Low-cost seawater-corrosion-resistant nodular cast iron and preparation method thereof

A technology of nodular cast iron and seawater resistance, applied in the field of nodular cast iron, can solve the problems of high production costs, achieve the effects of promoting graphitization and matrix ferritization, reducing consumption, and eliminating anti-graphitization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

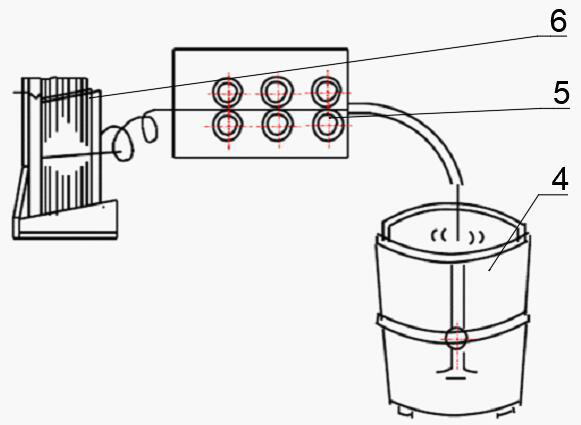

[0026] Specific example: Melting molten iron with a 2-ton intermediate frequency electric furnace.

[0027] The charge ratio is composed of 70% Q235 steel scrap and 30% nodular cast iron return charge by mass percentage, among which: the addition amount of Q235 scrap steel is 1400 kg, and the addition amount of ductile iron return charge is 600 kg.

[0028] The carbon content of charge (percentage) = 70% carbon content of Q235 steel scrap + 30% carbon content composition of ductile iron return charge = 0.70*0.14%+0.30*3.7=1.20%

[0029] The missing carbon content of the original molten iron in the furnace = the average carbon content of 3.5-3.9% in claim 1 3.7% - the carbon content of the charge = 3.7% - 1.2% = 2.5%

[0030] Calculate the amount of carburant added:

[0031] The amount of carburant added = the carbon content of the original molten iron in the furnace, the carbon content % ÷ the carbon content of the carburant ÷ the carbon comprehensive absorption rate of the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com