Preparation method of post-grouting reinforced CFG pile with anti-break pile head

A post-grouting, pile head technology, applied in sheet pile wall, construction, foundation structure engineering, etc., can solve the problems such as the inability to guarantee that the CFG pile will not have shallow pile breakage, the inability to withstand excessive shear stress, and the delay of construction period. , to achieve the effect of easy construction operation, easy construction and less cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

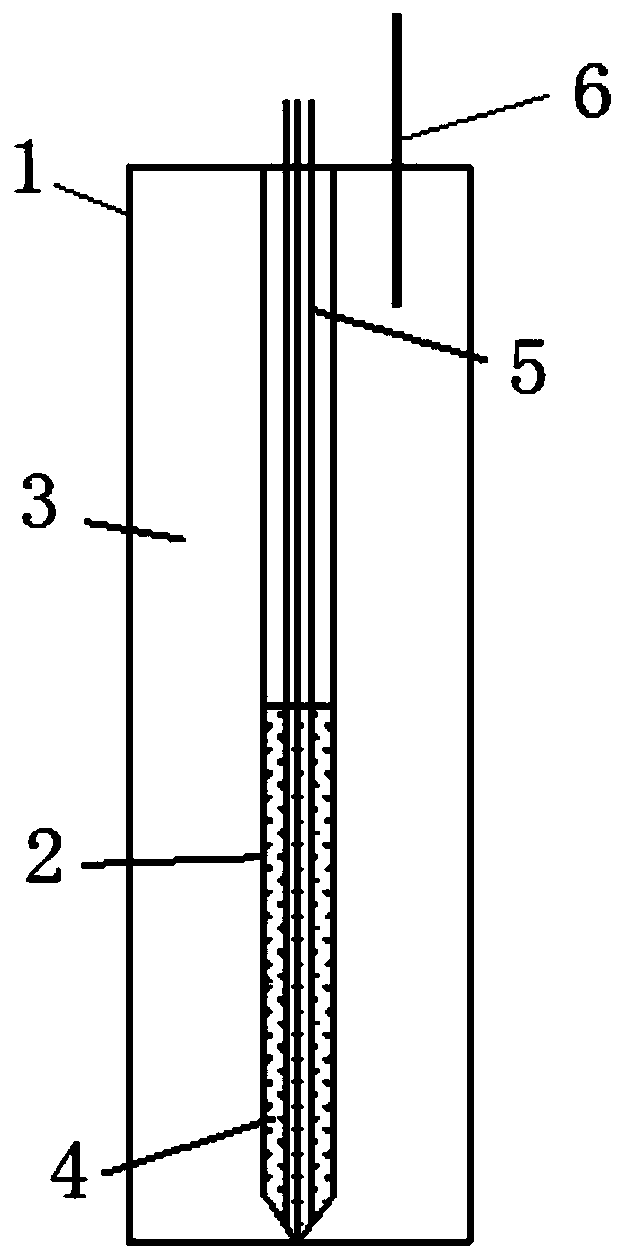

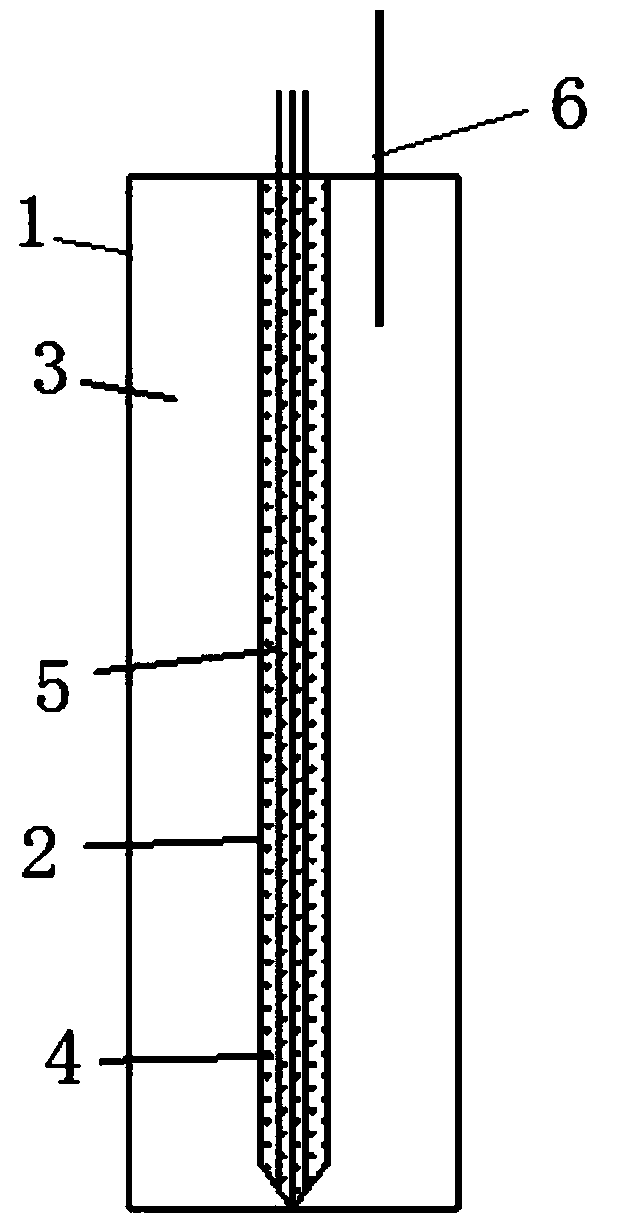

[0026] The following will be combined with Figure 1-2 , to clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, rather than all the embodiments.

[0027] Such as Figure 1-2 Shown, a kind of back grouting reinforced CFG pile preparation method of anti-breaking pile head is characterized in that, carries out according to the following steps:

[0028] Step 1: Drill holes with an auger drill;

[0029] Step 2, after drilling to the bottom of the hole and pouring concrete to the top of the pile, a concrete shaft (3) is formed, and the first steel bar (6) is inserted into the top of the pile by 0.5m-1m to form a pre-CFG pile;

[0030] Step 3: Insert a post-inserted steel pipe (2) with a grouting head from the center of the pre-CFG pile to the pile end, and extend the steel strand (5) from the rear end of the post-inserted steel pipe (2) t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com