High-strength cold-rolled steel plate and method for producing same

A technology of cold-rolled steel sheet and manufacturing method, applied in the field of high-strength cold-rolled steel sheet and its manufacture, can solve problems such as cracks, bendability, poor hole expandability, and easy cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] Hereinafter, examples of the present invention will be described. However, the present invention is of course not limited to the following examples, and can be appropriately modified and implemented within a range suitable for the gist of the present invention, and all of them are included in the technical scope of the present invention.

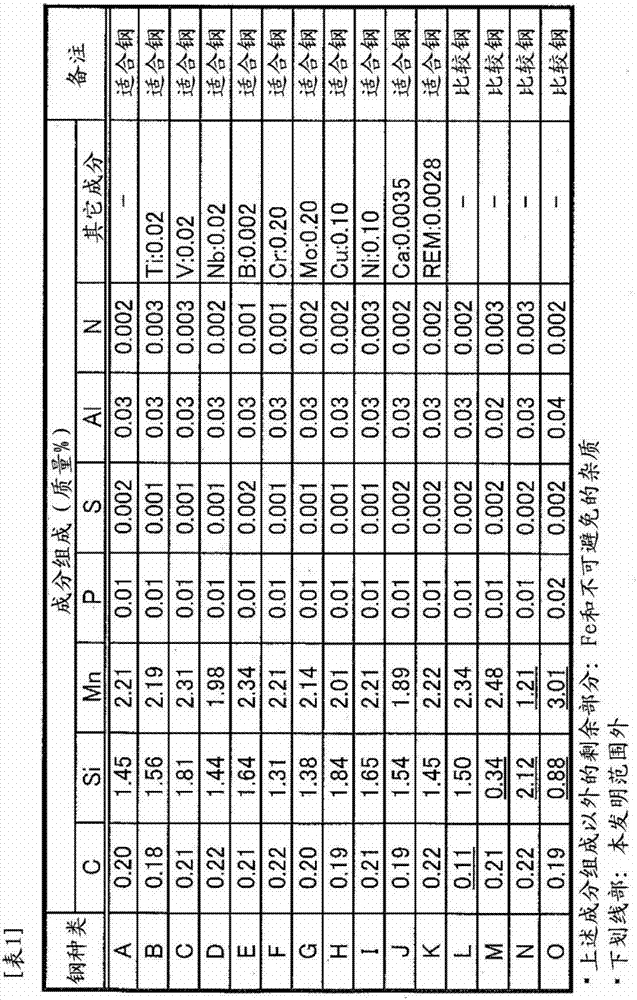

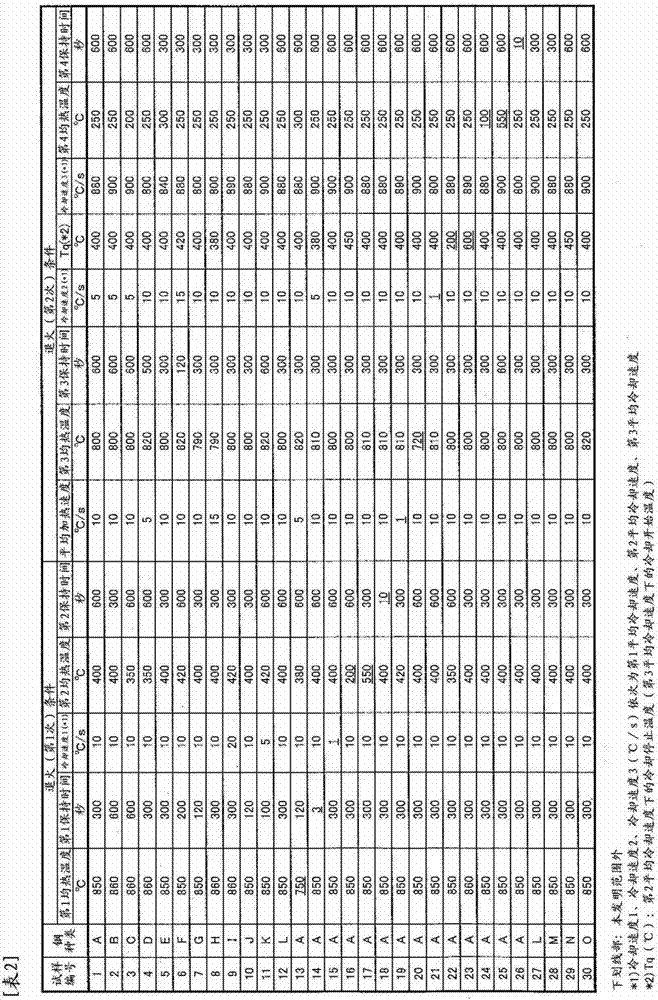

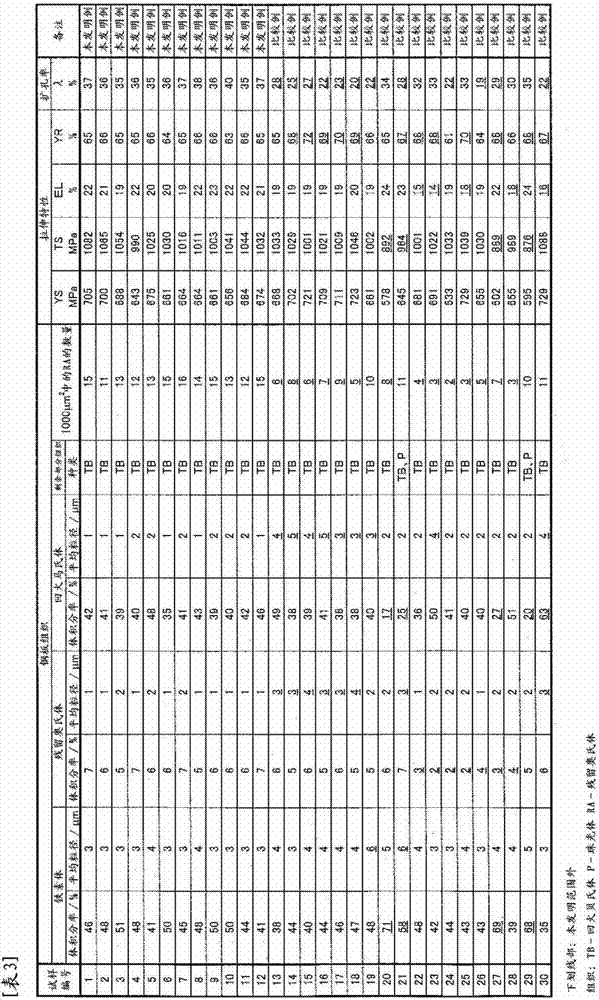

[0124] The steel with the composition shown in Table 1 was smelted and cast to produce a 230 mm thick slab, which was hot rolled at a hot rolling heating temperature of 1200°C and a finish rolling finish temperature of 900°C. After the hot rolling was completed, Cool at a cooling rate of 100°C / s to 650°C, then cool at a cooling rate of 20°C / s to form a hot-rolled steel sheet with a thickness of 3.2mm, and coil at a coiling temperature of 600°C. Next, the obtained hot-rolled steel sheet was pickled, and then cold-rolled to manufacture a cold-rolled steel sheet (thickness: 1.4 mm). Then, as the first annealing, heat to the first soakin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com