Battery diaphragm drying oven device

A battery diaphragm and oven technology, applied in the field of battery diaphragm production systems, can solve problems such as difficulty in ensuring stable heat treatment film performance, discontinuous heat treatment process, uneven oven temperature field, etc., and achieve compact structure, good heat treatment effect, and stable wind pressure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

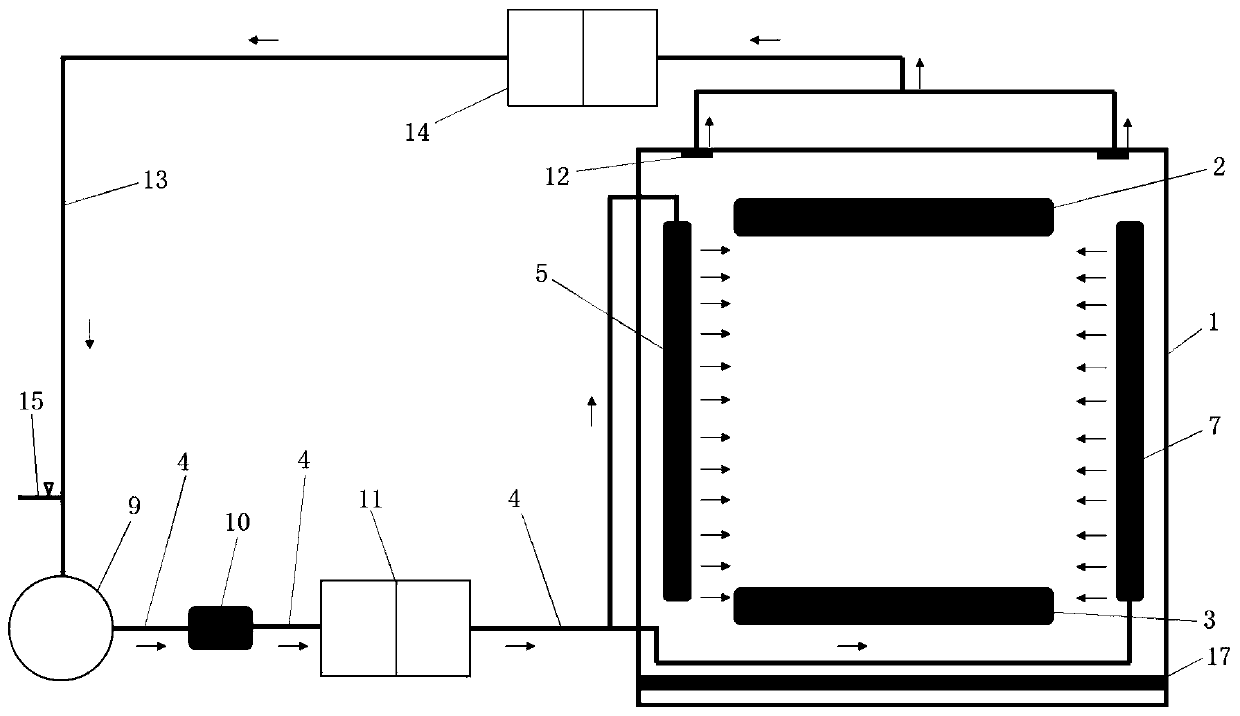

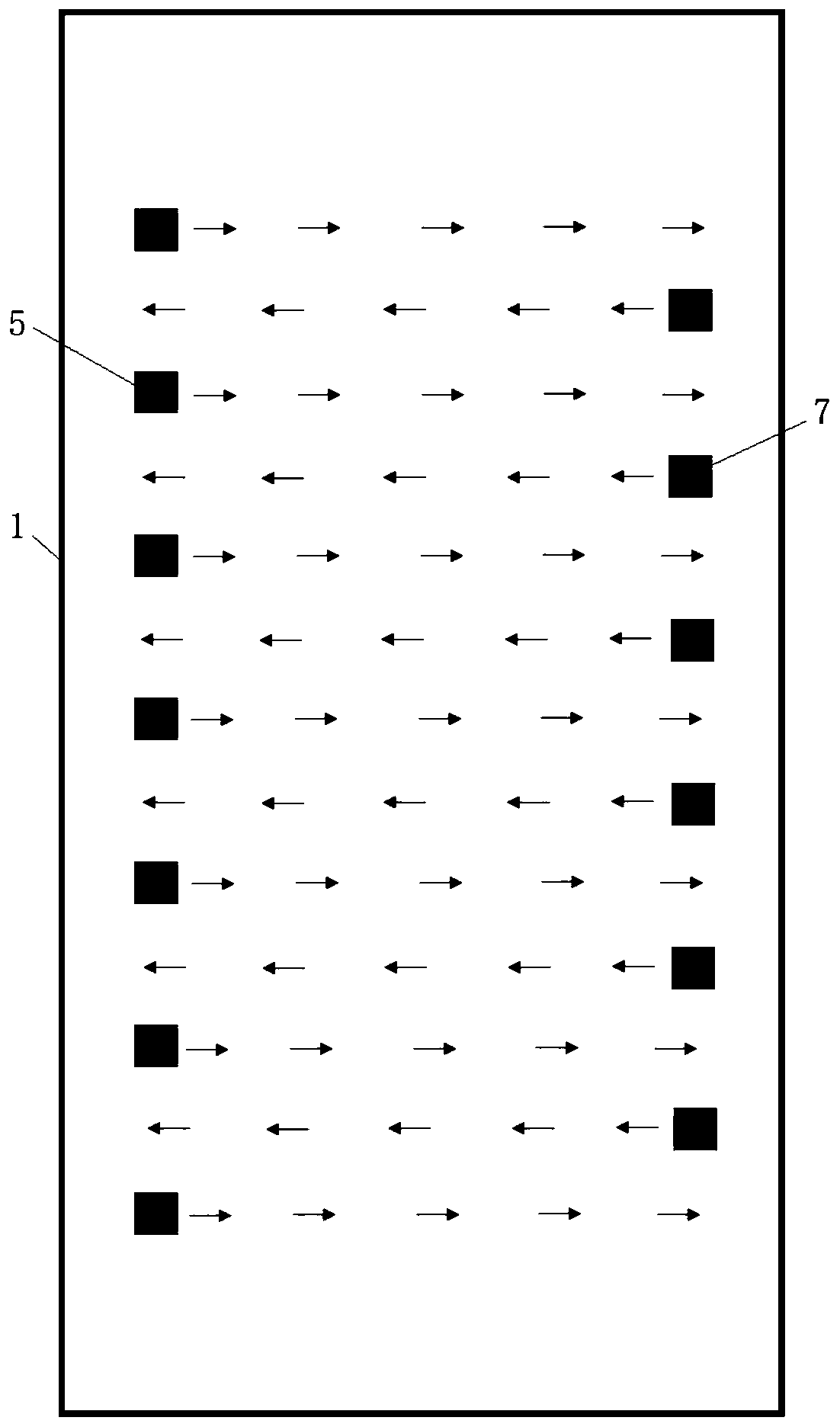

[0044] Such as figure 1 As shown, a battery separator oven device includes a box body 1 . The box body 1 is a frame structure welded with rectangular integral profiles. In order to ensure strength and rigidity, it must be made of metal profiles with corresponding strength according to the size of the box body 1. The overall frame is required to be flat and square, and the connection is firm. The surrounding and top are sealed with insulation boards, and the bottom is elevated with insulation boards. One side of the box body 1 is provided with a detachable manhole, which is convenient for maintenance personnel to enter the box body 1 for inspection and maintenance. The front side of the box body 1 is provided with a narrow rectangular film inlet, and the rear side of the box body 1 is provided with a narrow rectangular film outlet port for guiding the battery separator into and out of the box body 1 . The inlet guide roller and the outlet guide roller are fixed with brackets ...

Embodiment 2

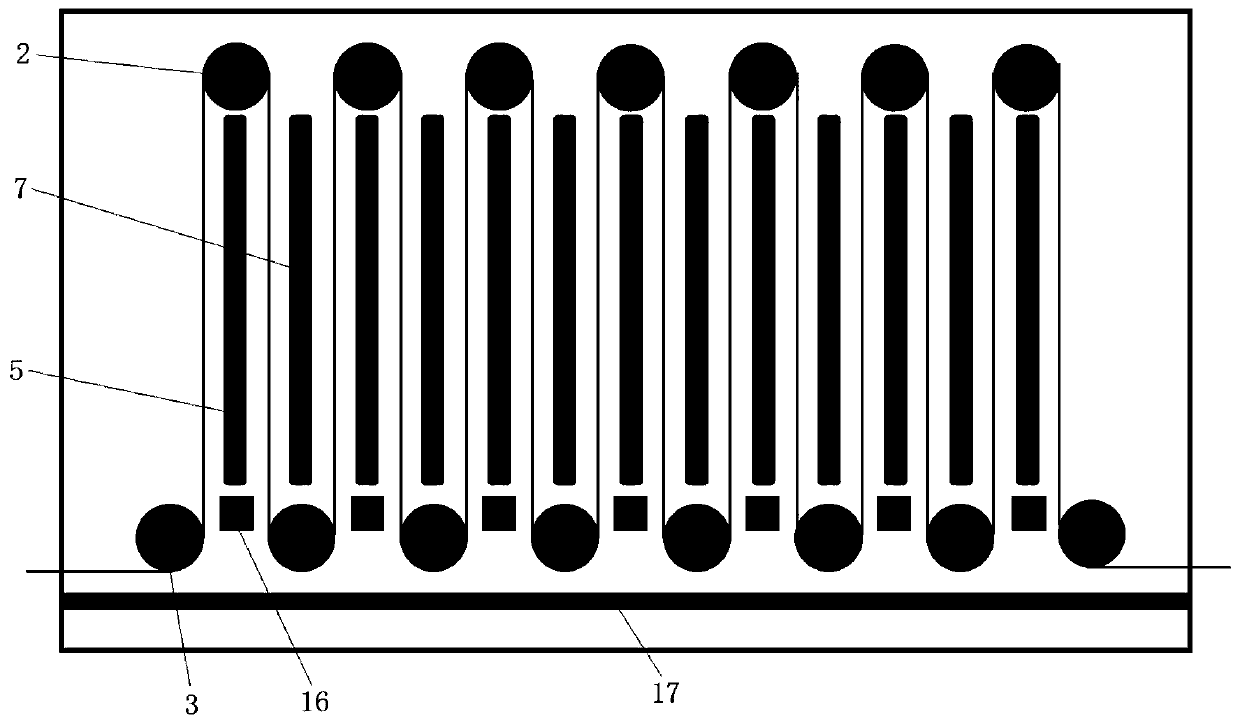

[0053] Such as Figure 5 and Figure 6 As shown, on the basis of the first embodiment, the second embodiment is provided with a partition 17 in the box body 1, and the partition board 17 divides the inner cavity of the box body 1 into an upper cavity and a lower cavity, and the upper cavity is the drying cavity. A plurality of cylinders 18 are arranged in the lower chamber, and the push rods of the cylinders 18 are connected with the partition 17, which are suitable for driving the partition 17 to move up and down in the casing 1, so as to regulate the space size of the drying chamber. The partition 17 moves up and down in the box body 1 to regulate the space size of the drying cavity, which can effectively reduce the volume of the drying cavity and improve the heat preservation effect.

[0054] The lithium battery diaphragm production line is connected in series with multiple battery diaphragm oven devices to form a complete set of dynamic heat treatment equipment to meet th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com