Shearing reinforcing type full-grouting sleeve

A semi-grouting sleeve and reinforced technology, applied in the direction of building reinforcements, structural elements, building components, etc., can solve the problems of complex processing, high technical requirements, large material consumption, etc., to avoid local stress concentration and broad engineering applications. Prospects, effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

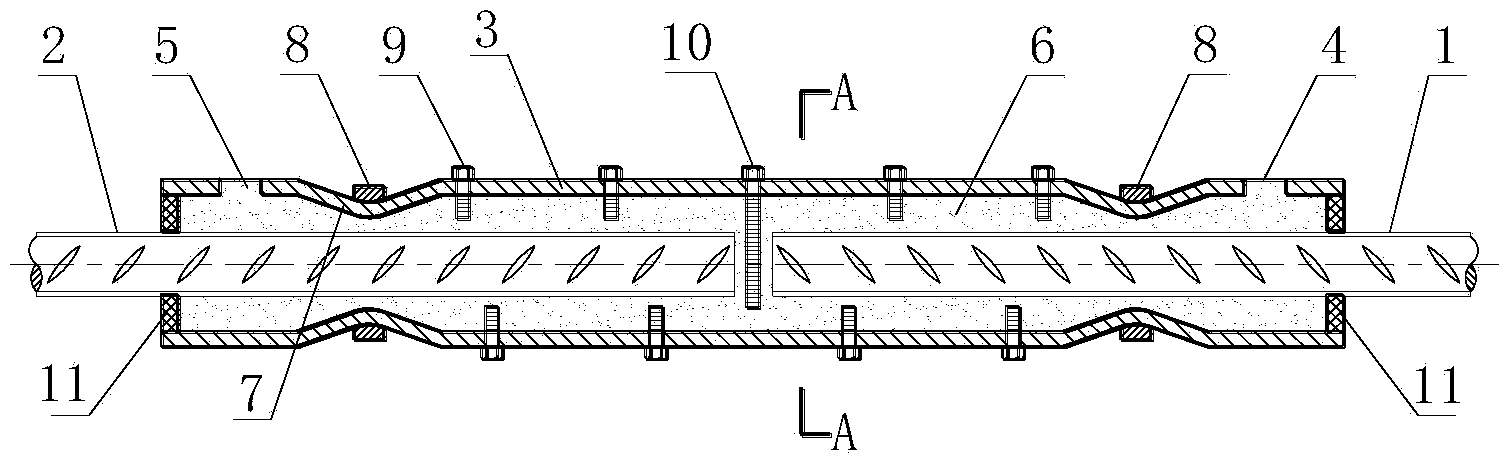

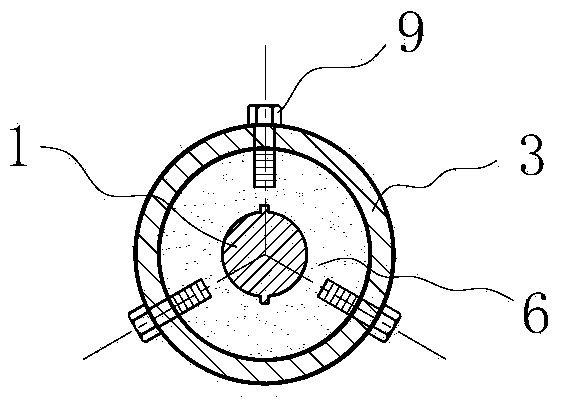

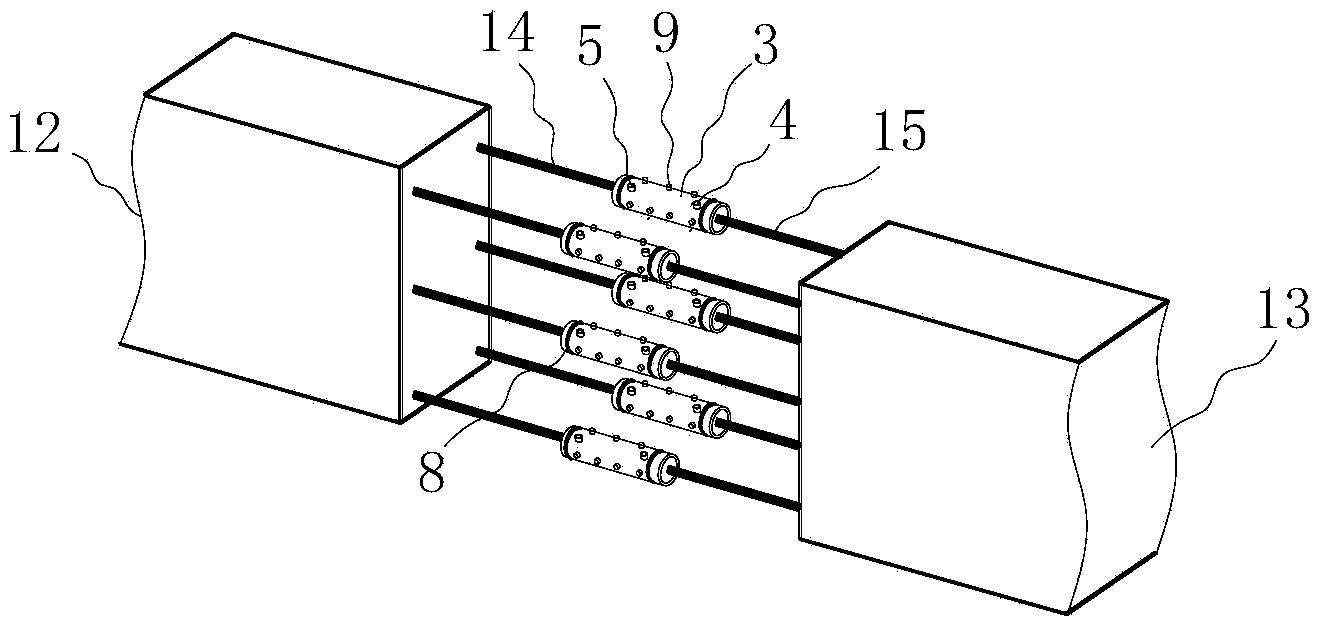

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 and figure 2 As shown, a shear-force-enhanced full-grouting sleeve includes a sleeve body 3, and the sleeve body 3 is a tubular structure processed from a low-carbon steel seamless steel pipe. Both openings of the sleeve body 3 are provided with elastic rubber sealing rings 11, which are respectively used to insert the steel bar A1 and the steel bar B2, and play a sealing role. A grout opening 4 is provided on the side wall near the opening of one end, and a grout outlet 5 is provided on the side wall near the opening of the other end; bolt holes are arranged along the side wall of the sleeve body 3, and the bolt holes have 3 rows with an interval of 120 degrees between each row are evenly distributed on the side wall of the sleeve body 3. Shear bolts 9 are installed in each bolt hole. The total number and diameter of the shear bolts 9 need t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com