Spherical tantalum powder, preparation thereof and application of spherical tantalum powder in 3D printing

A tantalum powder and spherical technology, which is applied in the field of metal powder preparation and spherical tantalum powder preparation, can solve the problems of high oxygen content, low strength, unsatisfactory particle size uniformity, etc., and achieves high spheroidization rate, excellent performance, The effect of improving the spheroidization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

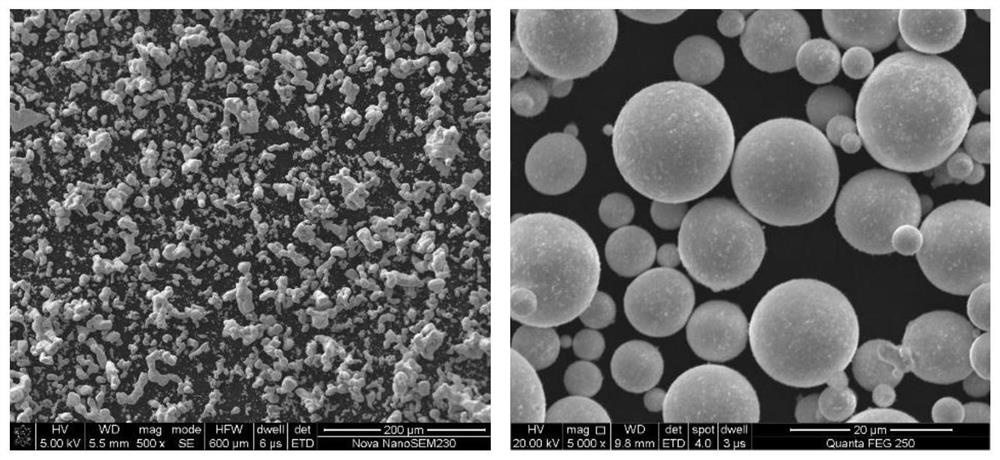

[0045] A preparation method of spherical tantalum powder, the method uses micron-scale irregular tantalum powder prepared by nano-reduction method as raw material, and performs plasma spheroidization treatment under 2L / min (2sccm) methane auxiliary gas to prepare irregular tantalum powder. Spherical tantalum powder.

[0046] The main parameters controlling the RF plasma spheroidization system include the following:

[0047] In the plasma spheroidization process, the pressure in the reactor is 14.7PSIA

[0048] The gate current set by the plasma spheroidization process is 0.45A

[0049] The plate voltage set by the plasma spheroidization process is 8.0KV

[0050] The plate current set by the plasma spheroidization process is 4.0A

[0051] The feeding speed set by the plasma spheroidization process is 8g / min

[0052] The argon sheath gas pressure set by the plasma spheroidization process is 90L / min

[0053] The central gas pressure of argon gas set by the plasma spheroidiza...

Embodiment 2

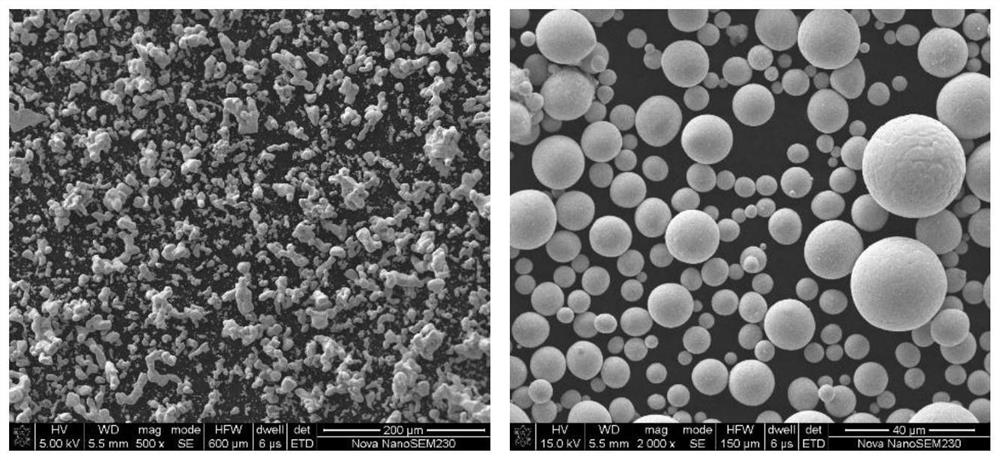

[0058] A preparation method of spherical tantalum powder, the method uses micron-scale irregular tantalum powder (same as Example 1) prepared by nano-reduction method as raw material, and carries out plasma spheroidization under the auxiliary gas of 2L / min acetylene, and the irregular The tantalum powder is prepared into spherical tantalum powder.

[0059] The main parameters controlling the RF plasma spheroidization system include the following:

[0060] In the plasma spheroidization process, the pressure in the reactor is 14.7PSIA

[0061] The gate current set by the plasma spheroidization process is 0.45A

[0062] The plate voltage set by the plasma spheroidization process is 8.0KV

[0063] The plate current set by the plasma spheroidization process is 4.0A

[0064] The feeding speed set by the plasma spheroidization process is 8g / min

[0065] The argon sheath gas pressure set by the plasma spheroidization process is 90L / min

[0066] The central gas pressure of argon g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com