Medium silicon molybdenum niobium spheroidal graphite cast iron material and preparation method thereof

A technology of ductile iron and silicon molybdenum, applied in the field of ductile iron materials and their preparation, can solve problems such as large cost differences, and achieve the effects of improving strength, improving spheroidization, tensile strength and yield strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

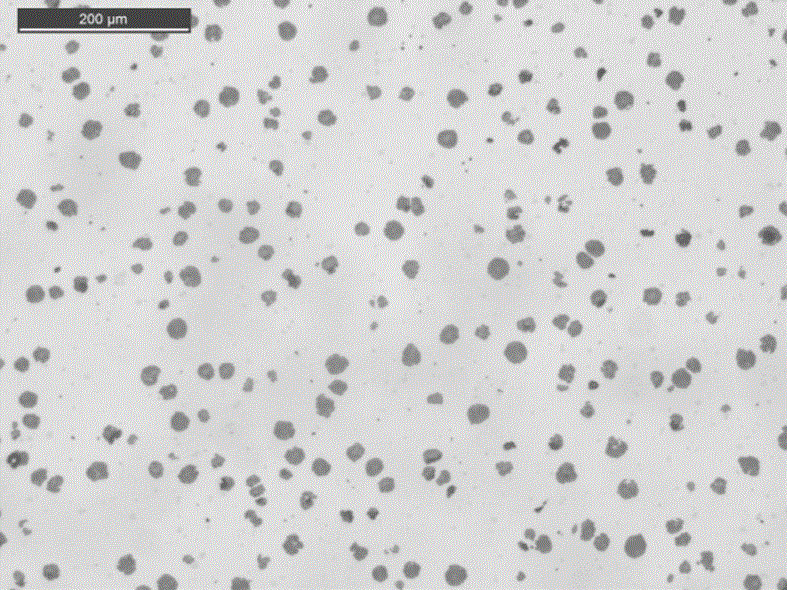

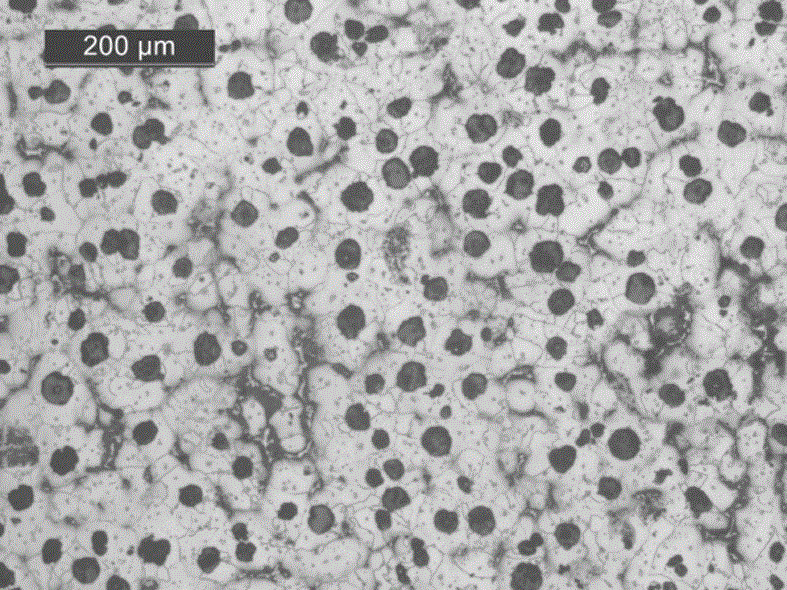

Image

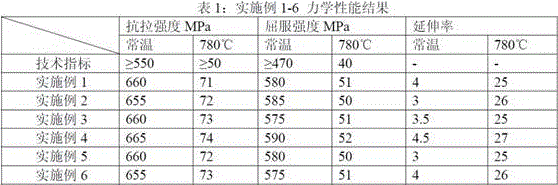

Examples

Embodiment 1

[0034] 1. A medium-silicon-molybdenum-niobium ductile iron material, including the following chemical composition in mass percentage: C 2.86%, Si 4.4%, Mn 0.3%, P 0.032%, S 0.006%, Mo 0.82%, Ni 0.69%, Nb 0.67 %, Mg 0.047%, V 0.24%, the balance is Fe and other unavoidable elements.

[0035] Its preparation method comprises the following preparation steps:

[0036] (1) Batching process: The selected raw materials and the quality ratio of raw materials are 39.3% of C04 high-purity pig iron, 54% of steel scrap, 1% of recarburizer, 0.7% of silicon carbide, 1.5% of molybdenum-iron alloy, 1.2% of niobium-iron alloy, and 0.8% of nickel plate %, ferrosilicon alloy 1.2%, vanadium iron alloy 0.3%;

[0037] Among them, the ferromolybdenum alloy is FeMo55-A molybdenum ferroalloy, the niobium ferroalloy is FeNb60-A niobium ferroalloy, and the vanadium ferroalloy is FeV50-A; the carbon content of the carburizer is ≥98%, the particle size is 2-6mm, and the nodulizer is FeSiMg6Re2 nodulizer, ...

Embodiment 2

[0043] 1. A medium-silicon-molybdenum-niobium ductile iron material, including the following chemical composition in mass percentage: C 3.2%, Si 4.2%, Mn0.28%, P 0.005%, S 0.012%, Mo 0.8%, Ni 0.9%, Nb 0.4%, Mg 0.03%, V 0.17%, the balance is Fe and other unavoidable elements.

[0044] Its preparation method comprises the following preparation steps:

[0045] (1) Batching process: The selected raw materials and the quality ratio of raw materials are 45% of C04 high-purity pig iron, 48% of steel scrap, 0.6% of recarburizer, 1.2% of silicon carbide, 1.5% of molybdenum-iron alloy, 1.4% of niobium-iron alloy, and 0.8% of nickel plate %, ferrosilicon alloy 1%, vanadium iron alloy 0.5%;

[0046] Among them, the ferromolybdenum alloy is FeMo55-A molybdenum ferroalloy, the niobium ferroalloy is FeNb60-A niobium ferroalloy, and the vanadium ferroalloy is FeV50-A; the carbon content of the carburizer is ≥98%, the particle size is 2-6mm, and the nodulizer is FeSiMg6Re2 nodulizer, The par...

Embodiment 3

[0052] 1. A medium-silicon-molybdenum-niobium ductile iron material, including the following chemical composition in mass percentage: C 2.8%, Si 4.5%, Mn0.1%, P 0.04%, S 0.015%, Mo 0.84%, Ni 0.6%, Nb 0.7%, Mg 0.004%, V 0.15%, the balance is Fe and other unavoidable elements.

[0053] Its preparation method comprises the following preparation steps:

[0054] (1) Batching process: The selected raw materials and the quality ratio of raw materials are 37% of C04 high-purity pig iron, 55% of steel scrap, 1.2% of recarburizer, 1.2% of silicon carbide, 2% of molybdenum-iron alloy, 1.1% of niobium-iron alloy, and 0.6% of nickel plate %, ferrosilicon alloy 1.4%, vanadium iron alloy 0.5%;

[0055] Among them, the ferromolybdenum alloy is FeMo55-A molybdenum ferroalloy, the niobium ferroalloy is FeNb60-A niobium ferroalloy, and the vanadium ferroalloy is FeV50-A; the carbon content of the carburizer is ≥98%, the particle size is 2-6mm, and the nodulizer is FeSiMg6Re2 nodulizer, The par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com