Instant inoculation method of large-section magnesium iron

A technology of instantaneous inoculation and large cross-section, which is applied in the field of instantaneous inoculation of large-section ductile iron poured in the sprue box, which can solve the problems of reduced nodularization rate, low nodularization rate, graphite distortion and fragmented graphite, etc., and achieve low temperature impact Good performance, improved quality stability, and the effect of eliminating fragmented graphite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

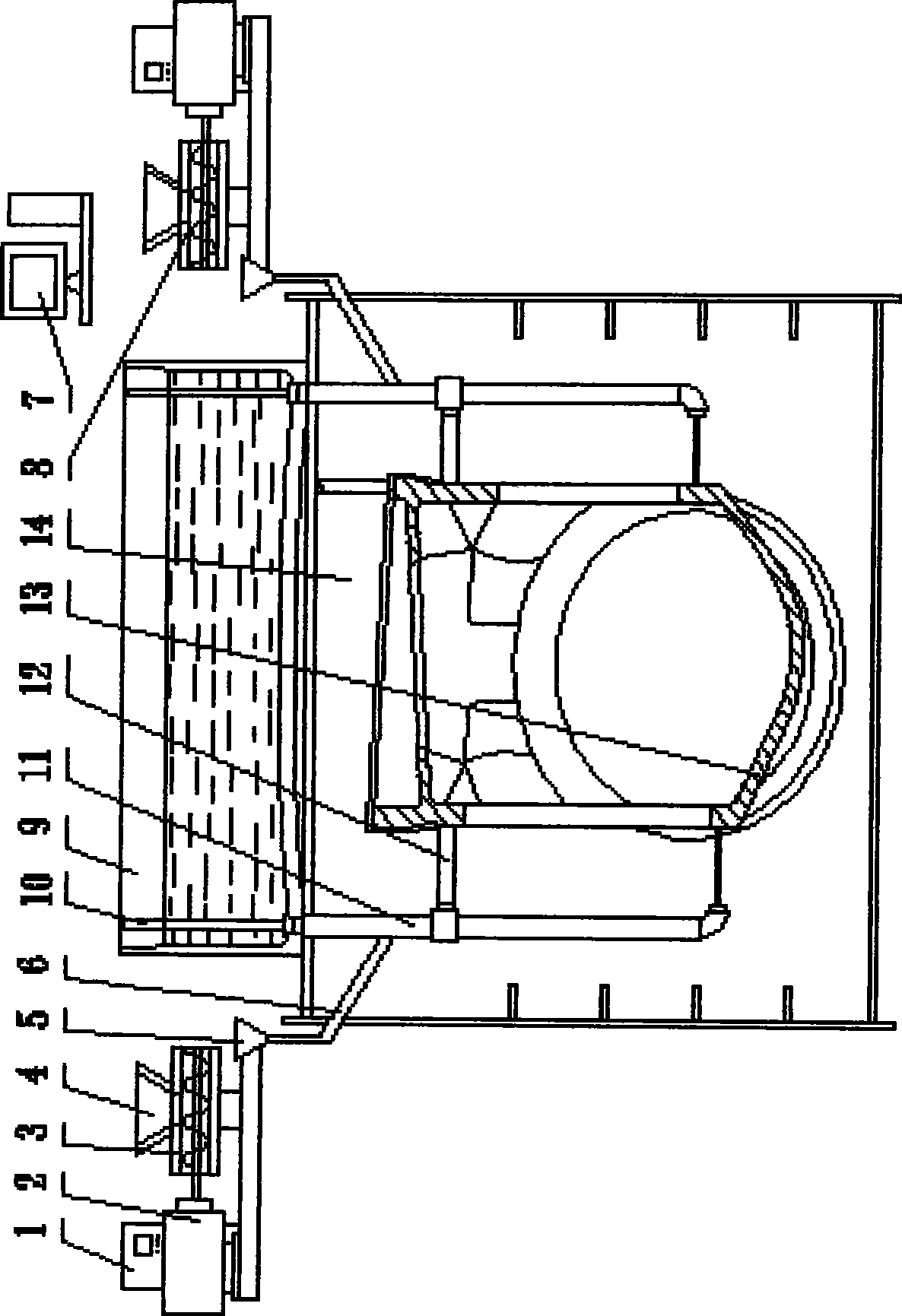

[0018] Embodiment: Taking the hub of a 1.5MW wind turbine as an example, the present invention will be further described with reference to the accompanying drawings.

[0019] 1. First determine the parameters and variable relationships:

[0020] A. Pouring time calculation

[0021] The weight of the casting is W=10500kg, and it is cast without a riser, and the process yield is designed to be 88%, so the weight of the casting is: G=11930Kg.

[0022] The pouring time is: t=(2 / 3)×mG 1 / 2 = 138s. In the formula, m is the wall thickness coefficient, which is 1.9; G is the pouring weight (kg).

[0023] B. Calculation of the molten iron flow at the exit of sprue box 9

[0024] The weight of molten iron is G=11930Kg, and the density of molten iron is r 铁水 =7×10 -3 kg / cm 3 ;

[0025] Set sprue box 9 diameter D 1 (cm), the cross-sectional area of gate box 9 is S 1 (cm 2 ), the initial liquid level height of sprue box 9 is h 1 (cm), the height of the choke section is h x (c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com