A spheroidizing annealing process for ml40cr hot-rolled wire

A spheroidizing annealing and wire rod technology, applied in heat treatment furnaces, manufacturing tools, heat treatment equipment, etc., can solve the problems of waste of finished product quality, increase of one time, cold heading cracking, etc. time, annealing time and precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

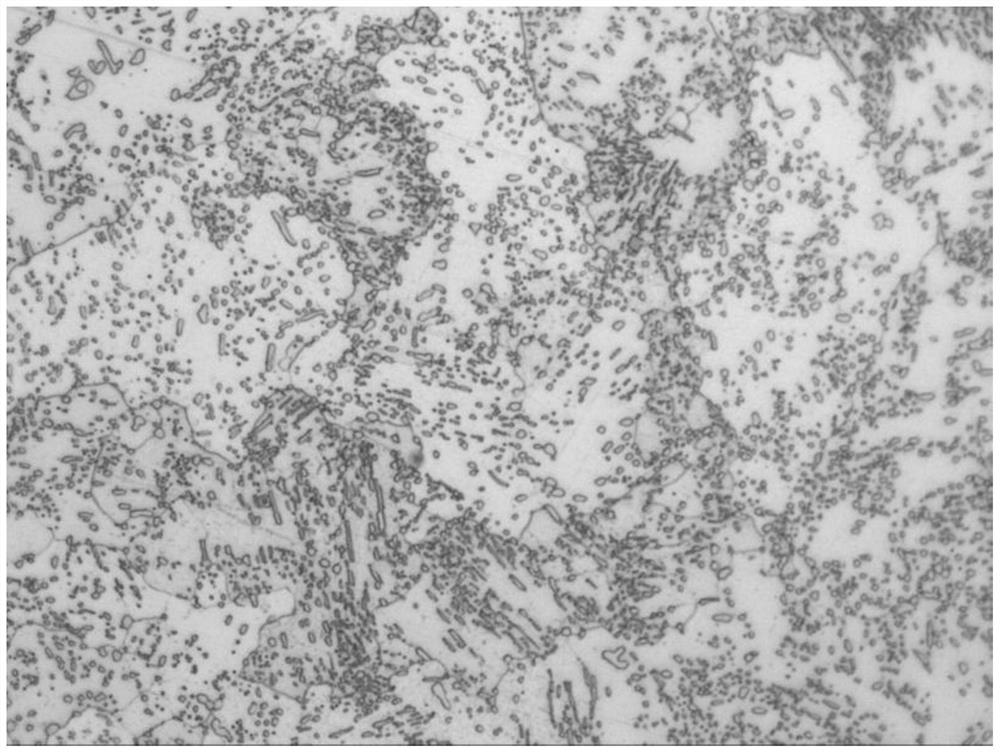

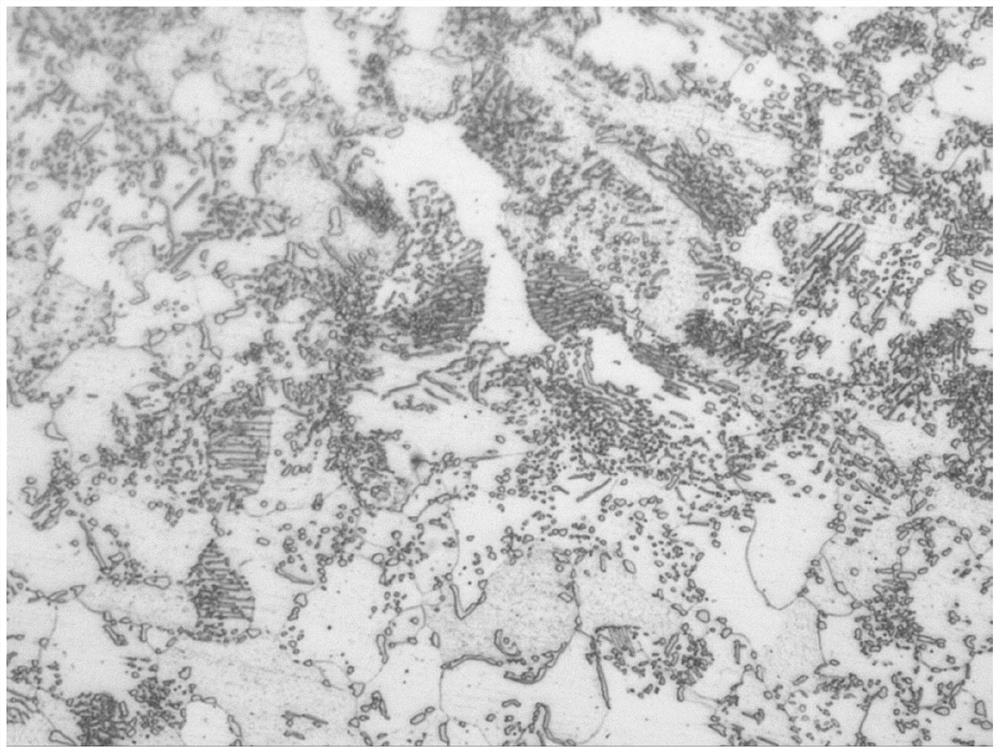

Embodiment 1

[0030] Choose ML40Cr hot-rolled wire with a diameter of 25mm, and the specific operation steps are as follows:

[0031] Step 1. Heat the ML40Cr hot-rolled wire rod to 765±2°C in the furnace for 2.5 hours, and keep it warm for 5 hours when the temperature reaches 765±2°C;

[0032] Step 2. After the ML40Cr hot-rolled wire rod is kept warm for 5 hours, the temperature of the furnace body is lowered. The cooling time is 3 hours, and the temperature is lowered from 765±2°C to 710±2°C. The wind pressure of the blower is transmitted to the main flow passage 9, and the main flow passage 9 imports nitrogen into the first side air passage 10 and the second side air passage 11 from the upper end, and the nitrogen passes through the first air valve 6 and the second air valve 7 and the third gas valve 8 enter the external circulation pipe 5, and the external circulation pipe 5 recycles nitrogen into the nitrogen box. When the temperature reaches 710±2°C, keep the furnace body warm for 4 ho...

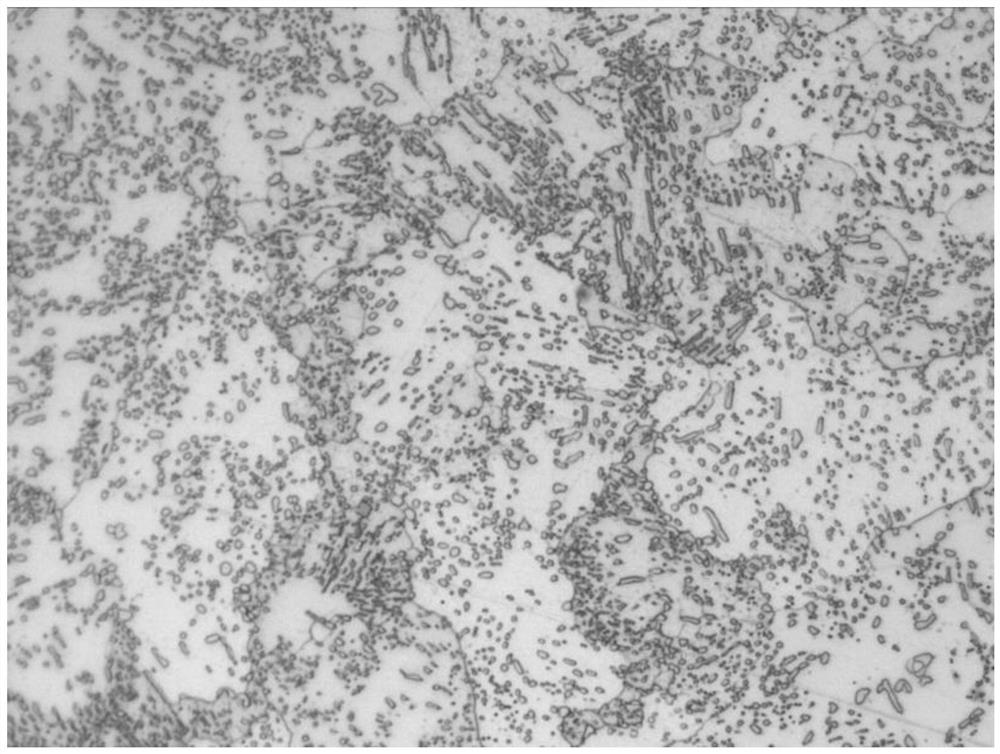

Embodiment 2

[0040] Choose ML40Cr hot-rolled wire with a diameter of 18mm, and the specific operation steps are as follows:

[0041]Step 1. Heat the ML40Cr hot-rolled wire rod to 765±2°C in the furnace for 5 hours, and keep it warm for 5 hours when the temperature reaches 765±2°C;

[0042] Step 2. After the ML40Cr hot-rolled wire rod is kept warm for 5 hours, the temperature of the furnace body is lowered. The cooling time is 3 hours, and the temperature is lowered from 765±2°C to 710±2°C. The wind pressure of the blower is transmitted to the main flow passage 9, and the main flow passage 9 imports nitrogen into the first side air passage 10 and the second side air passage 11 from the upper end, and the nitrogen passes through the first air valve 6 and the second air valve 7 and the third gas valve 8 enter the external circulation pipe 5, and the external circulation pipe 5 recycles nitrogen into the nitrogen box. When the temperature reaches 710±2°C, keep the furnace body warm for 4 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com