Preparation process of high-quality diesel engine bearing cover

A diesel engine and preparation technology, applied in the field of cast iron, can solve the problem of low nodularity grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A preparation process for a high-quality diesel engine bearing cover, comprising the following steps:

[0060] S1: Put the raw material in the melting furnace, melt it into molten iron at high temperature, and add silicon carbide once to obtain the original molten iron;

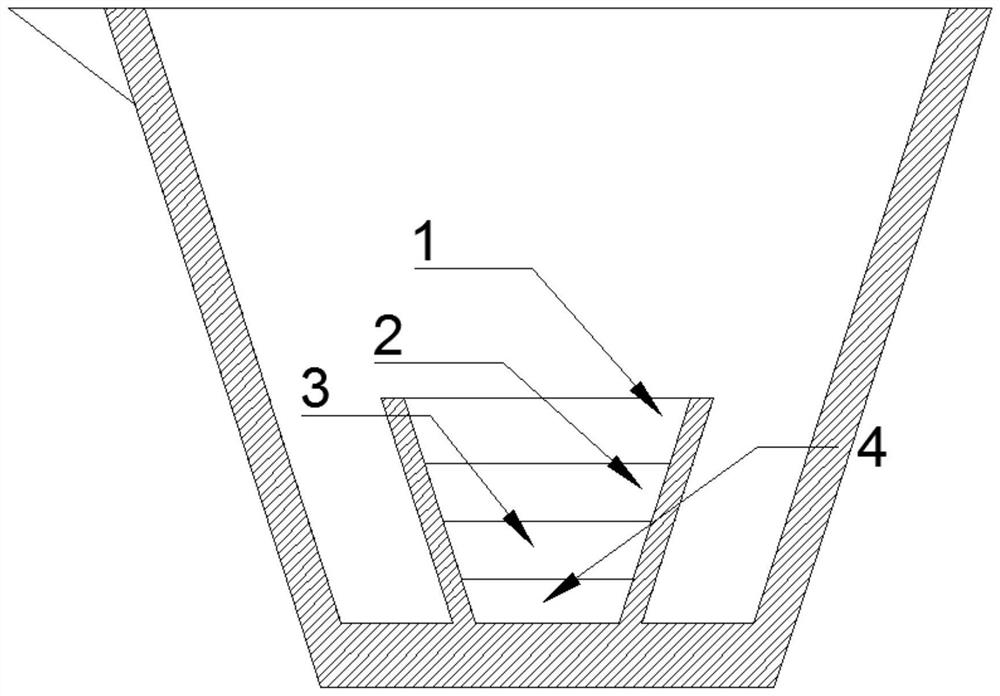

[0061] S2: Place small scrap iron 1, dry iron filings 2, primary inoculant 3, and nodulizer 4 in the nodular iron bag in sequence, and compact them;

[0062] S3: Pour the original molten iron into the ductile iron ladle, spheroidize and incubate for a period of time, add secondary silicon carbide and secondary inoculant to obtain ductile iron;

[0063] S4: Pouring spherical graphite molten iron into the bearing cap mold to obtain the original casting of the bearing cap;

[0064] S5: The original casting of the bearing cap is subjected to heat treatment to obtain the engine bearing cap.

[0065] Among them, S1:

[0066] Put the cast iron raw material in a melting furnace, heat it to 1580°C, melt all ...

Embodiment 2

[0089] A preparation process for a high-quality diesel engine bearing cover, comprising the following steps:

[0090] S1: Put the raw material in the melting furnace, melt it into molten iron at high temperature, and add silicon carbide once to obtain the original molten iron;

[0091] S2: Place small scrap iron 1, dry iron filings 2, primary inoculant 3, and nodulizer 4 in the nodular iron bag in sequence, and compact them;

[0092] S3: Pour the original molten iron into the ductile iron ladle, spheroidize and incubate for a period of time, add secondary silicon carbide and secondary inoculant to obtain ductile iron;

[0093] S4: Pouring spherical graphite molten iron into the bearing cap mold to obtain the original casting of the bearing cap;

[0094] S5: The original casting of the bearing cap is subjected to heat treatment to obtain the engine bearing cap.

[0095] Among them, S1:

[0096] Place the cast iron raw material in a melting furnace, heat it to 1590°C, melt al...

Embodiment 3

[0119] A preparation process for a high-quality diesel engine bearing cover, comprising the following steps:

[0120] S1: Put the raw material in the melting furnace, melt it into molten iron at high temperature, and add silicon carbide once to obtain the original molten iron;

[0121] S2: Place small scrap iron 1, dry iron filings 2, primary inoculant 3, and nodulizer 4 in the nodular iron bag in sequence, and compact them;

[0122] S3: Pour the original molten iron into the ductile iron ladle, spheroidize and incubate for a period of time, add secondary silicon carbide and secondary inoculant to obtain ductile iron;

[0123] S4: Pouring spherical graphite molten iron into the bearing cap mold to obtain the original casting of the bearing cap;

[0124] S5: The original casting of the bearing cap is subjected to heat treatment to obtain the engine bearing cap.

[0125] Among them, S1:

[0126] Put the cast iron raw material in a melting furnace, heat it to 1600°C, melt all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com