely, an ice layer will cover the water holding disc after a few of frost melting cycles, the drainage opening will be blocked, and a frost melting system will fail. The ship fan evaporator is different from the conventional an evaporators using hot air to melt frost, and is characterized in that a plurality of seamless tubes as heating coils are arranged under a water holding disc according to the area of the water holding disc, the heating coils heat the water holding disc during a frost melting process all the time so as to prevent frost molten water from freezing, and the frost molten water can be smoothly drained out from a drainage opening.

Description

technical field [0001] The invention relates to a marine fan evaporator using hot steam to defrost, and belongs to the field of agriculture, forestry, animal husbandry and fishery. Background technique [0002] The fan evaporator that uses hot steam to defrost is used in the market in the refrigeration system. The principle is to introduce the high-temperature refrigerant gas discharged from the refrigeration compressor into the evaporator after being separated by the oil separator, and use the superheated steam to release it. The heat melts the frost layer on the outer surface of the evaporator, and the superheated steam turns into liquid after heat release, and is discharged into the drain bucket or low-pressure circulation bucket together with the original oil in the evaporator. [0003] Once the frost layer on the outer surface of the evaporator melts into water, it will drip into the water receiving pan located below the evaporator, and the water will be drained away th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F25B39/02

Inventor 隋闯

Owner 广州中臣碧阳科技集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com