Pressing and flattening method for strip-shaped transverse tensile sample of steel pipe

A transverse stretching and flattening technology, applied in the preparation of test samples, etc., can solve problems such as yield strength reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The transverse yield strength test of Φ508×22mm X70 straight welded steel pipe is carried out as follows.

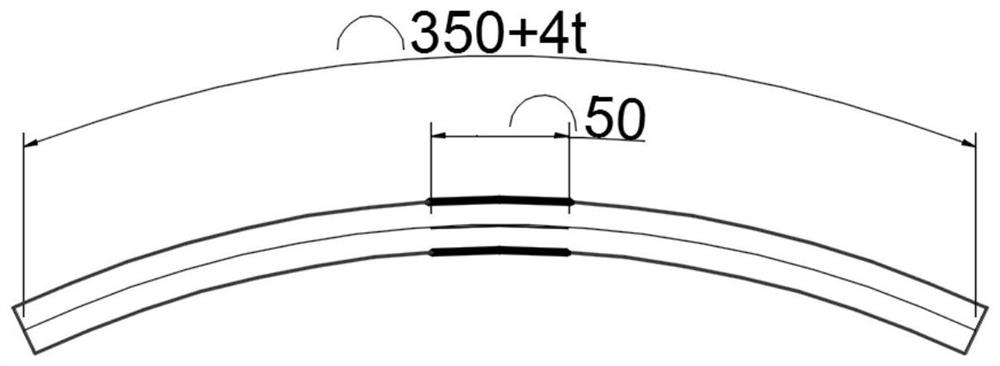

[0021] 1) According to the requirements of relevant standards, cut the raw material of the strip-shaped transverse tensile sample 3 at the position of 90° from the welding seam between the steel pipe, the arc length is about 440mm, and the width is 100mm, such as figure 1 shown. Because it is flame cutting, the effect of edge heat input on the final specimen is considered.

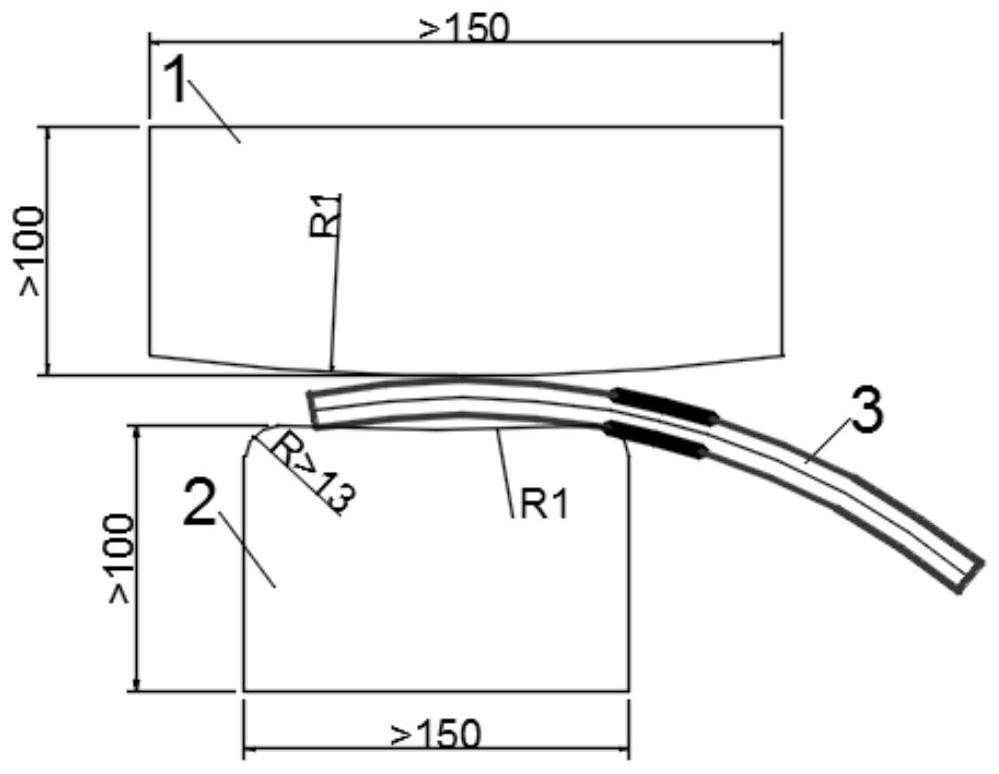

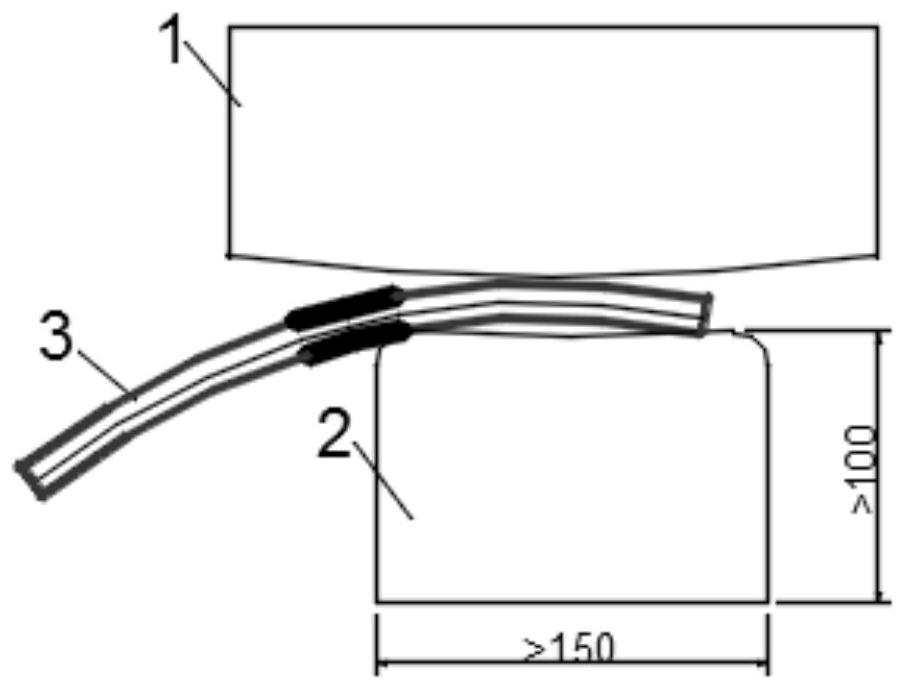

[0022] 2) Put one end of the strip-shaped sample 3 about 195mm long between the upper pressing plate 1 and the first lower supporting plate 2, such as figure 2 shown. Put t=22, σ=552MPa, E=210000MPa into the public announcement:

[0023] R1==t(E / σ-1) / 2==22×(210000 / 552-1) / 2≈4174≈4200;

[0024] R1 is 4200mm, and the chamfering radius of the two corners of the first lower support plate 2 in contact with the strip-shaped sample 3 is 13mm, and the width is 230mm. Press the upper platen 1 to t...

Embodiment 2

[0030] The transverse yield strength test of the Φ609×18mmX65 straight welded steel pipe of the shale gas well is carried out as follows.

[0031] 1) According to the requirements of relevant standards, cut the raw material of the strip-shaped transverse tensile sample 3 at the position of 90° from the welding seam between the steel pipe, the arc length is about 422mm, and the width is 100mm, such as figure 1 shown. Because it is flame cutting, the effect of edge heat input on the final specimen is considered.

[0032] 2) Put one end of the strip-shaped sample 3 about 185mm long between the upper pressing plate 1 and the first lower supporting plate 2, such as figure 2 shown.

[0033] Put t=18, σ=483MPa, E=210000MPa into the public announcement:

[0034] R1=t(F / σ-1) / 2=18×(210000 / 483-1) / 2≈3907≈3900;

[0035] R1 is 3900mm, the chamfering radius of the two corners of the first lower support plate 2 in contact with the strip-shaped sample 3 is 13mm, and the width is 220mm. P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc length | aaaaa | aaaaa |

| Arc length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com