As-cast high-strength and ductility synthetic nodular cast iron QT800-5 and preparation method thereof

A ductile iron, high-strength technology, applied in the field of high-performance metal material manufacturing, can solve the problem that the strength is difficult to meet the material requirements of higher fatigue strength and comprehensive performance, achieve good spheroidizing effect, reduce the amount of spheroidizing agent, increase The effect of the number of graphite balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

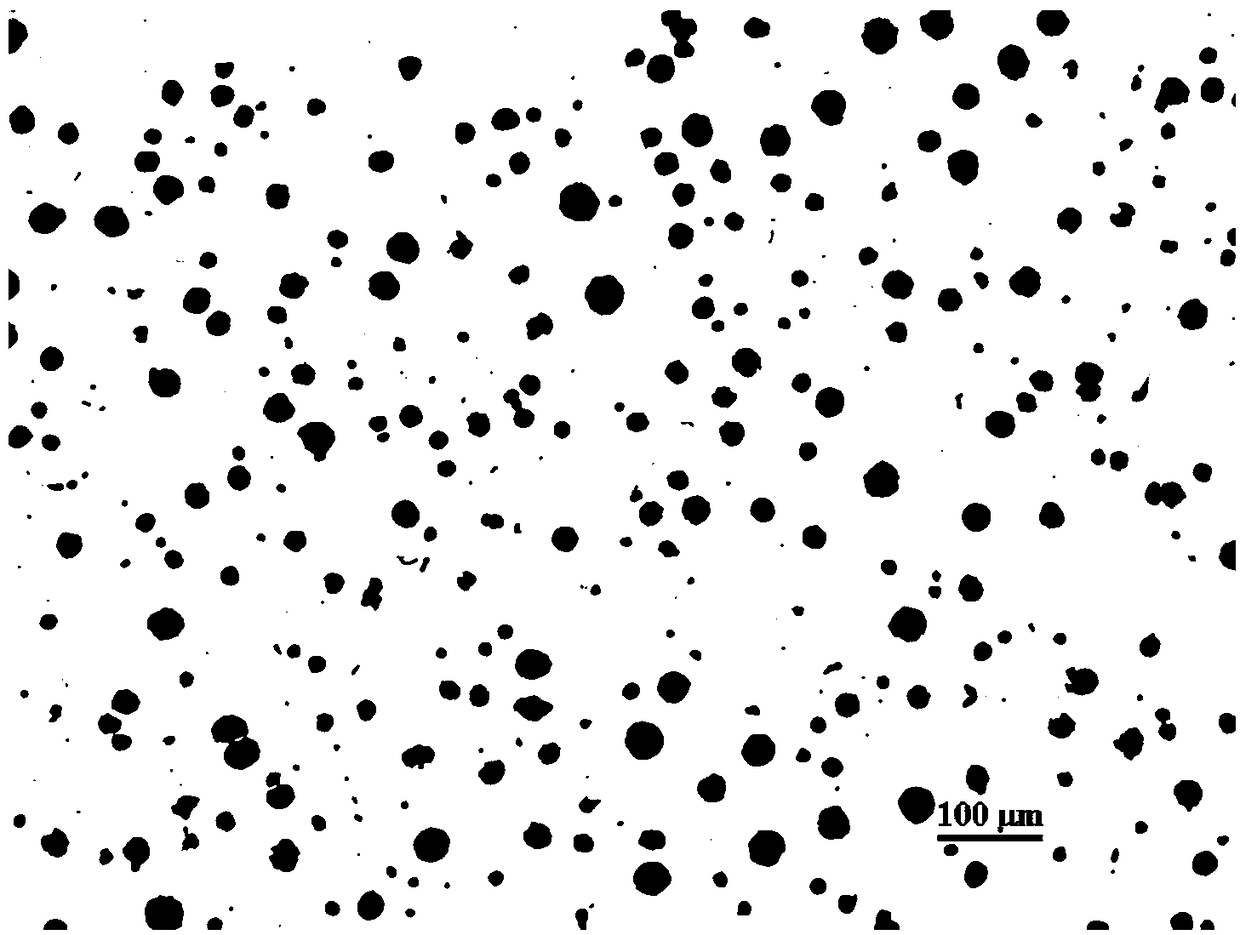

[0036] Example 1, see figure 1 :

[0037] The invention provides an as-cast high-strength and toughness synthetic ductile iron QT800-5, which comprises the following components and their mass percentages: C: 3.76%, Si: 3.35%, Mn: 0.197%, P: 0.022%, S: 0.016%, Ni: 0.714%, Cu: 0.633%, Mg 残 : 0.059%, Fe: 91.164%, other trace elements: balance.

[0038] A preparation method of as-cast high-strength and tough synthetic nodular cast iron QT800-5 (melting in a 100Kg medium-frequency induction furnace), comprising the following steps (percentages are mass fractions):

[0039] (1) Ingredients and smelting: Add 3.6% recarburizer, 27.1% scrap steel (45# steel), 59.3% pure iron with low sulfur and low manganese, and 10% ductile iron return charge to the intermediate frequency induction furnace, and heat up to 1550 ℃ for smelting to obtain the original molten iron;

[0040] (2) Alloying: Add 75% ferrosilicon and 0.6% cathode copper of its quality 3% to the original molten iron, and con...

Embodiment 2

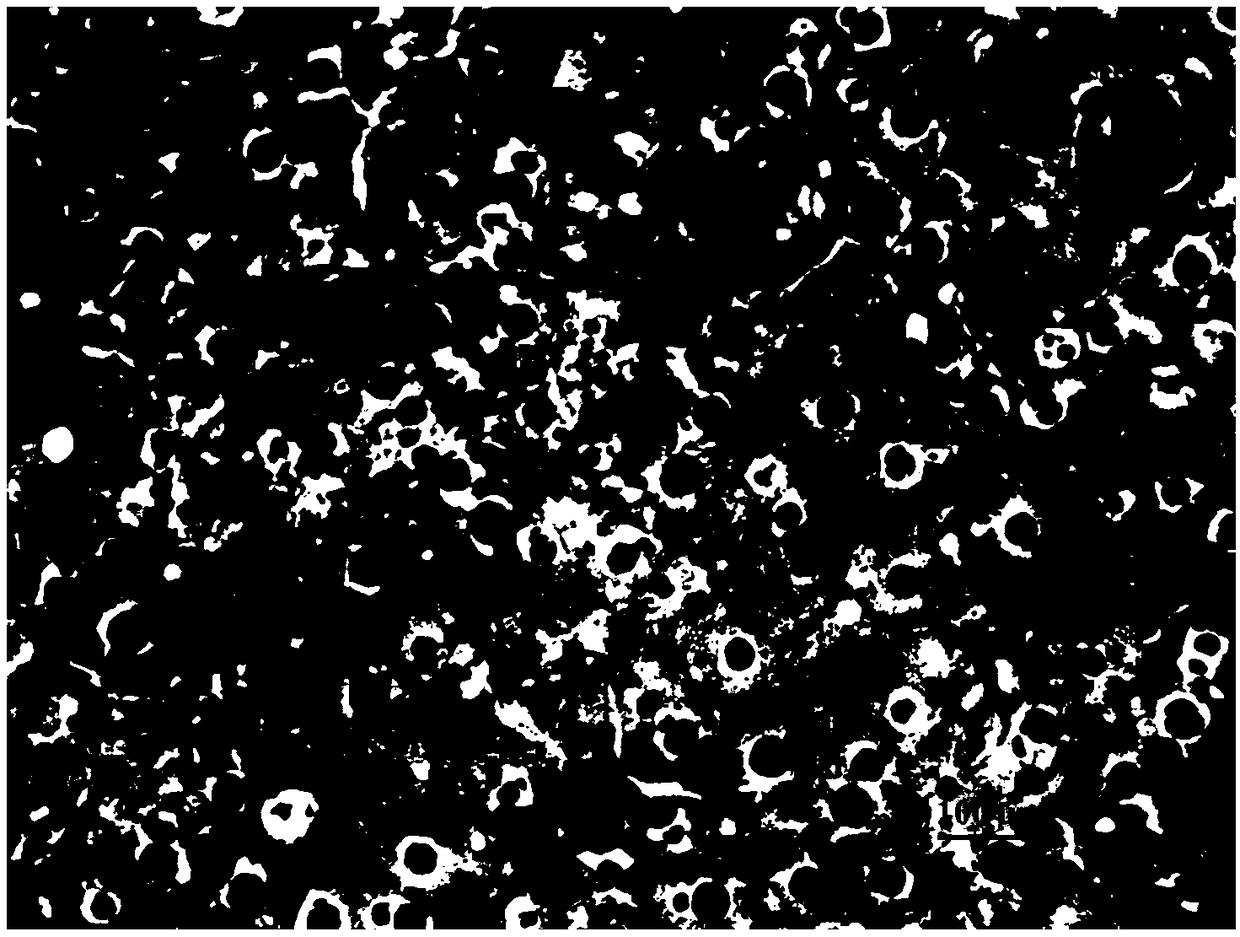

[0048] Example 2, see figure 2 :

[0049] The invention provides an as-cast high-strength and toughness synthetic nodular cast iron QT800-5, which comprises the following components and their mass percentages: C: 3.942%, Si: 3.423%, Mn: 0.173%, P: 0.030%, S: 0.016%, Ni: 0.738%, Cu: 0.623%, Mg 残 : 0.065%, Fe: 90.834%, other trace elements: balance.

[0050] A preparation method of as-cast high-strength and tough synthetic nodular cast iron QT800-5 (melting in a 100Kg medium-frequency induction furnace), comprising the following steps (percentages are mass fractions):

[0051] (1) Ingredients and smelting: Add 3.2% recarburizer, 27.9% steel scrap (45# steel), 56.9% pure iron with low sulfur and low manganese, and 10% ductile iron return charge to the intermediate frequency induction furnace, and heat up to 1550 ℃ for smelting to obtain the original molten iron;

[0052] (2) Alloying: Add 75 ferrosilicon and 0.62% cathode copper of its quality 3.4% to the original molten iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com