Processing method of aluminum alloy profile and aluminum alloy profile prepared with method

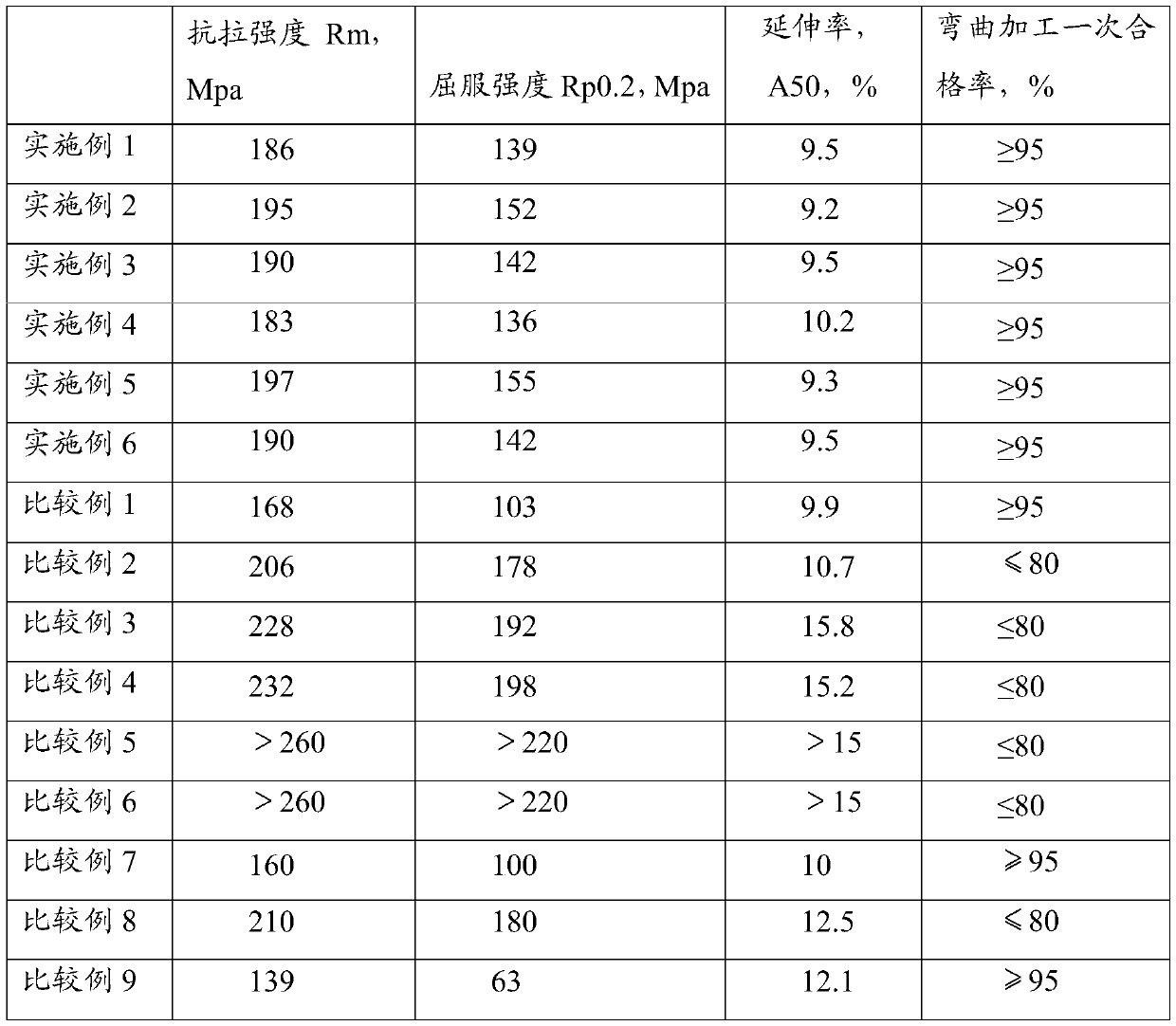

A technology of aluminum alloy profiles and processing methods, which is applied in the processing of aluminum alloy profiles and in the field of aluminum alloys, can solve the problems of low first pass rate and large fluctuation range of yield strength, etc., and achieve reduced production costs, good bending performance, and high yield strength. and tensile strength stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Take the processing method of embodiment 1 as example:

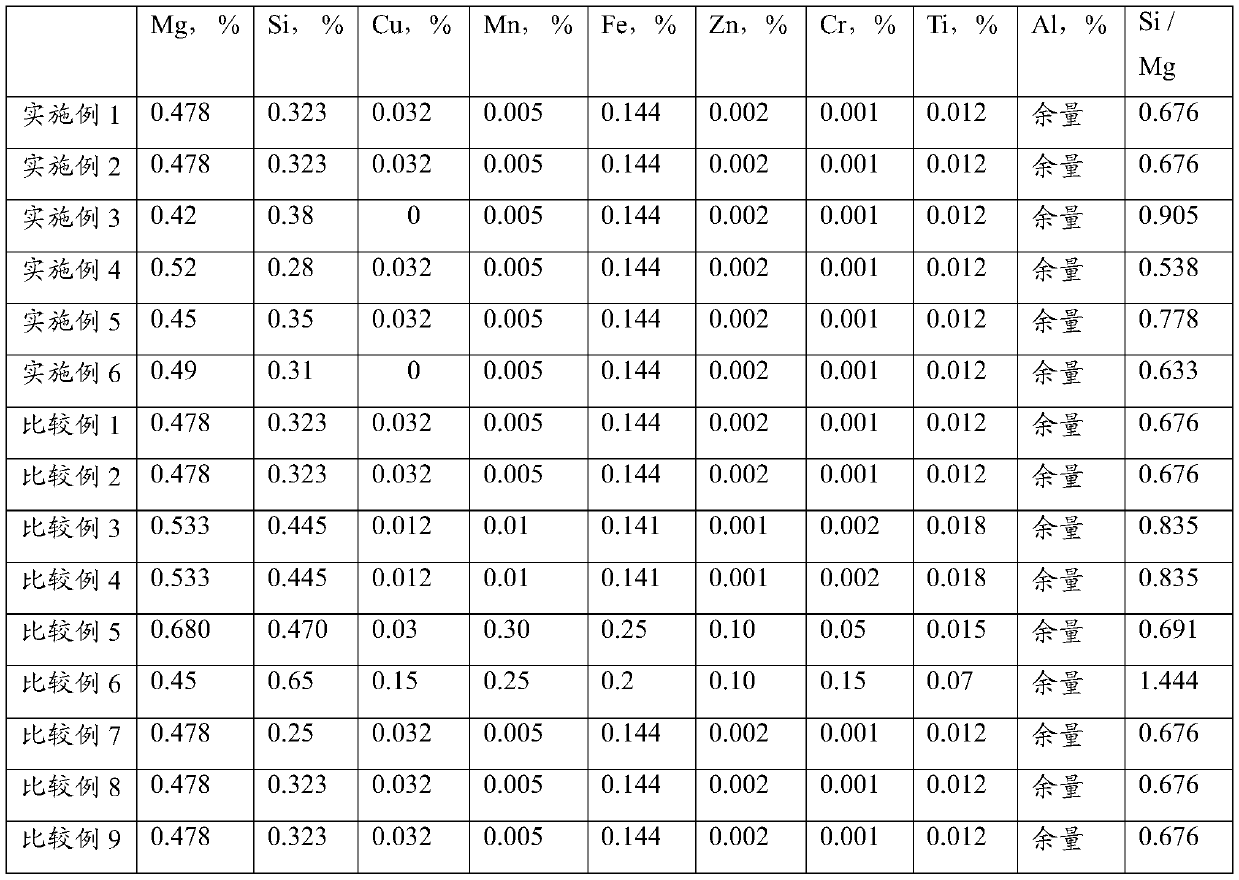

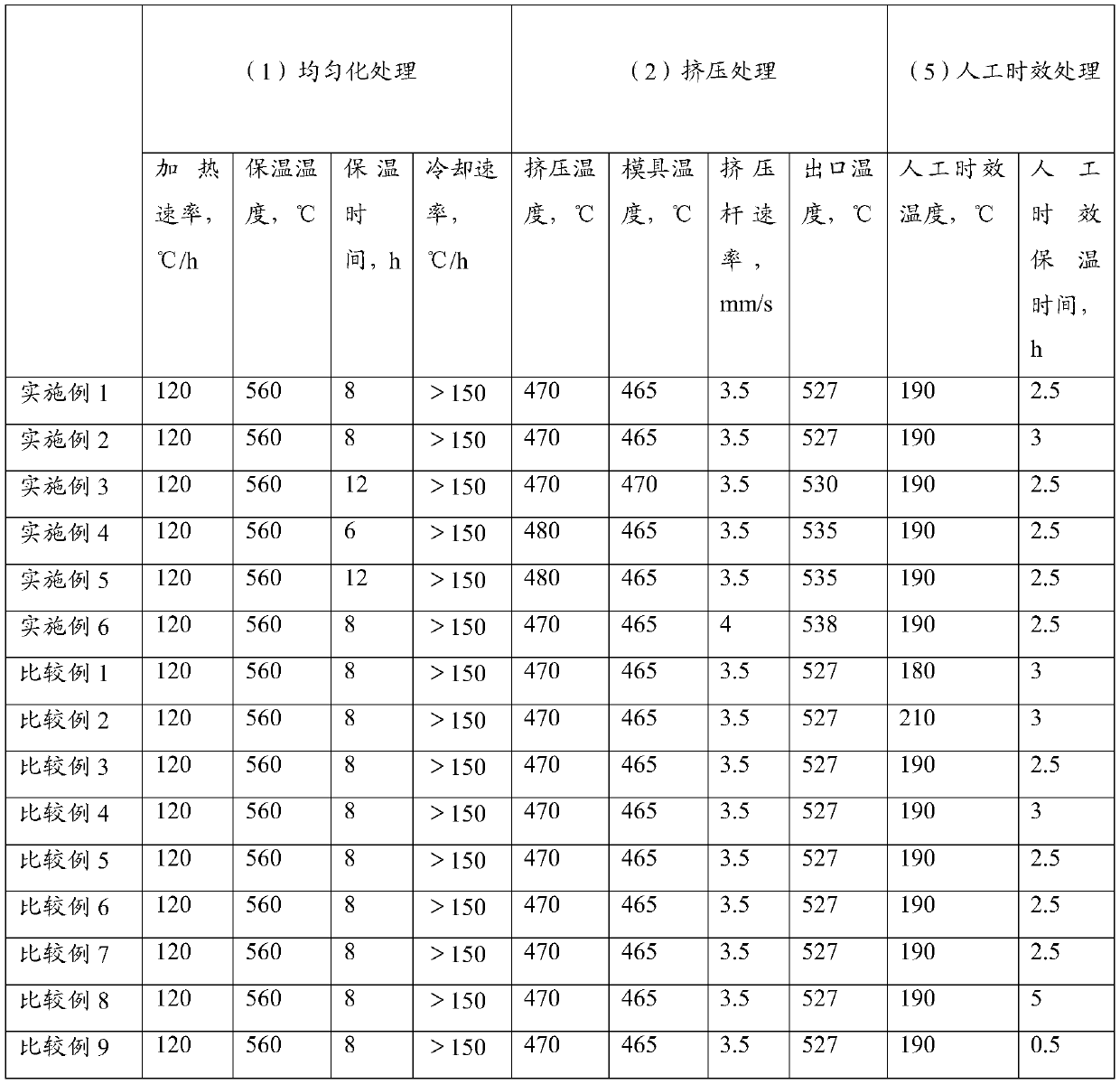

[0039] (1) Homogenization treatment: will include 0.478% of Mg, 0.323% of Si, 0.032% of Cu, 0.005% of Mn, 0.144% of Fe, 0.002% of Zn, 0.001% of Cr, 0.012% of Ti, and An aluminum rod with an amount of Al and a mass ratio of Si / Mg of 0.676 is heated from room temperature to 560°C at a heating rate of 120°C / h, and then kept at a temperature of 560°C for 8 hours, and then at a temperature of >150°C Cooling at a cooling rate of / h, cooling to <100°C;

[0040] (2) Extrusion treatment: the aluminum rod extrusion temperature is 470°C, the mold temperature is 465°C, the extrusion rod speed is 3.5mm / s, and the profile outlet temperature is controlled at 527°C;

[0041] (3) On-line strong wind cooling treatment: the cooling rate is > 80°C / min;

[0042] (4) Stretch straightening treatment: the stretch straightening rate is 0.1%-0.3%;

[0043] (5) Artificial aging treatment: the holding temperature is 190° C., and the holdi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com