Hot extrusion mold for producing profile for electrified high-speed railway feedback line clamps

A technology of hot extrusion dies and high-speed railways, applied in the direction of metal extrusion dies, etc., can solve problems such as inability to produce, and achieve the effects of easy realization, cost reduction, and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention and its beneficial effects will be further described below in conjunction with the accompanying drawings.

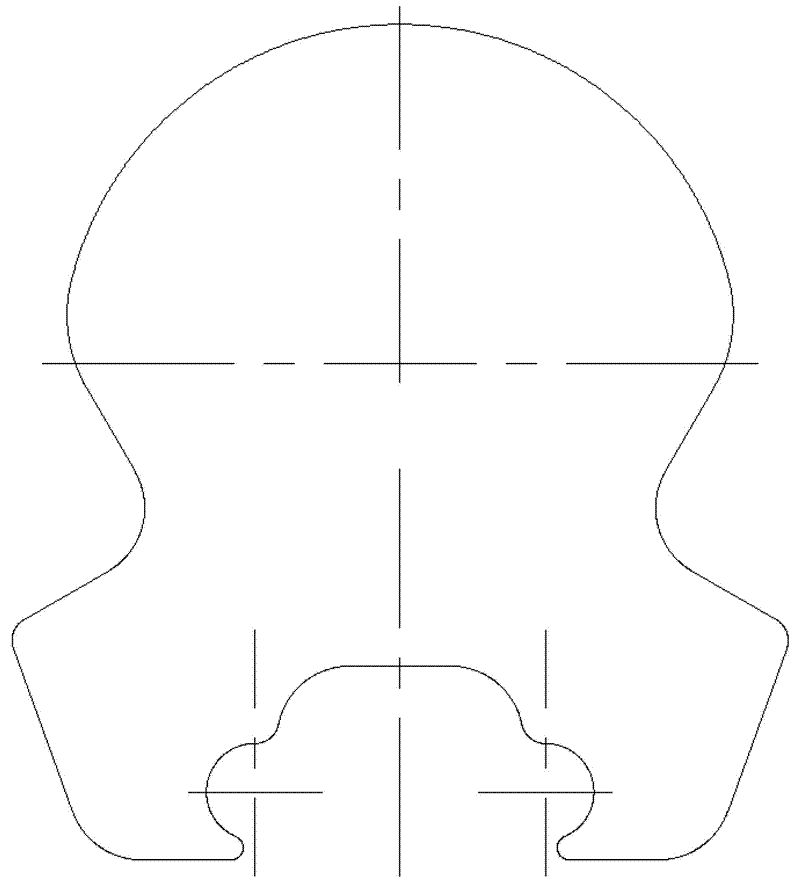

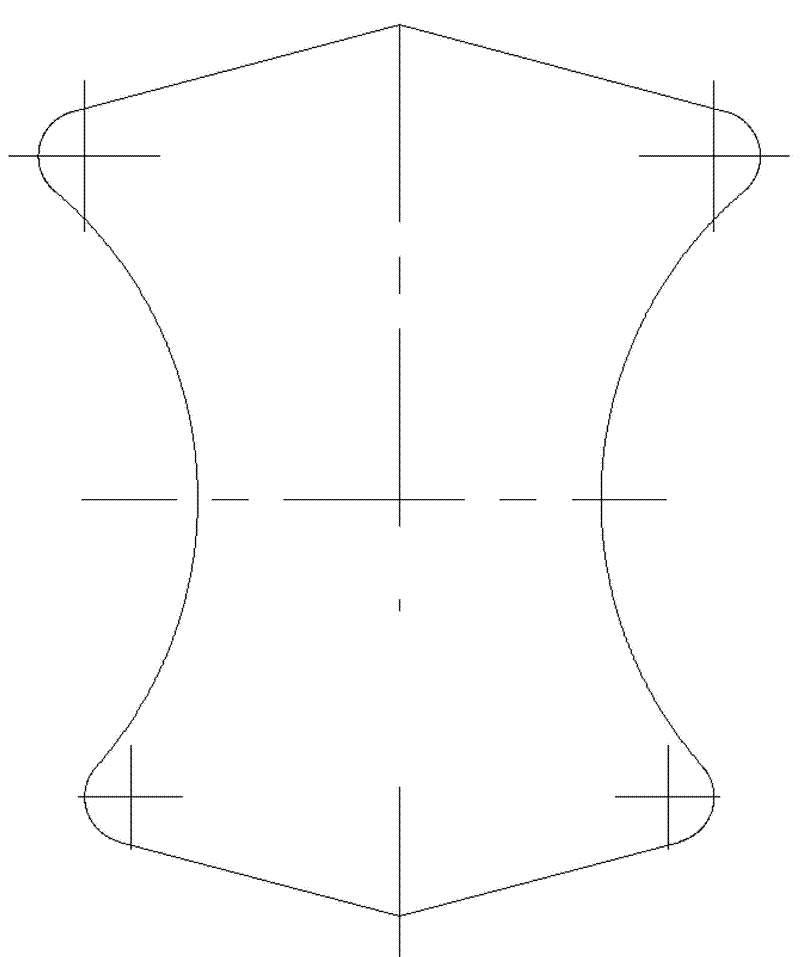

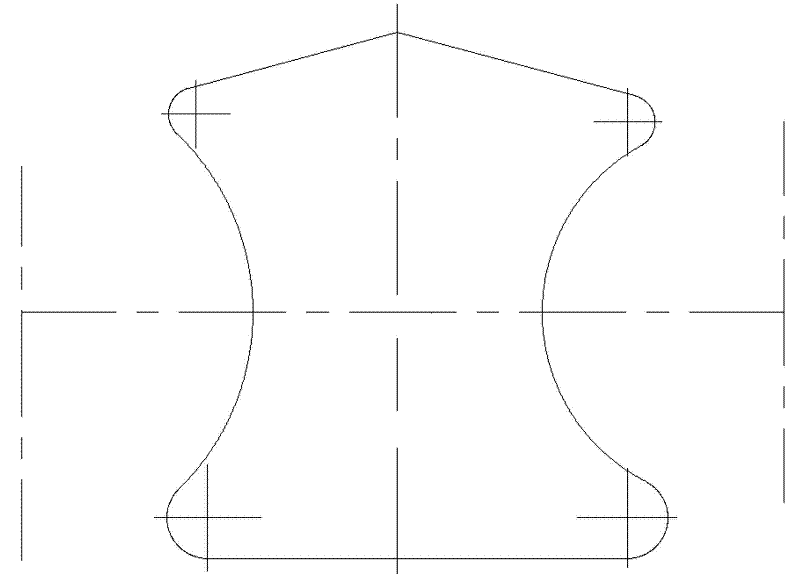

[0016] refer to Figure 1a , 1b , 1c, 1d, 2, 3, a kind of clamp used for producing electrified high-speed railway feedback wire different A hot extrusion die for profiles, the hot extrusion die 1 is a single cone integral type, and its inner cavity structure from the inlet to the outlet is: entrance area 2, sizing area 3, cone angle transition area 4 and outlet Zone 5; the sizing zone 3 tapers toward the front end of the mold 1 to form the entrance zone 2, and the transition between the sizing zone 3 and the exit zone 5 is enlarged by the taper angle transition zone 4; the entrance The cross-sectional shapes of the area 2, the sizing area 3, the cone angle transition area 4 and the exit area 5 are all used for the feedback line clamp of the electrified high-speed railway different The shapes of the profiles are consistent and the cross-sec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com