Rolling flattening method for strip-shaped transverse tensile sample of steel pipe

A transverse tensile and slat-like technology, which is applied to the rolling flattening of steel pipe slat-shaped transverse tensile specimens, can solve problems such as yield strength reduction, achieve stable yield strength, and avoid inaccurate overpressure parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The transverse yield strength test of Φ508×22mm X70 straight welded steel pipe is carried out as follows.

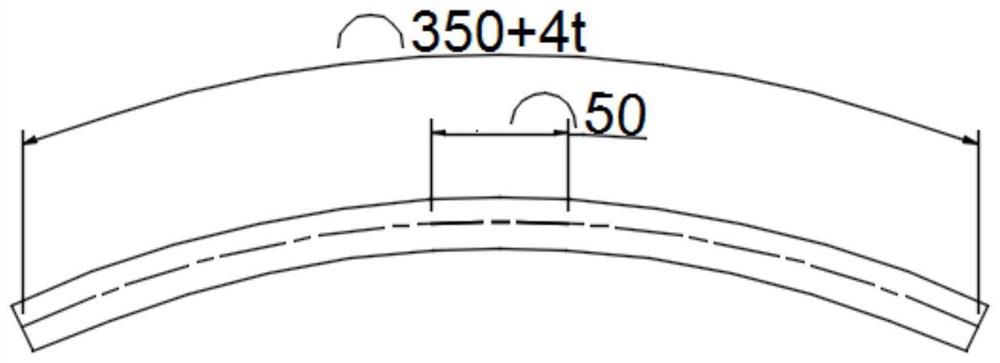

[0021] 1) According to the requirements of relevant standards, cut the raw material of the strip-shaped transverse tensile sample 3 at the position of 90° from the welding seam between the steel pipe, the arc length is about 440mm, and the width is 100mm, such as figure 1 shown. Because it is flame cutting, the effect of edge heat input on the final specimen is considered.

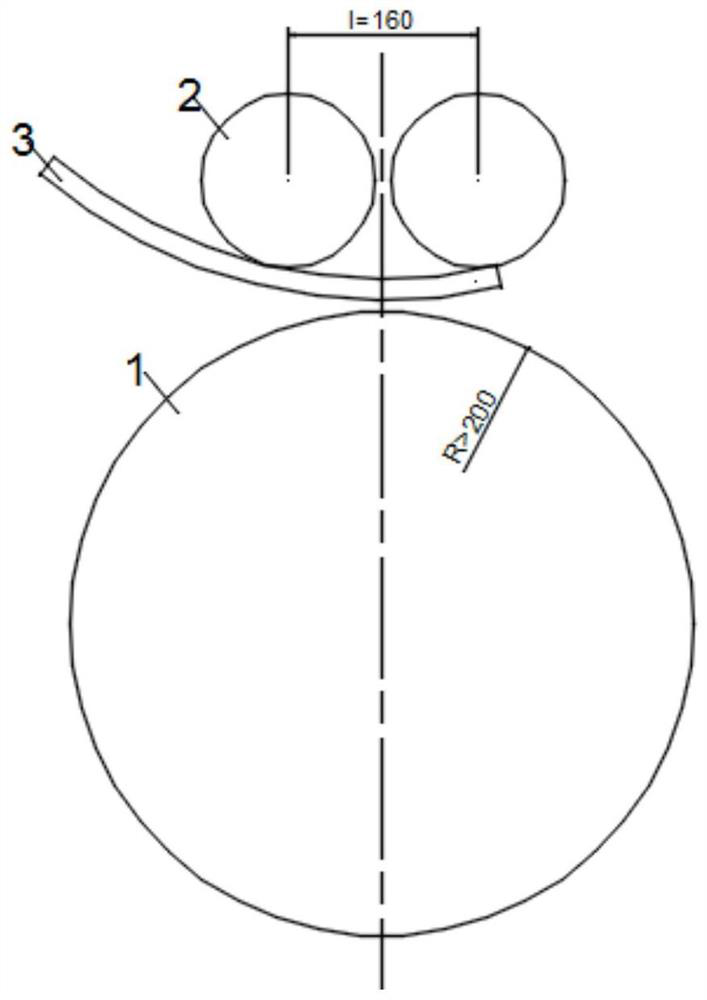

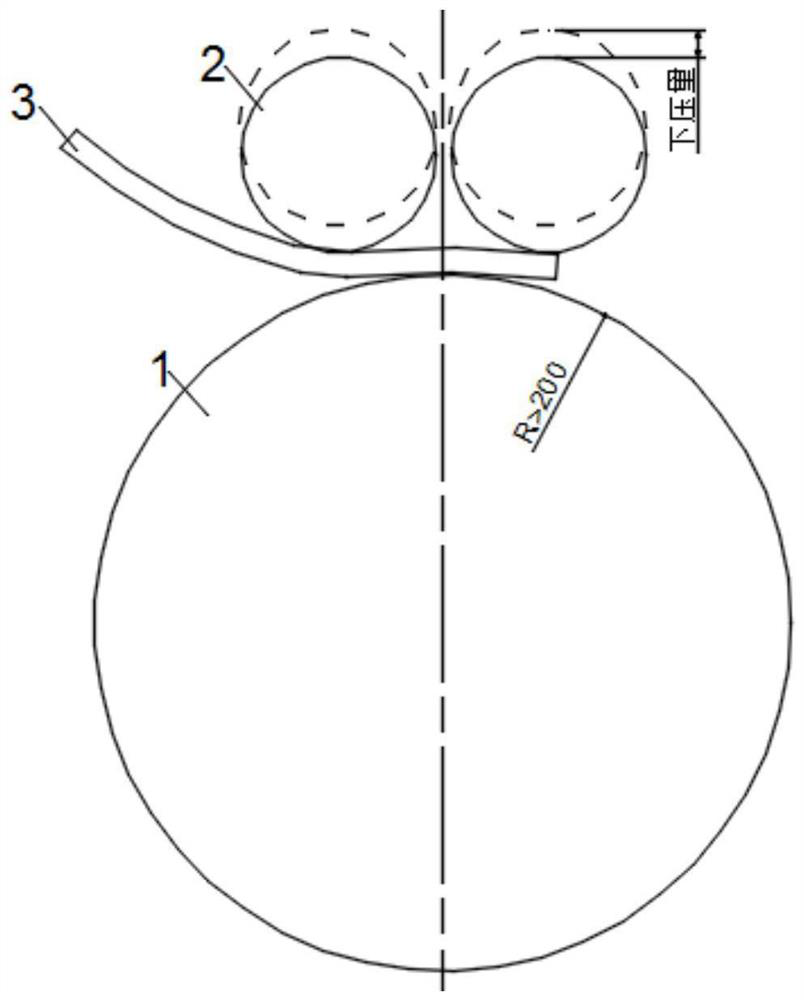

[0022] 2) Put the right end of the strip-shaped sample 3 between the upper pressing roller 2 and the lower supporting roller 1, such as figure 2 shown. The upper pressing roller 2 consists of two round rollers with a diameter of 140mm, which can move up and down. The lower support roller 1 is a round roller with a diameter of 400mm that rotates actively. Move the upper pressing roller 2 down slowly until the upper and lower surfaces of the strip-shaped sample 3 are in contact with the upp...

Embodiment 2

[0032] The transverse yield strength test is carried out on the Φ609×18mmX65 straight welded steel pipe of the shale gas well, which is realized as follows.

[0033] 1) According to the requirements of relevant standards, cut the raw material of the strip-shaped transverse tensile sample 3 at the position of 90° from the welding seam between the steel pipe, the arc length is about 440mm, and the width is 100mm, such as figure 1 shown. Because it is flame cutting, the effect of edge heat input on the final specimen is considered.

[0034] 2) Put the right end of the strip-shaped sample 3 between the upper pressing roller 2 and the lower supporting roller 1, such as figure 2 shown. The upper pressing roller 2 consists of two round rollers with a diameter of 140mm, which can move up and down. The lower support roller 1 is a round roller with a diameter of 500mm that rotates actively. Move the upper pressing roller 2 down slowly until the upper and lower surfaces of the strip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com