Preparation method of modified PVDF for heavy metal ion adsorption type separation films

A heavy metal ion and adsorption-type technology, which is applied in the direction of semi-permeable membrane separation, alkali metal compounds, chemical instruments and methods, etc., can solve problems affecting the stability of membrane performance, etc., achieve improved separation efficiency, easy industrial implementation, and increased cost little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029](1) Pretreatment of PVDF powder. Accurately weigh a certain mass of KOH, and use absolute ethanol to prepare 200mL of a solution with a concentration of 1.0mol / L, put it in a beaker, add 40g of PVDF powder, stir magnetically at 50°C for 15 minutes, suction filter, and use deionized Wash with water until the pH of the cleaning solution is about 7. After suction filtration, dry the pretreated PVDF powder for later use.

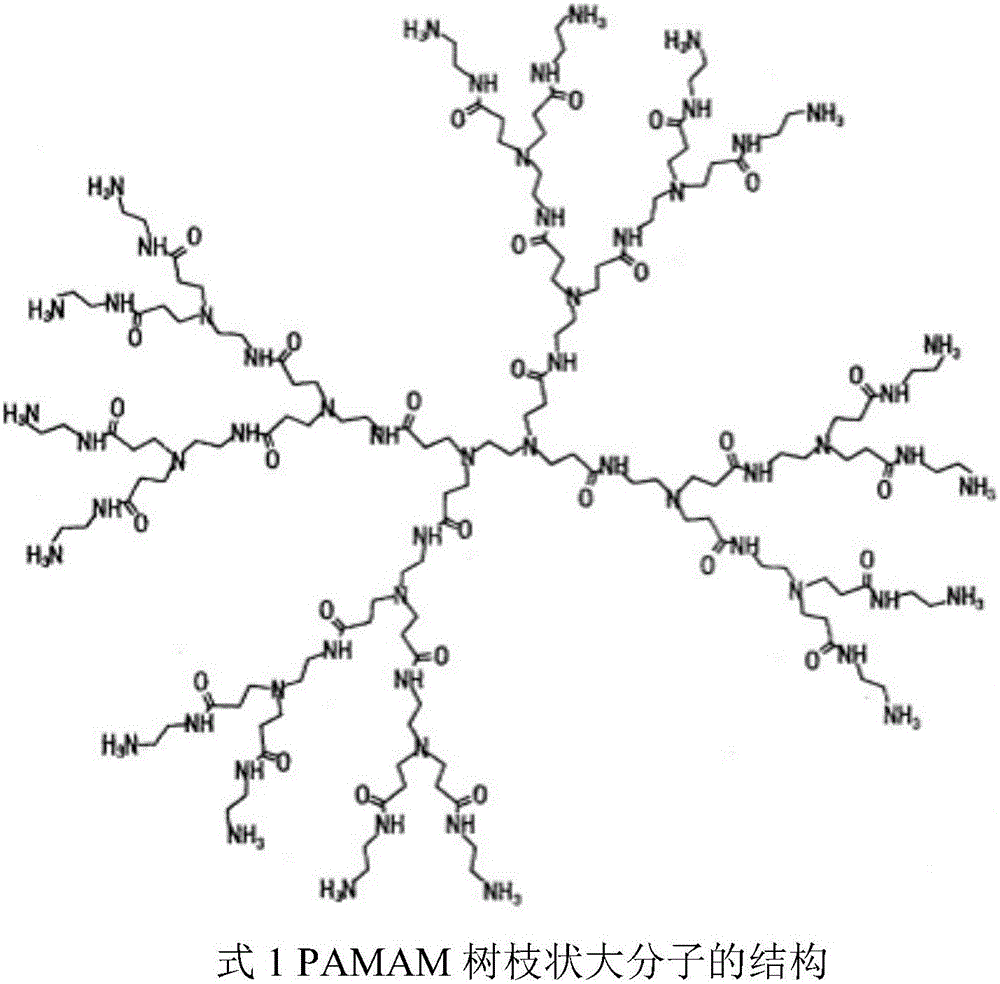

[0030] (2) Preparation of PAMAM. ①Dissolve 4g of EDA in 20mL of methanol, then transfer it to a 100mL three-necked flask, and place 30g of MA in a constant-pressure dropping funnel under the condition of maintaining an ice-water bath at 0°C and nitrogen protection to make it pour into the three-necked flask. Gradually added dropwise to the flask for 20 minutes. After 2 hours, it was raised to room temperature 20°C, and continued to stir for 45 hours, then transferred to a single-necked flask and used a rotary evaporator for rotary evaporation, and the t...

Embodiment 2

[0036] (1) Pretreatment of PVDF powder. Accurately weigh a certain mass of KOH, and prepare 200mL of a solution with a concentration of 1.0mol / L with absolute ethanol, put it in a beaker, add 42g of PVDF powder, stir magnetically at 50°C for 30 minutes, filter it with suction, and use deionized Wash with water until the pH of the cleaning solution is about 7. After suction filtration, dry the pretreated PVDF powder for later use.

[0037] (2) Preparation of PAMAM. ① Dissolve 6g of EDA in 20mL of methanol, then transfer it to a 100mL three-necked flask, and place 40g of MA in a constant-pressure dropping funnel under the condition of maintaining an ice-water bath at 0°C and nitrogen protection Gradually added dropwise to the flask for 20 minutes. After 2 hours, it was raised to room temperature 20°C, and continued to stir for 45 hours, then transferred to a single-necked flask and used a rotary evaporator for rotary evaporation, and the temperature was gradually increased fr...

Embodiment 3

[0043] (1) Pretreatment of PVDF powder. Accurately weigh a certain mass of KOH, and prepare 200mL of a solution with a concentration of 1.5mol / L with absolute ethanol, put it in a beaker, add 43g of PVDF powder, stir magnetically at 55°C for 30 minutes, filter it with suction, and use deionized Wash with water until the pH of the cleaning solution is about 7. After suction filtration, dry the pretreated PVDF powder for later use.

[0044] (2) Preparation of PAMAM. ①Dissolve 5g of EDA in 20mL of methanol, then transfer it to a 100mL three-necked flask, and place 40g of MA in a constant-pressure dropping funnel under the condition of maintaining an ice-water bath at 5°C and nitrogen protection The flask was gradually added dropwise for 30 minutes. After 2 hours, it was raised to room temperature 30°C, and continued to stir for 50 hours, then transferred to a single-necked flask and used a rotary evaporator for rotary evaporation, and the temperature was gradually increased fr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com