Pipe nodular cast iron manufacturing method

A technology of nodular cast iron and a manufacturing method, applied in the field of casting, can solve the problem that the high temperature mechanical properties and oxidation resistance requirements of exhaust manifold materials cannot be met, the high temperature creep resistance and creep rupture resistance are poor, and the exhaust manifold materials Anti-oxidation performance and other problems, to achieve the effect of improving high temperature creep resistance and creep rupture resistance, improving spheroidization, and improving high temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

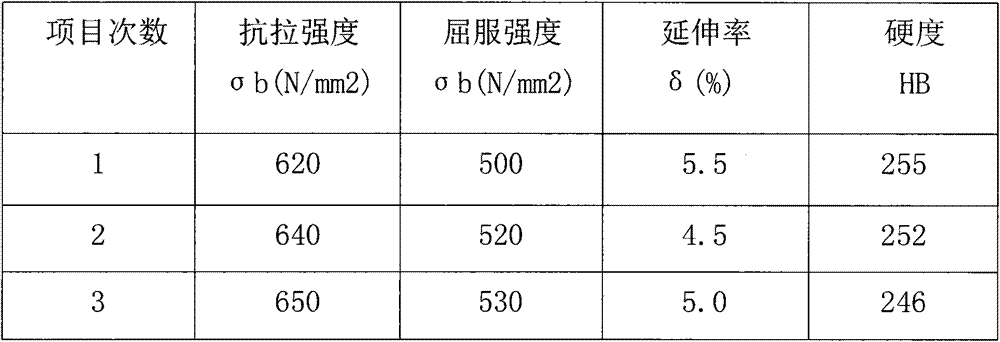

Examples

Embodiment 1

[0017] Prepared according to the above steps 1) and 2), wherein the components in the steel scrap and the mass fractions of each component in step 1) are: C: 0.17%, S: 0.012%, P: 0.020%, Mn: 0.24%, Si: 0.30%.

[0018] The mass fraction of Mg in the magnesium alloy in step 1) is 45%.

[0019] The mass fraction of Re in the rhenium alloy in step 1) is 35%.

[0020] The nodulizer in step 2) is a rare earth magnesium alloy FeS iMg8Re7 nodulizer.

[0021] The ferrosilicon inoculant in step 2) is FeSi75 alloy, wherein the mass fraction of Si is 60%.

[0022] The mass fraction of Si in the barium silicon inoculant in step 2) is 35%.

Embodiment 2

[0024] Prepared according to the above steps 1) and 2), wherein the components in the steel scrap and the mass fractions of each component in step 1) are: C: 0.19%, S: 0.014%, P: 0.023%, Mn: 0.25%, Si: 0.35%.

[0025] The mass fraction of Mg in the magnesium alloy in step 1) is 48%.

[0026] The mass fraction of Re in the rhenium alloy in step 1) is 38%.

[0027] The nodulizer in step 2) is a rare earth magnesium alloy FeSiMg8Re7 nodulizer.

[0028] The ferrosilicon inoculant in step 2) is FeSi75 alloy, wherein the mass fraction of Si is 66%.

[0029] The mass fraction of Si in the barium silicon inoculant in step 2) is 40%.

Embodiment 3

[0031] Prepared according to the above steps 1) and 2), wherein in step 1) the components in steel scrap and the mass fractions of each component are: C: 0.21%, S: 0.016%, P: 0.025%, Mn: 0.28%, Si: 0.40%.

[0032] The mass fraction of Mg in the magnesium alloy in step 1) is 50%.

[0033] The mass fraction of Re in the rhenium alloy in step 1) is 45%.

[0034] The nodulizer in step 2) is a rare earth magnesium alloy FeSiMg8Re7 nodulizer.

[0035] The ferrosilicon inoculant in step 2) is FeSi75 alloy, wherein the mass fraction of Si is 70%.

[0036] The mass fraction of Si in the barium silicon inoculant in step 2) is 45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com