Anti-microbial contamination hollow fiber membrane and preparation method thereof

A technology of microbial contamination and fiber membrane, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of anti-microbial pollution, etc., and achieve the effects of simple process, good inhibition of adhesion, and easy industrial implementation

Active Publication Date: 2011-06-15

TIANJIN POLYTECHNIC UNIV

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the deficiencies of the existing PVDF hollow fiber membrane anti-microbial pollution technology, the present invention provides an anti-microbial pollution hollow fiber membrane and its

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

example 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

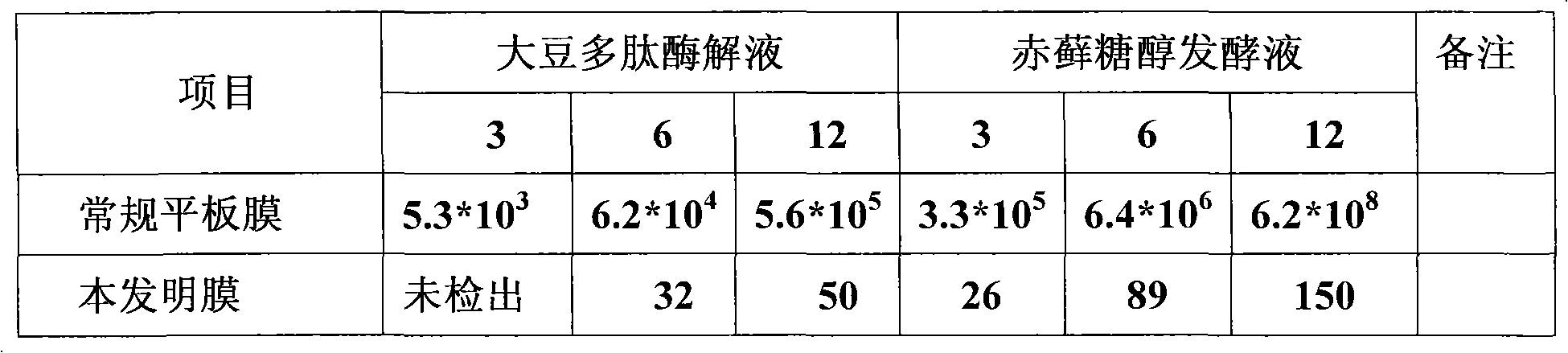

Login to View More Abstract

The invention discloses an anti-microbial contamination hollow fiber membrane and a preparation method thereof, belongs to the technical field of membranes, and particularly relates to an anti-contamination polymeric membrane technique. The anti-microbial contamination hollow fiber membrane contains carbon nanotubes; and the mass ratio of polyvinylidene fluorid (PVDF) to carbon nanotubes is 1:0.001 to 1:0.01. Compared with the conventional PVDF hollow fiber separation membrane preparation, the product disclosed by the invention can be produced without special equipment and the industrial implementation is easy; in a word, the process is simple and the increase in the cost of the membrane is low. The hollow fiber separation membrane product has high attachment inhibition effect on microbesin separation media, and has high microbial contamination resistance.

Description

A kind of anti-microbial pollution hollow fiber membrane and preparation method thereof technical field The invention belongs to the field of membrane technology, in particular to a pollution-resistant polymer membrane technology. Background technique Membrane fouling refers to the adsorption and deposition of particles, colloidal particles or solute macromolecules in the separation medium on the membrane surface or in the membrane pores due to the physical and chemical interaction or mechanical interaction with the membrane during the membrane separation process, causing the membrane pore size to become smaller or Clogging causes the membrane to produce irreversible changes in permeation flow and separation characteristics. For membrane fouling, membrane fouling begins once the separation medium feed liquid comes into contact with the membrane. There are many types and causes of membrane fouling, among which microbial fouling of separation membranes has attracted much a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D71/34B01D69/08

Inventor 陈莉赵义平白静娜冯霞申向

Owner TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com