Pure magnesium spheroidizing technology of lost foam ductile cast iron

A ductile iron and lost foam technology, applied in the field of foundry technology, can solve the problems of reduced process, unstable casting quality and high scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

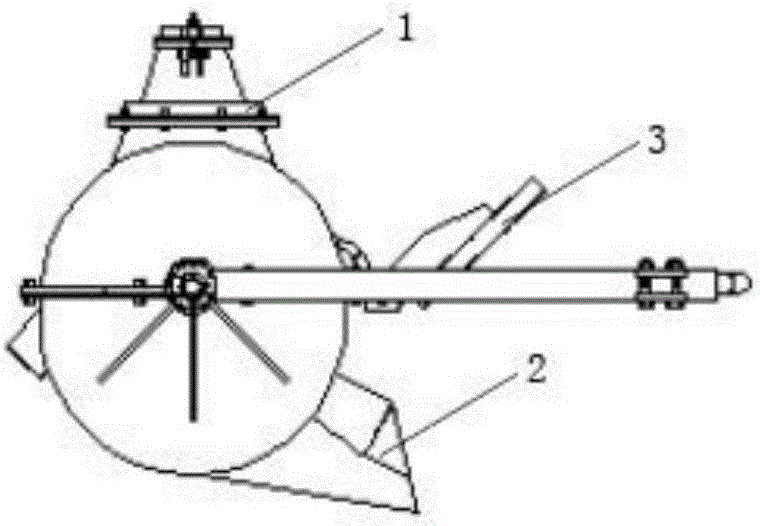

[0016] Such as figure 1 As shown, first heat the subcontractor to ensure that the temperature of the cladding wall is above 700°C; put the spheroidizing agent into the subcontractor reaction chamber 1, close the reaction chamber cover, and add the conventional inoculant ferrosilicon into the subcontractor; The molten iron in the furnace is slag removed and added to the subcontractor. The temperature of the molten iron is controlled at 1520°C. The weight percentage concentration of various components in the molten iron in the holding furnace is: carbon 3.7%, silicon 1.3%, sulfur 0.08%, phosphorus 0.07%, Manganese 0.12%; cover the nozzle 2 with the cover 3, and then quickly transfer the bag at 90° for 5-10s to carry out the nodularization reaction. The reaction time of the nodulizer is 70s; The pouring is accompanied by flow inoculation, and the amount of flow inoculant added is 0.13% of the weight of molten iron; the nodulizer is a mixture of pure magnesium ingot and calcium ch...

Embodiment 2

[0018] First, heat the subcontractor to ensure that the temperature of the cladding wall is 700°C; put the spheroidizing agent into the subcontractor reaction chamber 1, close the reaction chamber cover, and add conventional inoculant ferrosilicon into the subcontractor; The slag is added to the subcontractor, and the height of the molten iron is about two-thirds of the volume of the subcontractor, and the temperature of the molten iron is controlled at 1560°C; the weight percentage concentration of various components in the molten iron in the holding furnace is: carbon 3.8% , 1.5% silicon, 0.09% sulfur, 0.08% phosphorus, 0.09% manganese; cover the bag mouth 2 with the bag cover 3, and then quickly transfer the bag at 90° for 5-10s to carry out the nodularization reaction, and the nodulizer reaction time is 60s; After the spheroidizing reaction is completed, pouring is carried out directly with a subcontractor, accompanied by inoculation with flow, and the amount of inoculant a...

Embodiment 3

[0020] First, heat the subcontractor to ensure that the temperature of the cladding wall is 700°C; put the spheroidizing agent into the subcontractor reaction chamber 1, close the reaction chamber cover, and add conventional inoculant ferrosilicon into the subcontractor; The slag is then added to the subcontractor, and the temperature of the molten iron is controlled at 1540°C; the weight percentage concentration of various components in the molten iron in the holding furnace is: carbon 4.0%, silicon 1.8%, sulfur 0.07%, phosphorus 0.06%, manganese 0.1%; Cover the bag nozzle 2 with the bag cover 3, and then quickly transfer the bag at 90° for 5-10s to carry out the nodularization reaction. The reaction time of the nodulizer is 65s; For inoculation with flow, the addition of inoculant with flow is 0.15% of the weight of molten iron; the nodulizer is a mixture of pure magnesium ingot and calcium chloride, and the weight ratio of molten iron: pure magnesium ingot: calcium chloride:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com