Preparation method for semi-solid state blank of steel

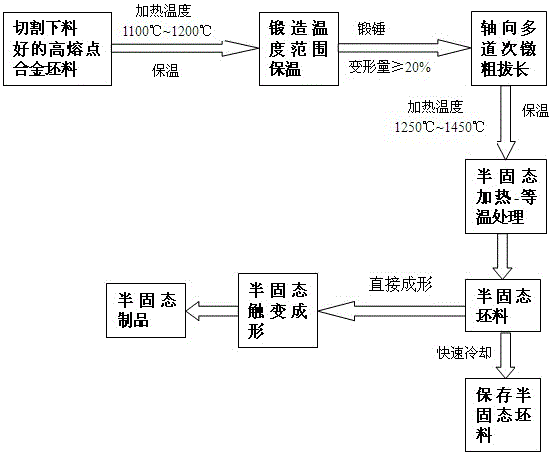

A semi-solid and billet technology, which is applied in the field of semi-solid billet preparation, can solve the problems of low spheroidization rate of semi-solid billet structure, difficulty in semi-solid billet preparation, and uneven grain size, so as to save the secondary heating process, The effect of low cost and reasonable solid phase fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Such as figure 1 As shown, the present embodiment takes 100Cr6 bearing steel as an example, and the preparation method of its semi-solid billet is as follows:

[0028] (1) The forging temperature range of 100Cr6 bearing steel obtained by searching the literature is 800°C~1100°C; the solid phase temperature point is 1307°C, and the liquid phase temperature point is 1491°C.

[0029] (2) Heat the high-temperature resistance furnace to the initial forging temperature of 1100°C, and then cut the 100Cr6 bearing steel billet that has been precisely cut by wire cutting. The billet size is Φ50mm×90mm, and put it into the high-temperature resistance furnace for heat preservation. About 30min.

[0030] (3) Clamp the 100Cr6 bearing steel treated in step 2 to the lower cutting board of a 400 kg air hammer, and use the wide flat anvil upsetting method with a forging ratio of 2.3 to upset the billet, and the final forging temperature is 800 °C.

[0031] (4) After the upsetting is co...

Embodiment 2

[0036] Present embodiment adopts 60Si2Mn spring steel as example, and the preparation method of its semi-solid blank is as follows:

[0037] (1) The forging temperature range of 60Si2Mn spring steel obtained by searching the literature is 850°C~1200°C; the solid phase temperature point is 1410°C, and the liquid phase temperature point is 1480°C.

[0038] (2) Heat the high-temperature resistance furnace to the initial forging temperature of 1200°C, and then cut the precisely blanked billet by wire cutting. The billet size is Φ50mm×90mm, put it into the high-temperature resistance furnace, and keep it warm for about 30 minutes.

[0039] (3) Clamp the 60Si2Mn spring steel treated in step 2 to the lower cutting board of a 400 kg air hammer, use the wide flat anvil upsetting method, the forging ratio is 2, upsetting the billet, and the final forging temperature is 850 °C.

[0040] (4) After the upsetting is completed, the billet is elongated and forged to return to the original bil...

Embodiment 3

[0044] This embodiment takes X210CrW12 tool steel as an example, and the preparation method of its semi-solid blank is as follows:

[0045] (1) The forging temperature range of X210CrW12 tool steel obtained by searching the literature is 850°C~1150°C; the solid phase temperature point is 1200°C, and the liquid phase temperature point is 1400°C.

[0046] (2) Heat the high-temperature resistance furnace to the initial forging temperature of 1150°C, and then cut the precisely blanked blank by wire cutting method. The blank size is Φ50mm×90mm, put it into the high-temperature resistance furnace, and keep it warm for about 30 minutes.

[0047] (3) Clamp the X210CrW12 tool steel treated in step 2 to the lower cutting board of a 400 kg air hammer, use the wide flat anvil upsetting method, the forging ratio is 2, and the billet is upset, and the final forging temperature is 850 °C.

[0048] (4) After the upsetting is completed, the billet is elongated and forged to return to the origi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com