Patents

Literature

90results about How to "Stable tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wire with tensile strength>=2000MPa for bridge cable and production method

ActiveCN102936688AUniform metallographic structureUniform performanceMetal rolling arrangementsAir volumeRoom temperature

The invention discloses a wire with tensile strength>=2000MPa for a bridge cable and a production method. The wire comprises, by weight, 0.95-1.2% of C, 0.1-0.48% of Si, 0.6-1.0% of Mn, 0.1-0.5% of Cr, 0.01-0.05% of V, Cu<=0.05%, 0.05-0.15% of Al, 0.01-0.03% of N, P<=0.025% and S<=0.015%. The production method includes smelting and continuously casting into blanks; heating the casting blanks; rolling; heating again; high-speed rolling; spinning; air cooling to the room temperature; and placing for standby. According to the wire and the method, continuous casting of blooms, rolling starting of billets and high speed wire rolling are adopted, therefore a metallographic structure and the like of the wire for the bridge cable are even, and grains are better refined; and processes of rapid cooling with a large air volume and the like are adopted, therefore the tensile strength of the wire for the bridge cable is >=2000MPa and stable, a twist number reaches >=15, and wire fracture caused by the wire quality does not happen during cold drawing.

Owner:武汉钢铁有限公司

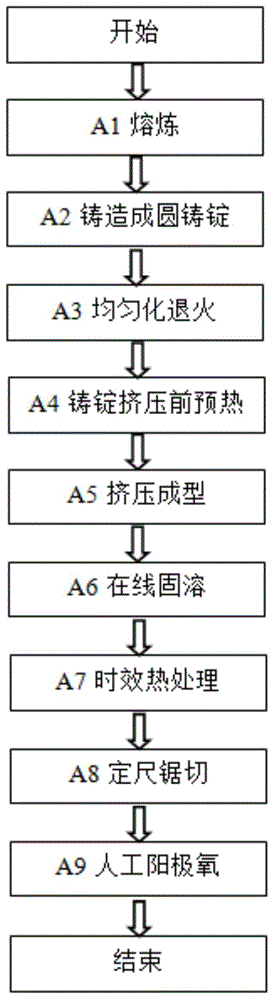

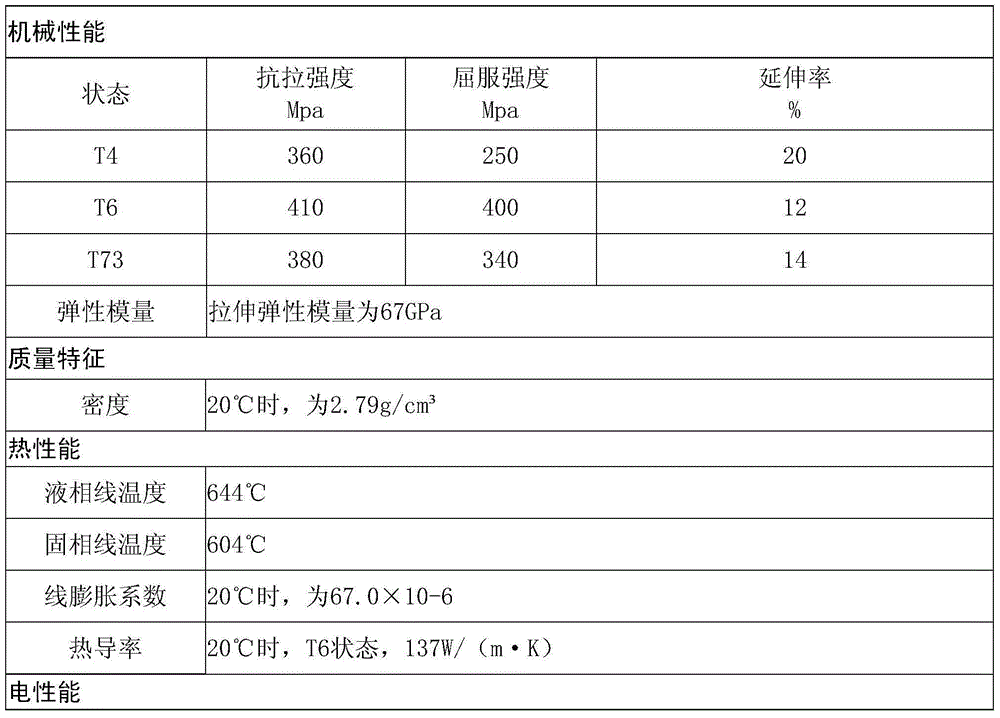

7XXX aluminum alloy

The invention relates to 7XXX aluminum alloy. The 7XXX aluminum alloy comprises the following components by weight percent: 6.6 to 7.6 percent of zinc, 1.25 to 1.80 percent of magnesium, 0.18 to 0.44 percent of copper, less than or equal to 0.06 percent of silicon, less than or equal to 0.16 percent of iron, , less than or equal to 0.03 percent of manganese, less than or equal to 0.03 percent of chromium, less than or equal to 0.02 percent of germanium, less than or equal to 0.02 percent of vanadium, less than or equal to 0.03 percent of titanium, less than or equal to 0.02 percent of zirconium, and less than or equal to 0.03 percent of total weight of manganese and chromium, less than or equal to 0.03 percent of each rest impurity element, less than or equal to 0.10 percent of total weight of rest impurity elements, and the balance of aluminum. On the basis of experiment, the material strength is improved by re-designing the mass fraction and a ratio of Zn to Mg; by re-designing the mass fraction of Cu, the alloy has excellent corrosion resistance, and the oxidation different color problem of silver white can be solved. By strictly controlling the weight percent of the impurity elements such as Mn and Cr, the crystal grains of the alloy material are uniform. Compared with the existing disclosed Al-Zn alloy system, the alloy has better comprehensive performance, and an oxidized membrane formed by oxidizing the material by virtue of anode is more delicate and beautiful.

Owner:TAISHAN CITY KAM KIU ALUMINUM EXTRUSION

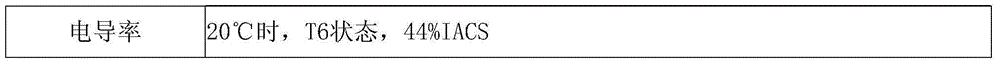

Rare earth molybdenum alloy wire and preparation method thereof

InactiveCN1876875ARaise the recrystallization temperatureHigh strengthTemperature control deviceHeat treatment process controlRare earthAlloy

The invention relates to a rare-earth molybdenum alloy wire and its process for preparing. The invention is characterized in that the said alloy wire contains two rare-earth oxides including lanthanum oxide and Y oxide(mass %) which is 0.4 %-1.0% of the alloy amount and the proportion by weight of lanthanum oxide and Y oxide is 4:1. The process for preparing is different from the traditional powder metallurgy productive technology, which includes performing double-cone vacuum drying and liquid-solid doping at molybdenum dioxide stage, then performing secondary reduction to prepare binary rare-earth doping molybdenum powder, finally preparing rare-earth doping molybdenum wire with Mo-La-Y of 0.5-0.8mm diameter by impression, agglomeration and pressure processing procedure. Compared with the pure molybdenum, the product is of good high-temperature behavior and high recrystallization temperature which increases by 300-500 DEG C than the pure molybdenum, and is of high intensity and abrasive resistance, low ductility and long durability, which has wide application in the mechanical process industry.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Production method of natural cellulose membrane

The invention discloses a production method of natural cellulose membranes, comprising the following steps: (a) immersion; (b) squeezing; (c) grinding; (d) maturing; (e) etiolation; (f) solution; (g) film formation; (h) desulfuration; (i) bleaching; (j) plastification; and (k) drying. The production method has the advantages of mild reaction condition, short spacings among the prepared natural cellulose membranes, stable expansion rate and tensile strength, proper stiffness and flexibility, better colour and luster, good transparence, high hygiene property, and the like, improves the surface property of paper through the plastification, in particular enhances the smoothness of paper surfaces, improves the printability, reduces the deformability of paper and the moisture absorption, thereby reaching the new requirement of modern printing and packaging.

Owner:绍兴柯德新材料股份有限公司

Heat-resisting aluminum alloy and preparation method thereof

InactiveCN107937773APoor high temperature performanceGood mechanical properties at room temperatureHeat resistanceRoom temperature

The first purpose of the invention is to solve the problem of poor heat resistance of an aluminum alloy in the prior art and to provide a heat-resisting aluminum alloy, and the second purpose is to provide a preparation method of the heat-resisting aluminum alloy which belongs to the technical field of aluminum alloy materials. The heat-resisting aluminum alloy comprises, by mass, 5-6% of Zn,2-3%of Mg,1-2% of Cu,0.3-0.5% of Sm, the balance Al and unavoidable impurities. The alloy element type of the heat-resisting aluminum alloy is few, the cost is low, the alloy composition is simple, the melting and mixing process is easy to control, and the difficulty of preparation is reduced; the obtained aluminum alloy microstructure is even, precipitation phase is evenly distributed and dispersed,and the high room temperature, high temperature tensile strength and yield intensity are achieved; and the tensile strength at 200 DEG C is more than 586 MPa , the yield strength is more than 521 MPa,meanwhile, the plasticity is also improved greatly, and the high cost performance is achieved.

Owner:LIAONING ZHONGDA ALUMINUM

Method for preparing reactive hot-press in-situ autogenesis aluminium-base composite material

The invention relates to a preparation technique of reaction heat pressing original position autogeny aluminium base material, relates to a preparation technique of a complex material. The invention resolves the problem that when prepare the complex material with external method, the performance of the material decreases and prepare ceramic complex material with original position reaction heat pressing method the raw material will easily cold welding when blended dry. The invention includes following steps: a, ball mill Al, B and TiO2 powder adding 8 to 21 ml ethanol and argon gas of 1 to 1.5 atmosphere, the weight ratio the blending material to milling material 1 to 10 : 1, the rotating speed is 100 to 400 round per minutes, the blending period lasts for 6 to 12 hours, dry off the material; b, cold shaping the dried blended powder to black lead mould and then sintering in vacuum heat pressing furnace. The technique is simple and easy operation.

Owner:HARBIN INST OF TECH

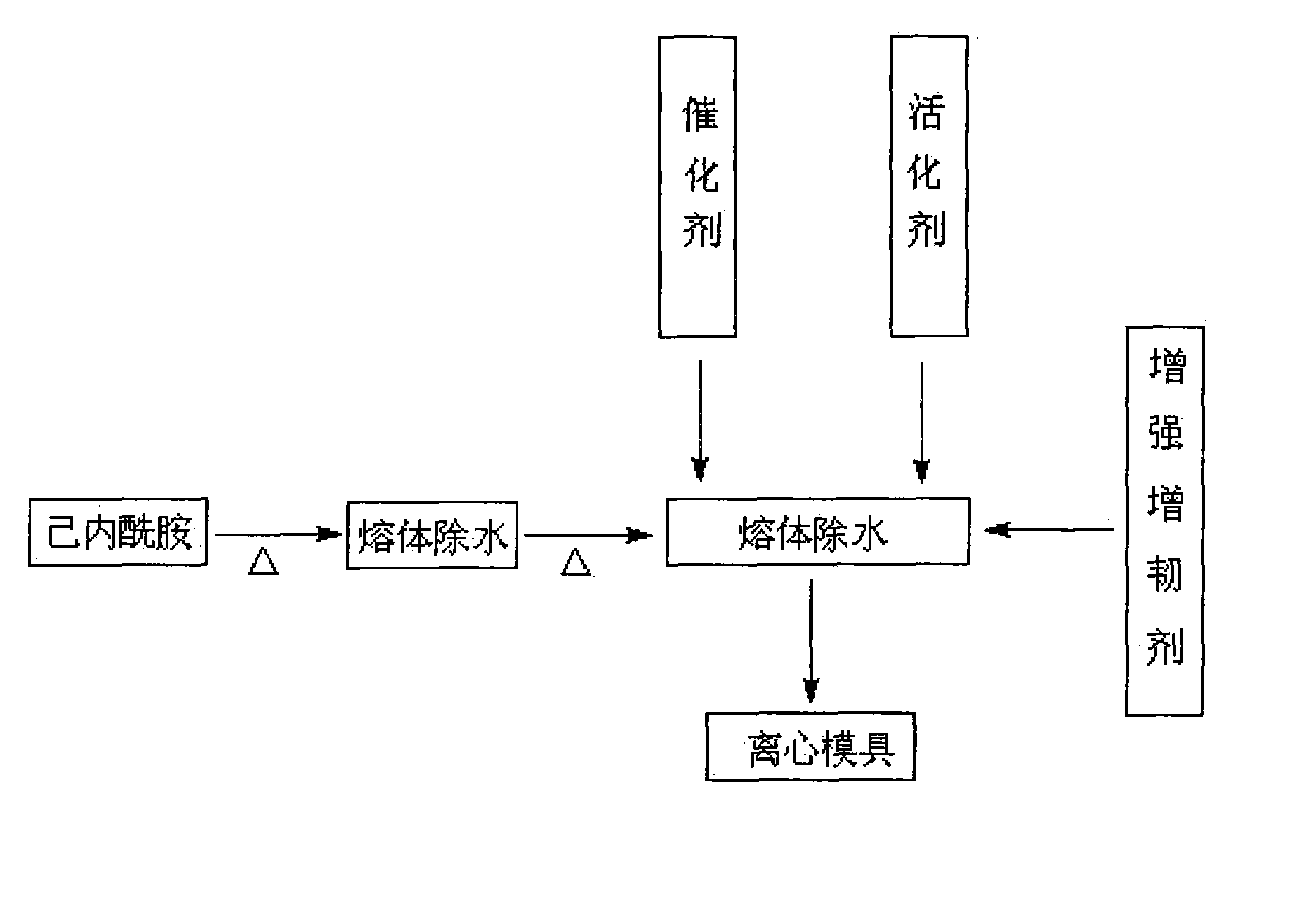

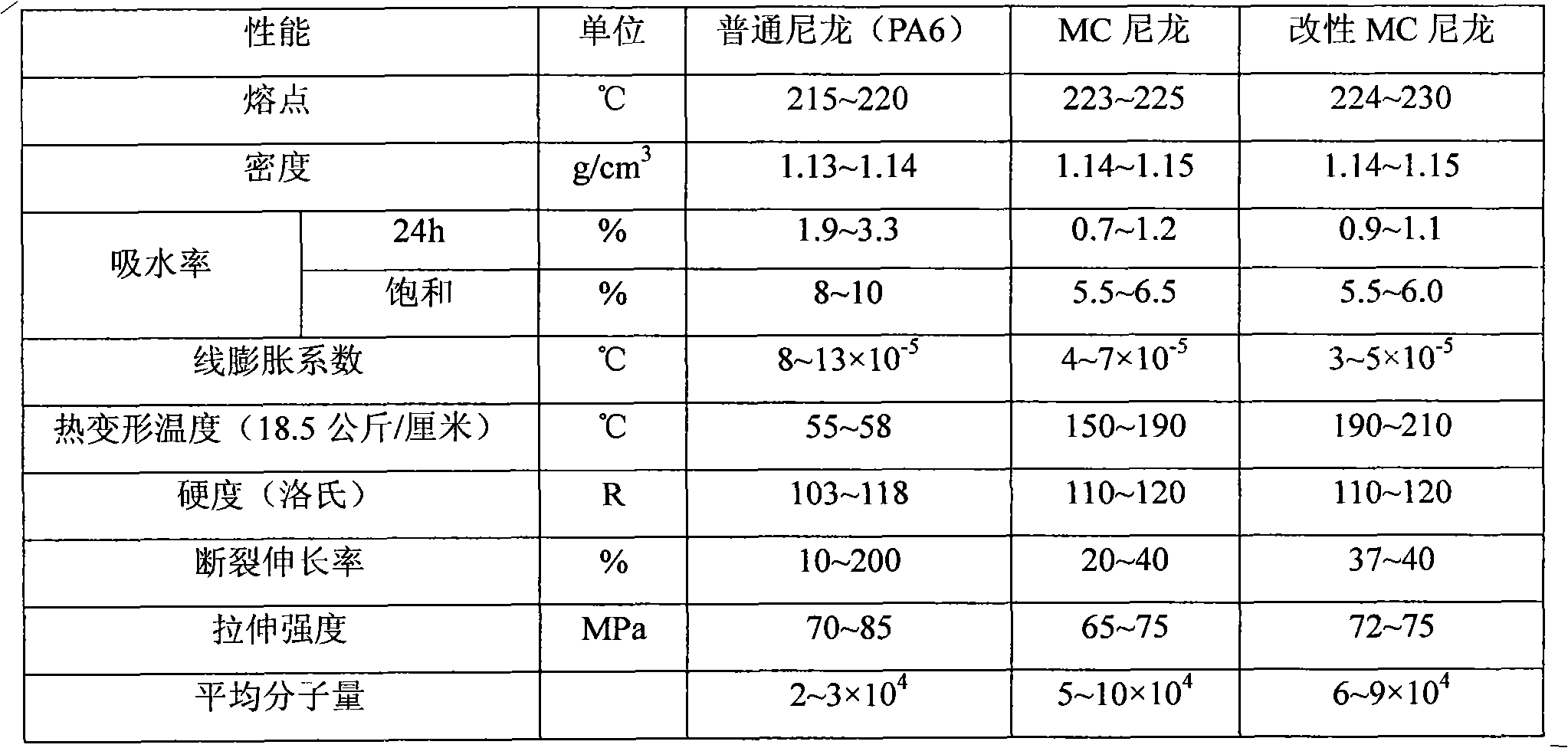

Modified MC nylon

The invention relates to modified MC nylon which is characterized in that: caprolactam is adopted as a raw material; a catalyst and an activating agent are added under special conditions; with a series of special combined modification technologies such as strengthening and toughening, and with mold direct injection, fast polymerization molding, and hot de-molding methods, a series of modified MC nylon materials is produced. According to the invention, on a basis of reduced reaction temperature and reduced reaction time, stable high-molecular-weight modified MC nylon material can be obtained. A product linear expansion coefficient is reduced ((3-5)*10<-5>), a product elongation at break is 37-40%, and a product tensile strength is 72-75MPa. The modified MC nylon product has good strength, good toughness, and good cold hardiness. The product has excellent dimensional stability and precise performance indexes. The modified MC nylon provided by the invention can be widely applied in the fields such as military industry, metallurgy, mining, textile, chemicals, papermaking, power energy, petroleum machinery, and the like.

Owner:QIQIHAR NORTH KUN SYNTHETIC POLYMER MATERIALS

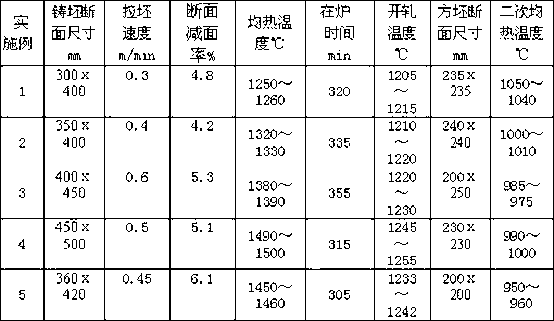

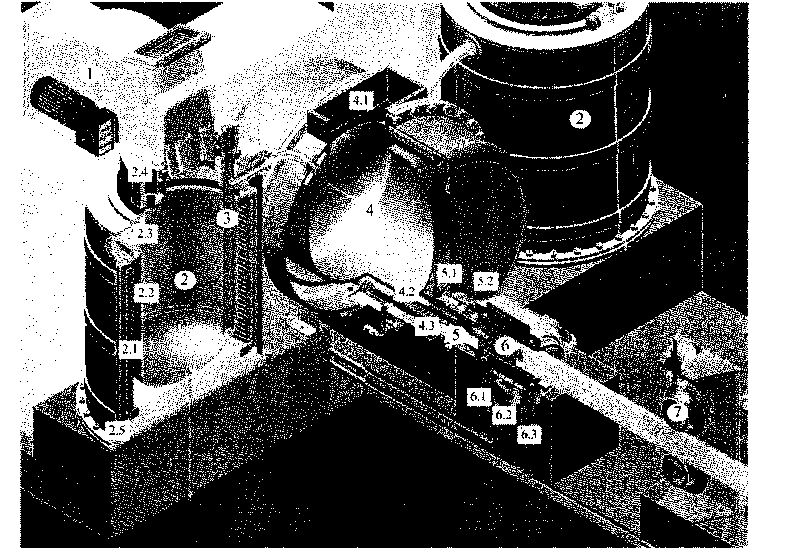

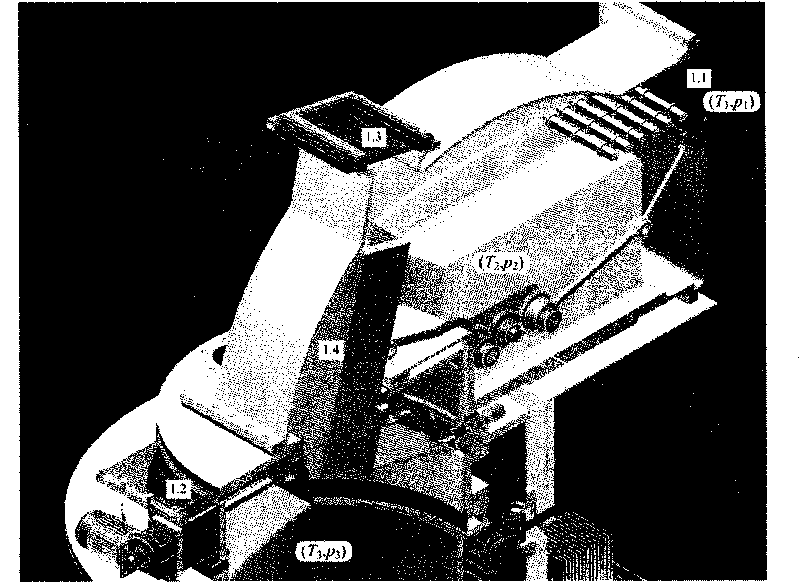

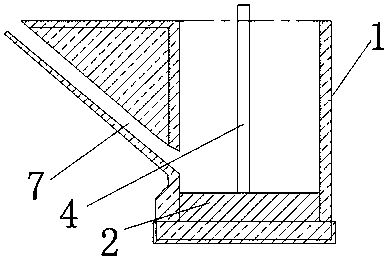

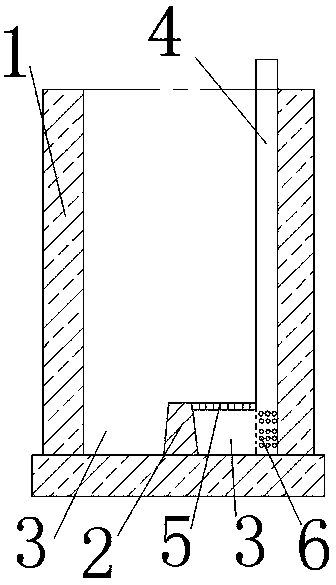

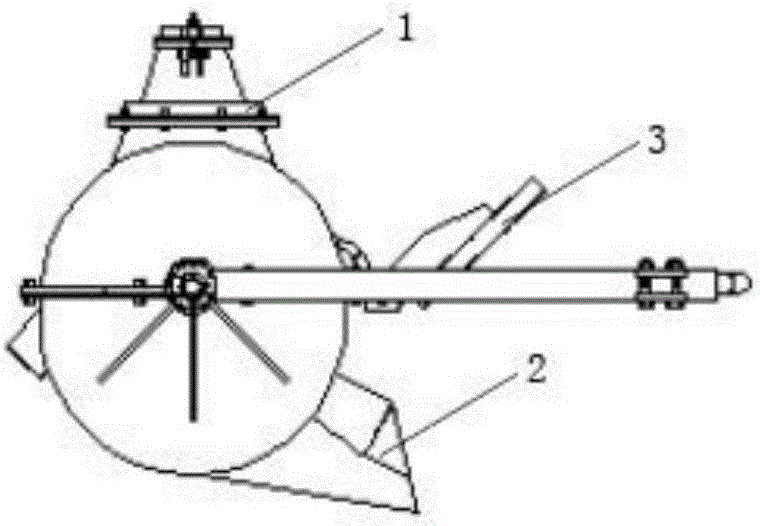

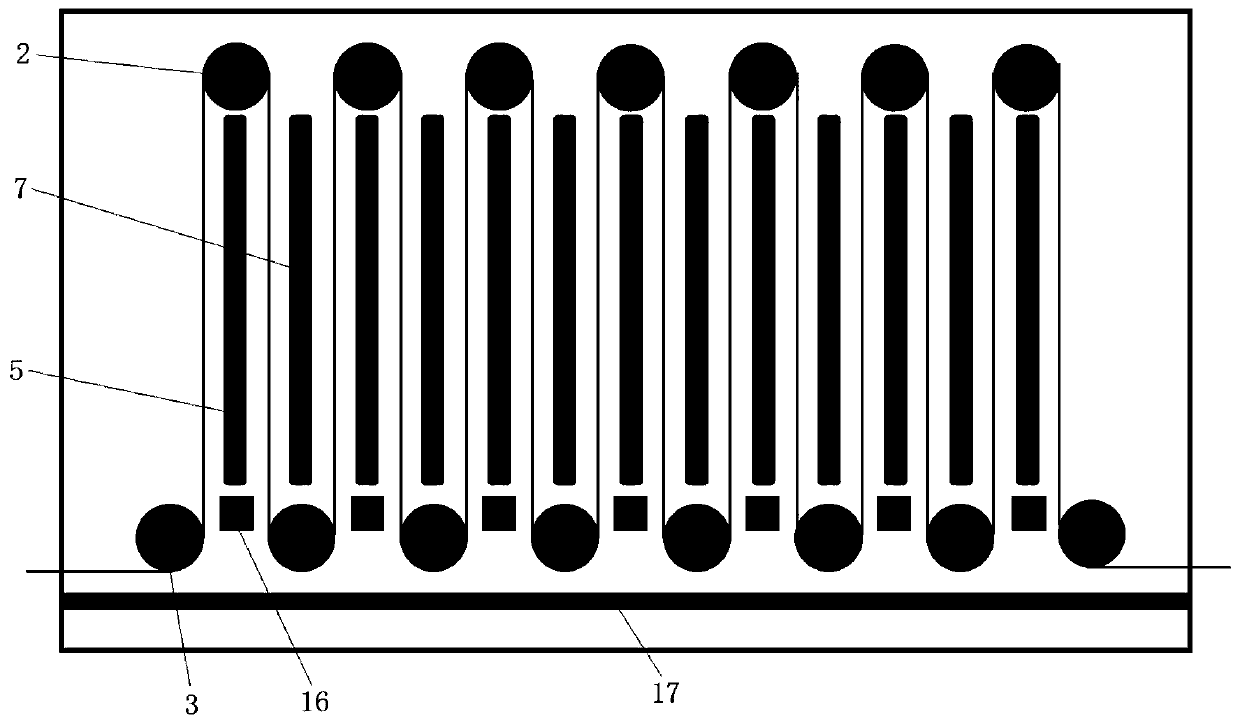

High-performance magnesium alloy parison continuous casting production line

The invention discloses a high-performance magnesium alloy parison continuous casting production line and relates to the technical fields of vacuum magnesium alloy metallurgy and material preparation. The production line is used for producing high-strength deformation magnesium alloy parison materials by whole-course vacuum protection. Equipment for the production line is provided with two vertical melting furnaces used for melting magnesium medium alloy or working alloy, wherein each melting furnace is divided into the two following parts in space: a hermetic melting chamber and a hermetic furnace body; and the pressure of the furnace body is lower than that of the melting chamber so as to form a vacuum barrier and double vacuum protection melting. Feeding cabins are arranged above furnace covers of the melting furnaces, and the opening and closing of doors of the cabins is matched with the conversion of pressure in the cabins so as to eradicate oxidization and burning of magnesium during feeding materials into hot furnaces. A heat insulation and homogenization furnace is arranged between the two melting furnaces to mix liquid coming from the melting furnaces and prepare magnesium alloy containing target components, and then the heat insulation and homogenization furnace stand still to preserve heat. An inoculation agent and leavening agent flowing addition mechanism is arranged on a gap bridge so as to effectively increase cores and prevent recession. Magnetic stirring is carried out in a crystallization process to control the pressing force and the traction speed of a tractor in real time. The equipment has compact structure, safe production and no pollution.

Owner:武汉镁里镁科技有限公司

Production method of preservative natural cellulose membrane

ActiveCN102154812AMild reaction conditionsEasy to controlConjugated cellulose/protein artificial filamentsBleaching apparatusCelluloseChitin formation

The invention discloses a production method of a preservative natural cellulose membrane. The method comprises the following steps: a-(1) soaking, a-(2) squeezing, a-(3) crushing, a-(4) maturing, a-(5) yellowing and a-(6) dissolving the cellulose; b-(1) soaking, b-(2) squeezing, b-(3) crushing, b-(4) yellowing and b-(5) dissolving chitin; c-(1) mixing viscose; c-(2) forming a membrane; and c-(3) desulphurizing, c-(4) bleaching, c-(5) plasticizing and c-(6) drying the membrane. The reaction conditions of the method disclosed by the invention are mild; and the prepared preservative natural cellulose membrane has small space, stable elongation rate and tensile strength, proper stiffness and flexibility, relatively good color and luster and transparency, high hygiene property, antibacterial and bacteriostatic characteristics and the like.

Owner:绍兴柯德新材料股份有限公司

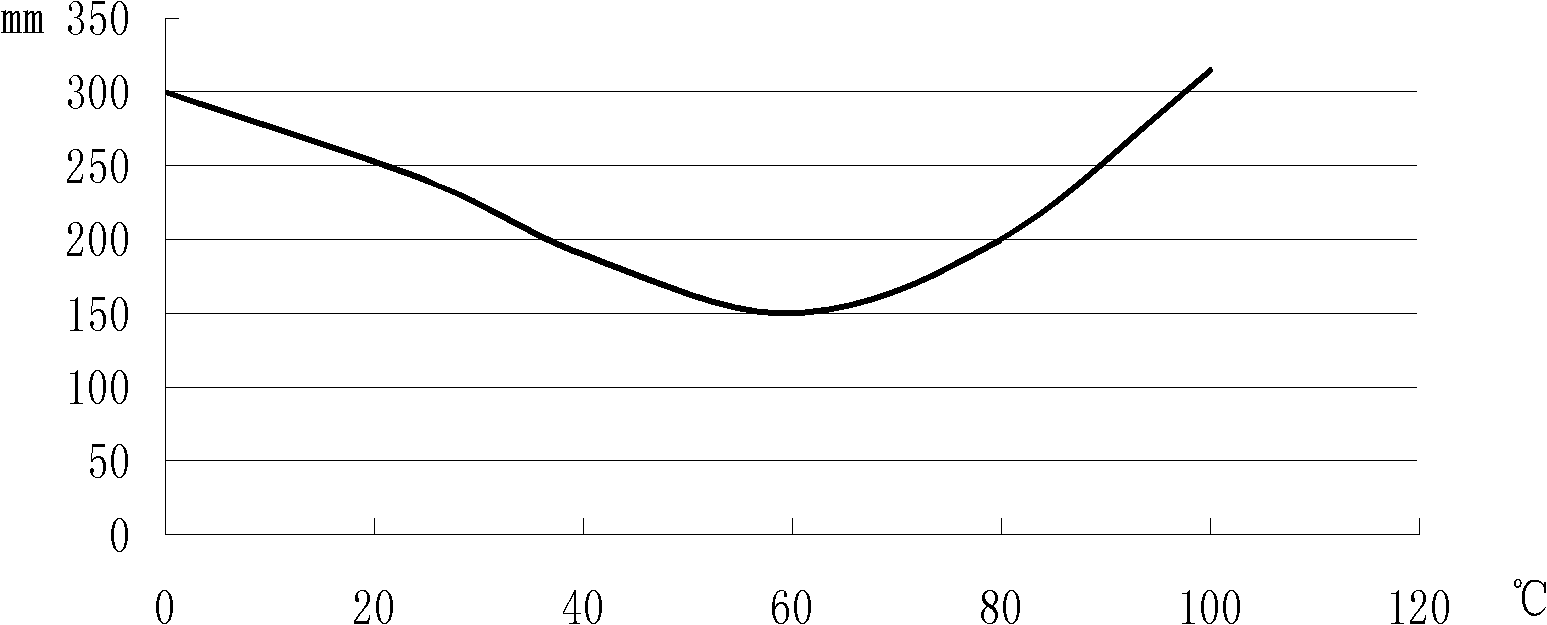

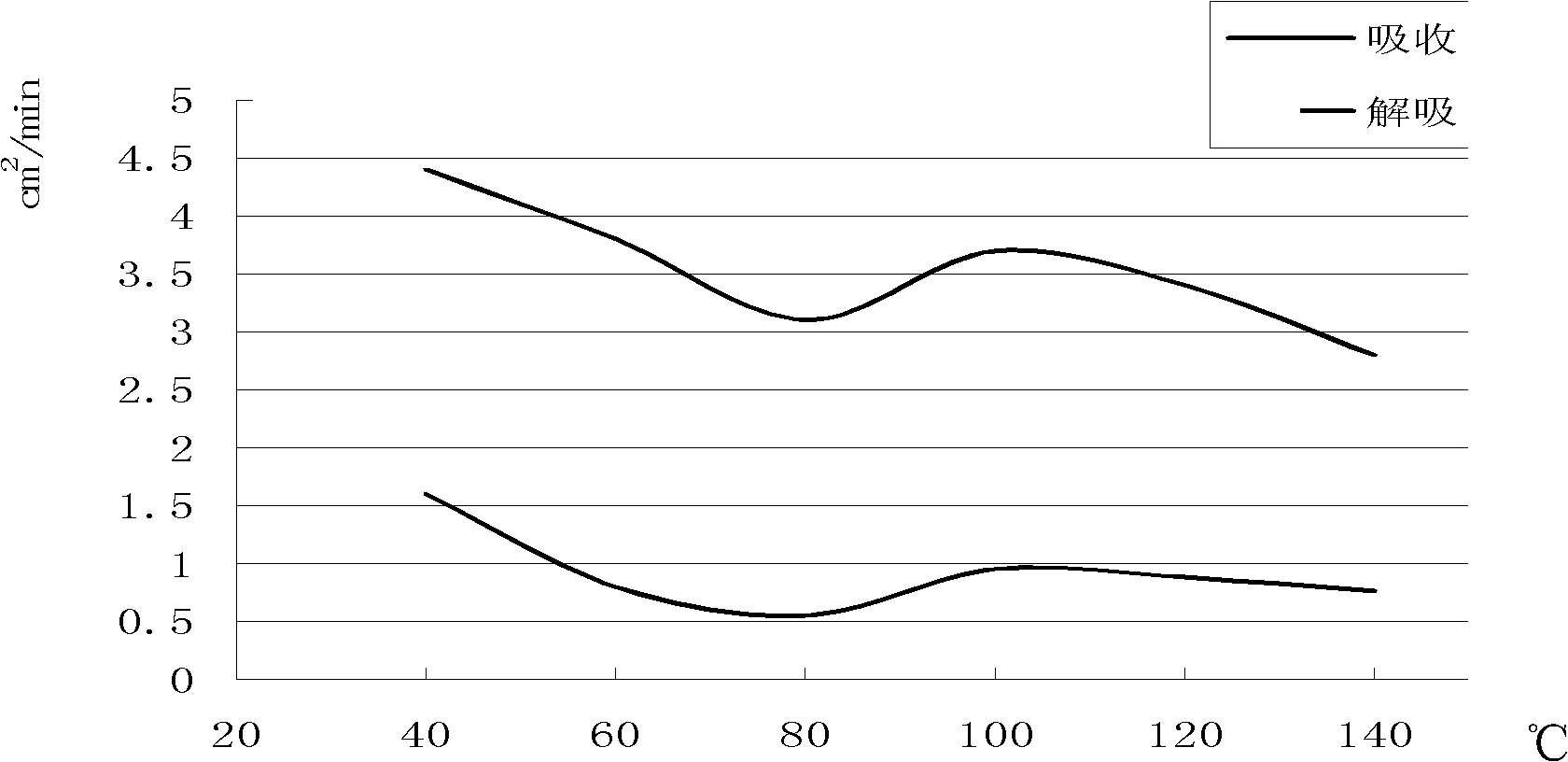

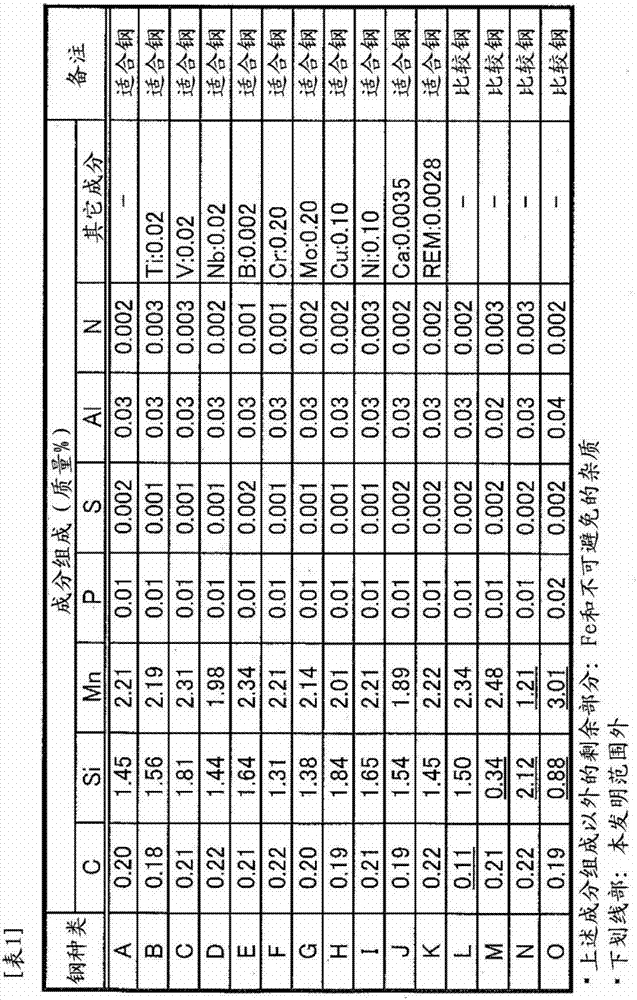

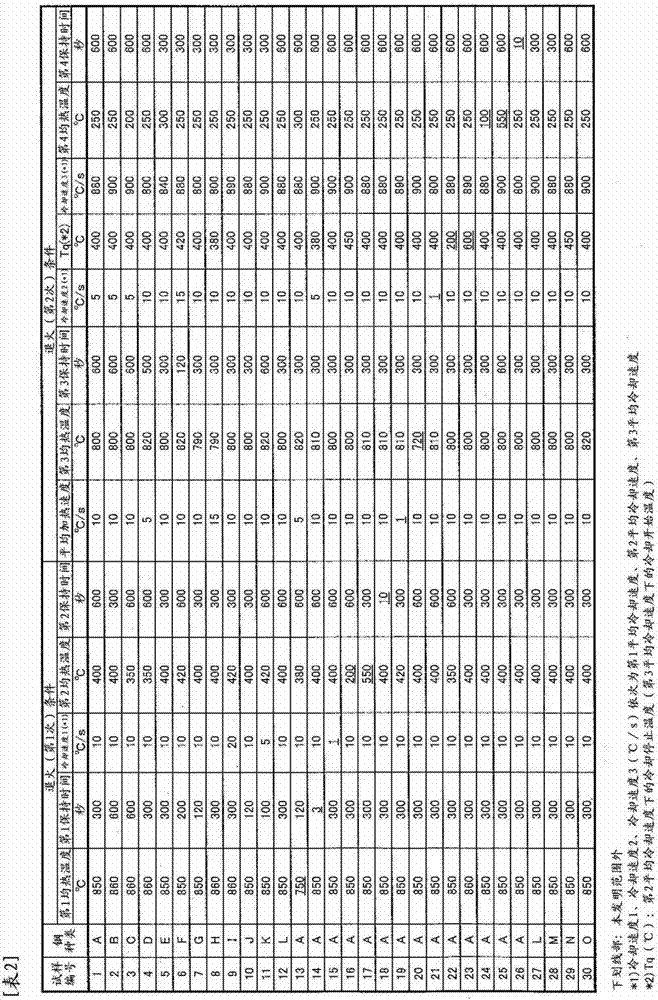

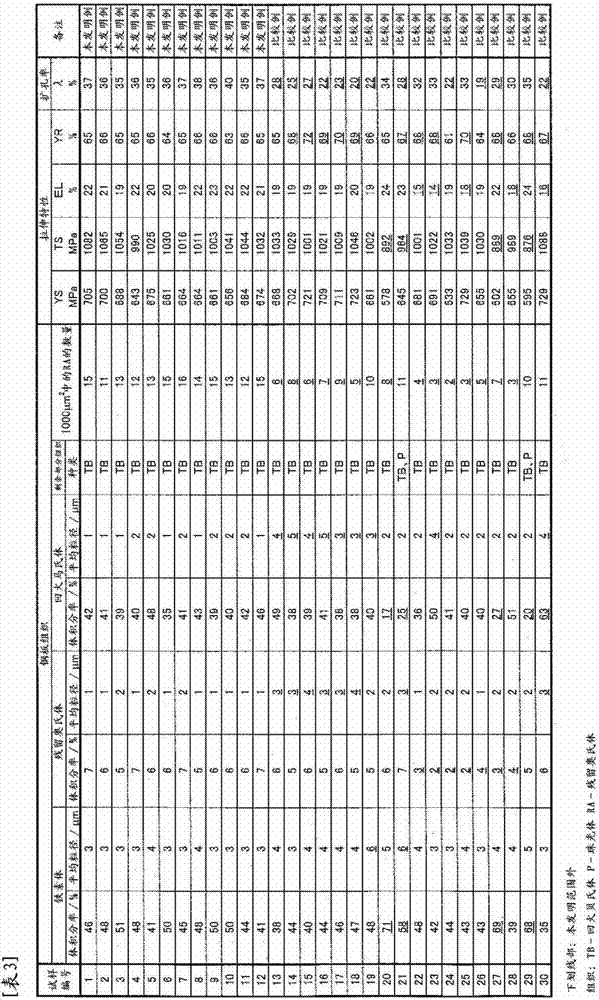

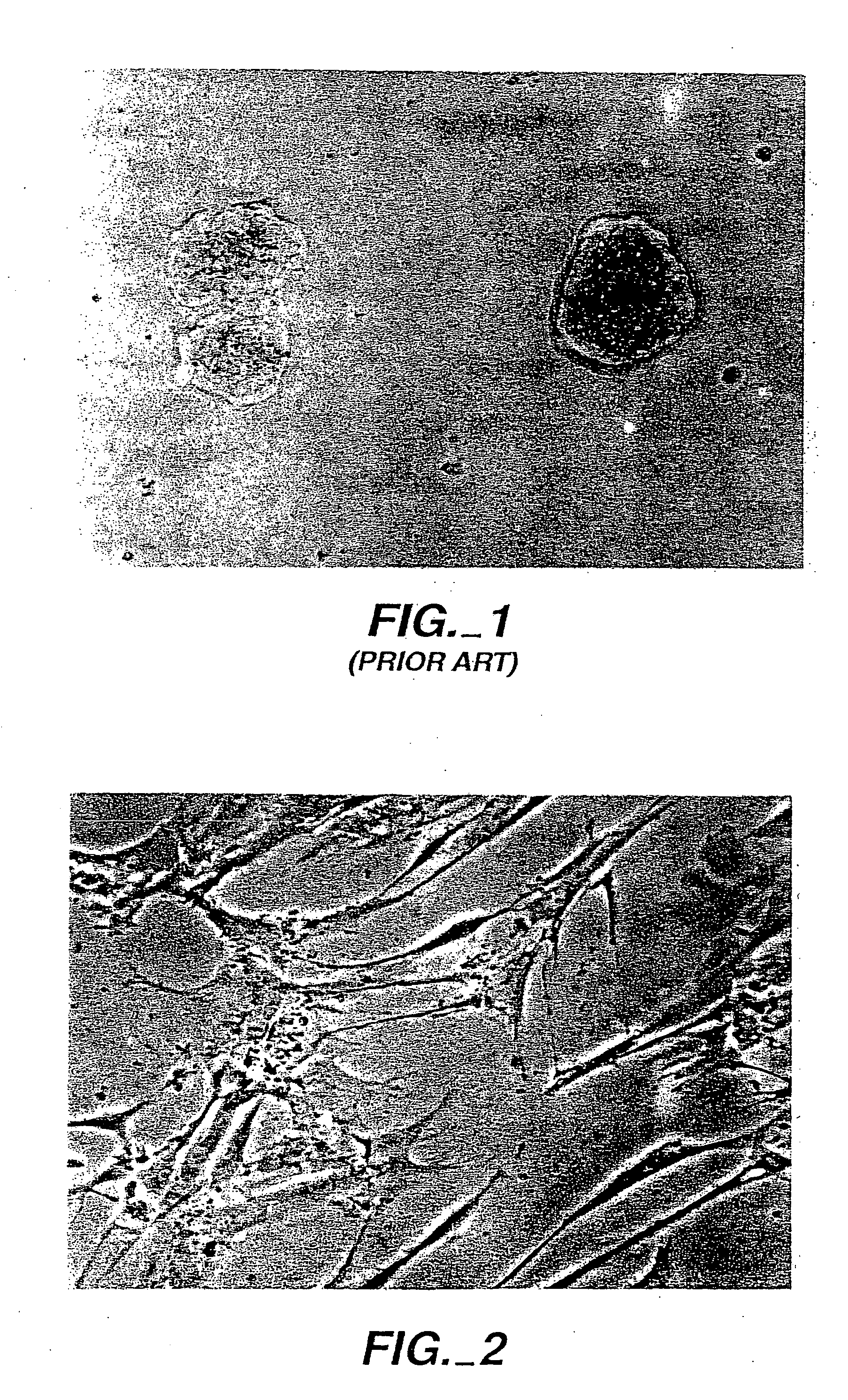

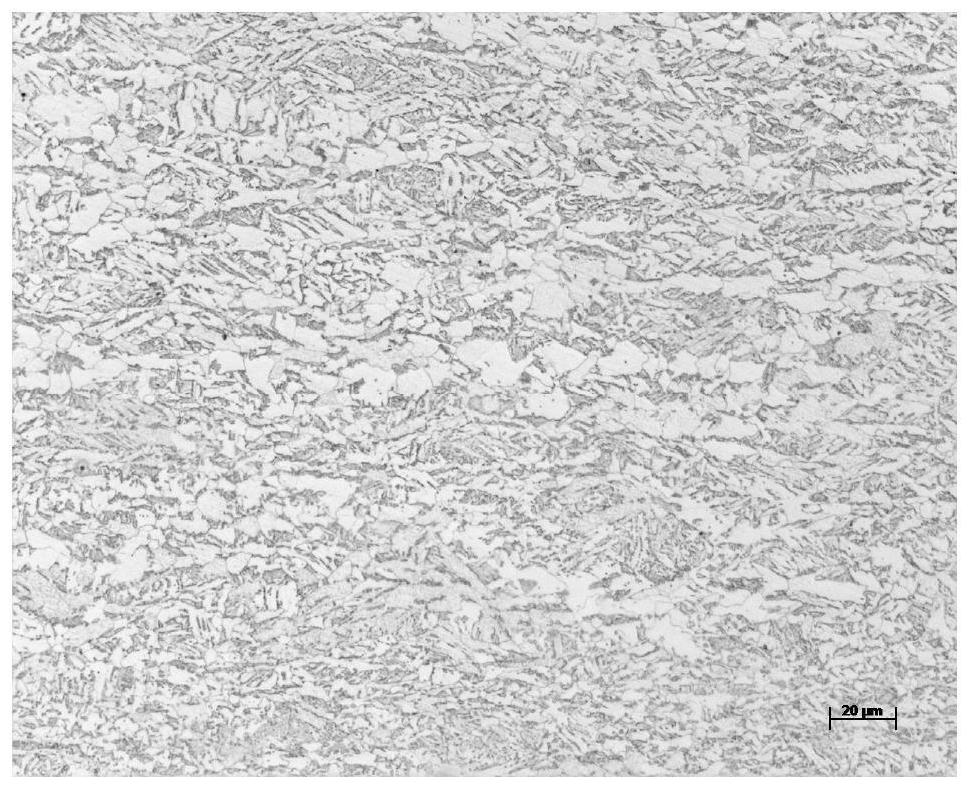

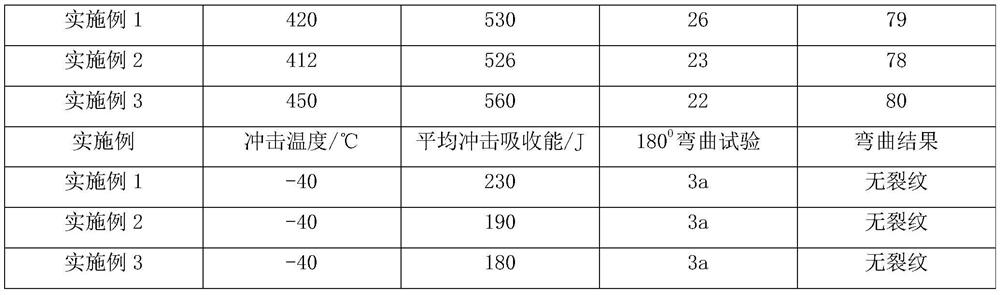

High-strength cold-rolled steel plate and method for producing same

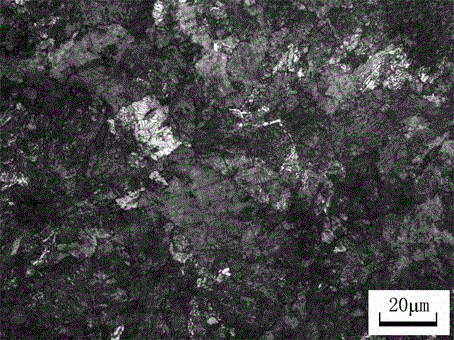

ActiveCN107406930AStable tensile strengthHigh tensile strengthFurnace typesHeat treatment furnacesSheet steelHigh intensity

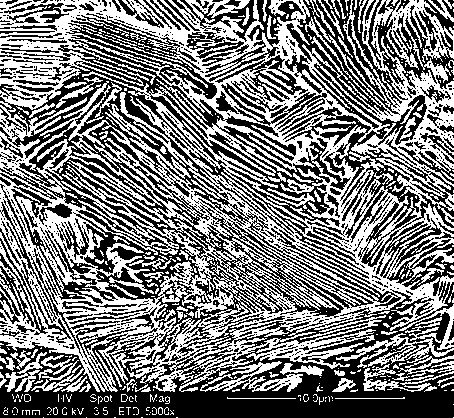

Provided are: a high-strength cold-rolled steel plate having excellent elongation (EL), an excellent hole expansion ratio (lambda), and a low yield ratio (YR); and a method for producing same. The high-strength cold-rolled steel plate has a component composition comprising, in mass%, 0.15-0.25% of C, 1.0-2.0% of Si, 1.8-2.5% of Mn, 0.10% or less of P, 0.010% or less of S, 0.10% or less of Al, 0.010% or less of N, and a remainder of Fe and unavoidable impurities. The high-strength cold-rolled steel plate has a composite structure comprising 30-55% by volume fraction of ferrite having an average crystal grain size of 5 [mu]m or less, 5-15% by volume fraction of residual austenite having an average crystal grain size of 2 [mu]m or less, and 30-60% by volume fraction of tempered martensite having an average crystal grain size of 2 [mu]m or less. The high-strength cold-rolled steel plate is configured so that 10 or more pieces of the residual austenite are present in 1000 [mu]m2 thereof.

Owner:JFE STEEL CORP

Synthetic compounds and compositions with enhanced cell binding

InactiveUS20050164944A1Enhanced cell bindingEasily hydrolyzedConnective tissue peptidesCell receptors/surface-antigens/surface-determinantsMolecular biologyCell surface receptor

Compositions of the invention include composites comprising a biomaterial having compounds thereon with enhanced cell binding with respect to collagen. These composites are useful for soft and hard tissue repair or reconstruction and for in vitro uses. Suitable compounds with enhanced cell binding include synthetic peptides that mimic the conformation necessary for recognition and docking of collagen binding species (such as cell surface receptors for collagen and fibronectin) and have the amino acid residues -Ile-Ala-folded in a β-bend.

Owner:RGT UNIV OF CALIFORNIA

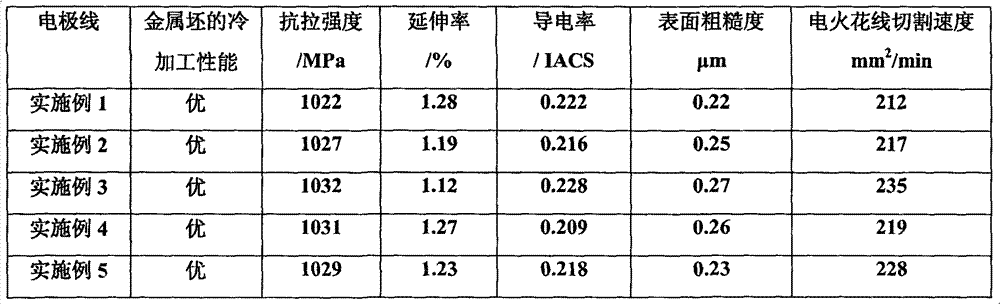

High-difficulty steel core wire electrode and manufacturing method thereof

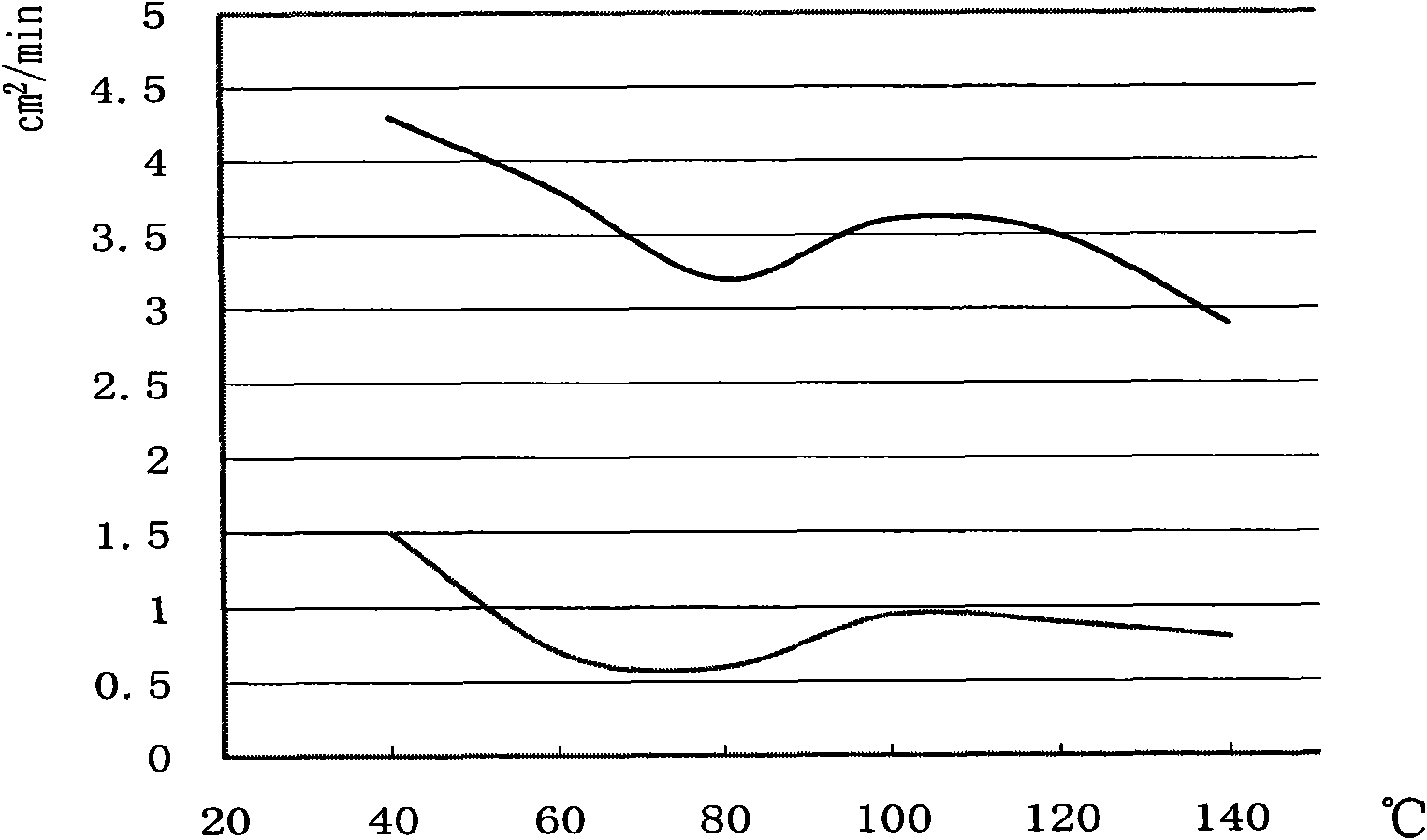

InactiveCN105772878ALow tensile strengthImprove conductivityElectrical-based machining electrodesCopper wireHeat conducting

The invention discloses a high-difficulty steel core wire electrode and a manufacturing method thereof. The high-difficulty steel core wire electrode comprises a core material, a middle clad layer and an outer clad layer. The core material is prepared from raw materials including, by weight, 30-54 parts of iron, 30-55 parts of carbon, 1.5-2.4 parts of tin, 4-9 parts of chromium, 1-3 parts of manganese, 2-5 parts of molybdenum, 1.3-5.1 parts of nickel, 2.3-5.4 parts of silicon, 3-6 parts of tungsten, 3-4 parts of vanadium, 2-6 parts of phosphorus, 5-10 parts of sulphur and 12-15 parts of heat conducting filler. The steel core wire electrode is a composite wire and is composed of the steel core, the middle red copper clad layer and the outer brass clad layer. At the normal temperature, the steel core and a brass wire almost have the same tensile strength, but with the increase of temperature, the tensile strength of the brass wire is rapidly reduced, and the tensile strength of the steel is higher than that of the brass wire. The red copper layer is wrapped outside the steel core to improve the electric conductivity, and the outer brass layer plays a role in improving the washing performance.

Owner:尚成荣

Synthetic compounds and compositions with enhanced cell binding

InactiveUS7199103B2Stable tensile strengthFunction increaseConnective tissue peptidesCell receptors/surface-antigens/surface-determinantsCell bindingBiological materials

Compositions of the invention include composites comprising a biomaterial having compounds thereon with enhanced cell binding with respect to collagen. These composites are useful for soft and hard tissue repair or reconstruction and for in vitro uses. Suitable compounds with enhanced cell binding include synthetic peptides that mimic the conformation necessary for recognition and docking of collagen binding species (such as cell surface receptors for collagen and fibronectin) and have the amino acid residues -Ile-Ala-folded in a β-bend.

Owner:RGT UNIV OF CALIFORNIA

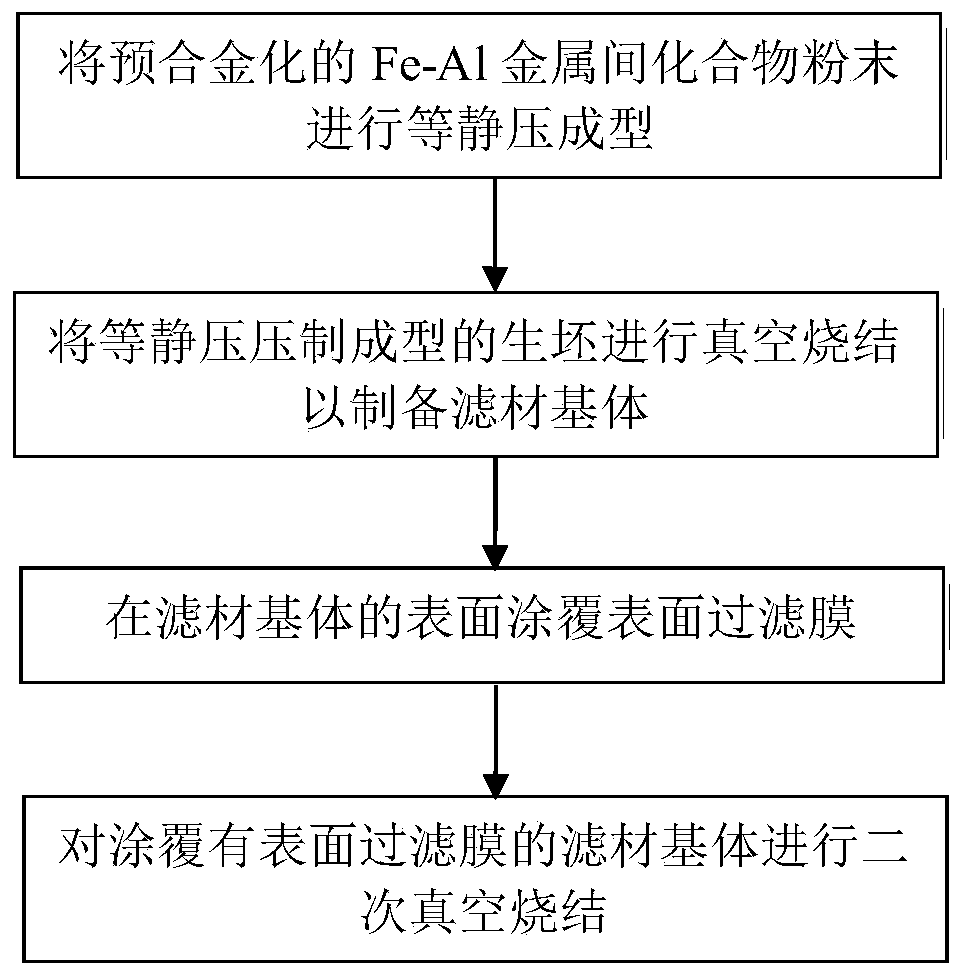

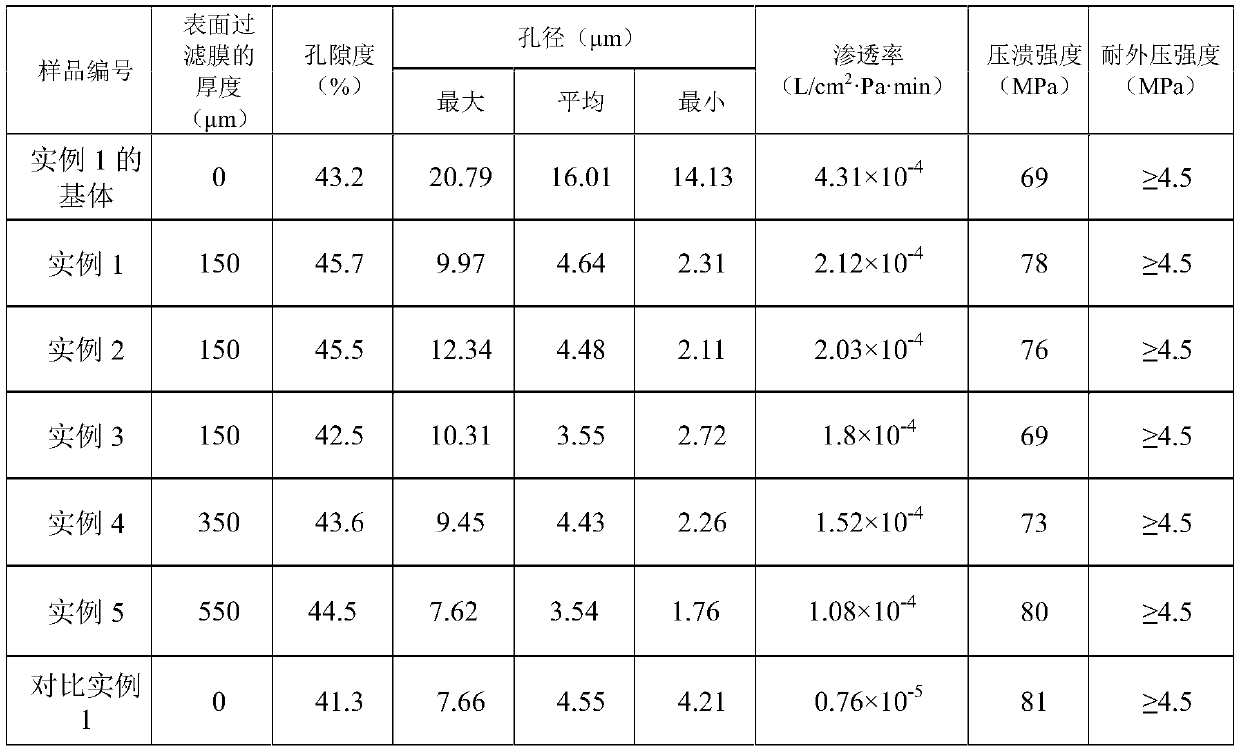

Gradient composite Fe-Al intermetallic compound microporous filter material and preparation method thereof

PendingCN111069590AHigh strengthImprove toughnessSemi-permeable membranesMembranesIntermetallicHigh-temperature corrosion

The invention discloses a gradient composite Fe-Al intermetallic compound microporous filter material and a preparation method thereof, and relates to the field of powder metallurgy preparation. Aiming at the problem that a Fe-Al filter material with high temperature corrosion resistance is difficult to prepare due to process limitation in the prior art, the invention provides the gradient composite Fe-Al intermetallic compound microporous filter material. The gradient composite Fe-Al intermetallic compound microporous filter material is characterized by comprising a matrix framework and a surface filter membrane outside the matrix framework, wherein the matrix framework is pressed and sintered prealloyed Fe-Al intermetallic compound powder; and the surface filter membrane is a mixture ofa binder, water and the prealloyed Fe-Al intermetallic compound powder which are coated on the outer surface of the matrix framework and then sintered for the second time. Therefore, the gradient composite Fe-Al intermetallic compound microporous filter material with high precision, large flux, low resistance drop, good back flushing regeneration characteristic, high strength and high temperaturecorrosion resistance is realized.

Owner:AT&M ENVIRONMENTAL ENG TECH CO LTD

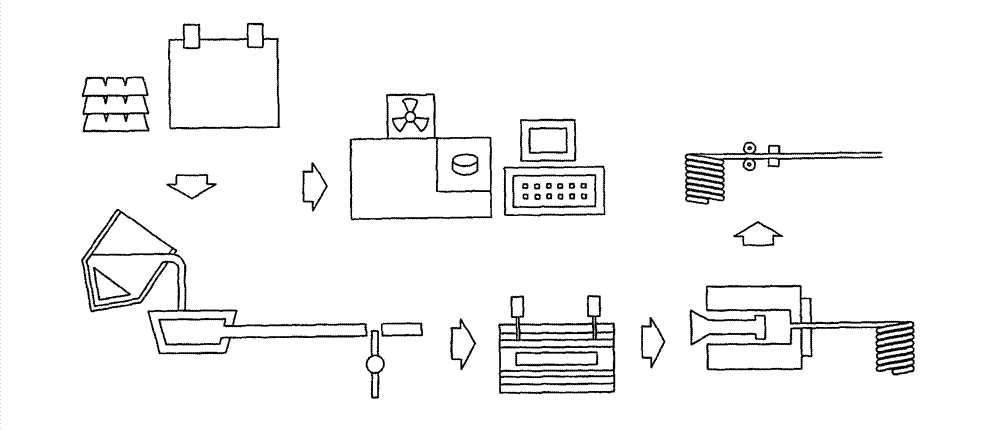

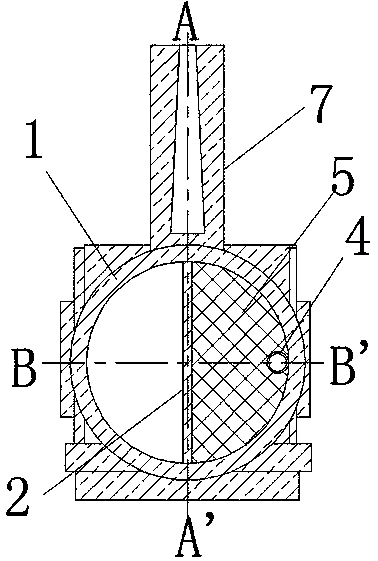

Slow-wire-walking electrospark wire-electrode cutting copper alloy electrode wire and manufacture method thereof

InactiveCN102784978AImprove corrosion resistanceImprove cutting performanceElectrical-based machining electrodesWorking fluidStress relief

The invention provides a slow-wire-walking electrospark wire-electrode cutting copper alloy electrode wire and a manufacture method thereof, wherein the components of the electrode wire include Al, Zn, Ni, Mg, W and Cu. The invention further discloses the manufacture method of the slow-wire-walking electrospark wire-electrode cutting copper alloy electrode wire. The manufacture method is characterized by comprising the following processing steps: (1) feeding materials into a vacuum induction melting furnace according to components and compositions, and melting the materials to obtain molten metal liquid; (2) guiding the molten metal liquid into a continuous casting device to manufacture alloy wire blank; and (3) performing cooling stretching, on-line annealing and stress relief annealing before product finishing on the alloy wire blank to obtain the electrode wire. The corrosion resistance and cutting performance of the electrode wire in working fluid are improved, and the electrode wire is stable in tensile strength and good in electrical conductivity.

Owner:KUNSHAN RUIJIE PRECISION MOLD

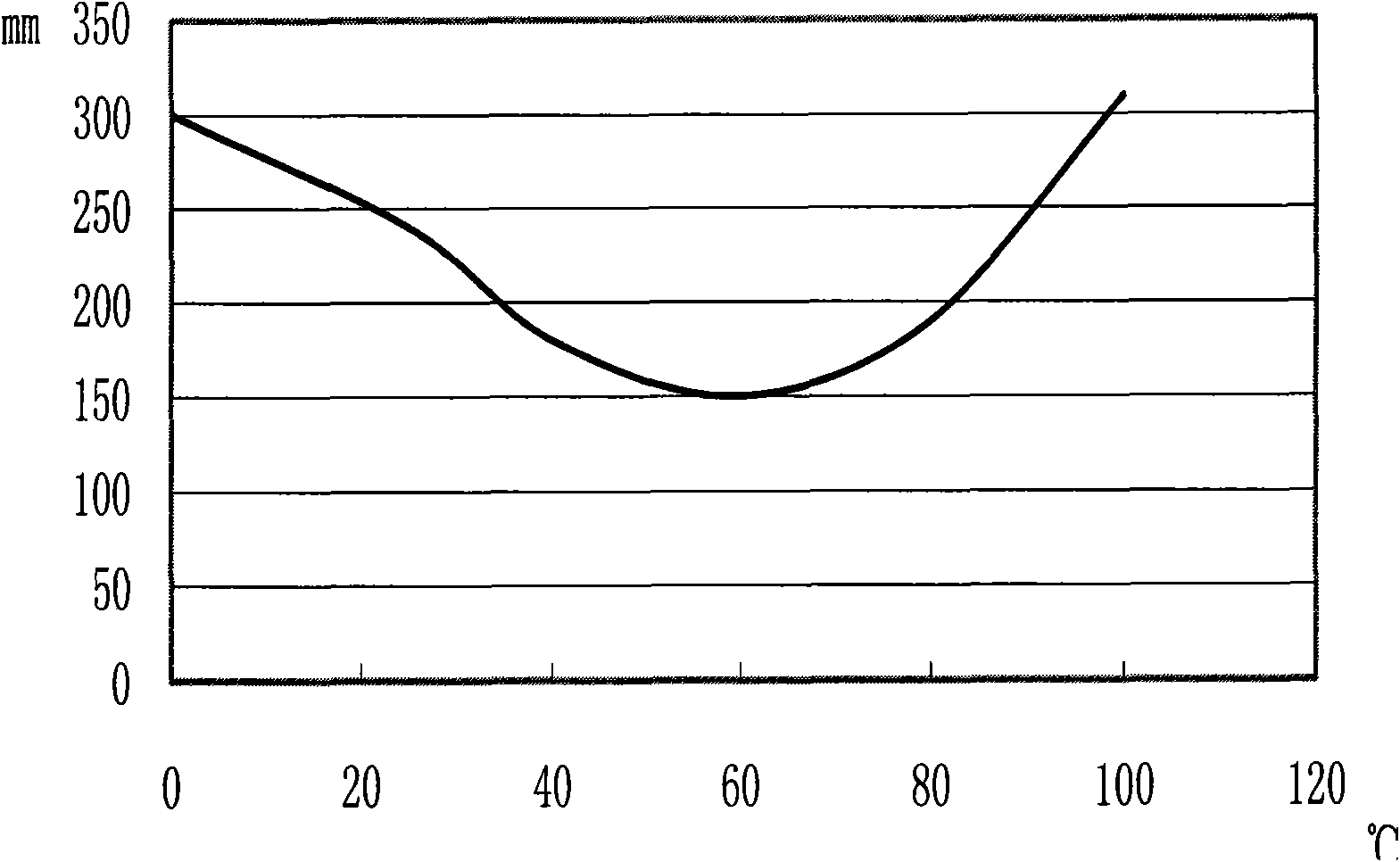

Heatproofing magnesium alloy with stable high-temperature strength

InactiveCN103774019AStable high temperature strengthStable high temperature tensile strengthRoom temperatureUltimate tensile strength

The invention discloses a heatproofing magnesium alloy with stable high-temperature strength. The heatproofing magnesium alloy comprises the following components by weight percent: 3%-5% of Y, 1%-2% of Gd, 0.5%-1.5% of Sm, 0.5%-1.5% of Nd, 0.5%-1% of Ca, and the balance of Mg and inevitable impurities. The heatproofing magnesium alloy has a prominent characteristic in heat-resistant quality, namely very stable high-temperature tensile strength, at 200 DEG C-300 DEG C, the tensile strength of the magnesium alloy reduces along with temperature rising in small amplitude about 10%, at room temperature, the tensile strength can reach 246MPa, at 300 DEG C, the tensile strength still can reach above 200MPa; compared with commercial heatproofing magnesium alloy WE54, the heatproofing magnesium alloy has lower cost and more stable high-temperature strength, and has wide application prospect in fields such as aerospace, automobile industry, weapons and the like.

Owner:HENAN UNIV OF SCI & TECH

Wire with tensile strength>=2000MPa for bridge cable and production method

ActiveCN102936688BUniform metallographic structureUniform performanceMetal rolling arrangementsWire rodAir volume

The invention discloses a wire with tensile strength>=2000MPa for a bridge cable and a production method. The wire comprises, by weight, 0.95-1.2% of C, 0.1-0.48% of Si, 0.6-1.0% of Mn, 0.1-0.5% of Cr, 0.01-0.05% of V, Cu<=0.05%, 0.05-0.15% of Al, 0.01-0.03% of N, P<=0.025% and S<=0.015%. The production method includes smelting and continuously casting into blanks; heating the casting blanks; rolling; heating again; high-speed rolling; spinning; air cooling to the room temperature; and placing for standby. According to the wire and the method, continuous casting of blooms, rolling starting of billets and high speed wire rolling are adopted, therefore a metallographic structure and the like of the wire for the bridge cable are even, and grains are better refined; and processes of rapid cooling with a large air volume and the like are adopted, therefore the tensile strength of the wire for the bridge cable is >=2000MPa and stable, a twist number reaches >=15, and wire fracture caused by the wire quality does not happen during cold drawing.

Owner:武汉钢铁有限公司

Production process of non-annealed wire material for pulling rivet pull rod

The invention discloses a production process of a non-annealed wire material for a pulling rivet pull rod. The production process comprises the following steps: (1) selecting materials, namely selecting an aluminum killed steel material which comprises the following chemical components in percentage by mass: 0.16% to 0.19% of C, 0.04% to 0.09% of Si, 0.61% to 0.89% of Mn, 0.015% to 0.25% of P, 0.010% to 0.020% of S, 0.03% to 0.070% of Al and the balance of Fe; (2) drawing, namely drawing the aluminum killed steel material by using a wire drawing machine; selecting a wire drawing mold of which the working taper angle is 14 to 16 degrees and the sizing length is 2.5mm to 3.0mm; simultaneously, performing wire drawing according to rules that the total compression rate is large and the part compression rate is small, wherein the total compression rate is larger than or equal to 60%, and the part compression rate is smaller than or equal to 15%. A wire material produced by the production process disclosed by the invention is small in scattering difference in tensile strength within a specific range so as to satisfy the riveting requirements of the type of products; a steel wire is bright and smooth in surface and stable in tensile strength and physical properties; a penetrating rod is good in uniformity; the product is small in wire diameter tolerance and high in wire diameter stability.

Owner:DONGGUAN KELEE STEEL WIRE

Intelligent preparation method for vermicular graphite cast iron brake drum

ActiveCN111139396APreliminary regulation of carbon contentRealize comprehensive utilizationFoundry mouldsProcess efficiency improvementFerrosiliconGraphite

The invention discloses an intelligent preparation method for a vermicular graphite cast iron brake drum. The intelligent preparation method comprises the following steps of adding part of pig iron, scrap steel and foundry returns into a low-frequency induction furnace for melting, and controlling the addition amount of a carburant; paving the bottom of a medium-frequency induction furnace with alayer of ferrosilicon to form a ferrosilicon layer, adding part of pig iron to form a pig iron layer, rising the temperature, and adding part of electrolytic copper and ferromanganese before the addedferrosilicon and pig iron are completely molten; pouring solution prepared in the low-frequency induction furnace into the medium-frequency induction furnace from the center of the top of the medium-frequency induction furnace through a pipeline; vermicularizing the solution in the medium-frequency induction furnace in vermicularizing casting ladles; and carrying out pouring. The intelligent preparation method for the vermicular graphite cast iron brake drum has the advantages of being high in brake drum production speed, good in brake drum quality and low in cost.

Owner:山东时风(集团)有限责任公司 +1

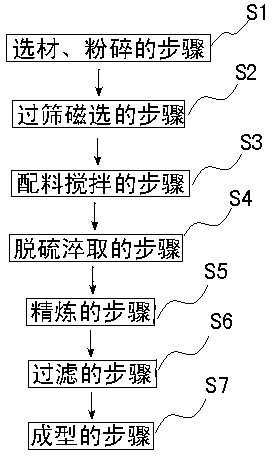

Production method and combination material formula of environment-friendly high-strength reclaimed butyl rubber

InactiveCN103275348AGuaranteed qualityReduce PAH contentPlastic recyclingChemical recyclingChemistryNational standard

The invention discloses a production method of environment-friendly high-strength reclaimed butyl rubber, which comprises the following steps: selecting good quality waste butyl rubber inner tube, and crushing into sheets; screening and magnetic separation; adding environment-friendly rubber softener and reinforcing agent for stirring so as to form a composition material; desulfuration and extraction; refining; filtering; and forming. According to the invention, the reclaimed butyl rubber is ensured in quality as good quality butyl rubber material is selected; the reclaimed butyl rubber conforms to requirements of environment-friendly laws and regulations of European Union as no contaminative rubber softener is added during the regeneration process, and also extracting process is added for extracting original rubber aromatic oil. The invention also discloses a composition material formula of the reclaimed butyl rubber. According to the invention, through improving formula processes and finely selecting raw materials, the tensile strength of the produced reclaimed butyl rubber is kept in the range of 8.5-9.5 MPa which is far higher than the national standard of being larger than or equal to 6.8 MPa.

Owner:NANTONG HUILI RUBBER +1

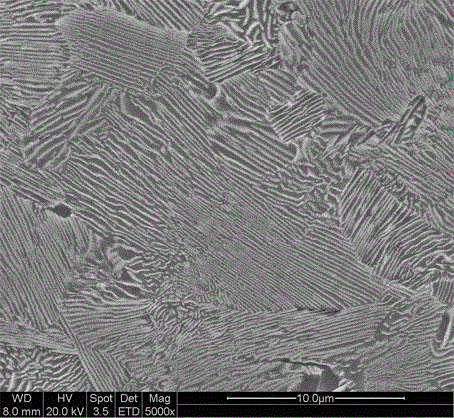

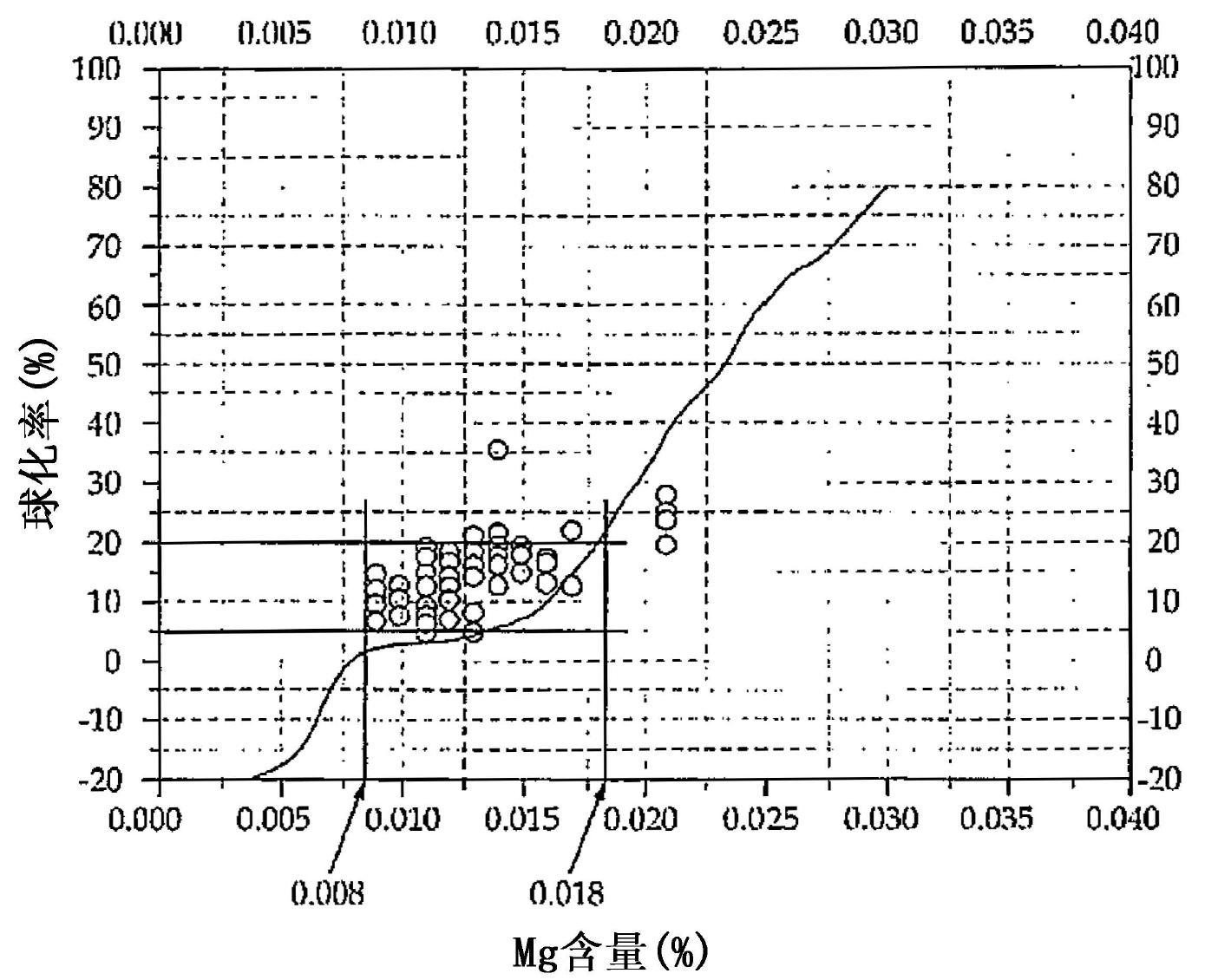

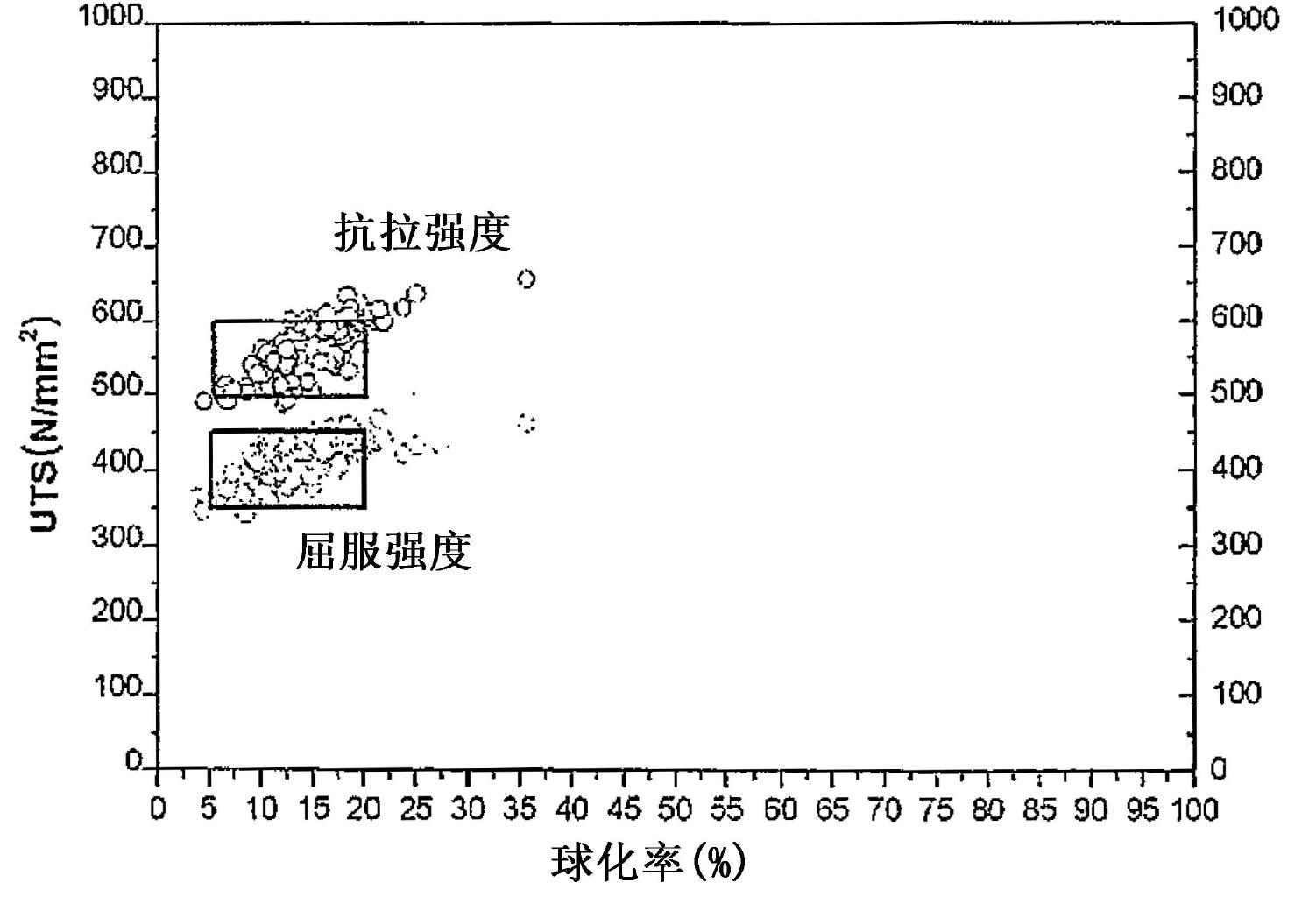

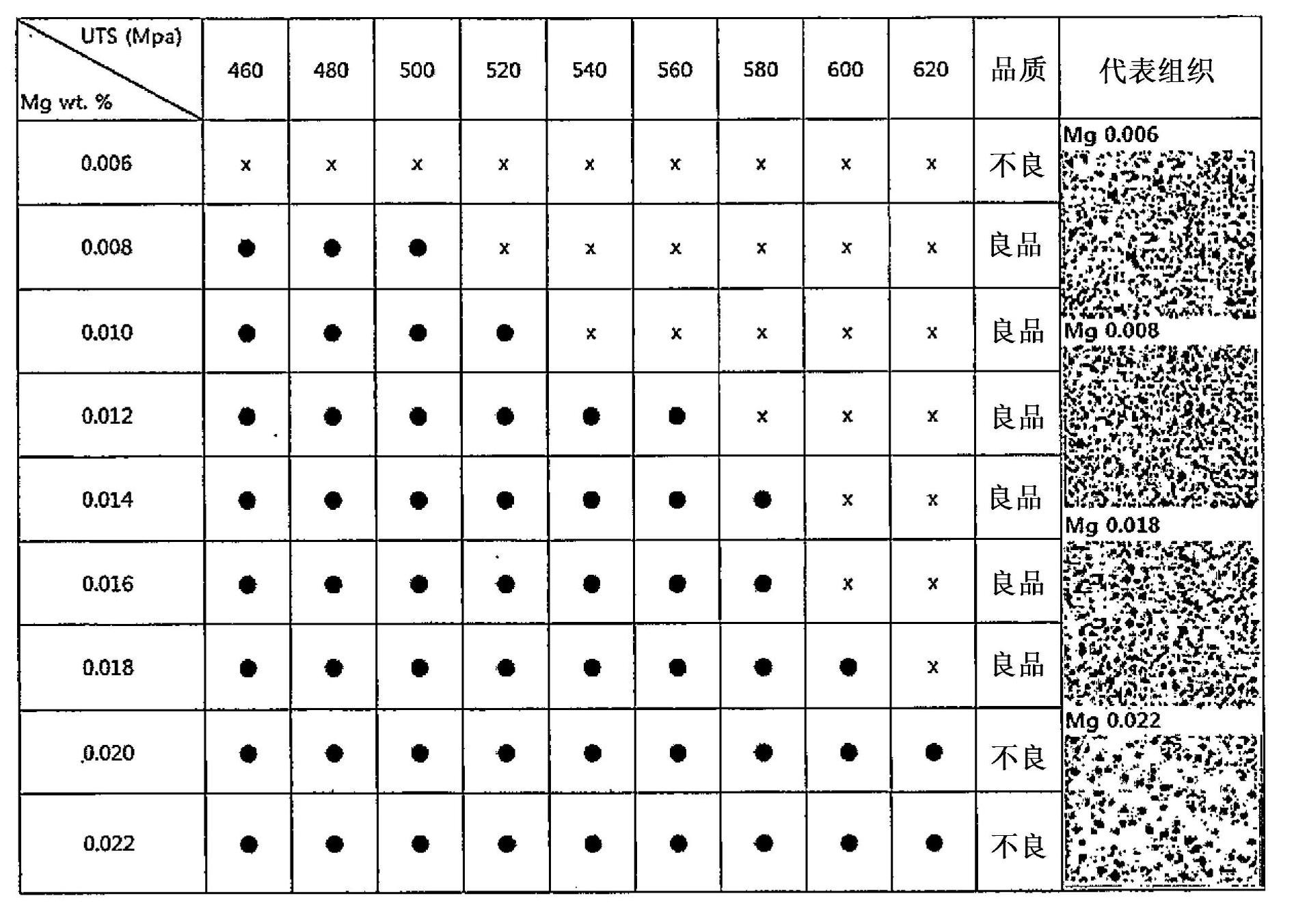

Cgi cast iron and a production method for the same

The present invention relates to cast iron, and more specifically relates to CGI (Compacted Graphite Iron) cast iron in which the amounts of carbon (C), silicon (Si), manganese (Mn), copper (Cu), tin (Sn) and magnesium (Mg) are controlled during production, thereby improving the castability and also giving a stable tensile strength and yield strength and giving an appropriate range of hardness, and also to a production method for the same.

Owner:DOOSAN INFRACORE CO LTD

Q370qE-HPS bridge steel with low cost and high performance, and production method

ActiveCN112195406APromote formationFacilitate organizational transformationTemperature control deviceManufacturing convertersMetallurgyYield ratio

The invention discloses Q370qEHPS bridge steel with low cost and high-performance, and relates to the technical field of steel production. The Q370qEHPS bridge steel comprises the following chemical components by mass: 0.05%-0.08% of C, 0.10%-0.40% of Si, 1.61%- 1.70% of Mn, no more than 0.015% of P, no more than 0.0030% of S, 0.030%-0.050% of Nb, 0.010%-0.018% of Ti, no more than 0.05% of residual Ni, 0.20%-0.30% of Cr, no more than 0.05% of residual Mo, no more than 0.05% of residual Cu, no more than 0.05% of residual B, no more than 0.005% of N, 0.020%-0.050% of Al, and the balance Fe and impurities. A TMCP rolling process is adopted, so that the bridge steel plate which is low in yield ratio, excellent in welding performance and capable of meeting standard requirements is obtained, andthe market competitiveness of enterprises is improved.

Owner:NANJING IRON & STEEL CO LTD

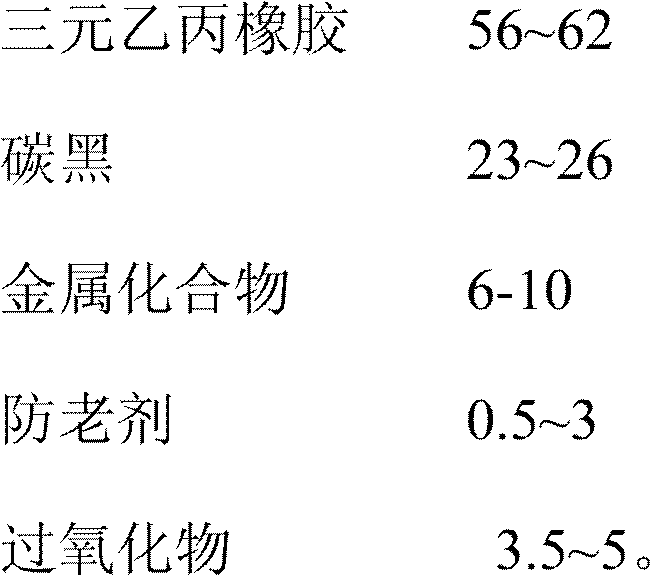

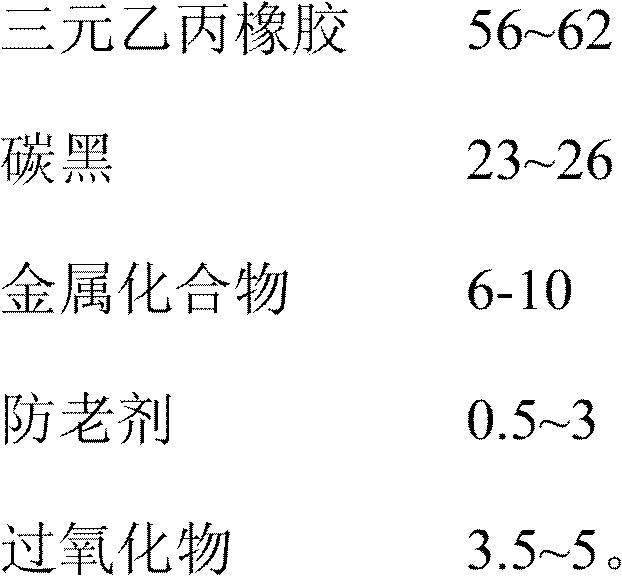

Formula of rubber for valve seat, preparation method for rubber, and valve seat

InactiveCN102250421AAvoid problems such as breeding bacteriaIncrease contentValve arrangementsPolymer scienceVulcanization

The invention discloses a formula of rubber for a valve seat. The rubber comprises the following components in percentage by weight: 56 to 62 percent of ethylene-propylene-diene mischpolymere rubber, 23 to 26 percent of carbon black, 6 to 10 percent of metallic compound, 0.5 to 3 percent of anti-aging agent and 3.5 to 5 percent of peroxide. The invention also discloses a preparation method for the rubber in the formula and a valve seat product. A main raw material is the ethylene-propylene-diene mischpolymere rubber which is terpolymer of ethylene, propylene and non-conjugated dialkene, has the main characteristics of excellent antioxidation, ozone resistance and corrosion resistance and good vulcanization characteristic, and can absorb massive fillers and oil but the characteristics are influenced hardly. The antibacterial, micro-poisonous and low-dissolution metal rubber can be applied to life industries abroad and at home to improve food safety.

Owner:天津市滨海新区塘沽于庄橡胶厂

Top pipe work pit supporting method

InactiveCN110792085ALarge clearance sizeControllable impactExcavationsBulkheads/pilesStructural engineeringPipe

The invention relates to a top pipe work pit supporting method. The method includes the following steps that firstly, construction preparation is made, field leveling is conduced according to the design elevation, setting out of pouring piles is conducted, pile spacing construction is conducted around a work pit, and ring-shaped row piles are formed; secondly, a high-pressure grouting water stop pile is constructed between every two adjacent pouring piles according to the geology and underwater distribution condition so that the high-pressure grouting water stop piles can be engaged with the pouring piles, and a closed water stop curtain is formed; thirdly, earthwork layered excavation is conducted in the work pit, after excavation is conducted till the design elevation of each layer is reached, ring beam construction is conducted, after ring beam construction of each layer reaches the design strength, excavation of the next layer of earthwork is conducted, and excavation is conductedtill the bottom of the work pit is reached; and fourthly, grouting and strengthening are conducted on the hole entering ground of a top pipe to form a hole inner lining wall, meanwhile, the position for the top pipe to enter the hole is reserved, cushion layer and rear seat wall combustion is conducted, top pipe equipment installation is conducted, and work pit construction is completed. The top pipe work pit supporting method has the beneficial effects that the structure is reliable, and top pipe construction is facilitated.

Owner:成都市市政工程设计研究院有限公司

Pure magnesium spheroidizing technology of lost foam ductile cast iron

ActiveCN106636870APrevent defects such as cold insulation wrinkle skinAvoid stickingSulfurFerrosilicon

The invention discloses a pure magnesium spheroidizing technology of lost foam ductile cast iron. The pure magnesium spheroidizing technology comprises the steps that a spheroidizing agent is placed into a lip-pour ladle reaction chamber, a cover of the reaction chamber is closed, and a conventional nucleating agent, ferrosilicon, is added into a lip-pour ladle; after molten iron in a heat-insulated furnace is subjected to deslagging, molten iron is added into the lip-pour ladle, and the temperature of molten iron is controlled to be 1520 DEG C to 1560 DEG C; then, the lip-pour ladle is overturned, and molten iron and the spheroidizing agent react for 60 s to 70 s; and pouring is carried out while stream inoculation is achieved, wherein the addition amount of the stream nucleating agent is 0.08% to 0.15% of the weight of molten iron; the spheroidizing agent is a mixture of pure magnesium ingots and calcium chloride; and the weight ratio of molten iron to the pure magnesium ingots to calcium chloride to ferrosilicon is 1000 to (1.4 to 2.0) to (0.2 to 0.5) to (4 to 8). According to the pure magnesium spheroidizing technology of lost foam ductile cast iron, the spheroidizing problem of high-sulfur high-silicon molten iron can be effectively solved, the spheroidizing grade is high, a required matrix structure can be obtained, the problems that the spheroidizing effect is poor, the quality of castings is not stable, and the rejection rate is high are solved, the technology does not require lip-pour ladle nucleating, the procedures can be decreased, and the labor intensity is reduced.

Owner:桃江新兴管件有限责任公司

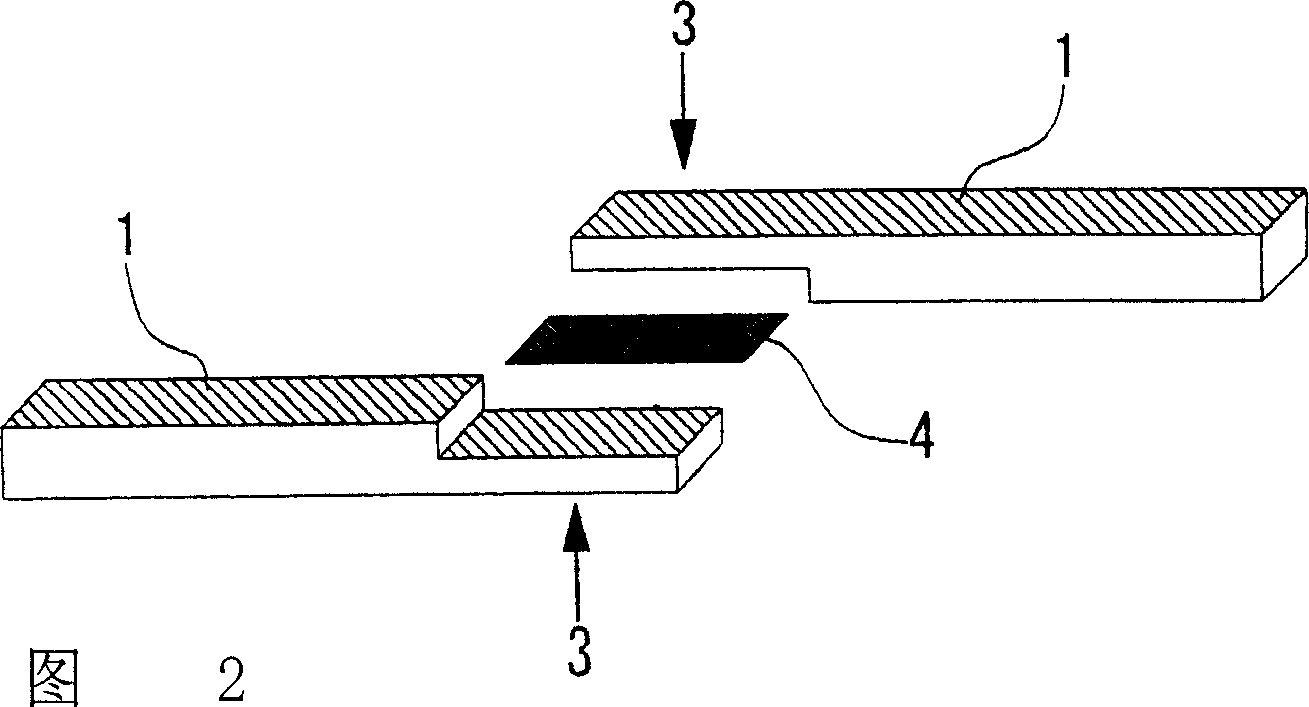

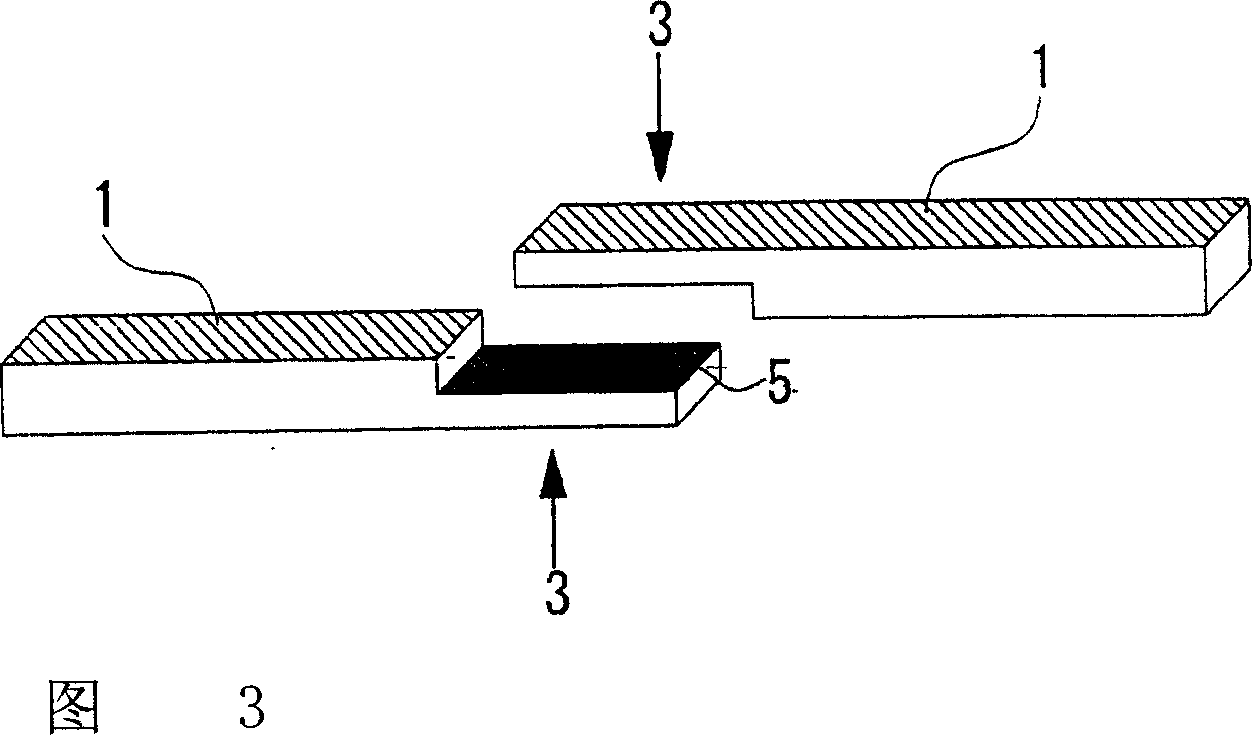

Laser ray transmitting colored resin composition and related technique

Laser ray transmitting colored resin composition comprising a polyphenylene sulfide resin and a colorant having an endothermic peak between 200°C and 300°C as determined by TG / DTA thermal analysis, wherein the difference T C -T N between the crystallization point T C of the laser ray transmitting colored resin composition and the crystallization point T N of the same composition as said composition except for not containing the aforementioned colorant, is not less than 0°C as determined by DSC thermal analysis. Laser ray transmitting material made of the laser ray transmitting colored resin composition, and having one exothermic energy peak and one endothermic energy peak as determined by DSC thermal analysis. The laser ray transmitting colored resin composition excellent in molding accuracy, good in molded product appearance and gloss, capable of preventing or effectively reducing the gap between the materials to be welded in the case of a molded product used for laser welding, and good in heat resistance and fastness, and the laser ray transmitting material excellent in dimension stability and shape stability and capable of preventing or effectively reducing the gap between the materials to be welded when used for laser welding.

Owner:ORIENT CHEM INDS

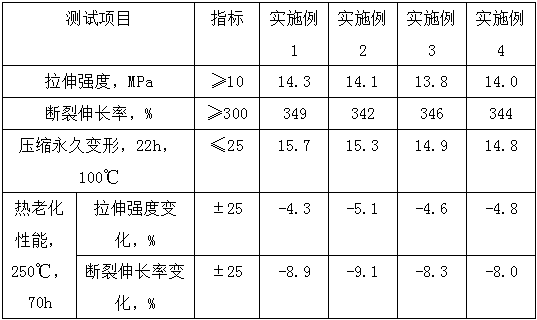

High-temperature-resistant pressing-resistant anti-deformation rubber used for mining machinery buffering cushion

The invention belongs to the technical field of rubber materials, and particularly relates to a high-temperature-resistant pressing-resistant anti-deformation rubber used for a mining machinery buffering cushion. The rubber is prepared from the following ingredients: matrix rubber, silicone oil, butadiene, zinc powder, silicon dioxide powder, aluminium oxide, white carbon black, magnesium oxide, stearic acid, a high-temperature modifier, an antiager, a coupling agent, a cross-linking agent and a catalyst, wherein the matrix rubber comprises butadiene rubber, nitrile rubber, chloroprene rubberand butadiene styrene rubber; the antiager selects an antiager RD or an antiager BLE; the coupling agent is a silane coupling agent; the cross-linking agent is methyl tripropanone oxime silane. The rubber is treated through multiple technologies including kneading, mixing, banburying, calendaring, vulcanization and the like. The rubber has excellent high-temperature-resistant performance and pressing-resistant performance and good material rebound resilience and is very suitable for manufacturing buffering cushions used for large equipment including mining machinery and the like.

Owner:HEFEI KANGZHIHENG MACHINERY TECH CO LTD

Conductive silicone rubber for cable accessories

InactiveCN104403327AImprove surface strengthGood aging resistanceInorganic pigment treatmentSurface strengthErythritol

The invention discloses conductive silicone rubber for cable accessories. The conductive silicone rubber comprises the following raw materials in parts by weight: 0.1 to 0.5 part of erythritol, 1 to 2 parts of polyacrylamide, 1 to 2 parts of an accelerant DBTU, 1 to 2 parts of hydroxyethyl cellulose, 2 to 3 parts of stearoyl-rac-glycerol, 1 to 2 parts of zinc dihydrogen phosphate, 15 to 25 parts of acetylene black, 1 to 2 parts of ammonium polyphosphate, 7 to 10 parts of chlorinated paraffin, 2 to 3 parts of calcium stearate, 1 to 2 parts of benzotriazole, 1 to 2 parts of dimethylacrylicacid 1,4-butylene terephthalate, 1 to 2 parts of butylene terephthalate potassium zirconium carbonate, 3 to 4 parts of a rare earth promoter, 100 to 116 parts of methyl vinyl phenyl polysiloxane rubber, 1 to 2 parts of a vulcanizing agent DCP, and 1 to 2 parts of Hexamethylcyclotrisiloxane. The rubber provided by the invention is black rubber, is high in surface strength, good in ageing resistance, high in acid and alkali corrosion resistance, good in water resistance and high and low temperature resistance, high in tensile strength, good in mechanical property, and particularly suitable for serving as conductive bushing and conductive rubber shock absorption products.

Owner:滁州君越高分子新材料有限公司

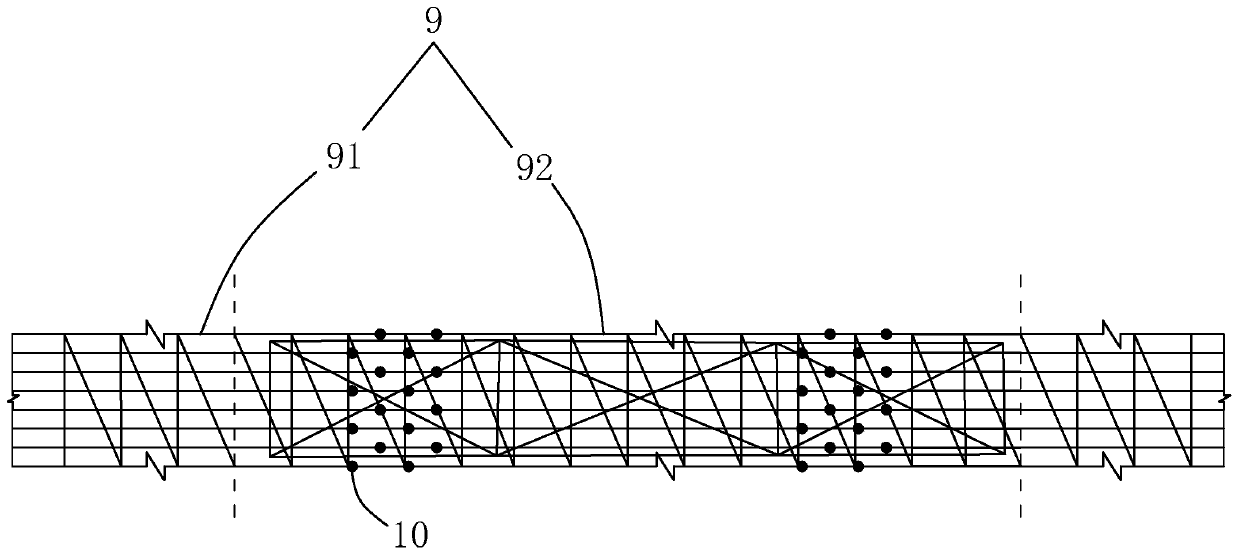

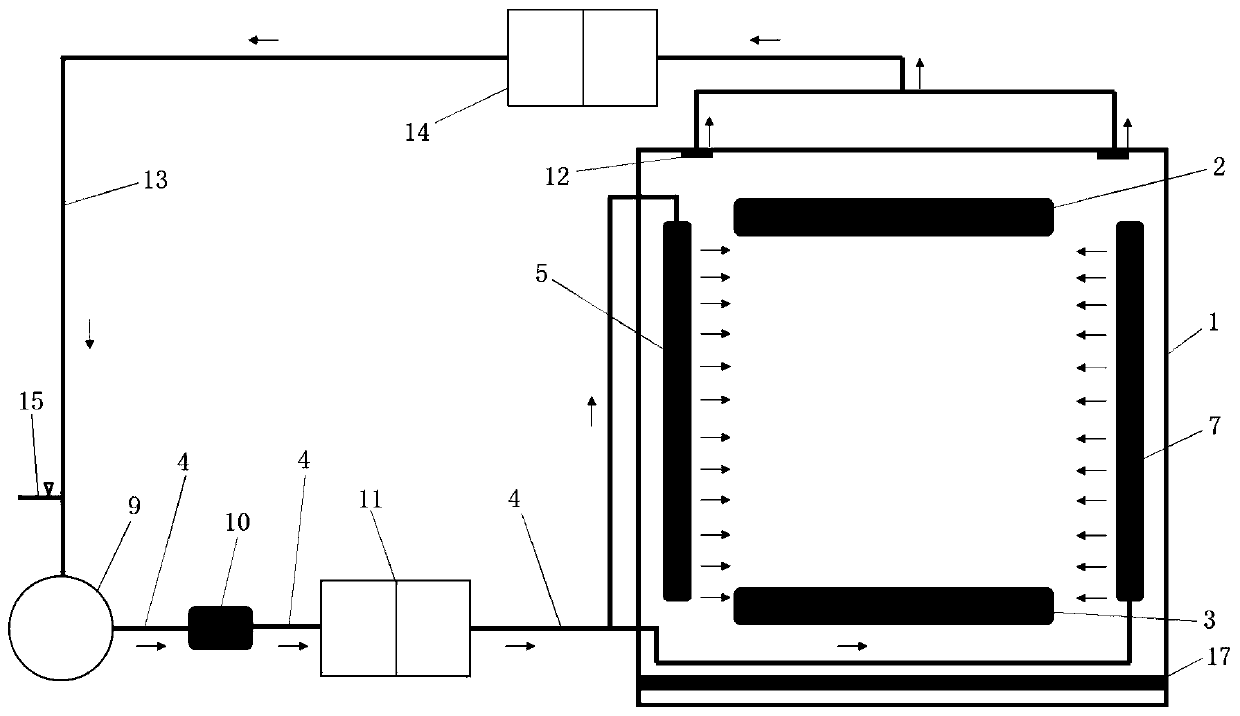

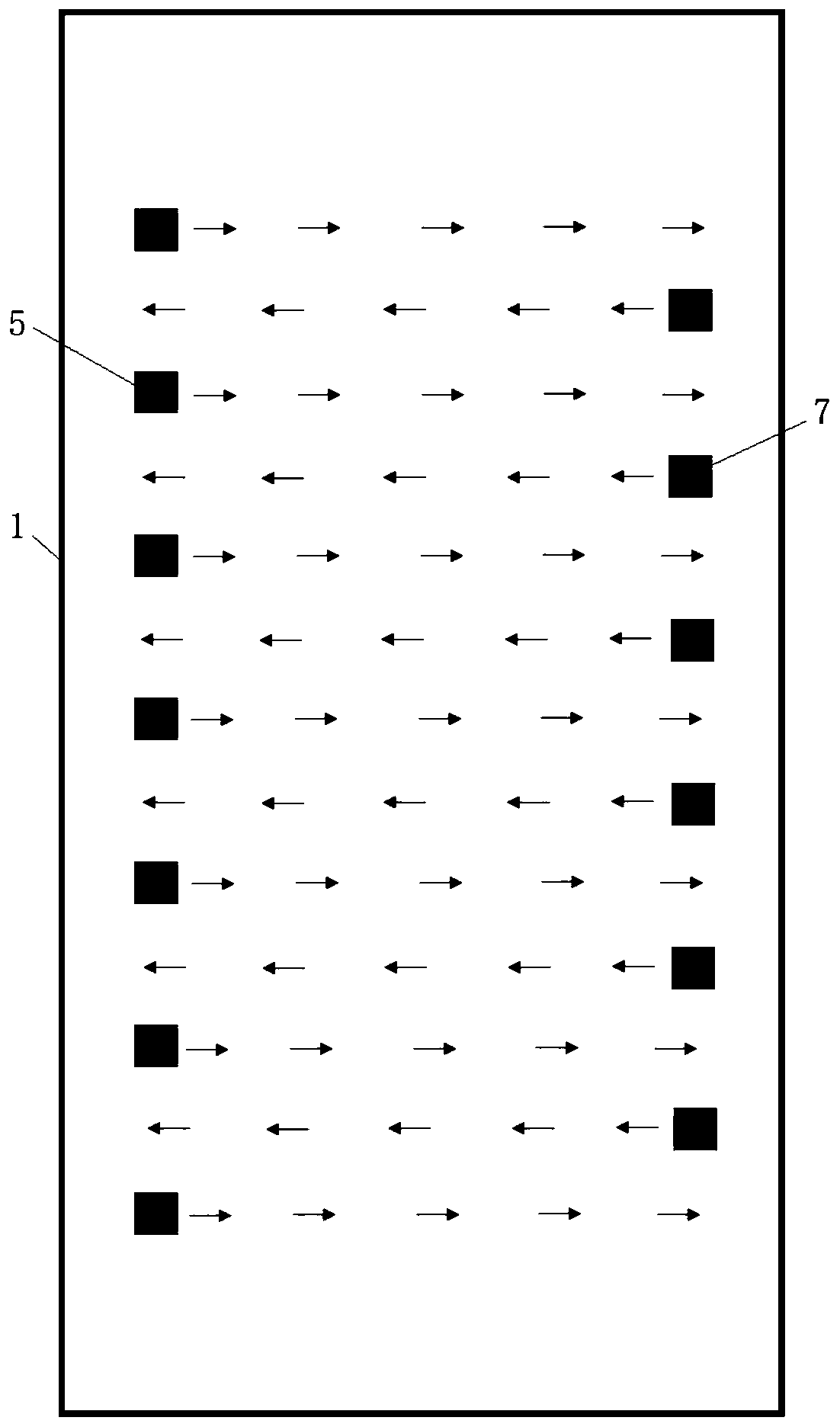

Battery diaphragm drying oven device

PendingCN110202726AHot air and uniform temperatureUniform air permeability and thicknessElectrical batteryWave shape

The invention relates to a battery diaphragm drying oven device which comprises a box body; the front side of the box body is provided with a film inlet; the rear side of the box body is provided witha film outlet; a drying cavity is formed in the box body and is internally provided with a diaphragm conveying device and an air blowing system; the diaphragm conveying device is suitable for conveying a battery diaphragm which enters the drying cavity; and the air blowing system is suitable for blowing air to the battery diaphragm conveyed in the drying cavity. For the battery diaphragm drying oven device, an upper transition roller set and a lower transition roller set of the diaphragm conveying device are arranged in a wave shape at intervals, each left air blowing pipe and each right airblowing pipe oppositely blow the air, and air inlet directions of each left air blowing pipe and the corresponding right air blowing pipe are opposite, so that hot air and temperature received by thesurfaces of the battery diaphragms located at different positions in the drying cavity are uniform; compared with single-side air blowing, the battery diaphragm with more uniform air permeability andthickness can be obtained through double-side air blowing; and through arrangement of a step cross beam, film penetrating operation is facilitated when a film roll is manually replaced, and maintenance of parts in the box body and wiping of the guide roller surface with the worker are facilitated.

Owner:JIANGSU ANREDA NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com