Patents

Literature

31results about How to "Improve nodularity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

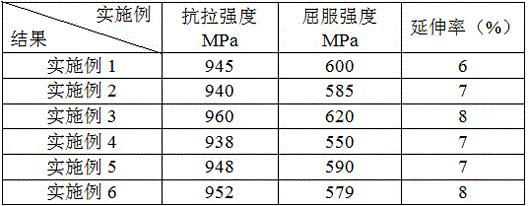

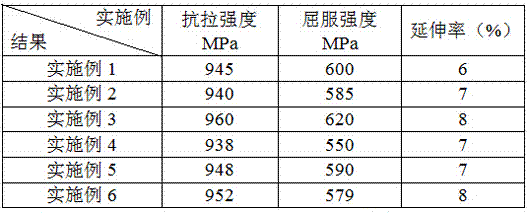

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

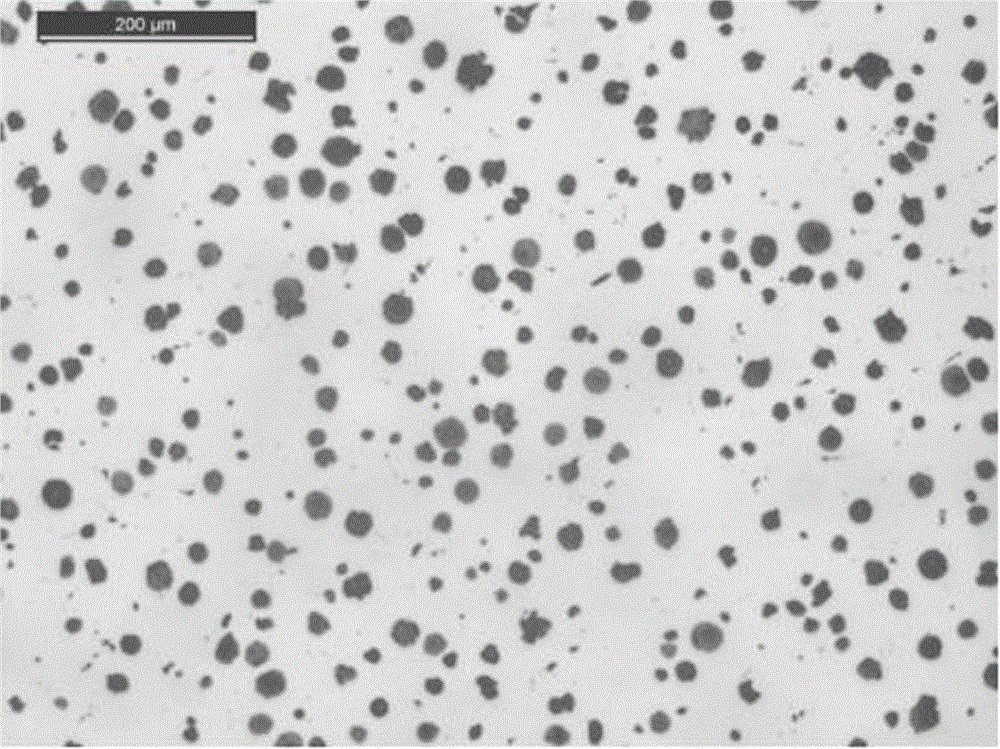

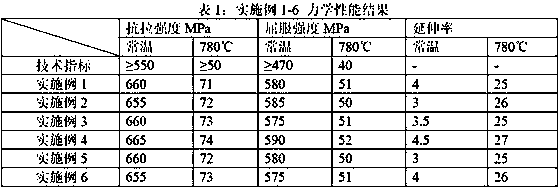

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

Working roll for rolling medium-thickness plate with high grade and high strength and manufacture method thereof

ActiveCN101954378AImproved roll shape retentionImprove wear resistanceRollsMetal rolling arrangementsChemical compositionHardness

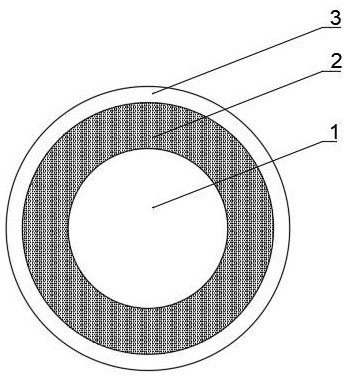

The invention discloses a working roll for rolling a medium-thickness plate with high grade and high strength and a manufacture method thereof. The working roll is applied to a medium-thickness plate rolling mill of a rolling steel industry. A working layer comprises the following alloy components in percentage by weight: 3.00-3.50 percent of C, 0.40-1.20 percent of Si, 0.50-1.20 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 1.30-2.50 percent of Cr, 3.20-4.50 percent of Ni, 0.20-1.00 percent of Mo, 0.20-2.00 percent of W and 1.00-1.50 percent of V. A roll core comprises the following chemical components in percentage by weight: 2.80-3.50 percent of C, 2.00-2.50 percent of Si, 0.50-1.00 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 0.20-0.50 percent of Cr, 0.20-0.60 percent of Ni, not more than 0.20 percent of Mo and not more than 0.30 percent of Re. The working roll manufactured by adopting a centrifugal composite casting process and two-section tempering production at 400-550 DEG C for 25-30 hours is the working roll for rolling the medium-thickness plate with high grade and high strength, which has the advantages of high abrasion resistance and less hardness reduction.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Medium silicon molybdenum niobium spheroidal graphite cast iron material and preparation method thereof

The invention discloses a medium silicon molybdenum niobium spheroidal graphite cast iron material and a preparation method thereof. The medium silicon molybdenum niobium spheroidal graphite cast iron material is prepared from the following chemical components in percentage by mass: 2.8-3.2% of C, 4.2-4.5% of Si, less than or equal to 0.4% of Mn, less than or equal to 0.04% of P, less than or equal to 0.015% of S, 0.8-0.9% of Mo, 0.6-0.9% of Ni, 0.4-0.7% of Nb, 0.03-0.06% of Mg, 0.15-0.25% of V and the balance of Fe and inevitable other elements. Since C04 high-purity pig iron and waste steel are taken as raw materials, a medium-frequency induction furnace is adopted for smelting, and a carburant, silicon carbide, ferrocolumbium, nickel plates, ferrosilicon and ferrovanadium are added in different time phases of smelting, raw iron chemical components and smelting temperature expected by design can be achieved, and the product disclosed by the invention can be prepared through nodulization and two times of inoculation. By adopting the edium silicon molybdenum niobium spheroidal graphite cast iron material disclosed by the invention, an exhaust manifold of an engine can work under a working condition of about 800 DEG C, the high-temperature use property of the exhaust manifold can be improved, and the service life of the exhaust manifold can be prolonged.

Owner:西峡县内燃机进排气管有限责任公司

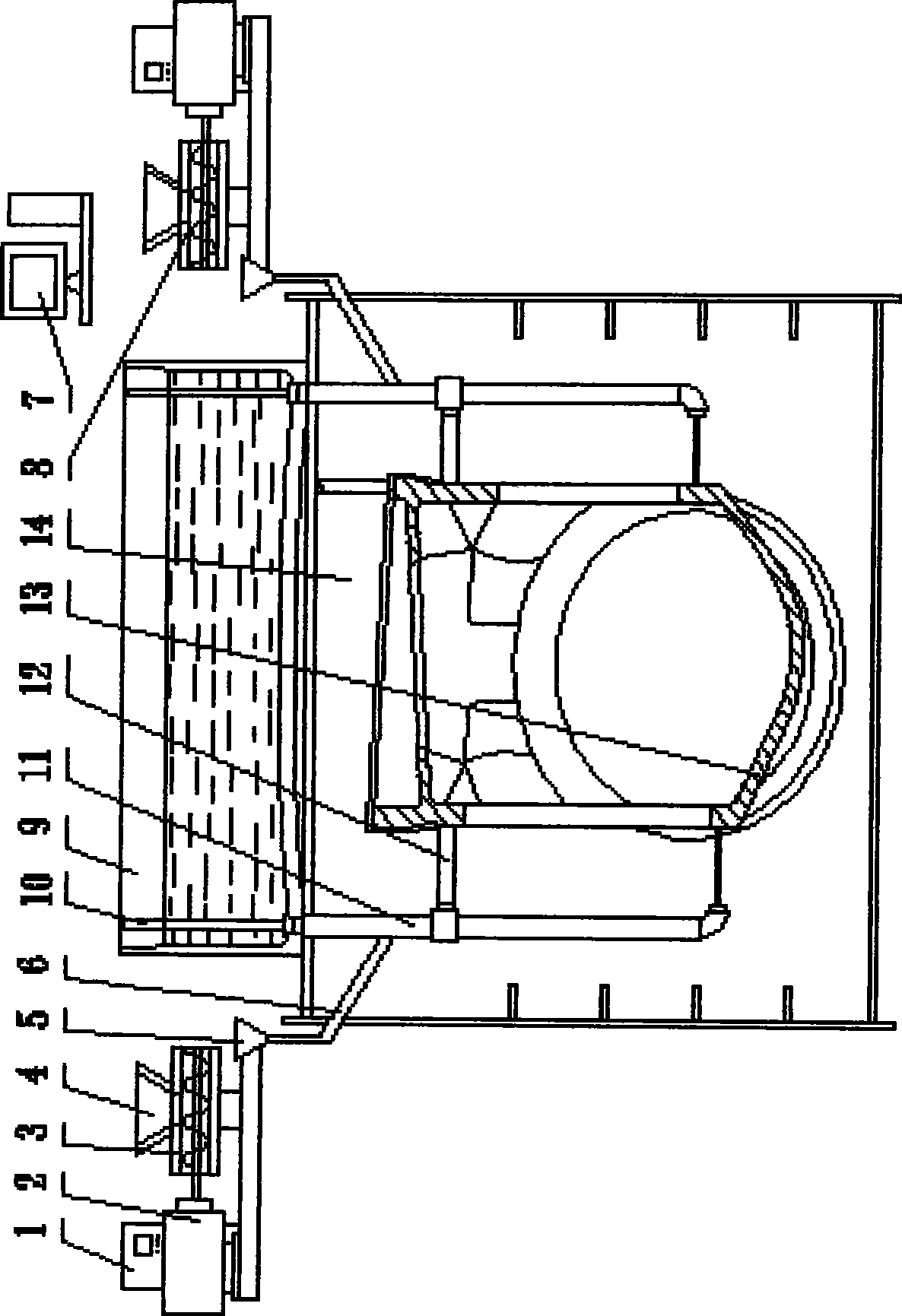

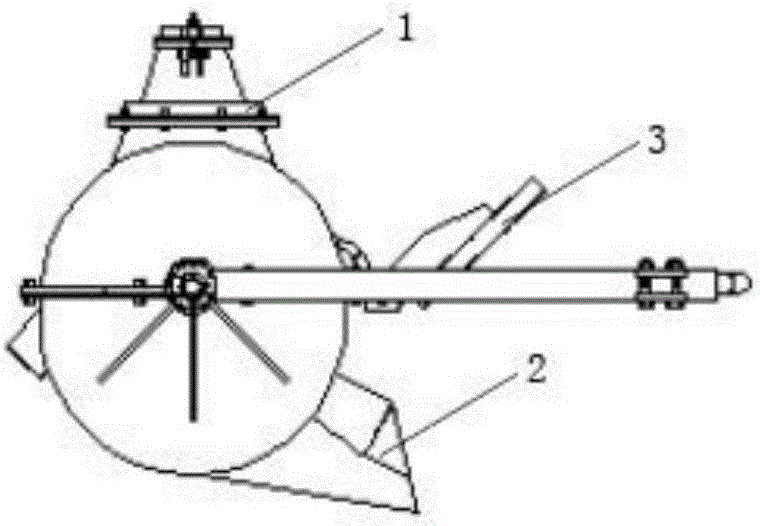

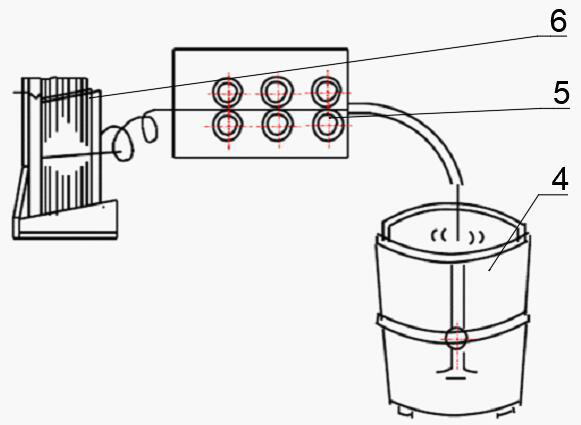

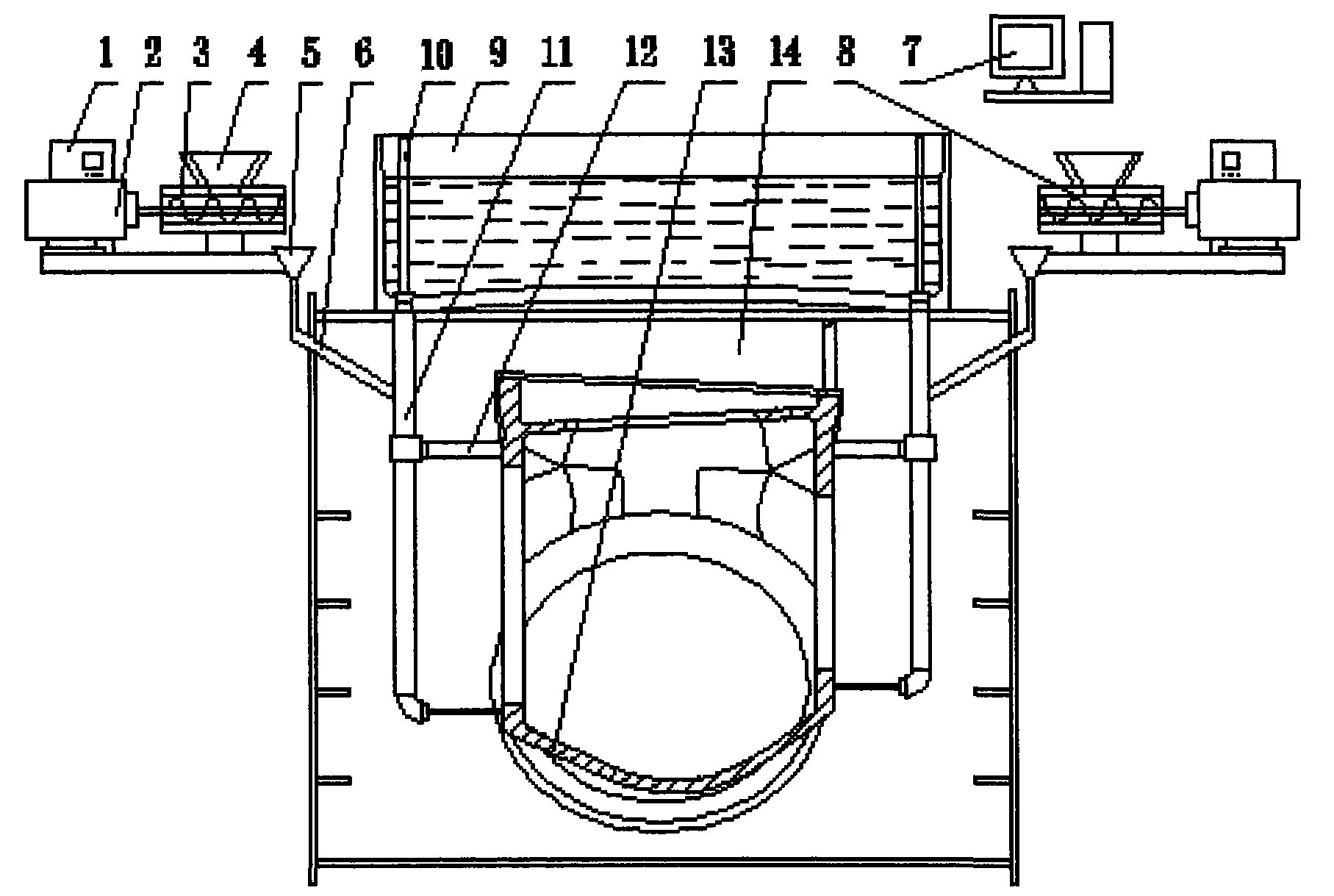

Instant inoculation method of large-section magnesium iron

The invention relates to an inoculation method for large-section ductile iron, which can accurately change the adding speed of inoculant according to different flow rates of molten iron during pouring. The method can be used for producing the large-section ductile iron with high performance requirement and capable of resisting low-temperature shock. The inoculation method for the large-section ductile iron is characterized in that the molten iron is poured into a straight pouring channel from a runner box, an automatic feeding device adds the inoculant into the straight pouring channel through a pipeline at the same time of pouring, the inoculant and the molten iron are in a half filling state in the straight pouring channel, mixed and then poured into a die cavity, and the automatic feeding device automatically adjusts the adding speed of the inoculant according to the flow change of the molten iron.

Owner:辽宁隆达集团百星达铸造有限责任公司

As-cast high-strength high-elongation synthetic nodular cast iron and preparation method thereof

The invention relates to the field of as-cast high-strength high-elongation synthetic nodular cast iron. The invention relates to as-cast high-strength high-elongation synthetic nodular cast iron anda preparation method thereof. The nodular cast iron is characterized in that under the as-cast condition, the nodular cast iron meets performance requirements that the tensile strength Rm is larger than or equal to 700 MPa, and the percentage elongation A after fracture is larger than or equal to 10%; the matrix is a pearlite-ferrite mixed matrix; the content of pearlite is 55%-75%, a spheroidizing grade is 1-2, a graphite size grade is 6-7, the nodular cast iron is composed of elements, by mass, 3.5%-3.7% of C, 2.9-3.3% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.035% ofP, less than or equal to 0.02% of S, 0.5%-0.7% of Cu, 0.55%-0.75% of Ni, 0.030%-0.065% of Mg and the balance of Fe and trace elements. The method has the beneficial effects that scrap steel and raw material pure iron are adopted for recarburization, base iron is smelted in a medium-frequency induction furnace, then pretreatment, spheroidizing treatment and inoculation treatment are conducted, final pouring is conducted, and QT700-10 is achieved under the as-cast condition.

Owner:湖北三环铸造股份有限公司

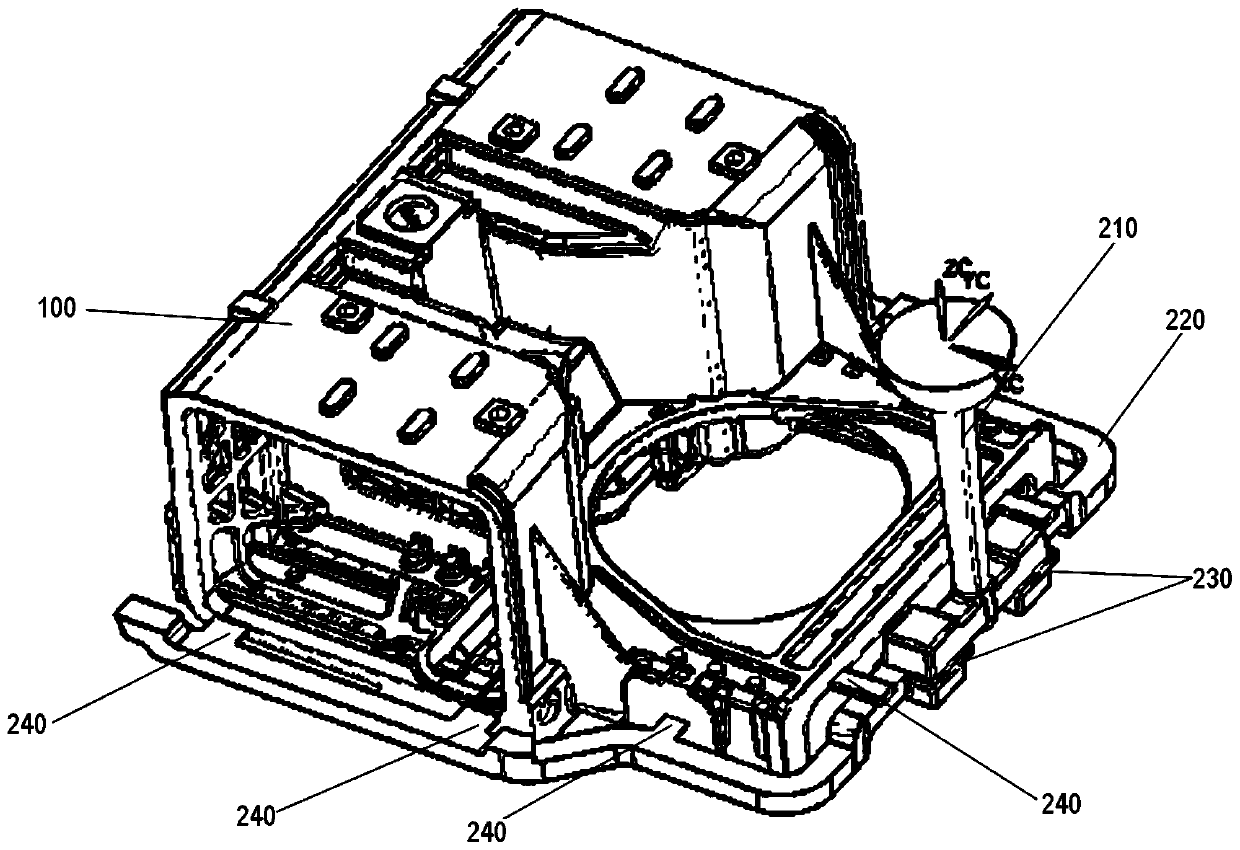

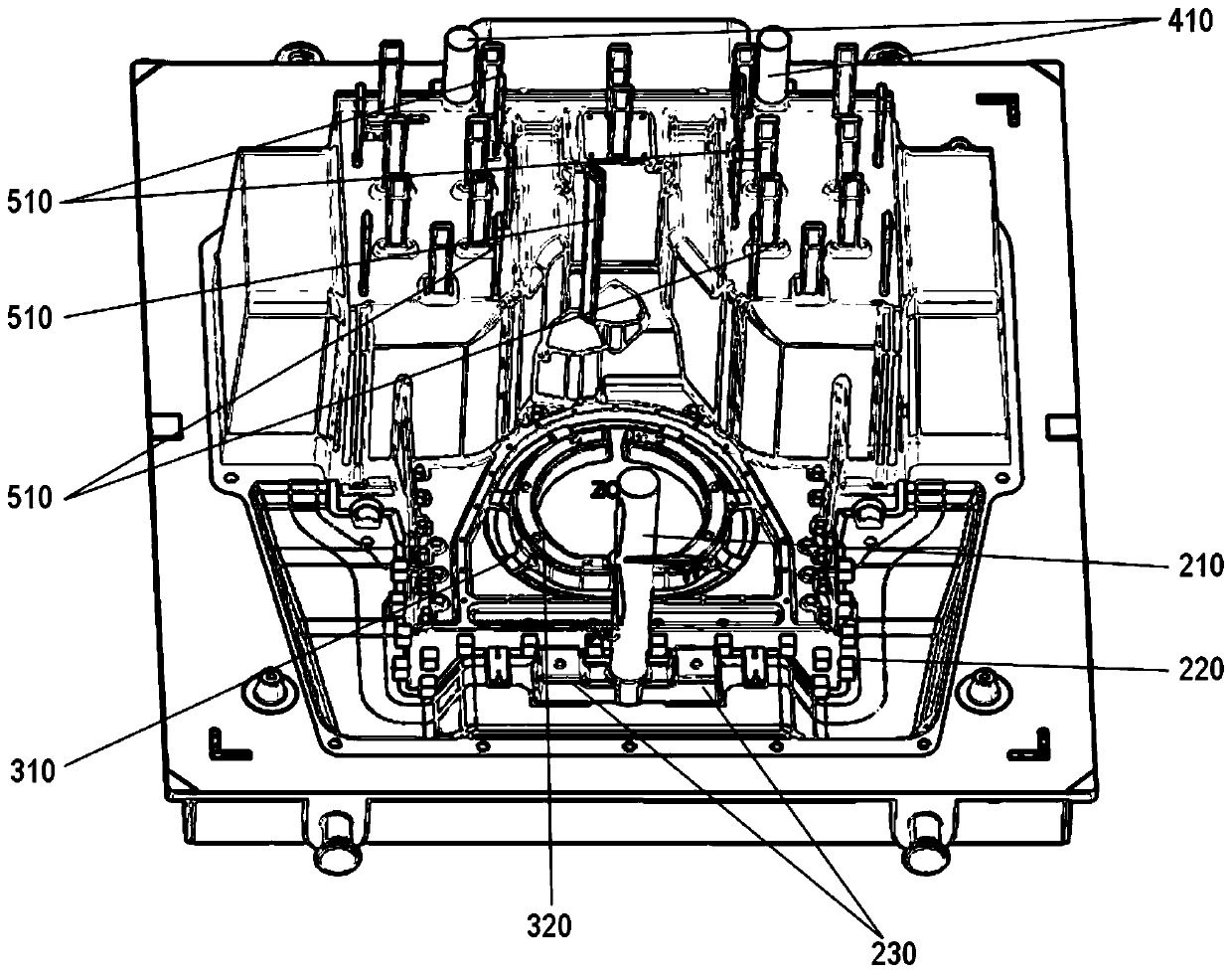

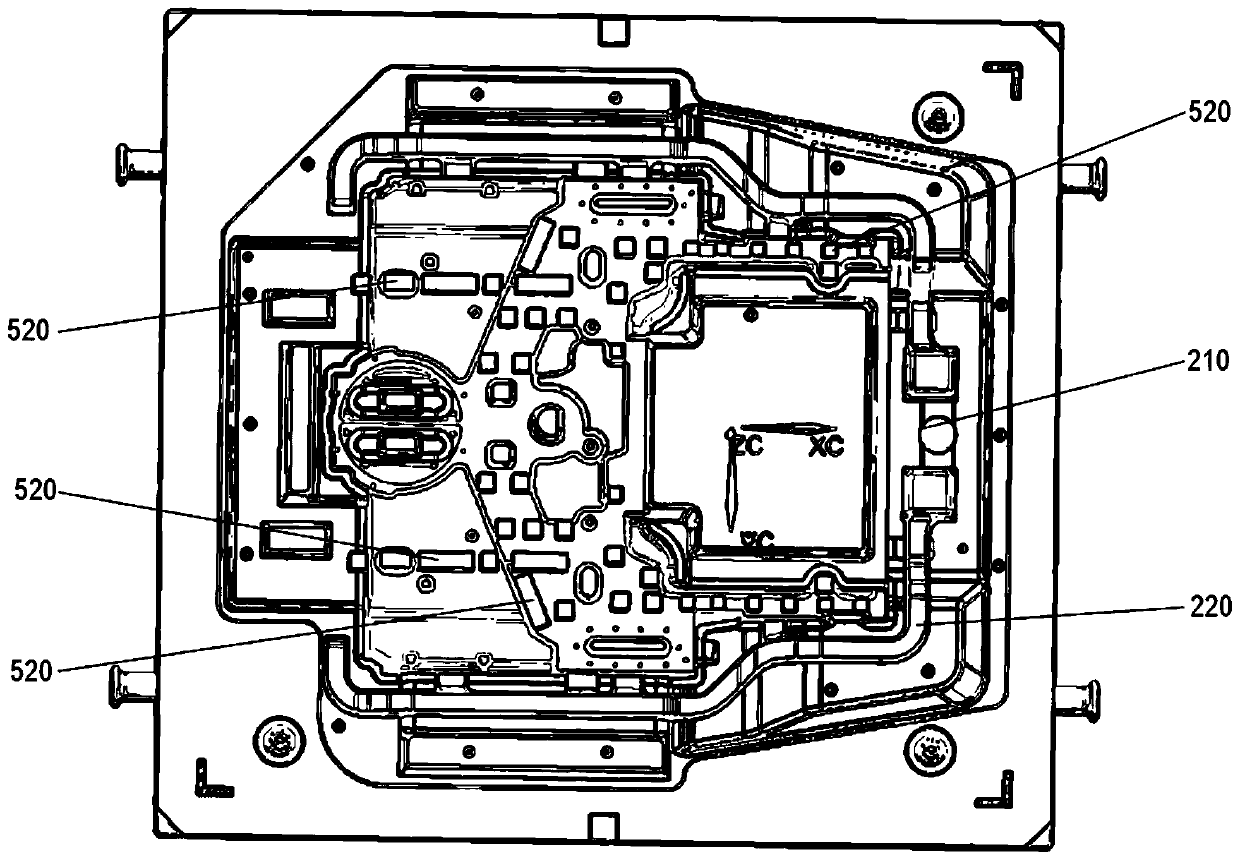

Casting method of high-powered engine box casting

PendingCN111451444AQuality improvementImprove yieldFoundry mouldsFoundry coresTemperature controlIndustrial engineering

The invention discloses a casting method of a high-powered engine box casting. The casting method comprises the steps of preparing moulding sand, performing modeling and core making to obtain a sand mould, preparing pouring iron liquid, taking pig iron, foundry returns and waste steel as raw materials to be fed into a smelting furnace to be smelted, carrying out in-package inoculation and spheroidization on the smelted iron liquid, carrying out stream inoculation before tapping, then carrying out tapping, pouring the iron liquid into the sand mould, carrying out stream inoculation, adopting acold iron riser process for feeding and temperature control, forming a casting after pouring is finished, and carrying out treatment on the formed casting. The obtained casting is good in quality, andquality problems of core clamping, shrinkage, cracks and the like are not prone to happening.

Owner:宜宾普什联动科技有限公司 +1

Pure magnesium spheroidizing technology of lost foam ductile cast iron

ActiveCN106636870APrevent defects such as cold insulation wrinkle skinAvoid stickingSulfurFerrosilicon

The invention discloses a pure magnesium spheroidizing technology of lost foam ductile cast iron. The pure magnesium spheroidizing technology comprises the steps that a spheroidizing agent is placed into a lip-pour ladle reaction chamber, a cover of the reaction chamber is closed, and a conventional nucleating agent, ferrosilicon, is added into a lip-pour ladle; after molten iron in a heat-insulated furnace is subjected to deslagging, molten iron is added into the lip-pour ladle, and the temperature of molten iron is controlled to be 1520 DEG C to 1560 DEG C; then, the lip-pour ladle is overturned, and molten iron and the spheroidizing agent react for 60 s to 70 s; and pouring is carried out while stream inoculation is achieved, wherein the addition amount of the stream nucleating agent is 0.08% to 0.15% of the weight of molten iron; the spheroidizing agent is a mixture of pure magnesium ingots and calcium chloride; and the weight ratio of molten iron to the pure magnesium ingots to calcium chloride to ferrosilicon is 1000 to (1.4 to 2.0) to (0.2 to 0.5) to (4 to 8). According to the pure magnesium spheroidizing technology of lost foam ductile cast iron, the spheroidizing problem of high-sulfur high-silicon molten iron can be effectively solved, the spheroidizing grade is high, a required matrix structure can be obtained, the problems that the spheroidizing effect is poor, the quality of castings is not stable, and the rejection rate is high are solved, the technology does not require lip-pour ladle nucleating, the procedures can be decreased, and the labor intensity is reduced.

Owner:桃江新兴管件有限责任公司

As-cast high-strength and ductility synthetic nodular cast iron QT800-5 and preparation method thereof

The invention provides a kind of as-cast high-strength and ductility synthetic nodular cast iron QT800-5 and a preparation method thereof. The as-cast high-strength and ductility synthetic nodular cast iron QT800-5 comprises, by mass, 3.70-3.95% of C, 3.3-3.5% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.035% of P, less than or equal to 0.02% of S, 0.5-0.7% of Cu, 0.55-0.75% ofNi, 0.035-0.65% of Mg residues, and the balance Fe and microelements. The preparation method of the as-cast high-strength and ductility synthetic nodular cast iron QT800-5 comprises the following steps of mixing and smelting; alloying; pretreatment and spheroidizing; and inoculation treatment and pouring. The preparation method comprises the steps of smelting base iron melt in a medium-frequencyinduction furnace through steel scrap recarburization; adding silicon iron and cathode copper to conduct alloying; bringing in alloying elements nickel through a spheroidizing agent; conducting pretreatment, spheroidizing and inoculation treatment; and finally conducting pouring. The as-cast high-strength and ductility synthetic nodular cast iron QT800-5 prepared through the method has high strength, good ductility and toughness and excellent comprehensive performance.

Owner:WUHAN UNIV OF TECH

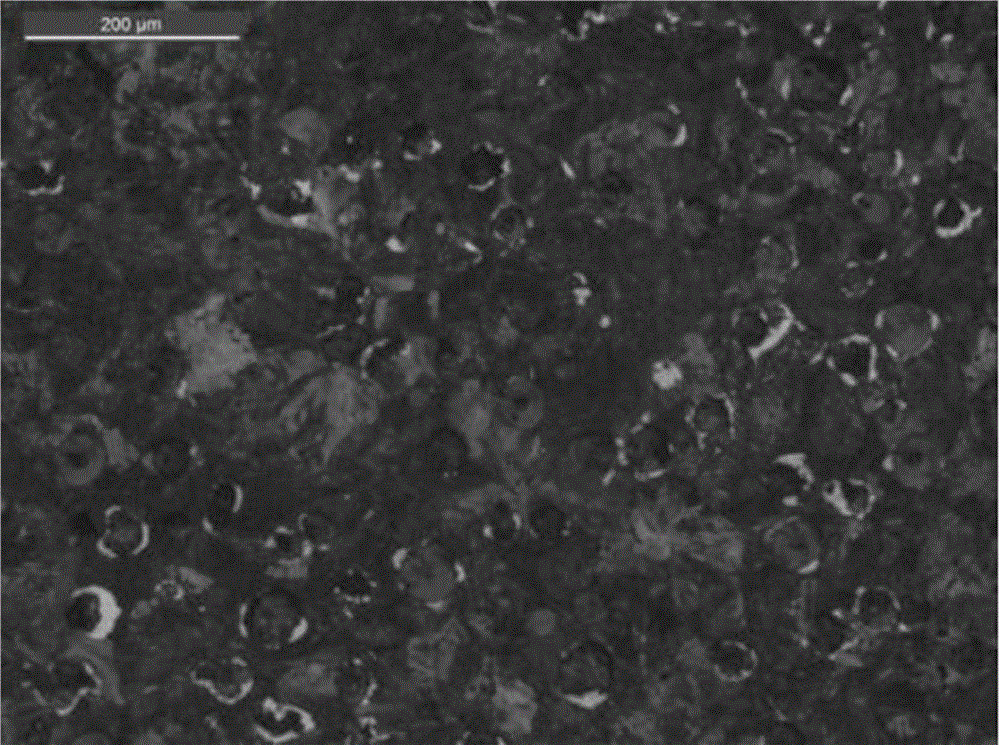

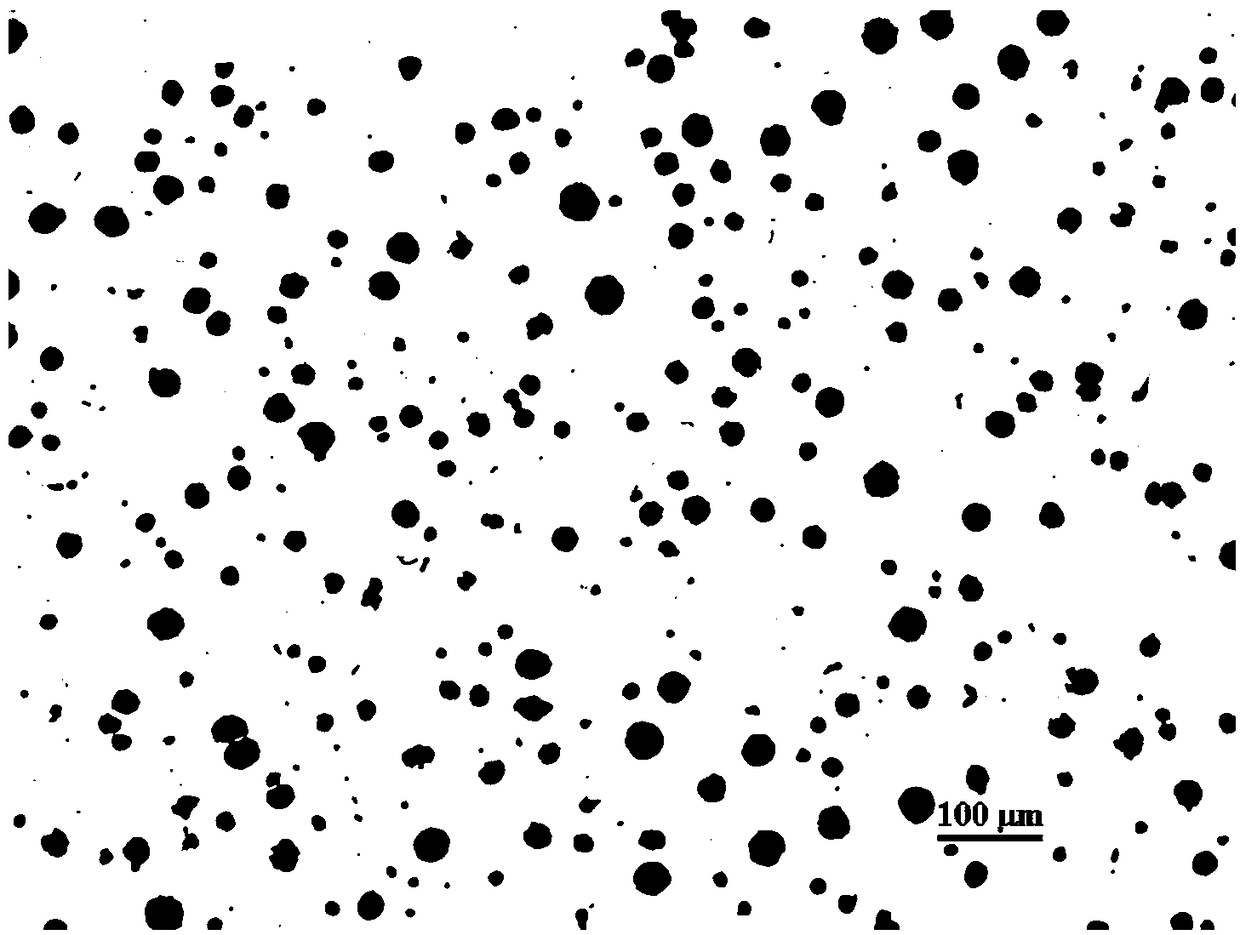

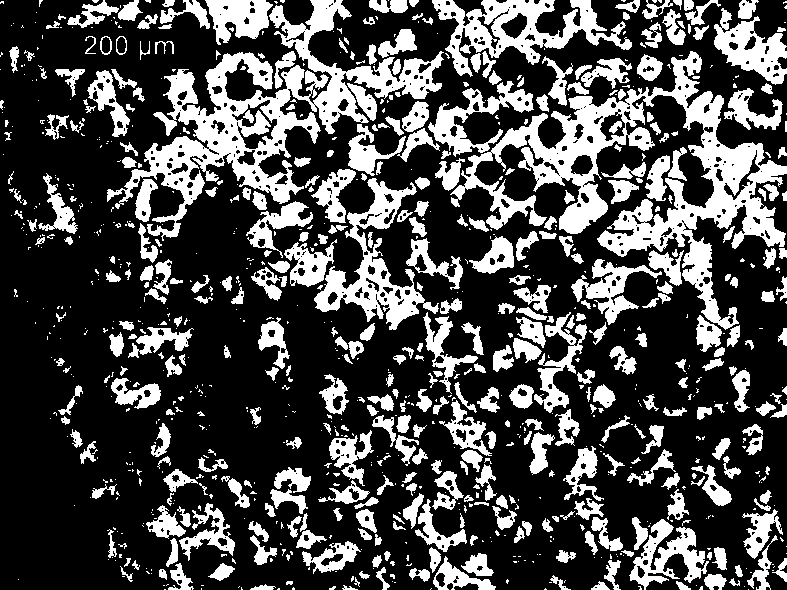

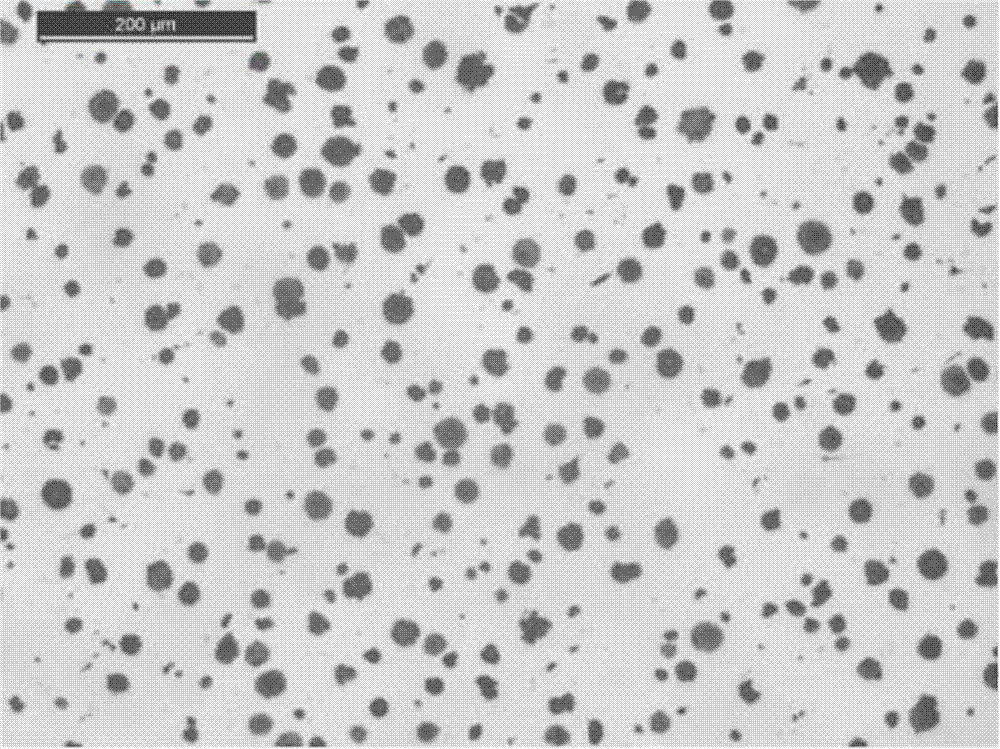

Method for controlling microporosity of large-section ductile iron casting

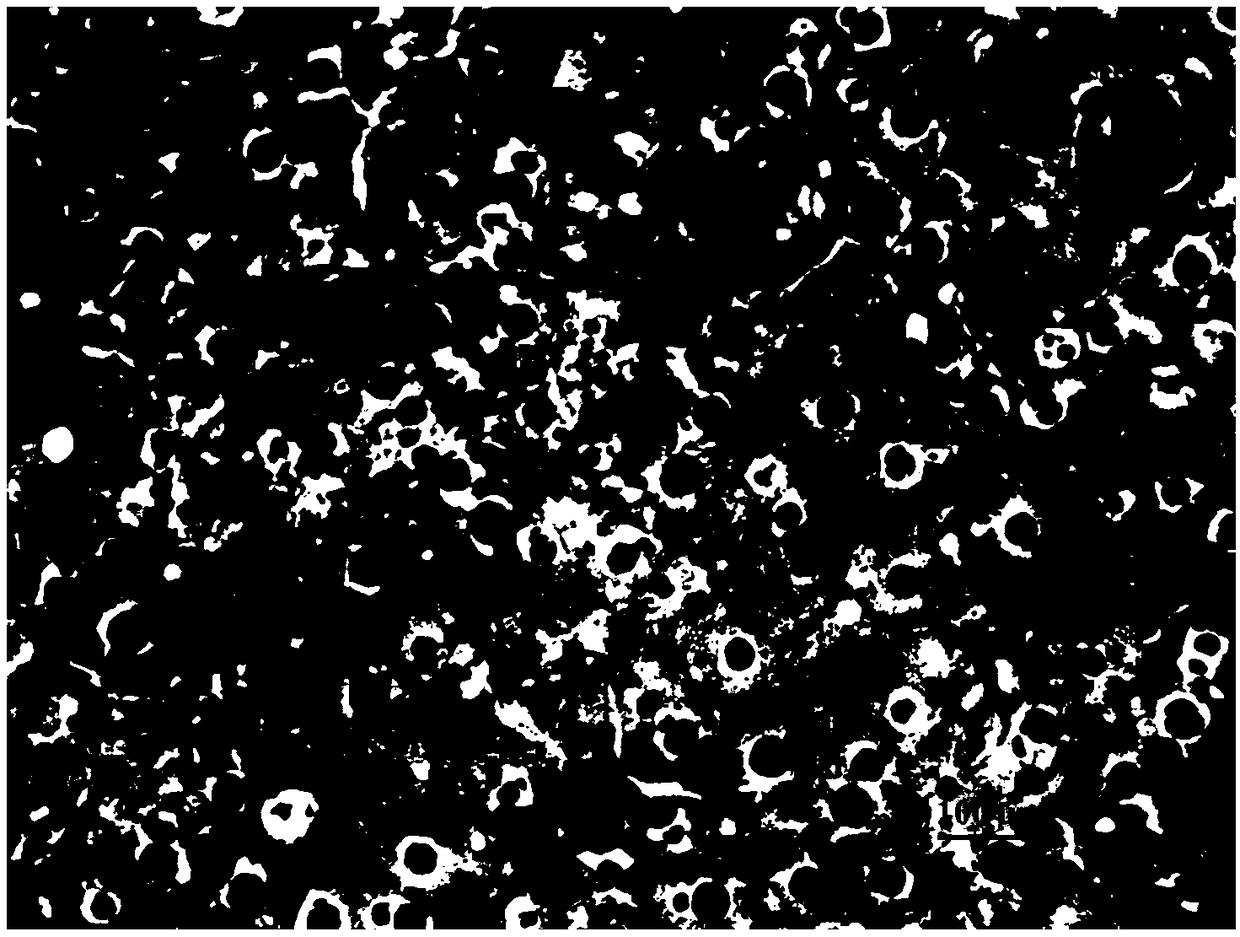

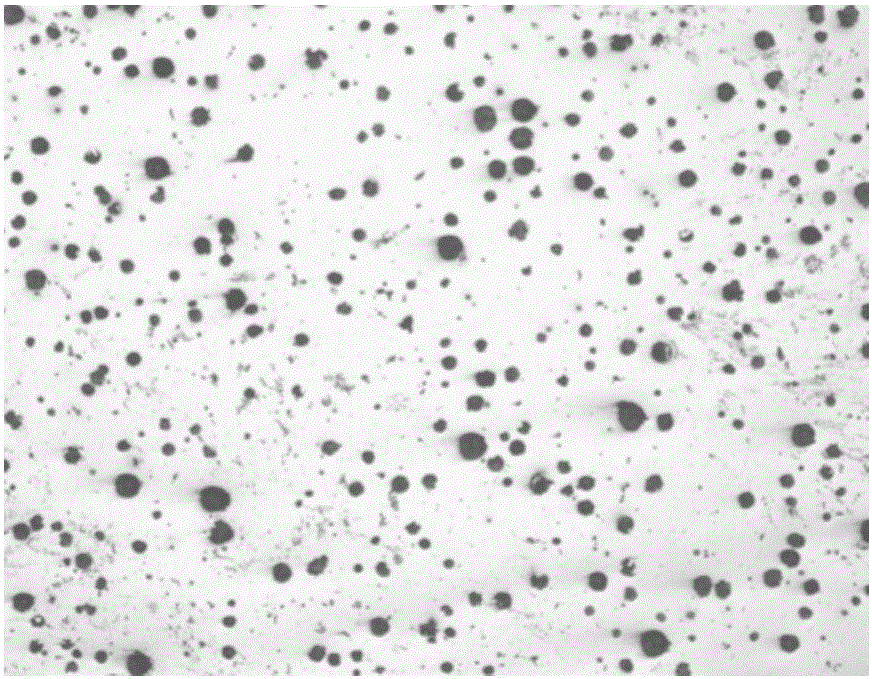

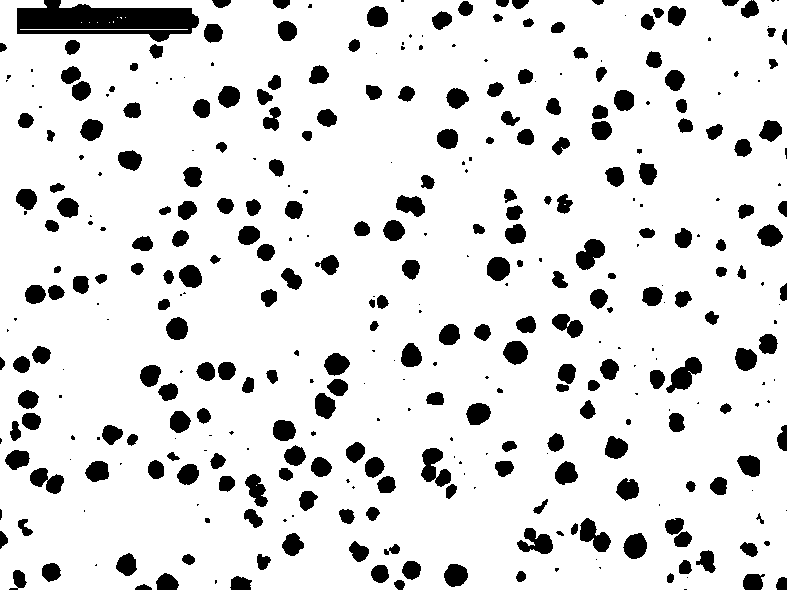

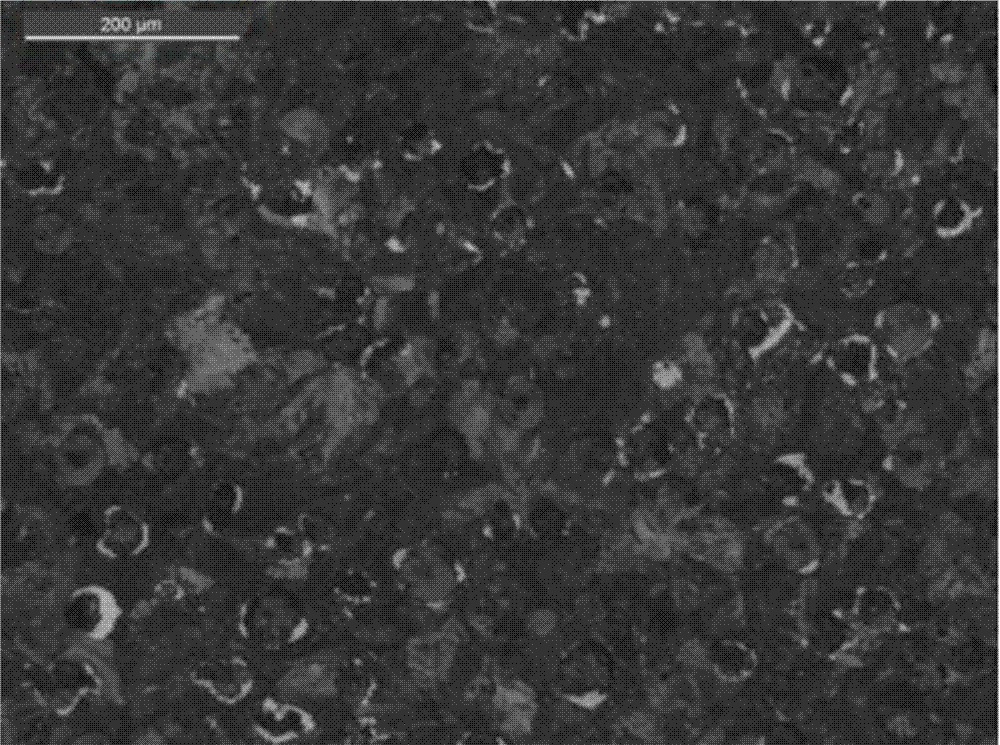

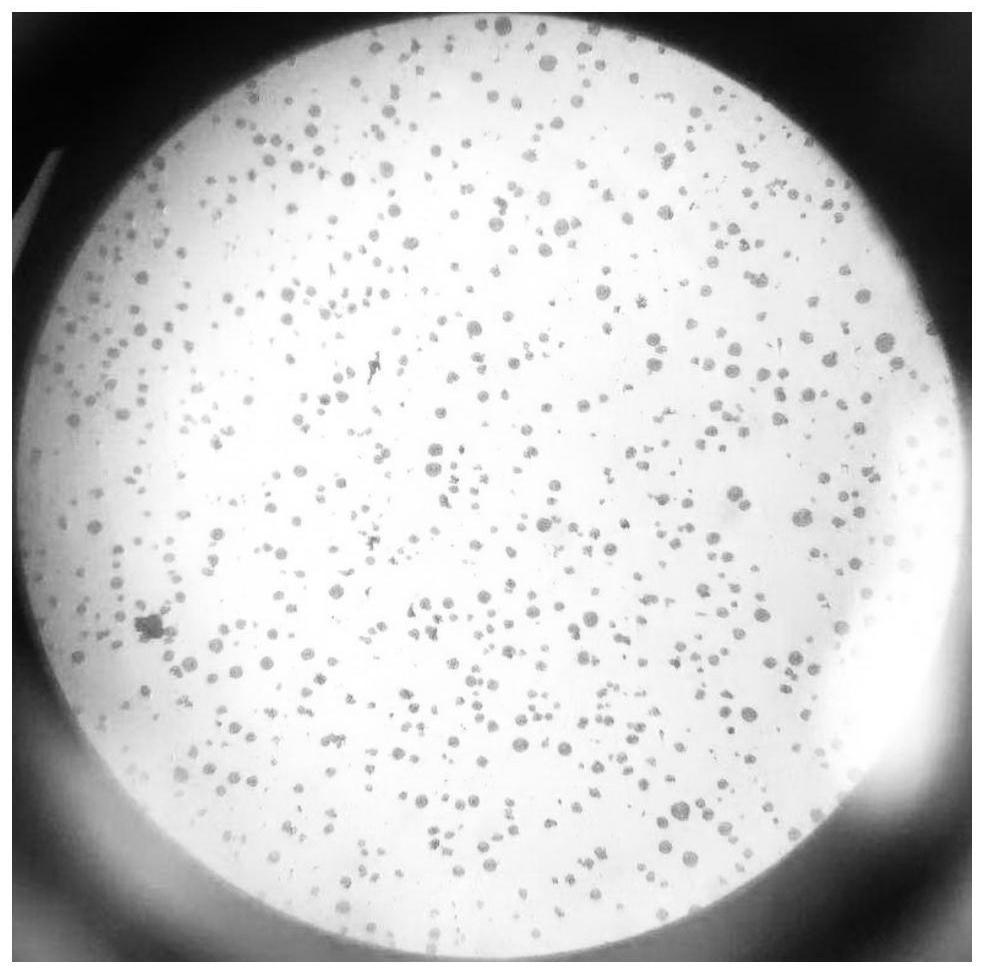

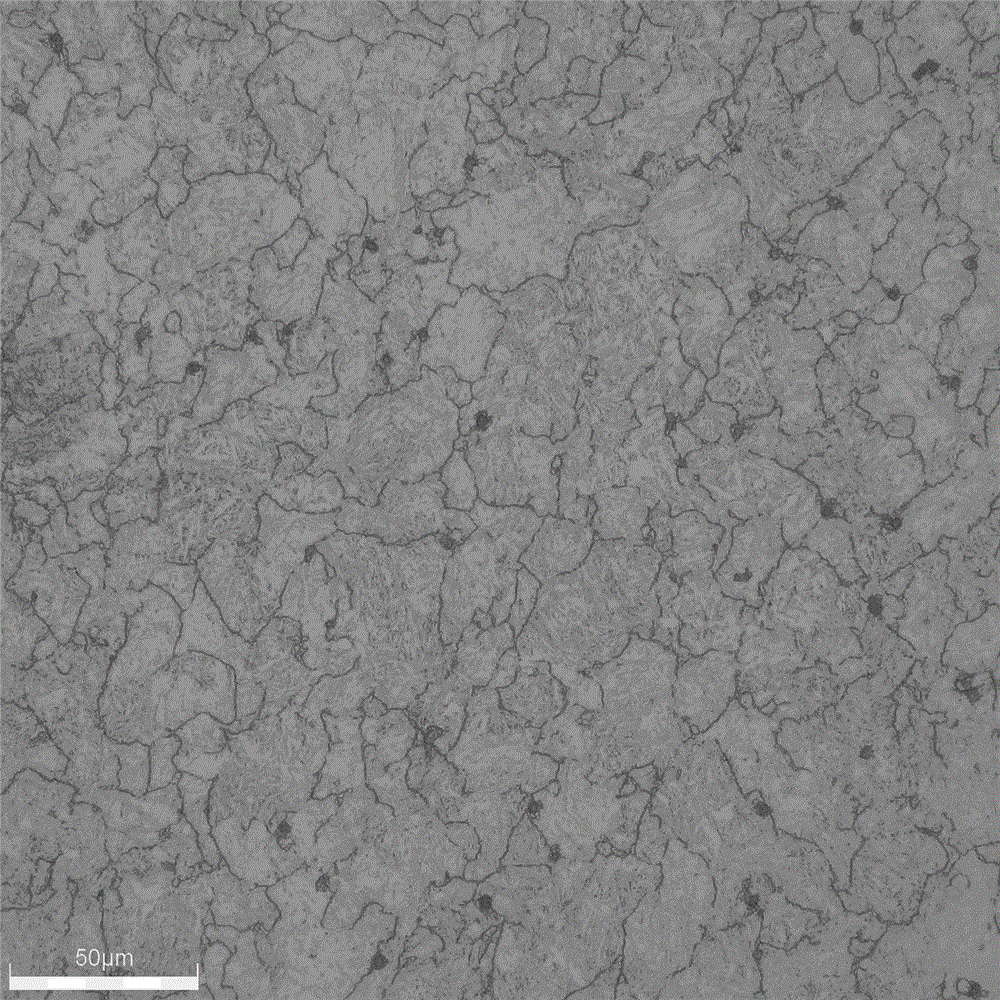

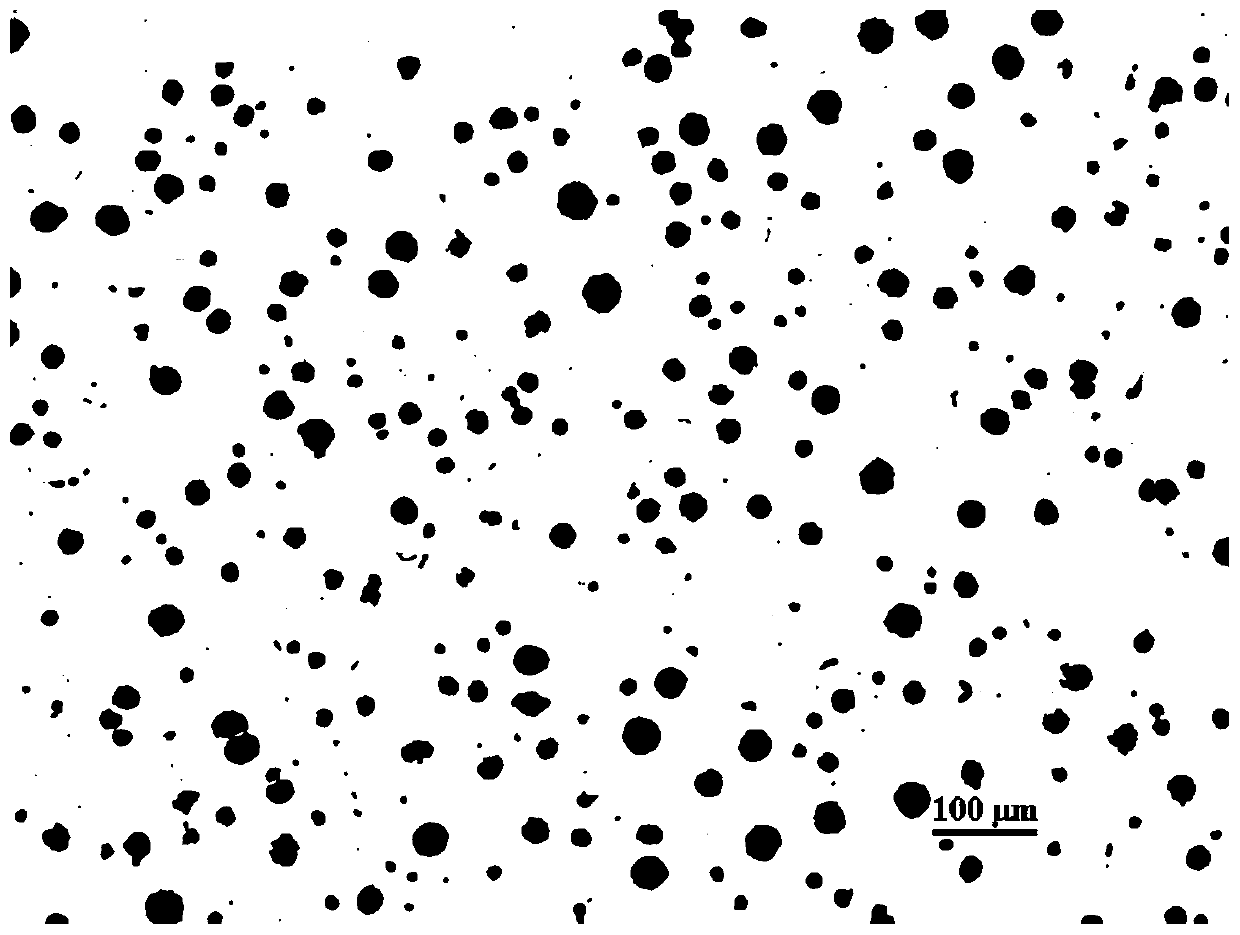

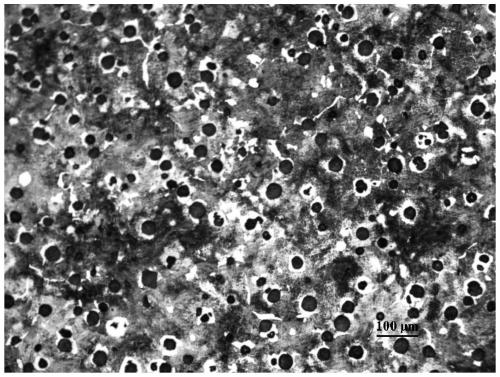

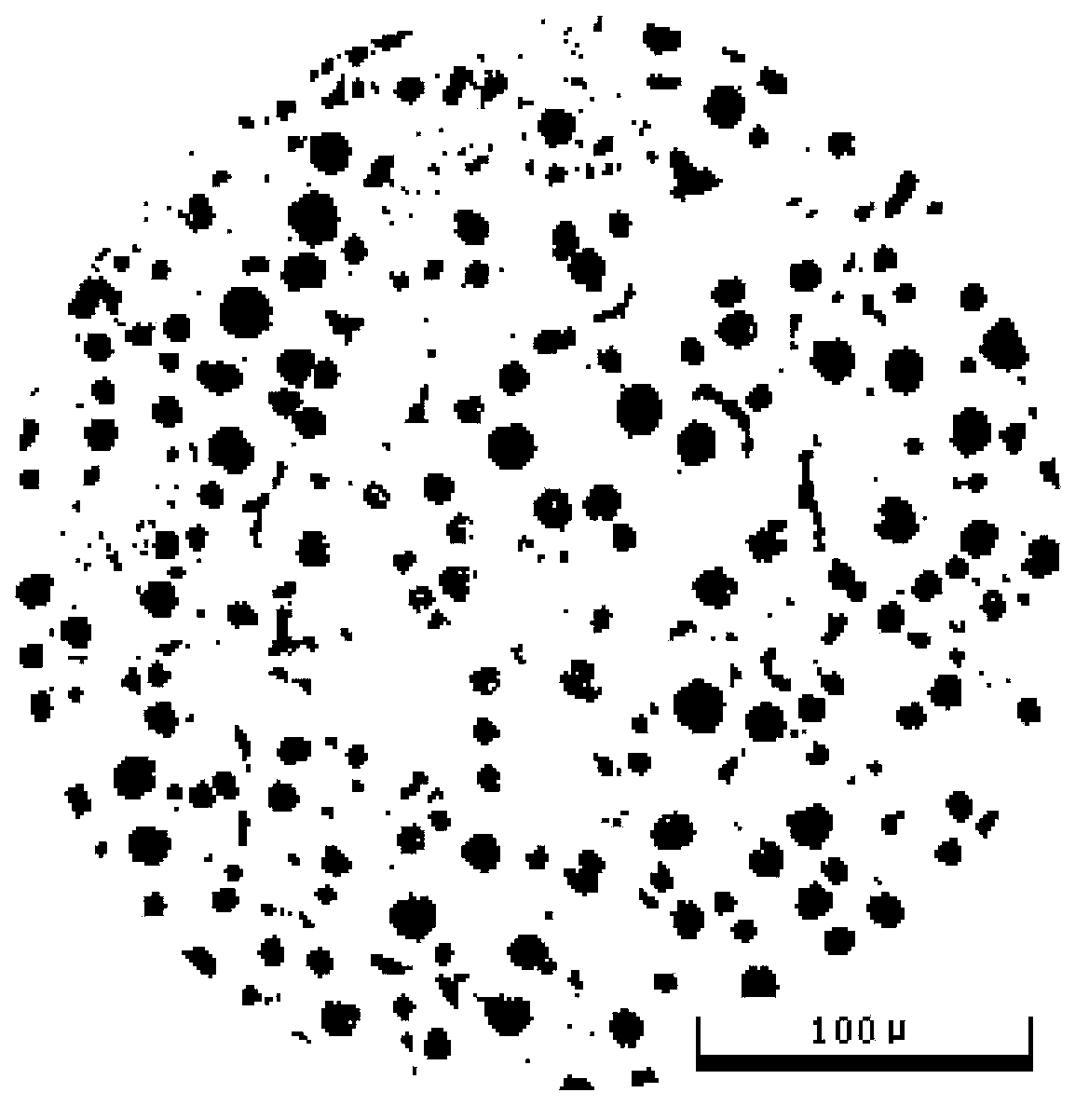

InactiveCN106222528AImprove nodularityIncrease the number ofProcess efficiency improvementDuctile ironRejection rate

The invention relates to a microalloying element and an instantaneous metal-stream inoculant for controlling the microporosity of a large-section ductile iron casting. The microalloying element and the instantaneous metal-stream inoculant are characterized in that the microalloying element is a combination of Cu and Sn, and SiRE is adopted as the instantaneous metal-stream inoculant and comprises, by weight percentage, 65-80% of Si, 1.0-2.5% of RE, 0.65-1.35% of Ca, 4-6% of Al and the balance Fe. A method for controlling the microporosity of the large-section ductile iron casting has the beneficial effects that through the synergistic effect of the microalloying element and the instantaneous metal-stream inoculant, the spheroidization grade of molten iron is increased, the number of graphite in the later period of the solidification of the molten iron is increased, the graphite is refined, and the rejection rate generated due to the fact the quality and performance of the large-section ductile iron casting do not meet the requirements due to the microporosity is reduced.

Owner:HUNAN UNIV

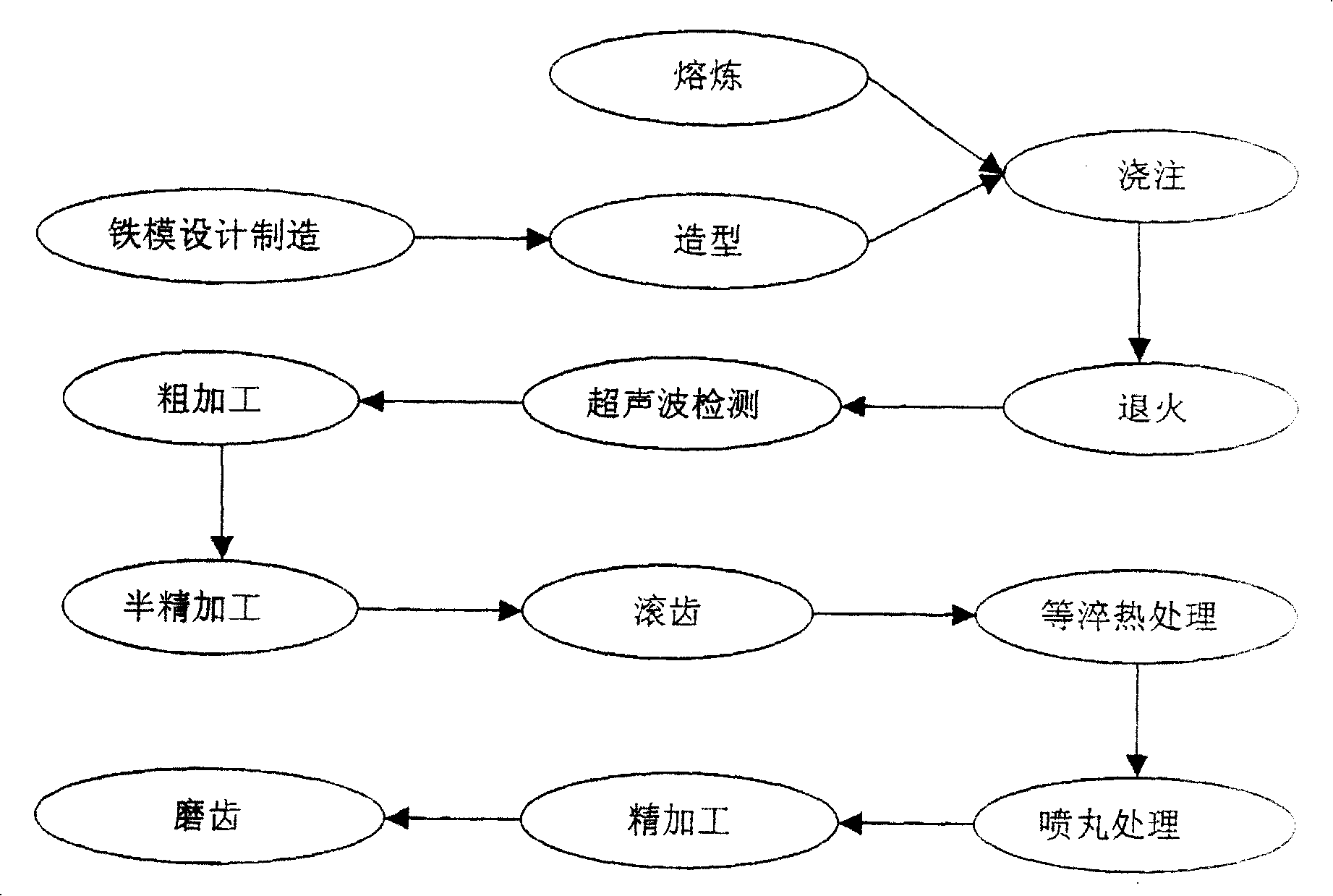

Art for manufacturing Austempered Ductile iron gear for diesel engine

A technology for manufacturing the gear with modular 'austenite plus residual bainite' iron and used for the diesel engine includes such steps as making iron mould, making sand mould, smelting in electric furnace, nodulizing, pouring, annealing, ultrasonic inspection, primary machining, semi-fine machining, hobbing gear, iso-quenching, blasting pills, fine machining, grinding teeth, marking, washing, and applying antirust oil. It has high mechanical performance and strength.

Owner:FAW GROUP

Preparation method of high-speed steel roller for headless strip steel rolling finish rolling rear section

The invention discloses a preparation method of a high-speed steel roller for a headless strip steel rolling finish rolling rear section. The preparation method comprises the following steps of performing three-layer centrifugal composite casting, correspondingly casting an outer layer, a middle layer and a core part through using high-strength nodular cast iron, controlling the content of castingmolten steel of the middle layer and the core part to comprise the following components of 1.8 wt%-2.8 wt% of C, 0.6 wt%-0.9 wt% of Si, 0.5 wt%-0.8 wt% of Mn, 0.4 wt%-0.8 wt% of Ni, less than or equal to 0.03 wt% of P, less than or equal to 0.03 wt% of S, 17 wt%-22 wt% of Cr+Mo+Nb+V+W and the balance Fe and inevitable impurities. According to the method, graphite obtained on the outer layer reduces the friction coefficient, a certain number of hard carbides enhance the wear resistance of the roller, and therefore such structure can effectively reduce damage of tail frame drifting to the roller; and meanwhile, the middle layer and the core part are subjected to methods of wire feeding spheroidizing and wire feeding inoculation (two wires for each method, so that four wires are fed at the same time), in this way, the nodulizing grade and tensile strength of the nodular cast iron are improved, and accident resistance of the roller can be greatly enhanced.

Owner:JIANGSU GONGCHANG ROLL

Degradated-spheroidization-resisting composite inoculant and preparation technology of composite inoculant

The invention discloses a degradated-spheroidization-resisting composite inoculant. The composite inoculant comprises the following components of, by mass percent, 55-65% of Si, 1.0-2.0% of Ca, 4.0-6.0% of Ba, 0.5-2.0% of Mg, 0.1-1.5% of RE, 1.5max% of Al and the balance Fe. According to the degradated-spheroidization-resisting composite inoculant, the nodularization effect can be improved, graphite nodules are refined, the quantity of the graphite nodules is increased, the roundness of the graphite nodules is improved, the graphite nodules are distributed uniformly, the degradated spheroidization is lowered, the effective inoculation time is prolonged, and the mechanical properties of nodular iron castings are further improved, the production cost is lowered, and the quality of nodular cast iron is improved.

Owner:南京浦江合金材料股份有限公司

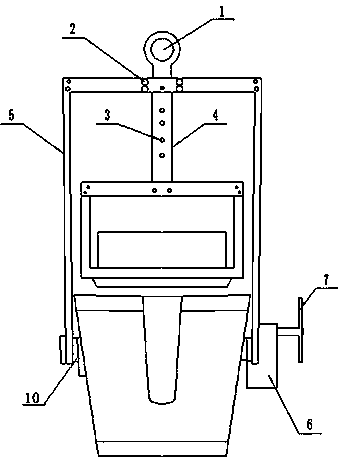

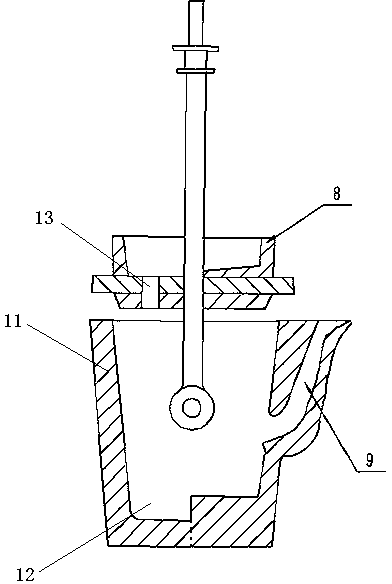

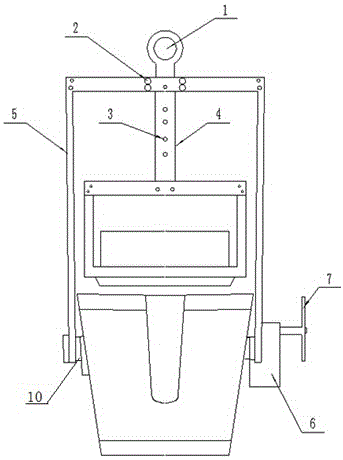

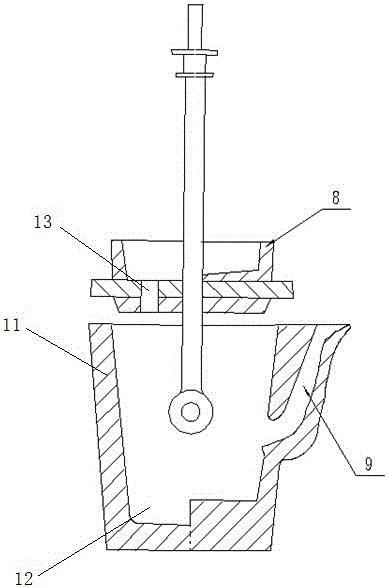

Integrated convenient-to-hang environment-friendly high-performance liquid alloy half-pressure container and using method

InactiveCN104259449AReduce pollutionAchieve environmental protection and green effectMelt-holding vesselsSlagEngineering

The invention discloses an integrated convenient-to-hang environment-friendly high-performance liquid alloy half-pressure container and a using method. The container comprises a container body capable of turning over, a receiving trough matched with the container body is arranged at the upper end of the container body, a cantilever is connected to the top end of the receiving trough and mounted on a frame which is connected with two side faces of the container body, an iron filling hole communicated with the inside of the container body is formed in the receiving trough, and a slag avoiding mouth communicated with the inside of the container body is connected to the side face of the container body. The container and the using method have the advantages that environmental protection and greenness are realized, and local environmental pollution is reduced by more than 90%; magnesium absorption rate and nodulizing grade are high; consumption of nodulizing agents is less, and heat insulation effect is good; nodulizing effect is stable; iron liquid is basically lossless; physical properties of castings are improved; a container cover is omitted, so that labor intensity of workers is reduced.

Owner:青岛源邦机械制造有限公司

Low-cost seawater-corrosion-resistant nodular cast iron and preparation method thereof

The invention relates to a low-cost seawater-corrosion-resistant nodular cast iron and a preparation method thereof, and belongs to the technical field of casting alloys. The nodular cast iron comprises the following chemical components: 3.5-3.9% of C, 2.3-2.9% of Si, 0.5-2.0% of Zn, less than 0.3% of Mn, less than 0.025% of S, less than 0.06% of P, 0.03-0.05% of Mg residues, 0.02-0.04%of Re residues and the balance of Fe. Low-price industrial waste steel is adopted as the main raw material for producing the nodular cast iron, zinc-containing core-spun yarn is added before discharging, precious metal such as nickel in the corrosion-resistant nodular cast iron is replaced with zinc, the production cost is low, and energy conservation and environmental protection are achieved. The preparation method comprises the following steps: (1) adding raw materials into a medium-frequency electric furnace to be smelted into molten iron, adding the zinc-containing core-spun yarn before discharging, and then performing discharging; (2) carrying out purification treatment during spheroidizing and inoculation treatment of molten iron; and (3) performing pouring to obtain the nodular cast iron. The spheroidization level of the prepared nodular cast iron is 1-2 level, the spheroidization rate is larger than or equal to 90%, the ferrite content is larger than or equal to 90%, the tensile strength is larger than or equal to 450 MPa, the elongation is larger than or equal to 10%, and the nodular cast iron can normally work in the marine environment and has remarkable beneficial effects.

Owner:CHANGSHA UNIVERSITY

A kind of medium silicon molybdenum niobium ductile iron material and preparation method thereof

The invention discloses a medium silicon molybdenum niobium spheroidal graphite cast iron material and a preparation method thereof. The medium silicon molybdenum niobium spheroidal graphite cast iron material is prepared from the following chemical components in percentage by mass: 2.8-3.2% of C, 4.2-4.5% of Si, less than or equal to 0.4% of Mn, less than or equal to 0.04% of P, less than or equal to 0.015% of S, 0.8-0.9% of Mo, 0.6-0.9% of Ni, 0.4-0.7% of Nb, 0.03-0.06% of Mg, 0.15-0.25% of V and the balance of Fe and inevitable other elements. Since C04 high-purity pig iron and waste steel are taken as raw materials, a medium-frequency induction furnace is adopted for smelting, and a carburant, silicon carbide, ferrocolumbium, nickel plates, ferrosilicon and ferrovanadium are added in different time phases of smelting, raw iron chemical components and smelting temperature expected by design can be achieved, and the product disclosed by the invention can be prepared through nodulization and two times of inoculation. By adopting the edium silicon molybdenum niobium spheroidal graphite cast iron material disclosed by the invention, an exhaust manifold of an engine can work under a working condition of about 800 DEG C, the high-temperature use property of the exhaust manifold can be improved, and the service life of the exhaust manifold can be prolonged.

Owner:西峡县内燃机进排气管有限责任公司

S195 ductile iron camshaft metal mold casting technology

The invention discloses an S195 ductile iron camshaft metal mold casting technology. The inclination of a metal mold cavity is between 40 degrees and 60 degrees; and a metal mold is made of HT20-40. The S195 ductile iron camshaft metal mold casting technology comprises the following steps: coating a paint by adopting a spray finishing method, heating a metal mold to a proper temperature before spraying and spraying, warming and preheating the metal mold by taking a drying mold with the coating thickness of about 0.4-0.6mm, pouring preferably at the preheated temperature of 200-250DEG C (heating pouring temperature to 1320-1380DEG C by adopting a drying oven; pouring time: 6-8s) and then performing air cooling, cooling a casting at 800-850DEG C and performing casting discharge and immediately embedding into dry sand. The S195 ductile iron camshaft metallic casting technology has the advantages that the spheroidization rate is improved, textures are fined, and comprehensive mechanical property can be improved; in addition, due to the coagulating property of ductile iron, not only can the microporosity of the casting be reduced by the metal mold, but also the casting is accurate in dimensions, energy can be saved, and no environment pollution exists.

Owner:QINGDAO HEDELONG MACHINERY

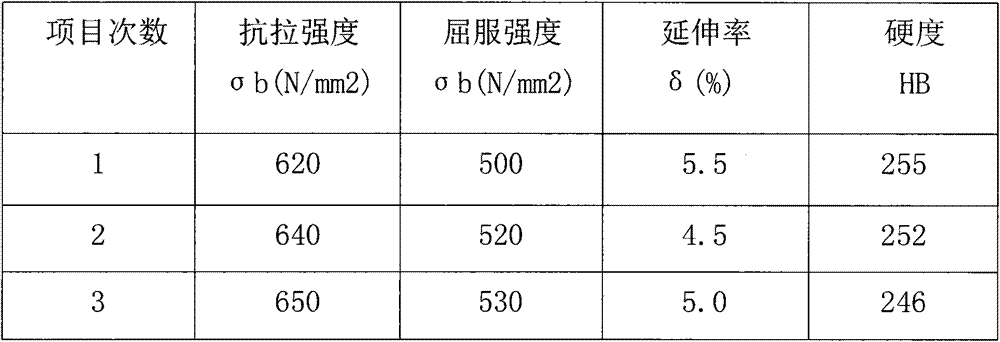

Pipe nodular cast iron manufacturing method

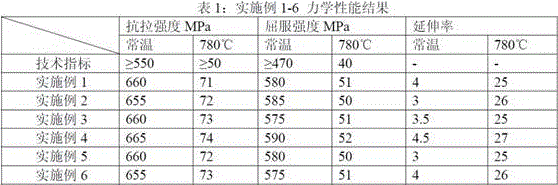

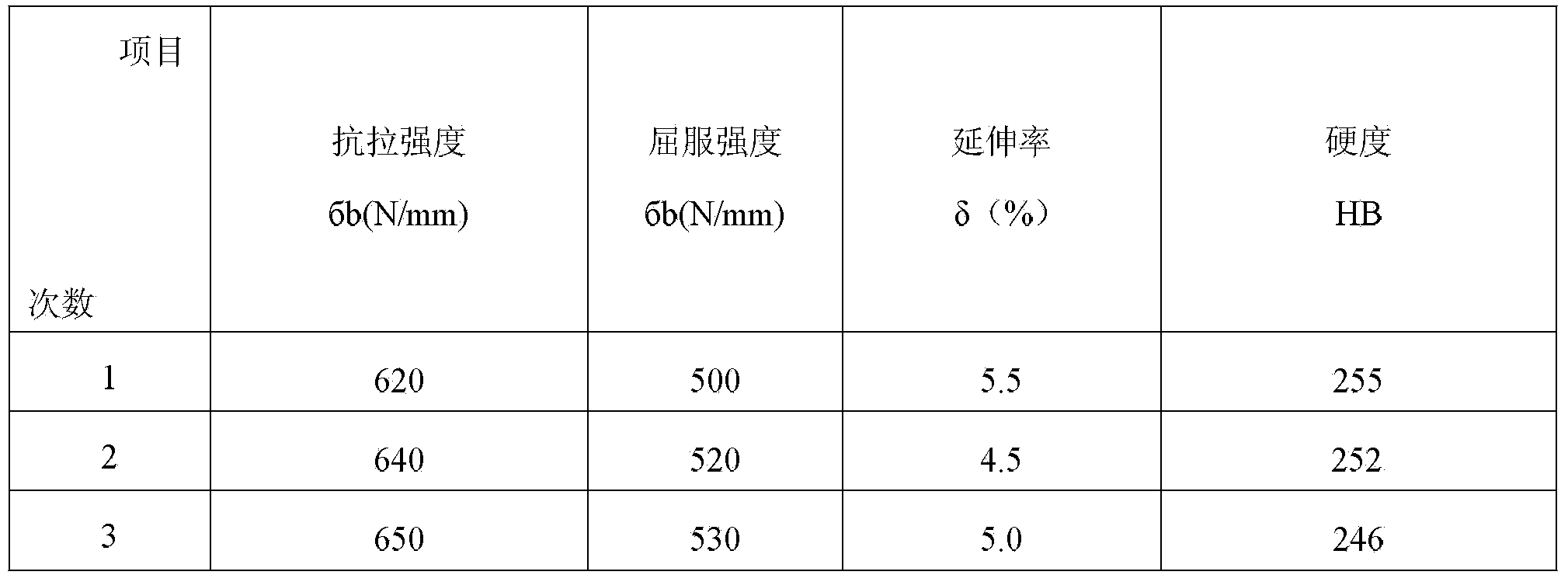

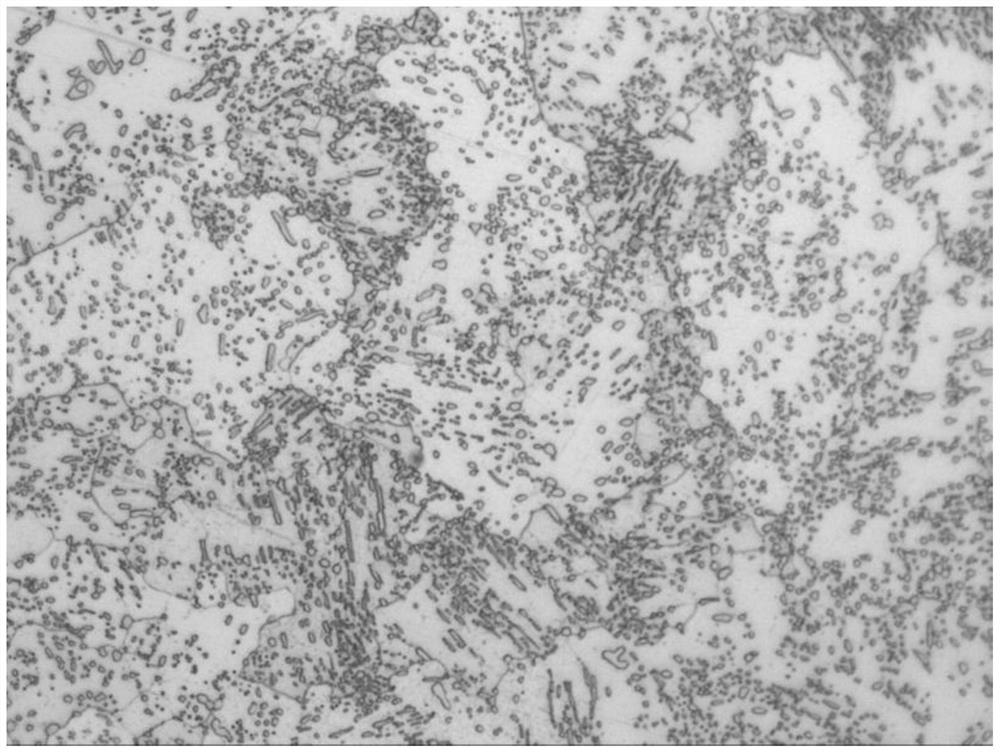

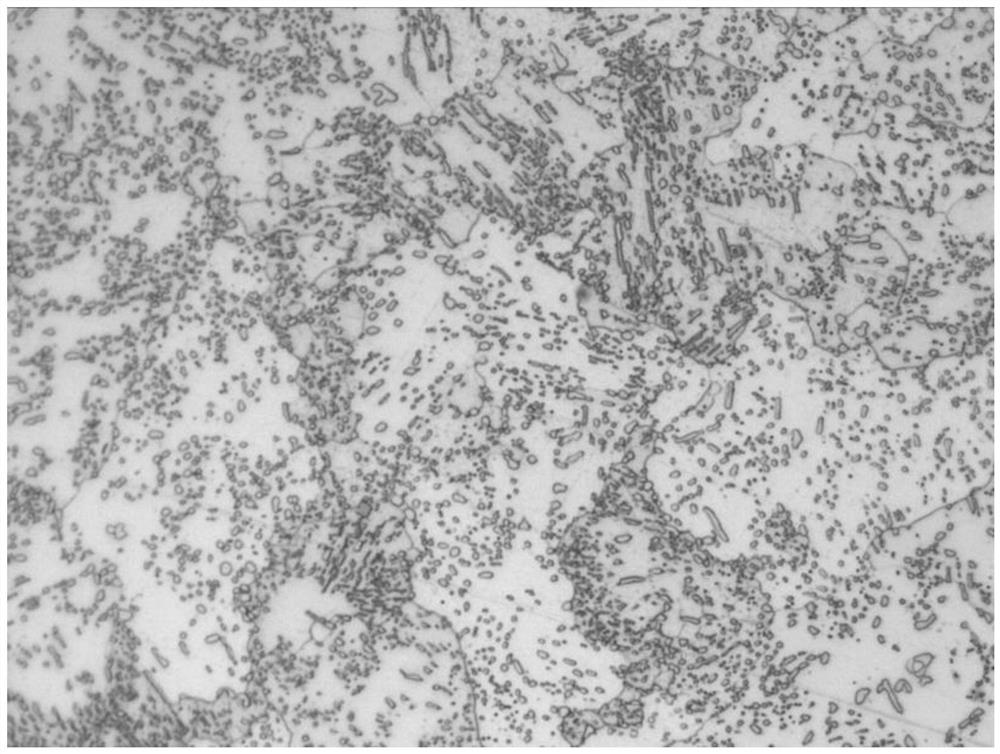

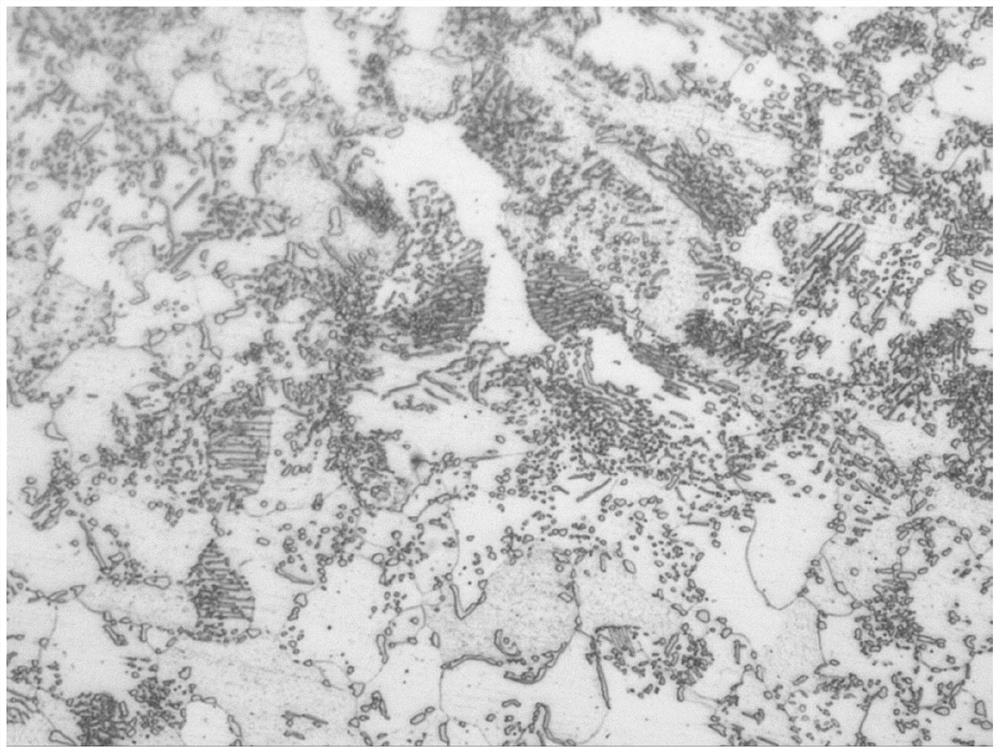

InactiveCN104775066AImprove antioxidant capacityImprove high temperature mechanical propertiesProcess efficiency improvementHeat resistanceRoom temperature

The invention belongs to the technical field of casting and relates to a pipe nodular cast iron manufacturing method. The method comprises iron liquid melting preparation, nodulizing and inoculation treatment. The pipe nodular cast iron greatly improves high temperature creep resistance and creep fracture resistance of a casting, has cyclic failure frequency of 410-440 times at a thermal cyclic temperature of 500-600 DEG C, has high temperature tensile strength of 130-140N / mm<2> at a temperature of 600 DEG C, and has tensile strength of 620-650N / mm<2>, yield strength of 500-530N / mm<2>, elongation percentage of 4.5-5.5%, hardness of 245-255HB and a yield ratio of 0.8-0.9 at a room temperature. The pipe nodular cast iron has a high yield ratio and good heat resistance, reduces casting deformation probability, prolongs a service life and satisfies requirements on high temperature mechanical properties and antioxidation performances of nodular cast iron.

Owner:天津中联金属制品有限公司

A Method of Controlling the Micro-shrinkage of Ductile Iron Parts with Large Section

InactiveCN106222528BImprove nodularityIncrease the number ofProcess efficiency improvementDuctile ironRejection rate

The invention relates to a microalloying element and an instantaneous metal-stream inoculant for controlling the microporosity of a large-section ductile iron casting. The microalloying element and the instantaneous metal-stream inoculant are characterized in that the microalloying element is a combination of Cu and Sn, and SiRE is adopted as the instantaneous metal-stream inoculant and comprises, by weight percentage, 65-80% of Si, 1.0-2.5% of RE, 0.65-1.35% of Ca, 4-6% of Al and the balance Fe. A method for controlling the microporosity of the large-section ductile iron casting has the beneficial effects that through the synergistic effect of the microalloying element and the instantaneous metal-stream inoculant, the spheroidization grade of molten iron is increased, the number of graphite in the later period of the solidification of the molten iron is increased, the graphite is refined, and the rejection rate generated due to the fact the quality and performance of the large-section ductile iron casting do not meet the requirements due to the microporosity is reduced.

Owner:HUNAN UNIV

A kind of high-strength ductile iron Qt900-6 and preparation method thereof

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

One-piece convenient hanging environment-friendly high-performance liquid alloy semi-pressure vessel and using method

InactiveCN104259449BReduce pollutionAchieve environmental protection and green effectMelt-holding vesselsSlagEngineering

The invention discloses an integrated convenient-to-hang environment-friendly high-performance liquid alloy half-pressure container and a using method. The container comprises a container body capable of turning over, a receiving trough matched with the container body is arranged at the upper end of the container body, a cantilever is connected to the top end of the receiving trough and mounted on a frame which is connected with two side faces of the container body, an iron filling hole communicated with the inside of the container body is formed in the receiving trough, and a slag avoiding mouth communicated with the inside of the container body is connected to the side face of the container body. The container and the using method have the advantages that environmental protection and greenness are realized, and local environmental pollution is reduced by more than 90%; magnesium absorption rate and nodulizing grade are high; consumption of nodulizing agents is less, and heat insulation effect is good; nodulizing effect is stable; iron liquid is basically lossless; physical properties of castings are improved; a container cover is omitted, so that labor intensity of workers is reduced.

Owner:青岛源邦机械制造有限公司

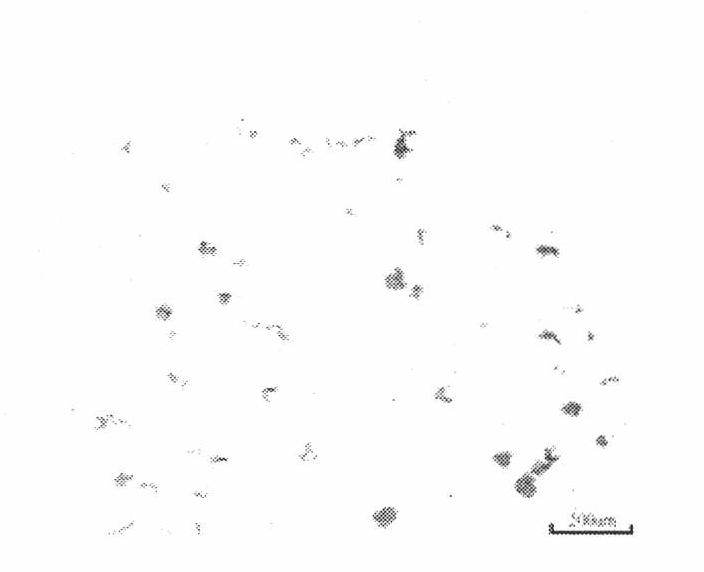

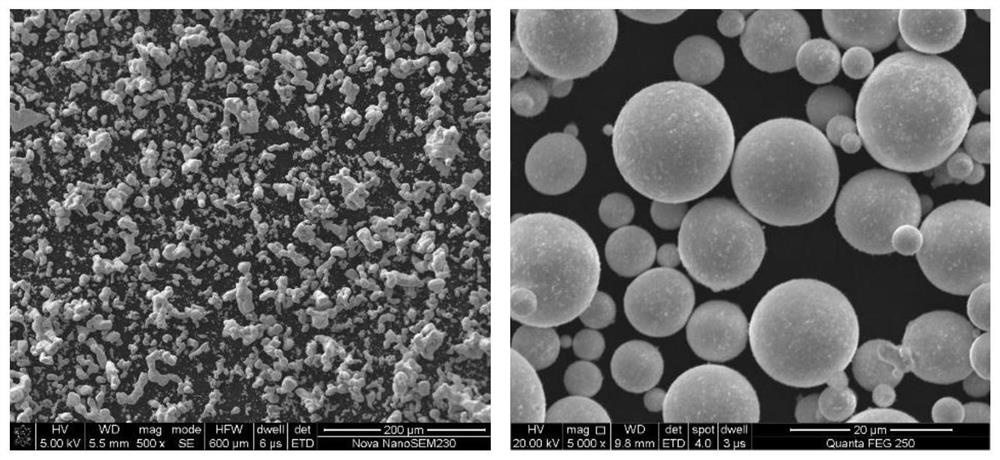

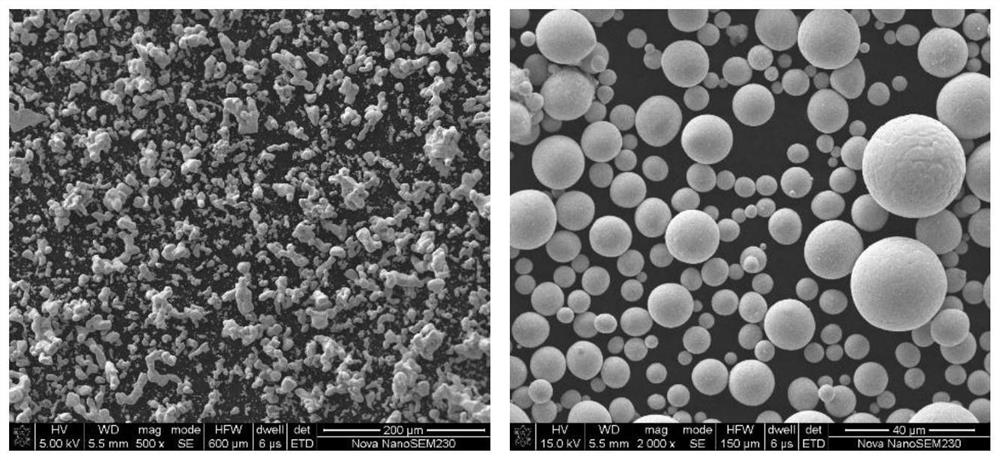

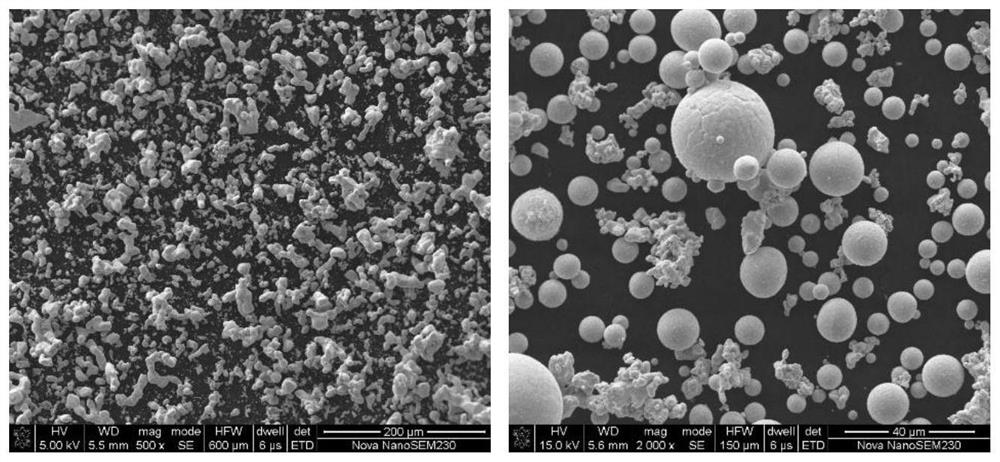

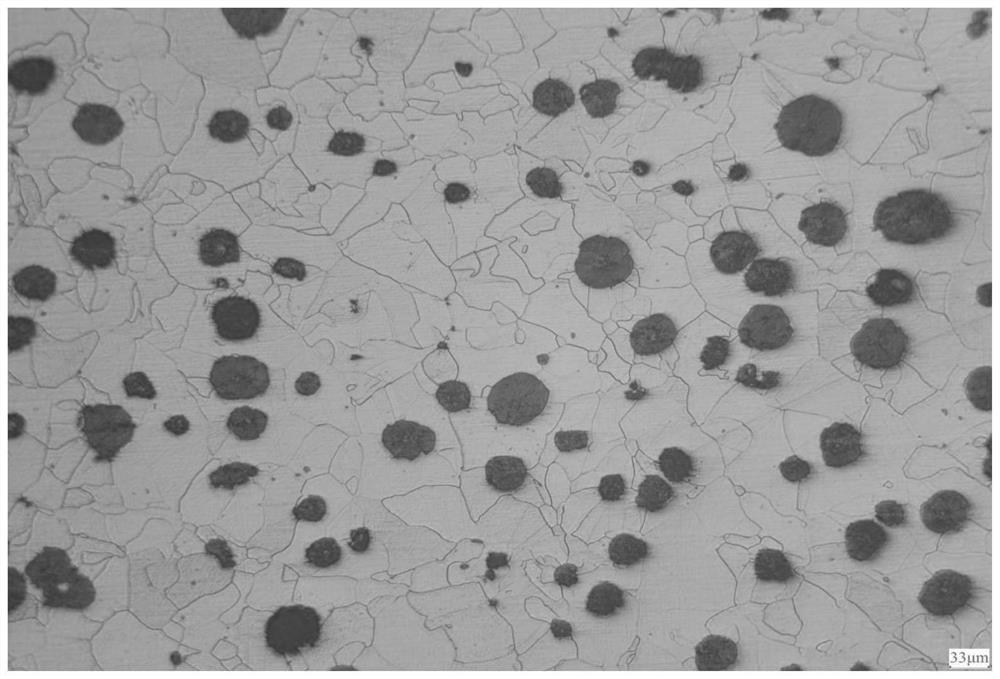

Spherical tantalum powder, preparation thereof and application of spherical tantalum powder in 3D printing

ActiveCN114653959AImprove nodularityImprove particle size uniformityAdditive manufacturing apparatusTransportation and packagingMixed gasMaterials science

The invention relates to a preparation method of spherical tantalum powder, which is characterized in that tantalum powder is subjected to plasma spheroidizing treatment in a mixed gas containing a protective gas and an auxiliary gas, and the auxiliary gas is a C1-C4 hydrocarbon compound. The invention further provides the tantalum ball prepared through the method and application of the tantalum ball in 3D printing. Plasma spheroidizing treatment is innovatively carried out under carrier gas containing C1-C4 hydrocarbon compounds, combined control over components and concentration of the hydrocarbon compounds is further matched, synergy can be achieved accidentally, the spheroidizing rate and particle size distribution of the prepared particles can be improved accidentally, in-situ dispersion strengthening can be achieved, and the particle size distribution of the particles can be improved accidentally. The application requirements in the aspect of 3D printing are better met.

Owner:CENT SOUTH UNIV

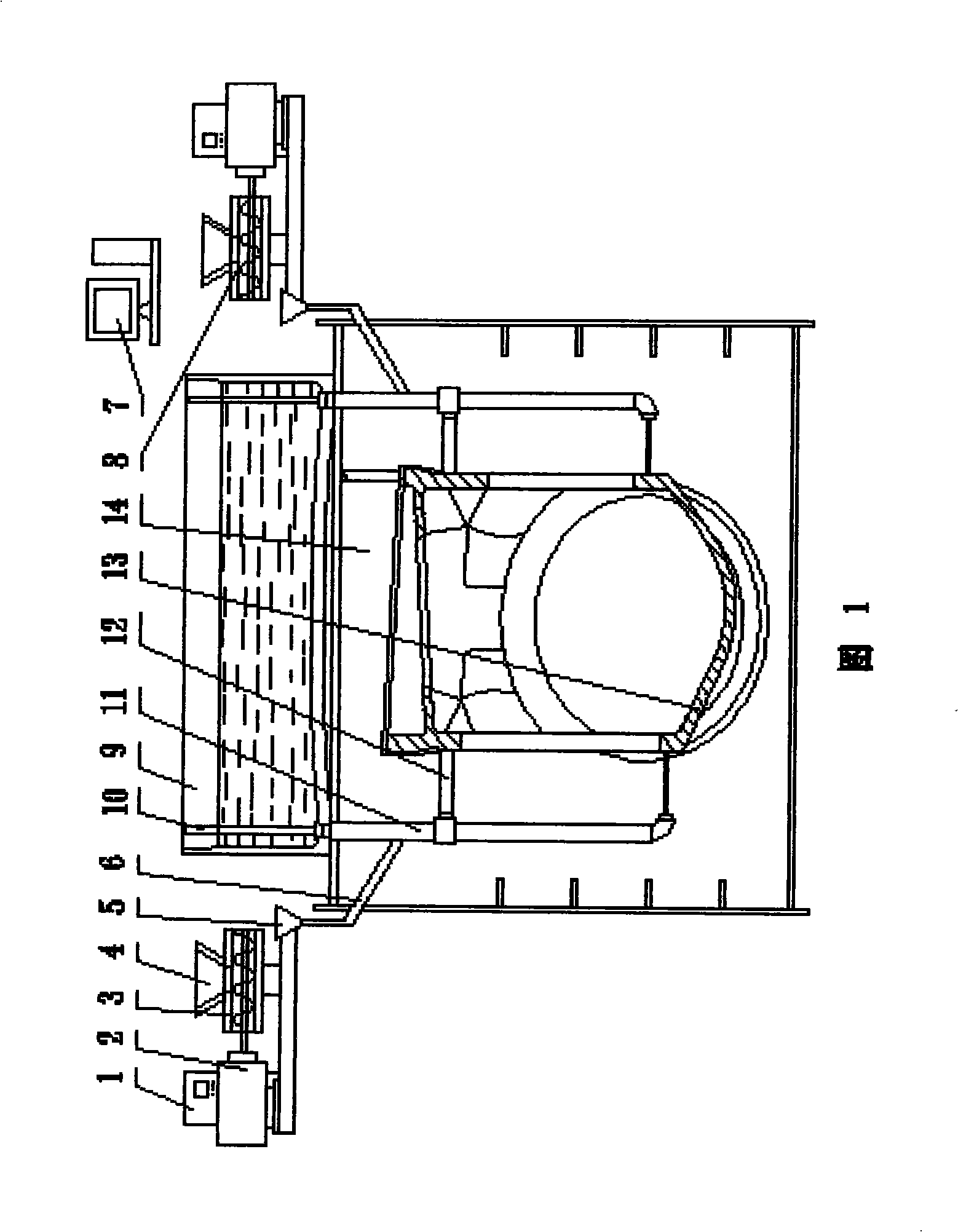

Method for spheroidizing inoculation treatment of large-scale wind power casting

PendingCN114807490AIncrease the number ofHigh nodularityProcess efficiency improvementAlloyDuctile iron

The invention provides a spheroidizing inoculation treatment method for a large-scale wind power casting, and belongs to the technical field of smelting of spheroidal graphite cast iron. The method comprises the following four steps: S1, furnace charge selection; s2, smelting furnace charge, and controlling the tapping temperature of molten iron to be 1480-1520 DEG C; s3, spheroidizing inoculation treatment is conducted; s4, pouring is conducted, and the pouring temperature ranges from 1330 DEG C to 1350 DEG C; wherein in the step S3, an inoculant is embedded in hollow spheres made of silicon steel sheets with different structures and through holes to obtain inoculant slow-release balls, then the inoculant slow-release balls are placed at different positions in a casting ladle, and after molten iron is poured into the casting ladle, the inoculant in the slow-release balls is gradually slowly released as time goes on to perform inoculation reaction; and meanwhile, the added antimony alloy improves the roundness of the graphite nodules, which is the uniqueness of the process. According to the method, the number, roundness and spheroidization grade of the graphite nodules can be improved without repeated inoculation, so that the strength and impact absorbing energy of the casting are improved, and finally the mechanical property of the wind power casting is improved.

Owner:武汉武重铸锻有限公司

Preparation process of high-quality diesel engine bearing cover

ActiveCN113930570AAvoid direct contactPrevent splashFurnace typesProcess efficiency improvementCarbide siliconMischmetal

The invention discloses a preparation process of a high-quality diesel engine bearing cover. After spheroidizing and inoculating treatment are performed on base iron for a period of time, secondary silicon carbide and a secondary inoculant are added; the purity of the secondary silicon carbide is limited to be 95 percent or above; graphitization is promoted in the base iron through rare earth metal lanthanum and magnesium in a spheroidizing agent and a silicon-barium inoculant, and graphite nucleation is formed; silicon carbide with the purity being 95 percent or above is added; the dendritic crystals of austenite in the molten iron can be micronized; the micronized austenite dendritic crystals can increase graphite cores formed among the dendritic crystals; and the number of graphite nodules in the molten iron is increased, and the spheroidization rate is increased. The engine bearing cover prepared by the preparation process is processed by using a proper formula and adjusting the element proportion, and the bearing cover with good spheroidization rate and mechanical property is obtained by adopting a processing technology of secondarily adding silicon carbide and the inoculant, so that the engine bearing cover has good practicability and production value.

Owner:JIANGYIN HONGCHUANG CASTING

Instant inoculation method of large-section magnesium iron

The invention relates to an inoculation method for large-section ductile iron, which can accurately change the adding speed of inoculant according to different flow rates of molten iron during pouring. The method can be used for producing the large-section ductile iron with high performance requirement and capable of resisting low-temperature shock. The inoculation method for the large-section ductile iron is characterized in that the molten iron is poured into a straight pouring channel from a runner box, an automatic feeding device adds the inoculant into the straight pouring channel through a pipeline at the same time of pouring, the inoculant and the molten iron are in a half filling state in the straight pouring channel, mixed and then poured into a die cavity, and the automatic feeding device automatically adjusts the adding speed of the inoculant according to the flow change of the molten iron.

Owner:辽宁隆达集团百星达铸造有限责任公司

A Method for Improving the Microstructure and Properties of Ductile-Grinded Cast Iron

The invention discloses a method for improving the structure and performance of ductile cast iron; it relates to the technical field of cast iron, and introduces graphene composite particles into ductile cast iron to obtain finished ductile iron castings; the introduction is added to molten ductile cast iron after ball milling treatment Graphene composite particles; the ball milling process is mixed ball milling of iron powder and graphene composite particles; the added amount of graphene composite particles in the finished ductile iron casting is 0.25-0.33wt.%; the graphite prepared by the inventive method Graphene composite particles can significantly improve the spheroidization rate of nodular cast iron. By improving the spheroidization rate, the graphite spheres are more rounded. During the solidification process, graphite distortion mainly occurs during the growth of spheroidal graphite in molten iron. Among them, the reduction of growth rate can reduce the probability of distortion. Therefore, by introducing the graphene composite particles prepared by the present invention, the nodularization rate of ductile iron can be greatly increased, and its mechanical properties can be further improved.

Owner:安徽军明机械制造有限公司

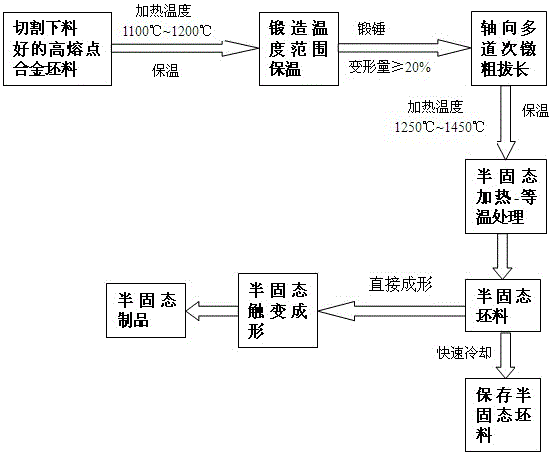

Preparation method for semi-solid state blank of steel

The invention discloses a preparation method for semi-solid state blank of steel. The preparation method comprises the following steps of: 1) heating a high-temperature resistance furnace to 1100-1200 DEG C, and putting blank which precisely drops into the high-temperature resistance furnace to heat and preserve heat; 2) clamping blank onto a lower cutting board of a forging hammer, upsetting in the axial direction of the blank for enabling the blank to reach set deformation amount; 3) after upsetting, drawing the blank to the initial size; 4) repeating steps 2) and 3) within the range of a forging temperature, quickly cooling the blank to the room temperature; and 5) rising the furnace temperature of the high-temperature resistance furnace to a semi-solid state temperature being 1250-1450 DEG C of steel, and putting the blank to heat and perverse heat, thereby obtaining semi-solid state blank of steel. Semi-solid state blank prepared by the preparation method can be directly subjected to semi-solid state forging formation, so that a secondary heating process is avoided, a blank making mould does not need to manufacture, process flow is shortened, operations are simple, efficiency is high and cost is high.

Owner:XIANGTAN UNIV

Working roll for rolling medium-thickness plate with high grade and high strength and manufacture method thereof

ActiveCN101954378BImprove wear resistanceImproved roll shape retentionRollsMetal rolling arrangementsChemical compositionWork roll

The invention discloses a working roll for rolling a medium-thickness plate with high grade and high strength and a manufacture method thereof. The working roll is applied to a medium-thickness plate rolling mill of a rolling steel industry. A working layer comprises the following alloy components in percentage by weight: 3.00-3.50 percent of C, 0.40-1.20 percent of Si, 0.50-1.20 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 1.30-2.50 percent of Cr, 3.20-4.50 percent of Ni, 0.20-1.00 percent of Mo, 0.20-2.00 percent of W and 1.00-1.50 percent of V. A roll core comprises the following chemical components in percentage by weight: 2.80-3.50 percent of C, 2.00-2.50 percent of Si, 0.50-1.00 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 0.20-0.50 percent of Cr, 0.20-0.60 percent of Ni, not more than 0.20 percent of Mo and not more than 0.30 percent of Re. The working roll manufactured by adopting a centrifugal composite casting process and two-section tempering production at 400-550 DEG C for 25-30 hours is the working roll for rolling the medium-thickness plate with high grade and high strength, which has the advantages of high abrasion resistance and less hardness reduction.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

A kind of as-cast high strength and toughness synthetic nodular cast iron qt800-5 and its preparation method

The invention provides a kind of as-cast high-strength and ductility synthetic nodular cast iron QT800-5 and a preparation method thereof. The as-cast high-strength and ductility synthetic nodular cast iron QT800-5 comprises, by mass, 3.70-3.95% of C, 3.3-3.5% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.035% of P, less than or equal to 0.02% of S, 0.5-0.7% of Cu, 0.55-0.75% ofNi, 0.035-0.65% of Mg residues, and the balance Fe and microelements. The preparation method of the as-cast high-strength and ductility synthetic nodular cast iron QT800-5 comprises the following steps of mixing and smelting; alloying; pretreatment and spheroidizing; and inoculation treatment and pouring. The preparation method comprises the steps of smelting base iron melt in a medium-frequencyinduction furnace through steel scrap recarburization; adding silicon iron and cathode copper to conduct alloying; bringing in alloying elements nickel through a spheroidizing agent; conducting pretreatment, spheroidizing and inoculation treatment; and finally conducting pouring. The as-cast high-strength and ductility synthetic nodular cast iron QT800-5 prepared through the method has high strength, good ductility and toughness and excellent comprehensive performance.

Owner:WUHAN UNIV OF TECH

Preparation method of high-temperature-resistant antioxidant exhaust manifold nodular cast iron

ActiveCN102888551BEnhanced antioxidant growth propertiesImprove high temperature mechanical propertiesHeat resistanceDuctile iron

The invention discloses a preparation method of a high-temperature-resistant antioxidant exhaust manifold nodular cast iron, relates to the preparation method of the exhaust manifold nodular cast iron and aims to the solve the technical problems of poor heat resistance and less failure circulation time at high thermal cycling temperature of the traditional exhaust manifold nodular cast iron. The preparation method of the high-temperature-resistant antioxidant exhaust manifold nodular cast iron comprises the following steps of:1, molten iron smelting; and 2, spheroidization and inoculation treatment. According to the high-temperature-resistant antioxidant exhaust manifold nodular cast iron obtained through the preparation method, the volume fraction of ferrite reaches 95-99 percent, the tensile strength is 160N / mm<2> at high temperature of 650 DEG C, the heat resistance is good, the failure circulation time is 410-440 times at thermal cycling temperature of 500-700 DEG C, the high-temperature creep resistance and the creep-resistance breaking ability are good, and the high-temperature-resistant antioxidant exhaust manifold nodular cast iron can be applied to exhaust manifolds of automobile engines.

Owner:齐齐哈尔英格机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com