Method and equipment used for refining of corn starch milk

A corn starch, starch milk technology, applied in chemical instruments and methods, angiotensin, specific peptides, etc., can solve the problems of many impurities, high energy consumption, high maintenance costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

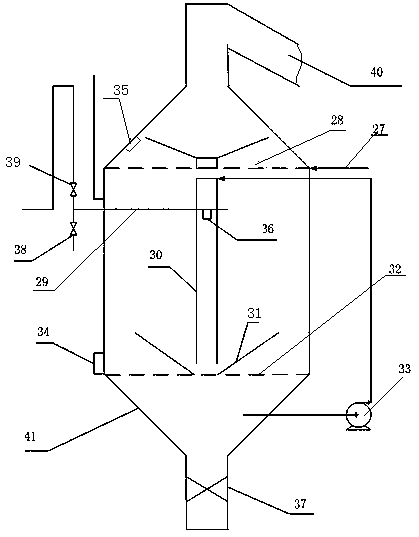

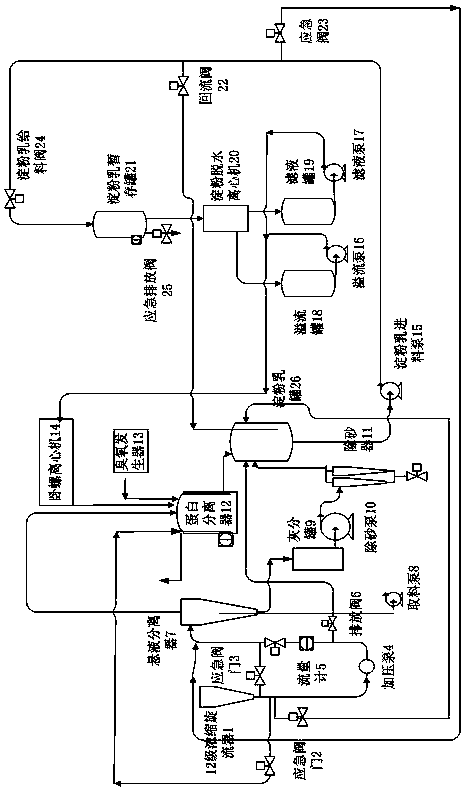

[0027] according to figure 1 As shown, the present invention mainly includes a 12-stage concentrated cyclone 1, an emergency valve 2, an emergency valve 3, a booster pump 4, a flow meter 5, a discharge valve 6, a suspension separator 7, a reclaiming pump 8, and an ash tank 9. Desander pump 10, desander 11, refining reactor 12, ozone generator 13, decanter centrifuge 14, starch milk feed pump 15, overflow pump 16, filtrate pump 17, overflow tank 18, filtrate Tank 19, starch dehydration centrifuge 20, starch milk temporary storage tank 21, return valve 22, emergency valve 23, starch milk feeding valve 24, emergency discharge valve 25, and starch milk tank 26;

[0028] Among them, the underflow material of the 12-stage concentrated cyclone 1 is boosted by the booster pump 4, then passes through the flow meter 5, and then enters the suspension separator 7 for suspension separation. In the process of high-quality starch milk, the starch milk on the outside of the underflow of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com