Integrated convenient-to-hang environment-friendly high-performance liquid alloy half-pressure container and using method

A liquid alloy, high-performance technology, used in casting melt containers, metal processing equipment, manufacturing tools, etc., can solve problems such as harm to workers' health, low utilization of alloy magnesium, frequent hoisting equipment, etc., and achieve stable spheroidization effect. , Reduce the labor intensity of workers, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

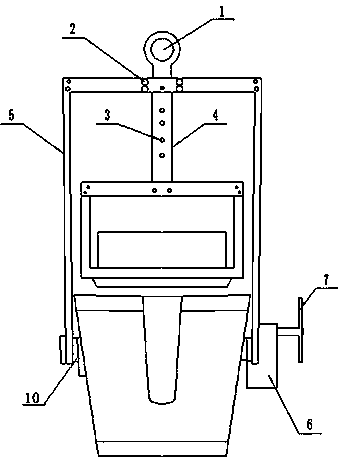

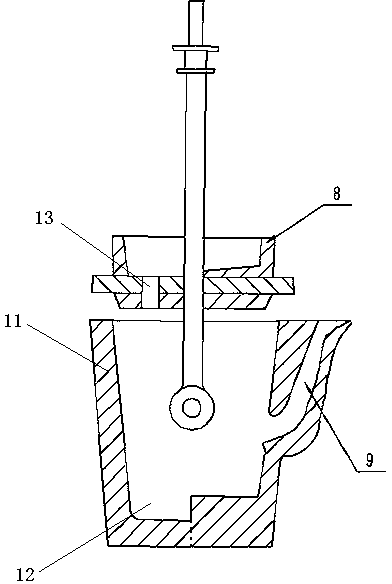

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

[0037] An integrated portable hanging type environment-friendly high-performance liquid alloy semi-pressure container, including a reversible container 11, the upper end of the container 11 is provided with a material receiving trough 8 matched with it, and the top of the material receiving trough 8 is connected with a cantilever 4, The cantilever 4 is installed on a frame 5, and the frame 5 is connected to the two sides of the container 11. An iron injection hole connected to the inside of the container is provided in the receiving tank 8, and a hole connected to the inside of the container is connected to the side of the container. The slag avoidance nozzle 9, the material receiving trough and the container cover are integrated, basically no smoke and dust leakage, reducing local environmental pollution by more than 90%, achieving environmental protection and green effects; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com