Patents

Literature

32results about How to "Increase the number of graphite balls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength high-tenacity cast-state QT700-10 and production method thereof

ActiveCN106811676AIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

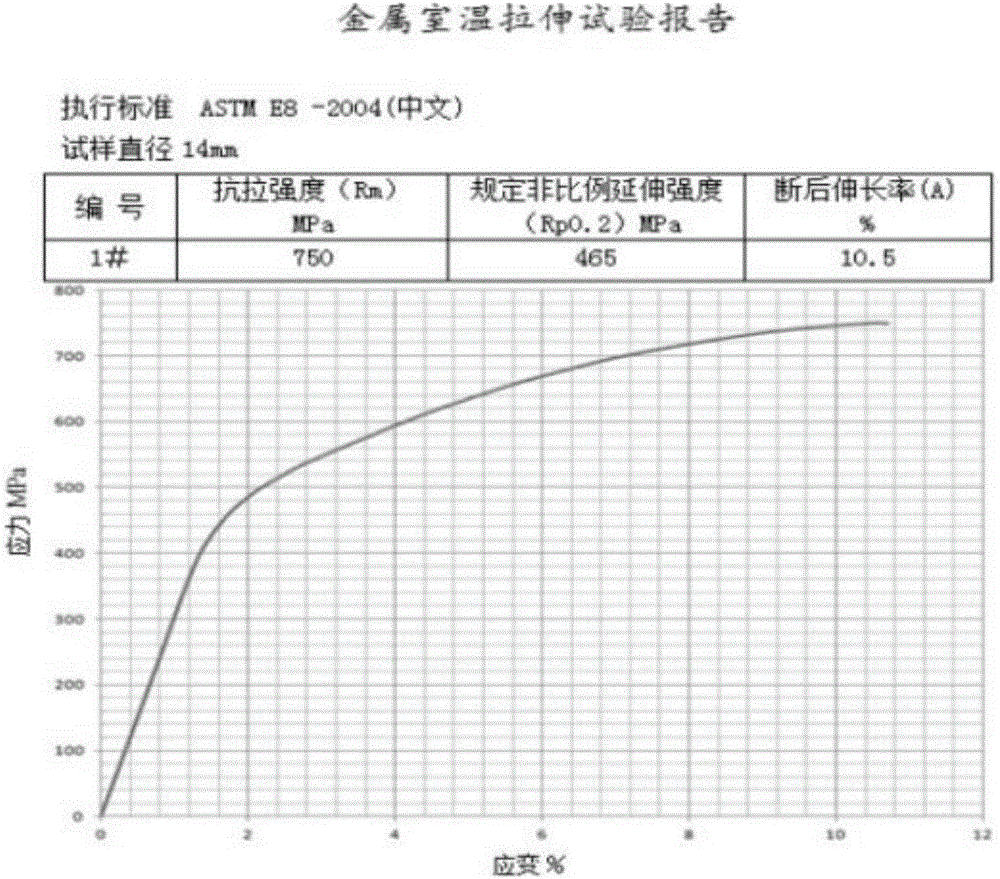

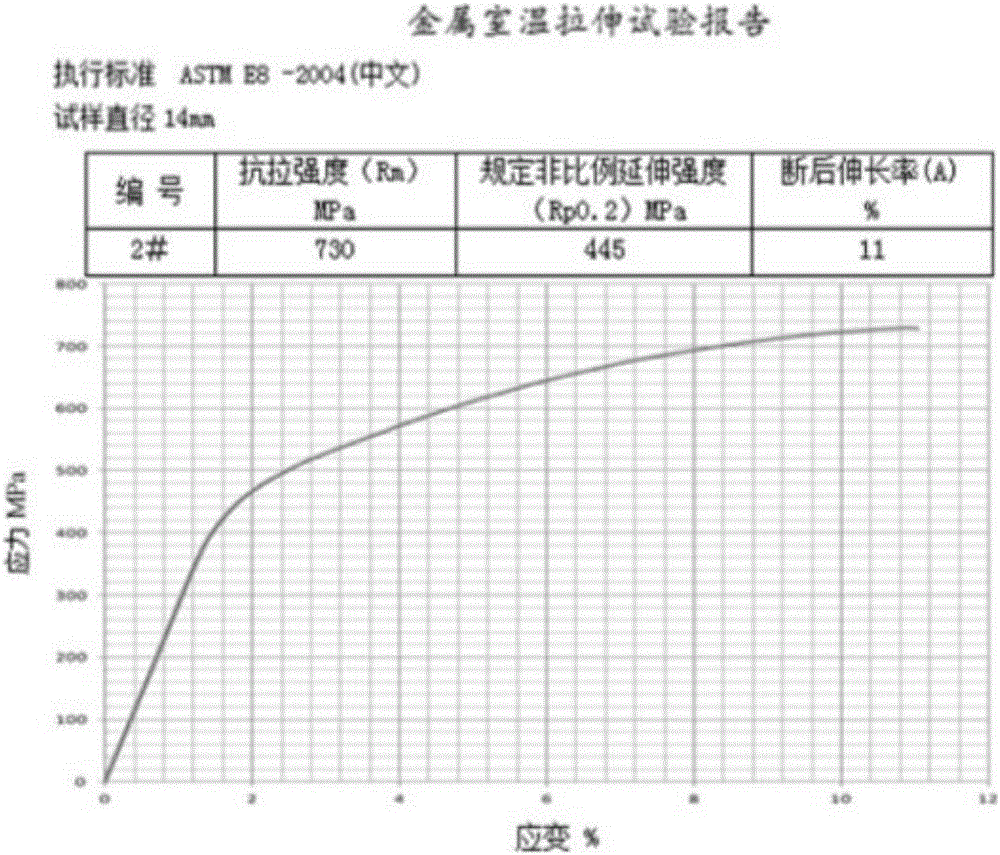

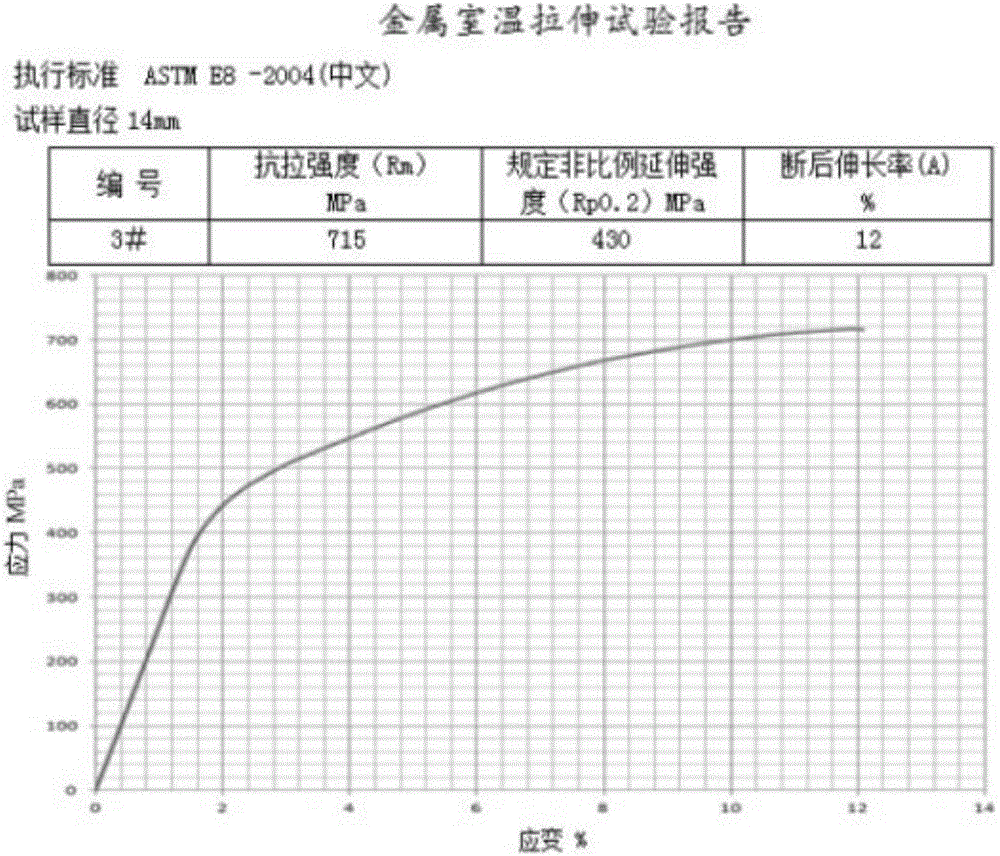

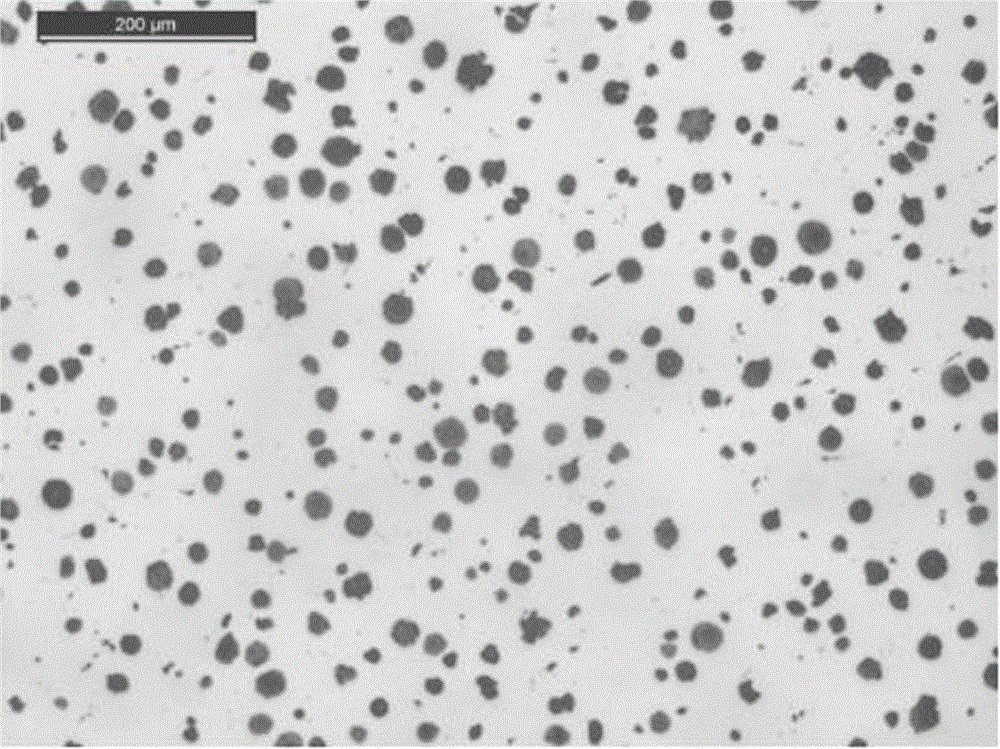

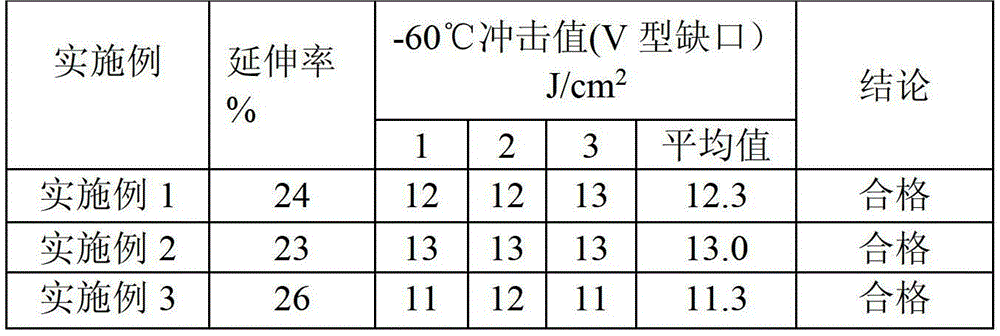

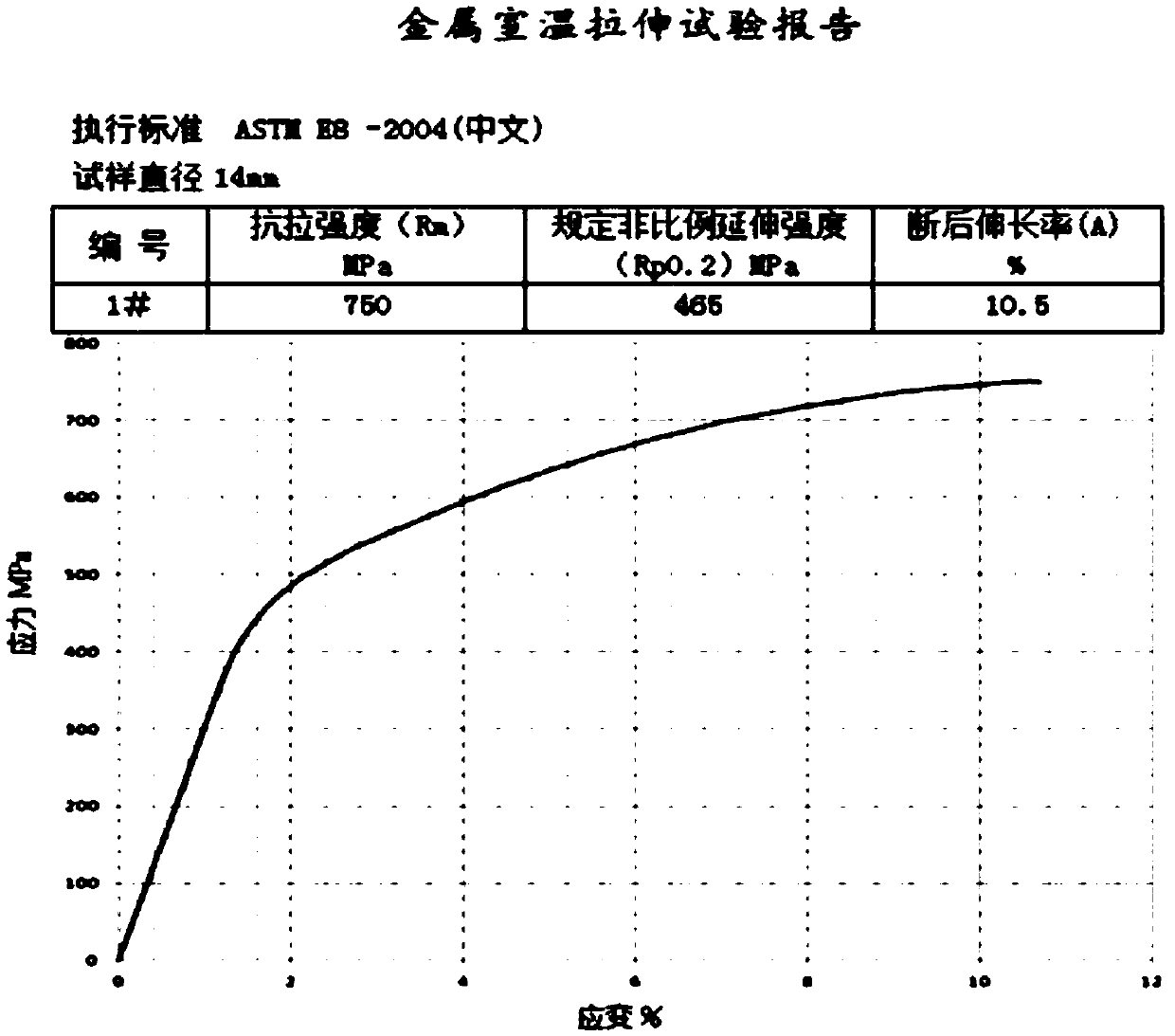

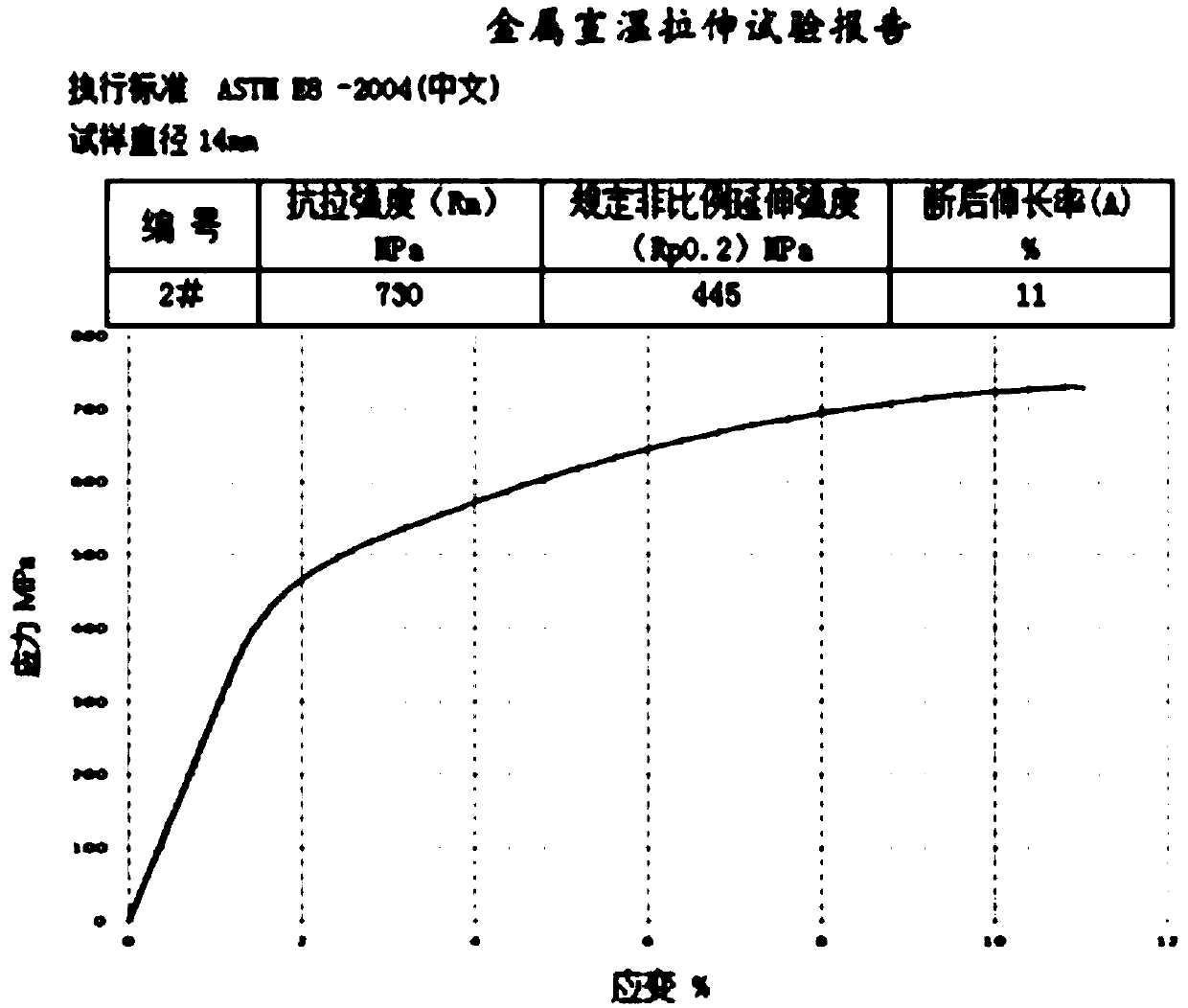

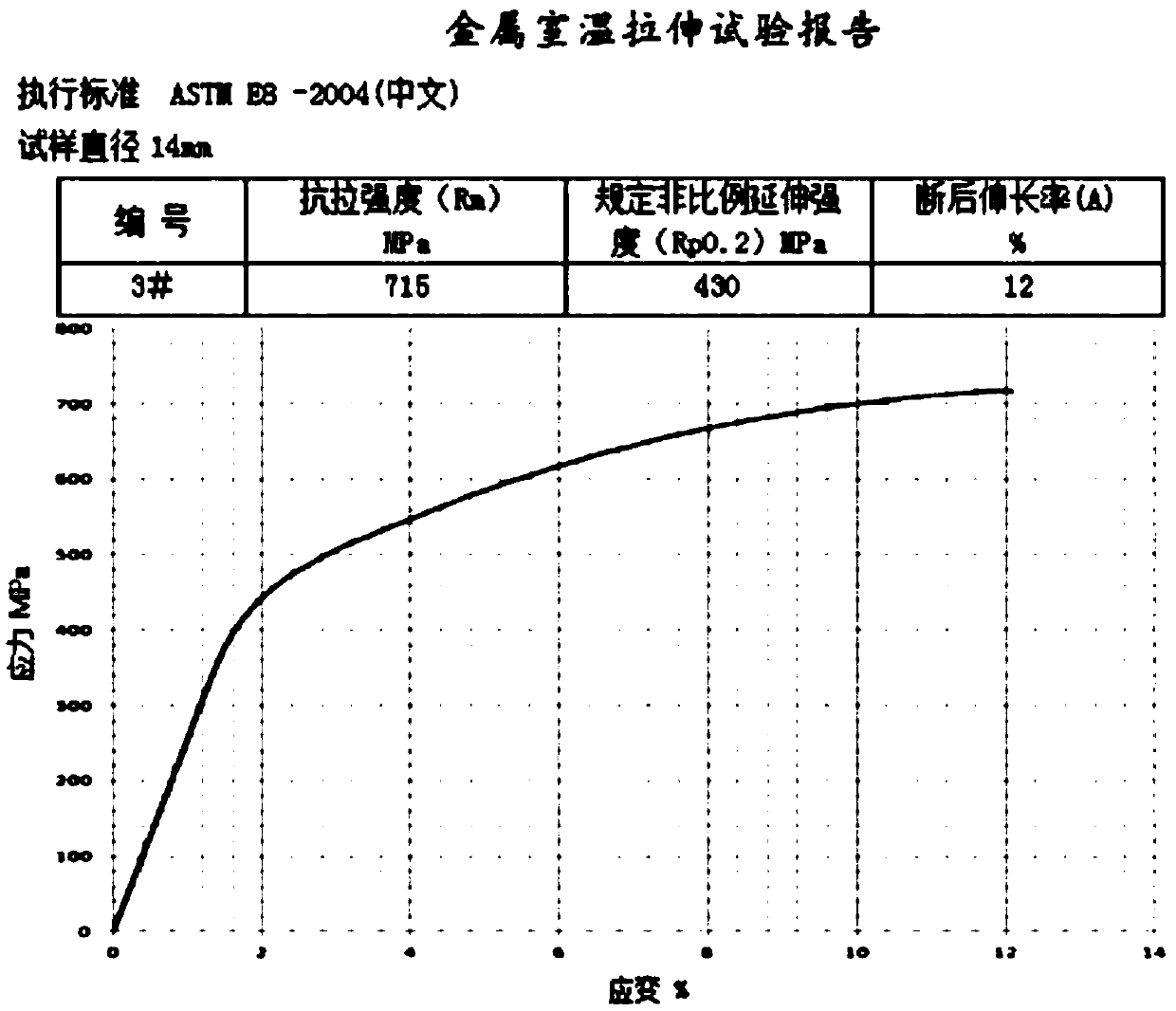

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

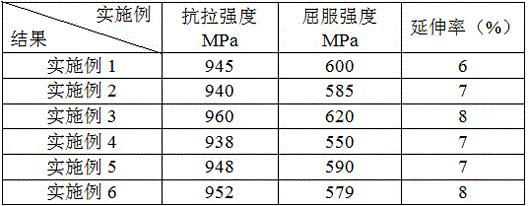

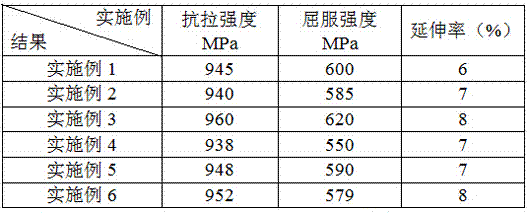

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

Nodulizer Companion

The invention relates to a nodulizing agent partner used for producing nodular cast iron. When the nodulizing agent partner used for producing nodular cast iron is used together with the nodulizing agent, decaying spheroidisation time of molten iron can be delayed, the nodulizing level of nodular iron casting is improved and stabilized, and the number of graphite nodules in the nodular iron is increased. The nodulizing agent partner used for producing nodular cast iron comprises the following elements in parts by weight: 11-13 parts of Ba, 6-11 parts of Bi, 0-10 parts of Sb, 13-15 parts of La, 7-9 parts of Ce, 40-44 parts of Si and 9-15 parts of Fe.

Owner:南平市建阳区月玥工贸有限公司

High-silicon solution-strengthening ferrite spheroidal graphite iron casting and manufacturing method thereof

InactiveCN108611551AReduce the content of trace elementsGuaranteed to beProcess efficiency improvementSlagDuctile iron

The invention relates to a high-silicon solution-strengthening ferrite spheroidal graphite iron casting, and further relates to a manufacturing method of the high-silicon solution-strengthening ferrite spheroidal graphite iron casting. The high-silicon solution-strengthening ferrite spheroidal graphite iron casting comprises the components of, by weight, 3.25%-3.35% of C, 3.70%-3.80% of Si, 0.15%of Mn or the less, 0.03% of P or the less, 0.012% of S or the less, 0.035%-0.05% of Mg, 0.004%-0.015% of Re, 0.004%-0.006% of Sb and the balance iron. The manufacturing method comprises the steps of raw material batching, smelting in a cupola, molten iron desulphurization, smelting in an electric furnace, sampling analysis and blending, tapping, spheroidization and primary inoculation treatment, slag removal, and pouring. The high-silicon solution-strengthening ferrite spheroidal graphite iron casting and the manufacturing method thereof have the advantage that the defects of shrinkage porosity and cavity generated when the QT500-14 spheroidal graphite iron casting with the wall thickness being larger than 60 mm is manufactured by high-silicon solution-strengthening ferrite spheroidal graphite cast iron can be effectively overcome.

Owner:宁波日星铸业有限公司

High-strength sulfur-oxygen nucleating agent

The invention provides a high-strength sulfur-oxygen nucleating agent. The high-strength sulfur-oxygen nucleating agent comprises the following elements in percentages by mass: 70-76% of Si, 0.2-1.0%of Ca, 0.3-0.5% of Ba, 1.5-2.0% of La, 0.5-1.5% of Al, 0.3-0.9% of S, 0.3-0.9% of O, 0.5-1.5% of Sb and the balance of iron. The sulfur-oxygen nucleating agent is prepared from the following raw materials in parts by weight: 2-4 parts of steel scrap, 130-140 parts of silicon iron, 1-1.4 parts of silicon barium, 1-1.8 parts of calcium silicon, 2-4 parts of pure lanthanum, 1.5-2.5 parts of stibonium, 1-2 parts of FeS and 1-1.4 parts of FeO. By the prepared high-strength sulfur-oxygen nucleating agent, the number of graphite nodules in nodular cast iron can be increased obviously, the strength and toughness of the nodular cast iron can be improved, the chilling tendency of the nodular cast iron is relieved obviously, the nodularity, the number of graphite nodules and the number of ferrites ofthe nodular cast iron are increased, shrinkage in a casting process is eliminated, and complicated castings with excellent quality can be formed.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

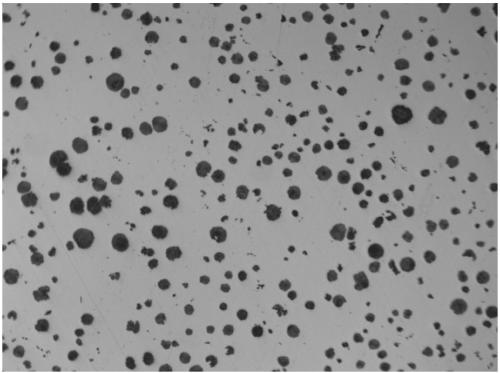

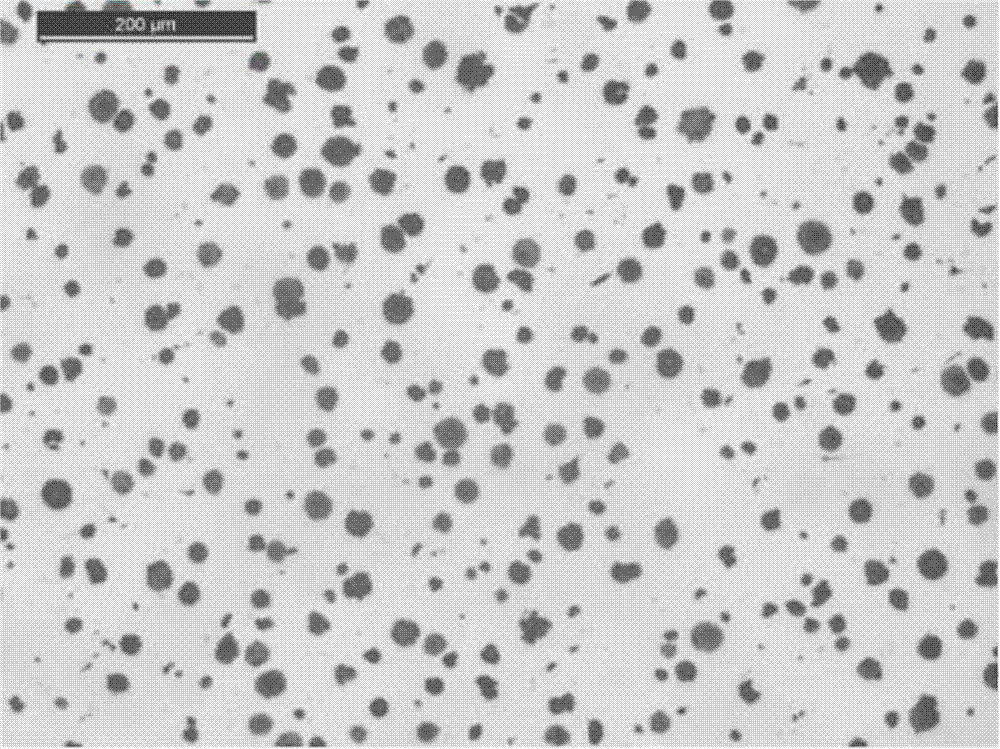

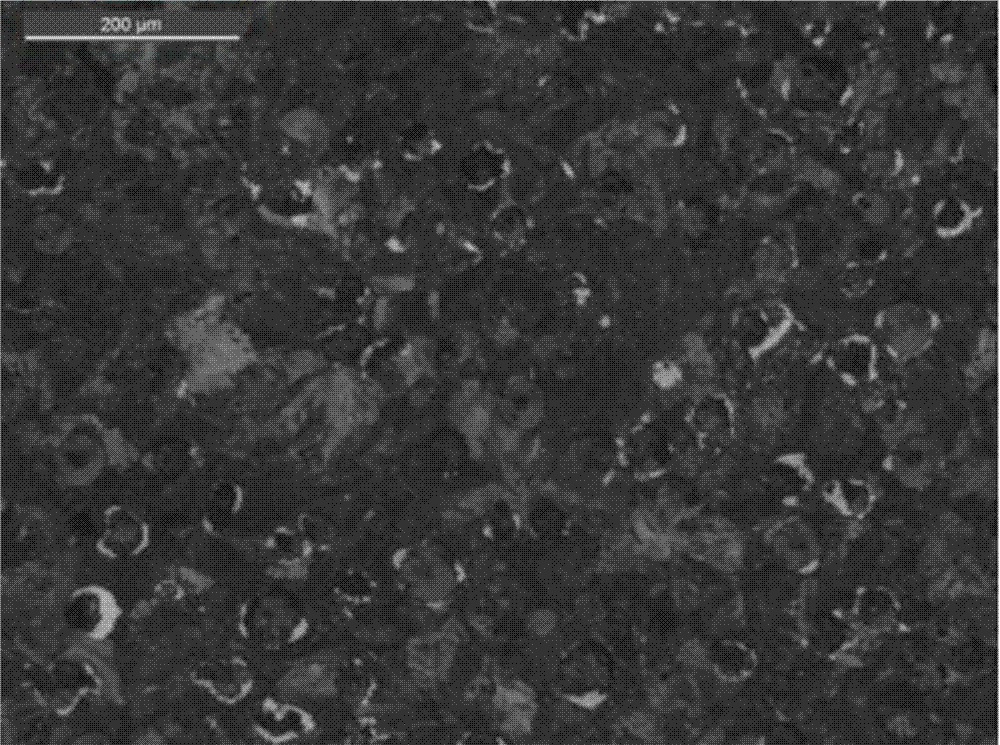

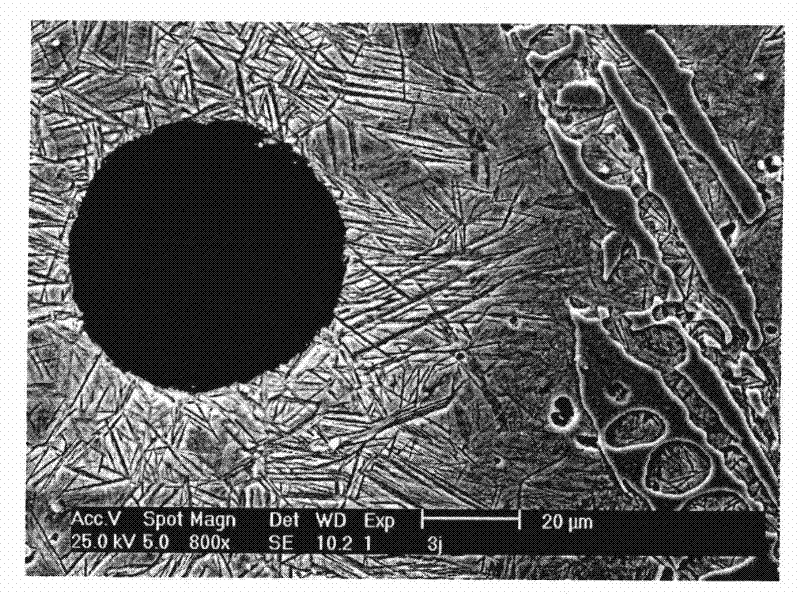

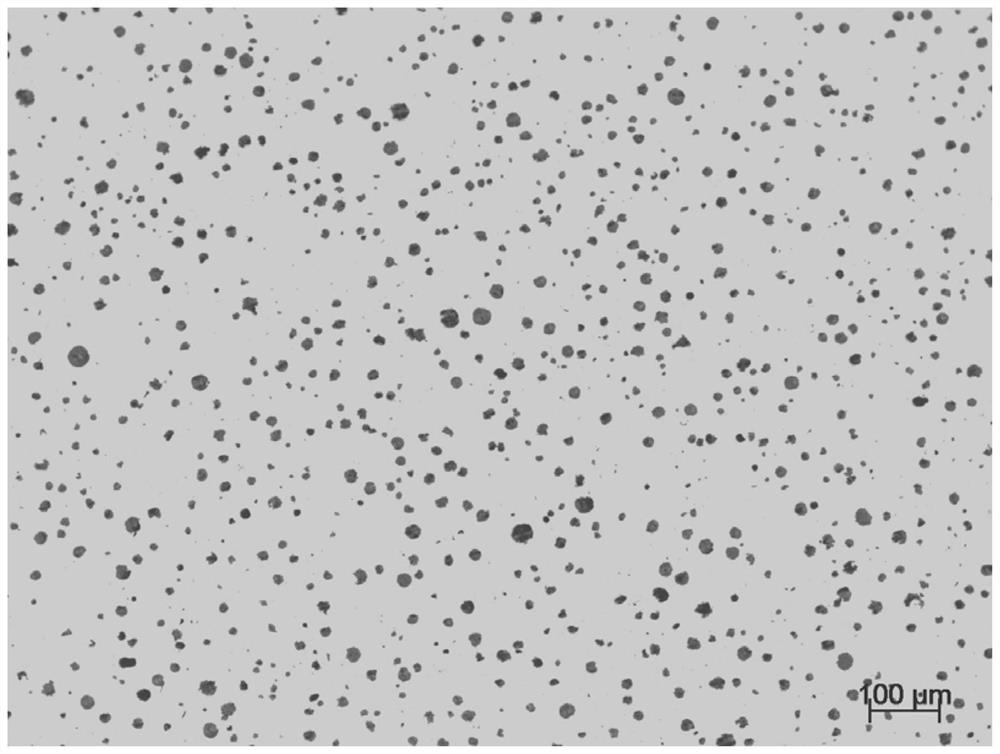

Control method for increasing number of graphite nodule by solid solution strengthening ferrite nodular cast iron with thick and large cross section

ActiveCN109402491AGuaranteed performanceGuaranteed uniformityProcess efficiency improvementPerformance indexSolid solution strengthening

The invention discloses a control method for increasing the number of graphite nodules by solid solution strengthening ferrite nodular cast iron with a thick and large cross section, which comprises the following steps: selecting materials: 50-70 percent of pig iron and 30-50 percent of scrap steel; smelting: adding the materials into an electric furnace for smelting, wherein the tapping temperature of the molten iron is 1420-1450 DEG C; spheroidizing: adding a spheroidizing agent, adding a covering agent on the spheroidizing agent, and then spheroidizing, wherein the spheroidizing temperatureis 1420-1450 DEG C; inoculating: adding a silicon-aluminum-calcium-barium type inoculant during a primary inoculation, and respectively adding the inoculant on the surface of the covering agent and the other side of a ladle dam before tapping, wherein the distribution proportion is 50 percent; adding a trace amount of alloy Sb along with the flow of the molten iron during casting, wherein the adding amount of the alloy Sb is 0.003-0.005% of the total amount of the molten iron, molding, casting and cooling: ensuring that the casting opening temperature is controlled to be <= 300 DEG C, and thecasting is obtained by air cooling after the casting is opened. The control method has the advantages of obtaining higher number of the graphite nodules, ensuring a metallographic structure and goodconsistency of performance indexes, thereby improving the quality of the castings and prolonging the service life.

Owner:宁波日星铸业有限公司

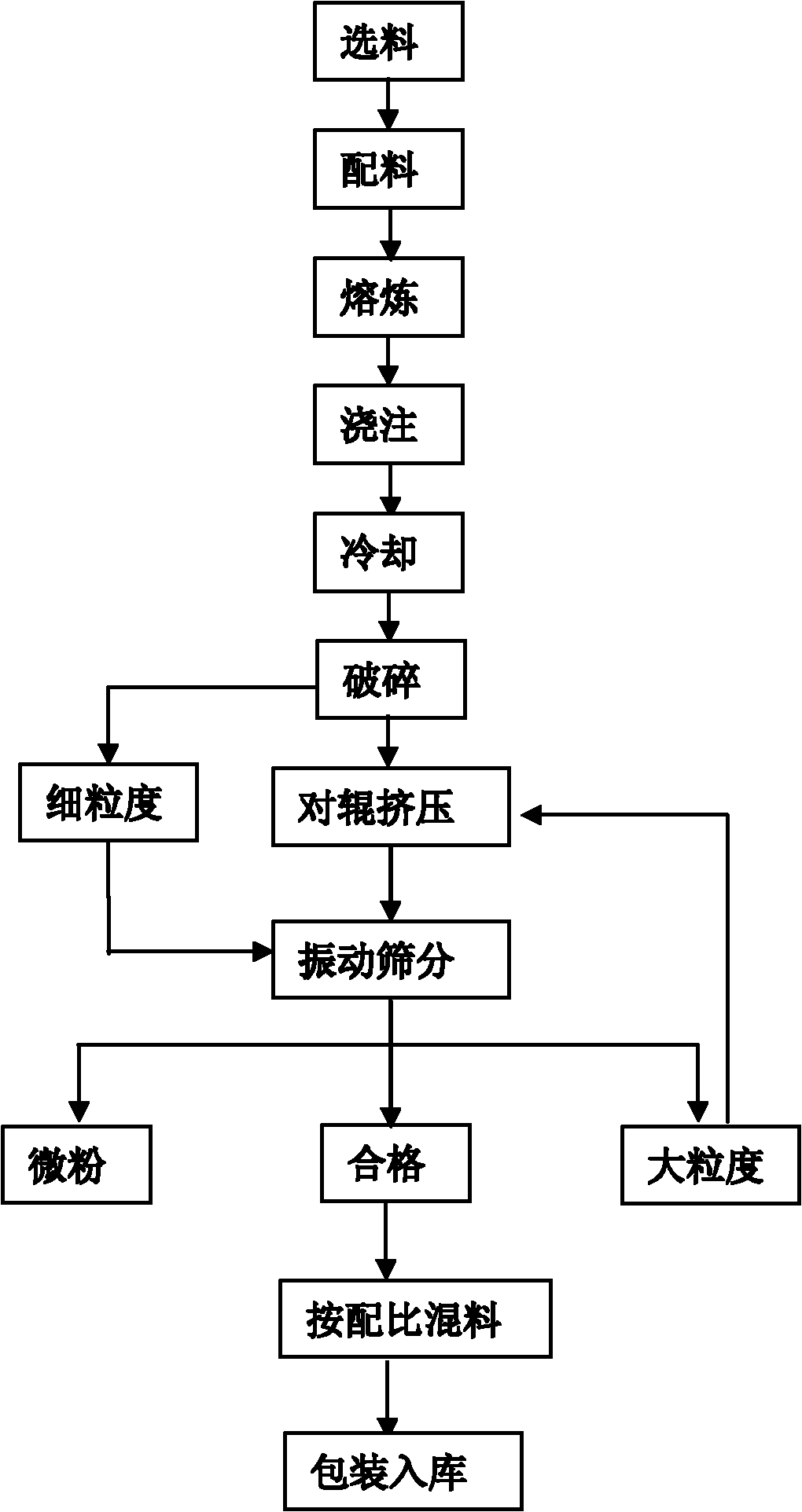

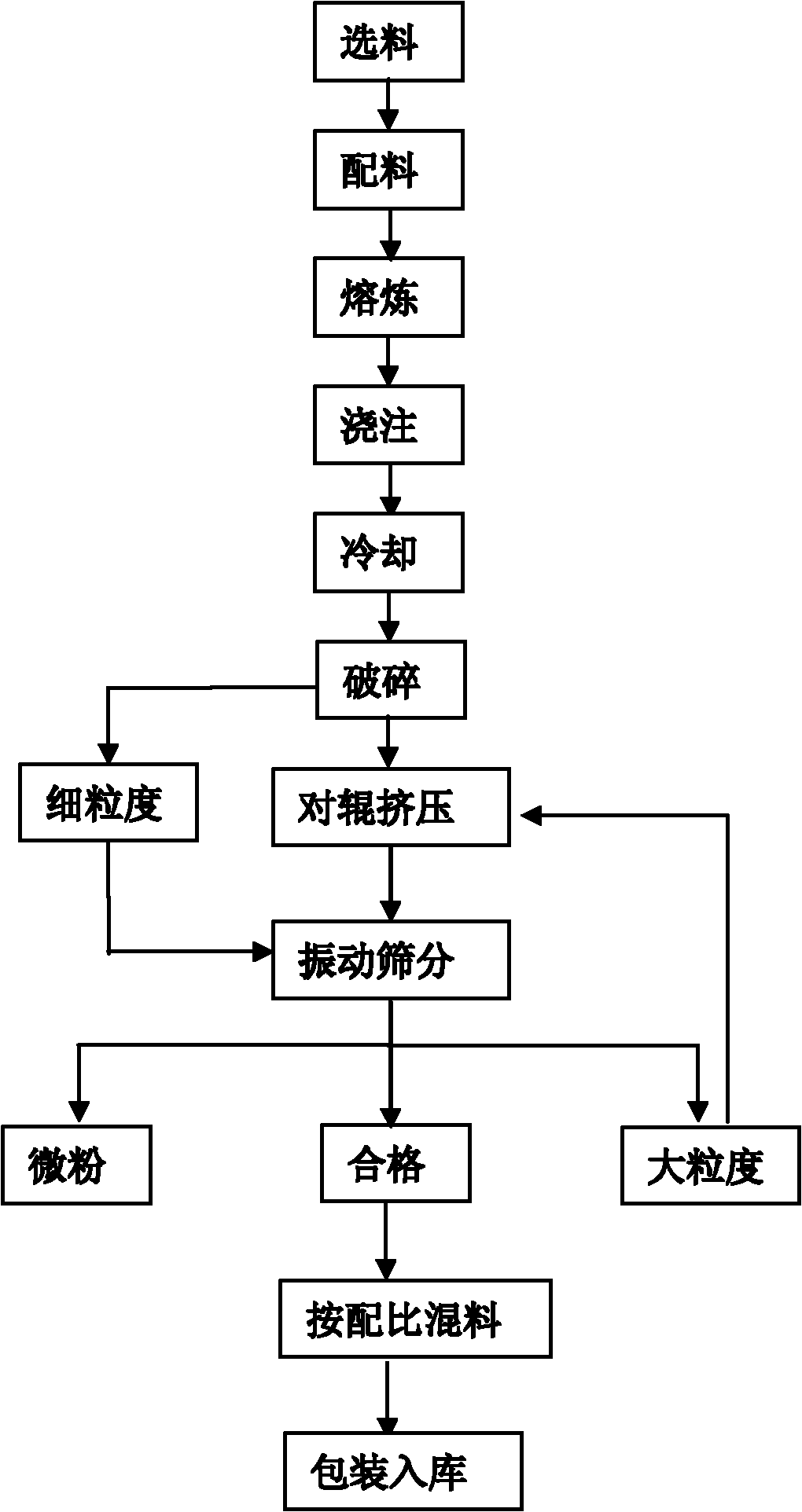

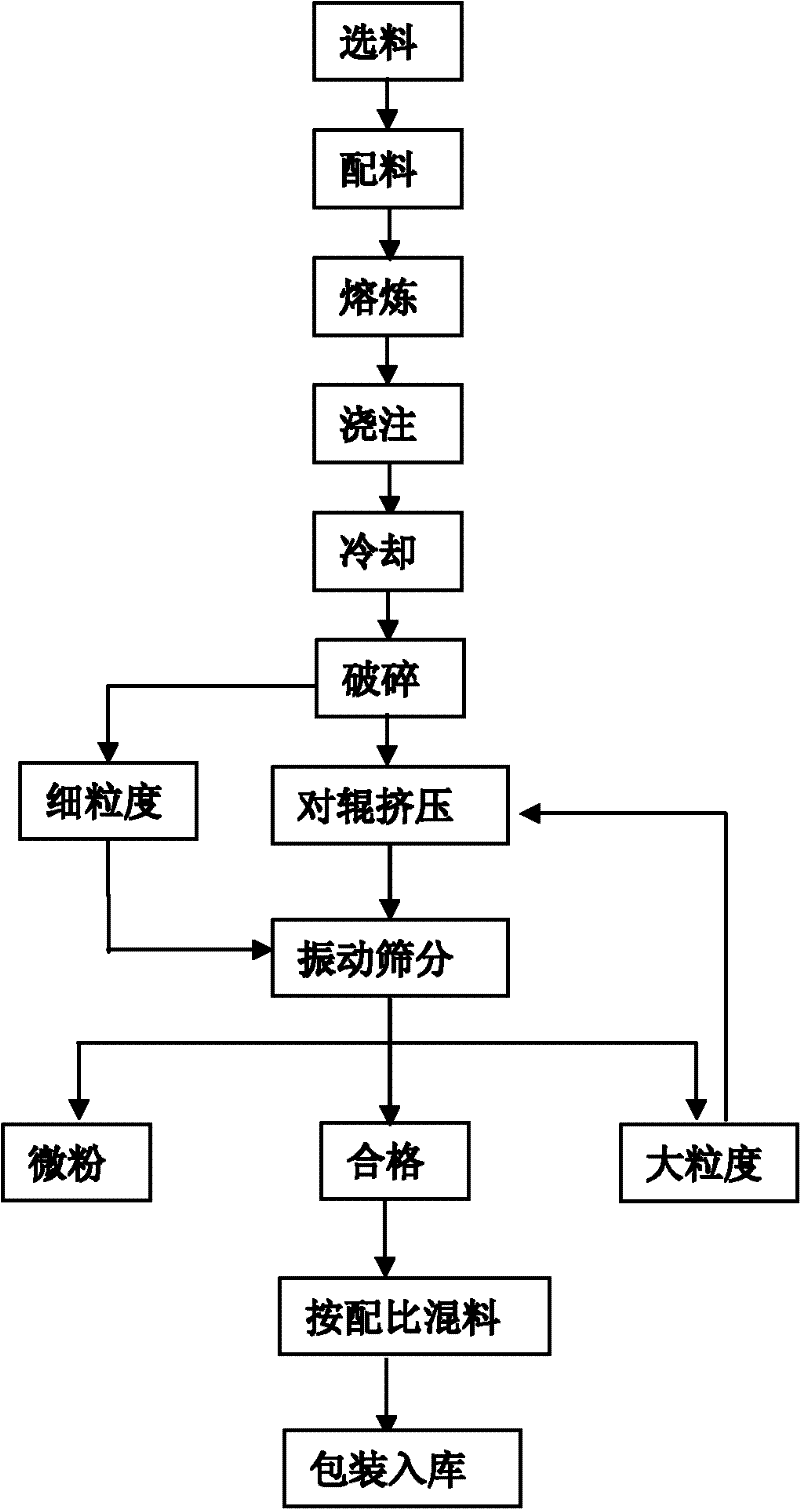

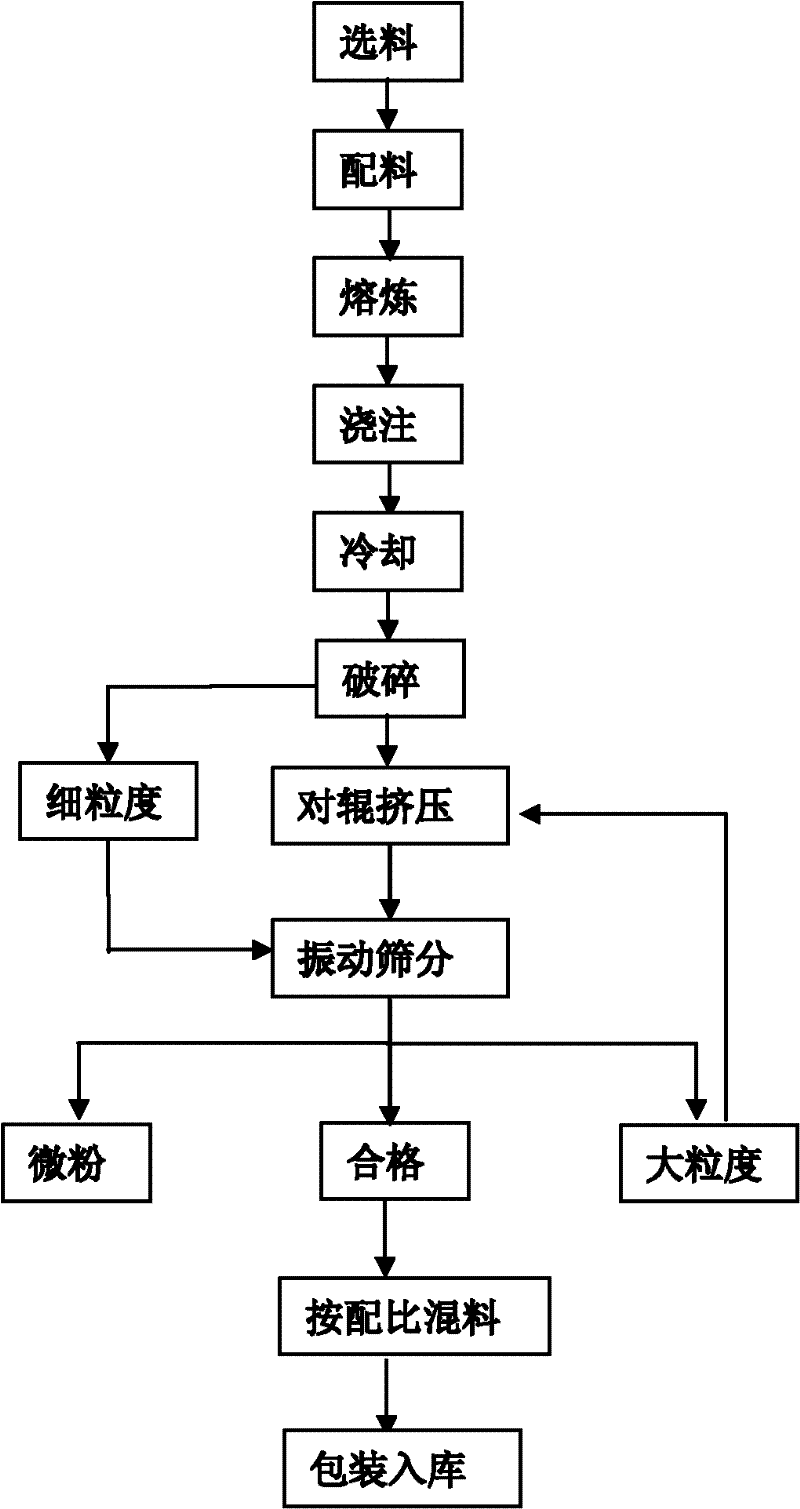

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

Method for preparing megawatt wind power high-strength high-toughness and low-temperature spheroidal iron casting

The invention relates to a method for preparing a megawatt wind power high-strength high-toughness and low-temperature spheroidal iron casting. The method comprises the following steps of: smelting cast iron serving as a raw material, wherein the smelting temperature is between 1,400 and 1,450 DEG C; spheroidizing, inoculating and recarburizing the raw material, wherein the spheroidizing temperature and the inoculating temperature are between 1,350 and 1,400 DEG C; and casting the obtained product to obtain the low-temperature Ni-free spheroidal iron casting. The formula of the spheroidal iron casting comprises the following components: 3.6 to 3.9 wt percent of C, 1.7 to 2.3 wt percent of Si, 0.1 to 0.3 wt percent of Mn, 0.01 to 0.06 wt percent of Sn, and 0.03 to 0.07 wt percent of residual Mg content. The components of high-strength high-toughness and low-temperature spheroidal iron are obtained by adding a spheroidizing agent and an inoculating agent and using a post inoculation method, wherein the spheroidizing agent comprises the following components: 5 to 8 wt percent of Mg, 1 to 2 wt percent of Re, 40 to 50 wt percent of Si, and balance of Fe. The method can make domestically-manufactured cast iron reach high strength and high toughness as cast condition by optimizing spheroidizing and inoculating methods and recarburization treatment under the condition of adding Sn.

Owner:JIANGSU JIXIN WIND ENERGY TECH

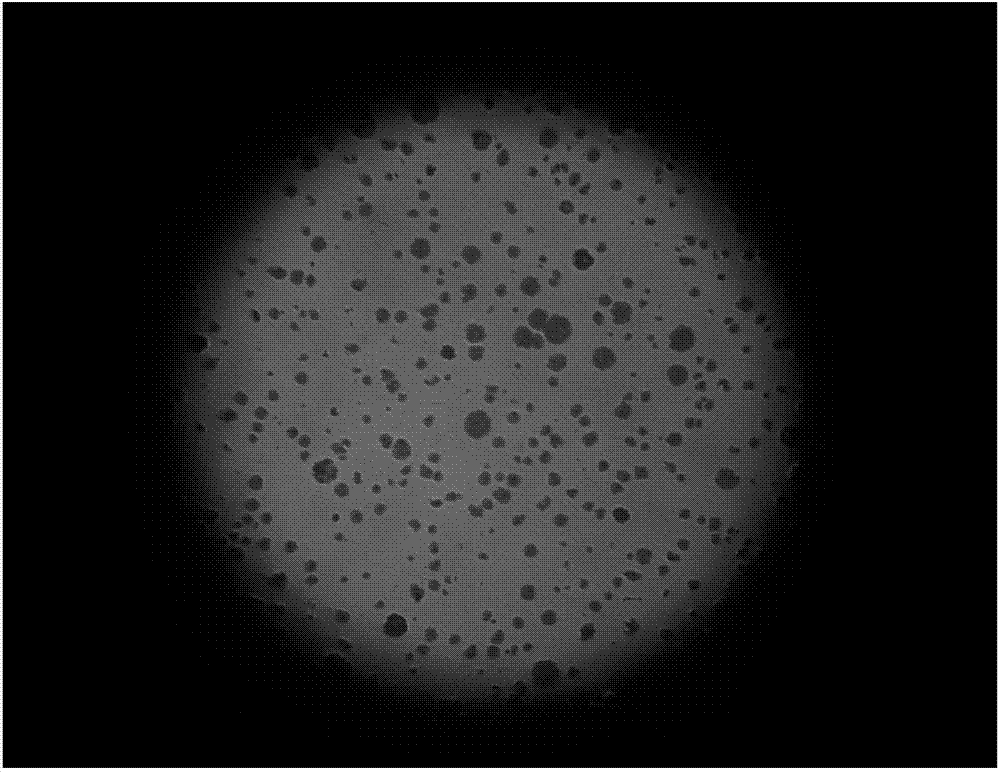

Inoculant for ferritic nodular cast iron and preparation method of inoculant

InactiveCN103146985APromote nucleationImprove the straightness effectExtensibilityChemical composition

The invention discloses an inoculant for a ferritic nodular cast iron and a preparation method of the inoculant, and the inoculant can be used for solving the problems that the nodular graphite cast iron prepared by an existing inoculant is less in graphite nodule quantity, low in ferrite content and poor in extensibility and impact ductility. The inoculant for the ferritic nodular cast iron comprises the following chemical compositions in percentage by mass: 65-70% of Si, 1.0-5.0% of Bi, 2.0-5.0% of Ca, 1.0-4.0% of Ba, less than 0.5% of Al, less than 0.05% of T1, less than 0.4% of Mn, less than 0.02% of S, less than 0.05% of P, and the balance of Fe; and the inoculant is prepared by smelting and granulating the raw materials. The ferritic nodular cast iron produced by using the inoculant can accelerate graphite nucleation, reduce the chilling tendency, increase the graphite nodule quantity, improve the graphite nodule element integration action, further improve the ferrite content under a cast condition, and improve the extensibility and impact ductility of ductile iron.

Owner:SHANDONG HUIFENG CASTING TECH

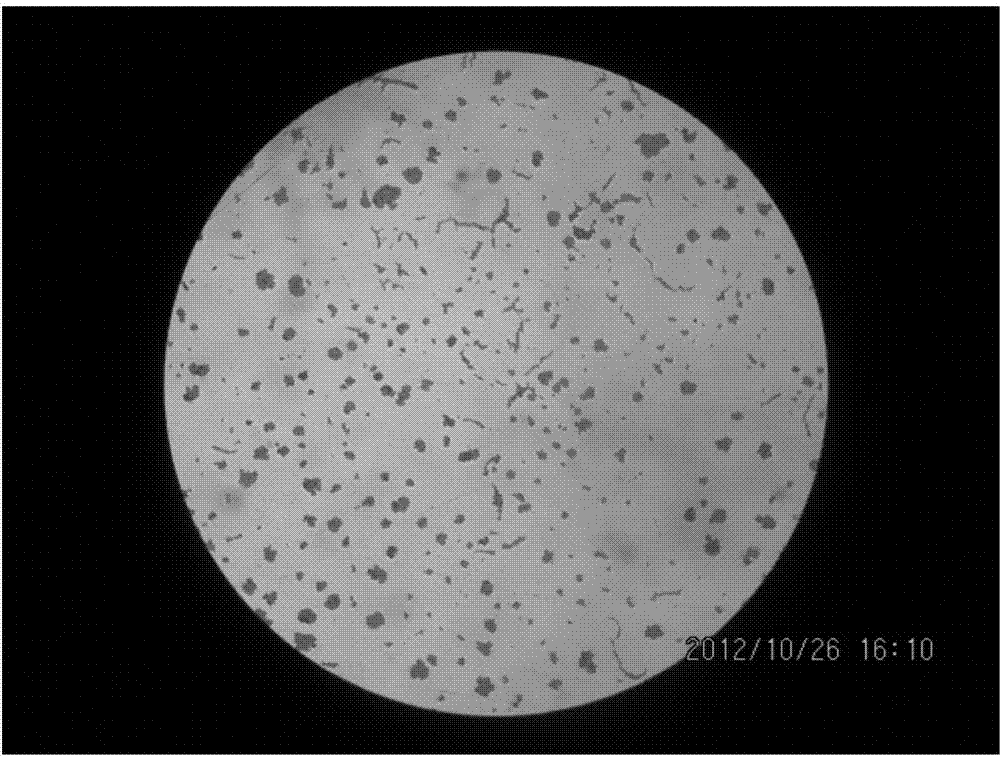

As-cast high-strength high-elongation synthetic nodular cast iron and preparation method thereof

The invention relates to the field of as-cast high-strength high-elongation synthetic nodular cast iron. The invention relates to as-cast high-strength high-elongation synthetic nodular cast iron anda preparation method thereof. The nodular cast iron is characterized in that under the as-cast condition, the nodular cast iron meets performance requirements that the tensile strength Rm is larger than or equal to 700 MPa, and the percentage elongation A after fracture is larger than or equal to 10%; the matrix is a pearlite-ferrite mixed matrix; the content of pearlite is 55%-75%, a spheroidizing grade is 1-2, a graphite size grade is 6-7, the nodular cast iron is composed of elements, by mass, 3.5%-3.7% of C, 2.9-3.3% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.035% ofP, less than or equal to 0.02% of S, 0.5%-0.7% of Cu, 0.55%-0.75% of Ni, 0.030%-0.065% of Mg and the balance of Fe and trace elements. The method has the beneficial effects that scrap steel and raw material pure iron are adopted for recarburization, base iron is smelted in a medium-frequency induction furnace, then pretreatment, spheroidizing treatment and inoculation treatment are conducted, final pouring is conducted, and QT700-10 is achieved under the as-cast condition.

Owner:湖北三环铸造股份有限公司

Preparation method of pipe mold powder for nodular cast iron and application thereof

Owner:成都宏源铸造材料有限公司

Production process of QT500-12 spheroidal graphite iron casting

The invention discloses a production process of a QT500-12 spheroidal graphite iron casting. The production process comprises the following steps: A, raw material selection: selecting 60-80 parts of scrap steel, 20-40 parts of scrap returns, 2.5-3.5 parts of a carburant, 0.4-1.0 part of 75# ferrosilicon, 0.3-0.6 part of copper, 1-1.2 parts of a spheroidizing agent, 0.8-1.2 parts of a 75# ferrosilicon inoculant and 0.2-0.4 part of a silicon-strontium inoculant; B, weighing; C, smelting; D, spheroidizing; E, secondary inoculation; and F, pouring. The overall performances of the QT500-12 spheroidal graphite iron casting produced by using the production process are improved, and the tensile strength is larger than or equal to 500Mpa on the premise that the elongation percentage is larger than or equal to 12%; the consistency of a matrix structure of the spheroidal graphite iron casting is also realized, and the local function of the spheroidal graphite iron casting is prevented from being deteriorated; and the weight of the spheroidal graphite iron casting is reduced on the premise that the elongation percentage and tensile strength indexes of the spheroidal graphite iron casting reach standards, so that the lightweight of the spheroidal graphite iron casting is realized.

Owner:山东力嘉轻量化科技有限公司

Preparation method of pipe powder for nodular cast iron and application of pipe powder

The invention discloses pipe powder for nodular cast iron. The formula of the pipe powder comprises the following components in percentage by weight: 62-70% of Si, 3-10% of Ba, 1-2% of Ca, 0.8-1.8% of Al, 0.5-1.5% of Fe3O4, the balance of Fe and inevitable microelements. According to the pipe powder for the nodular cast iron disclosed by the invention, the overall performance of the nodular cast iron can be improved, and the inoculation efficiency is improved.

Owner:成都宏源铸造材料有限公司

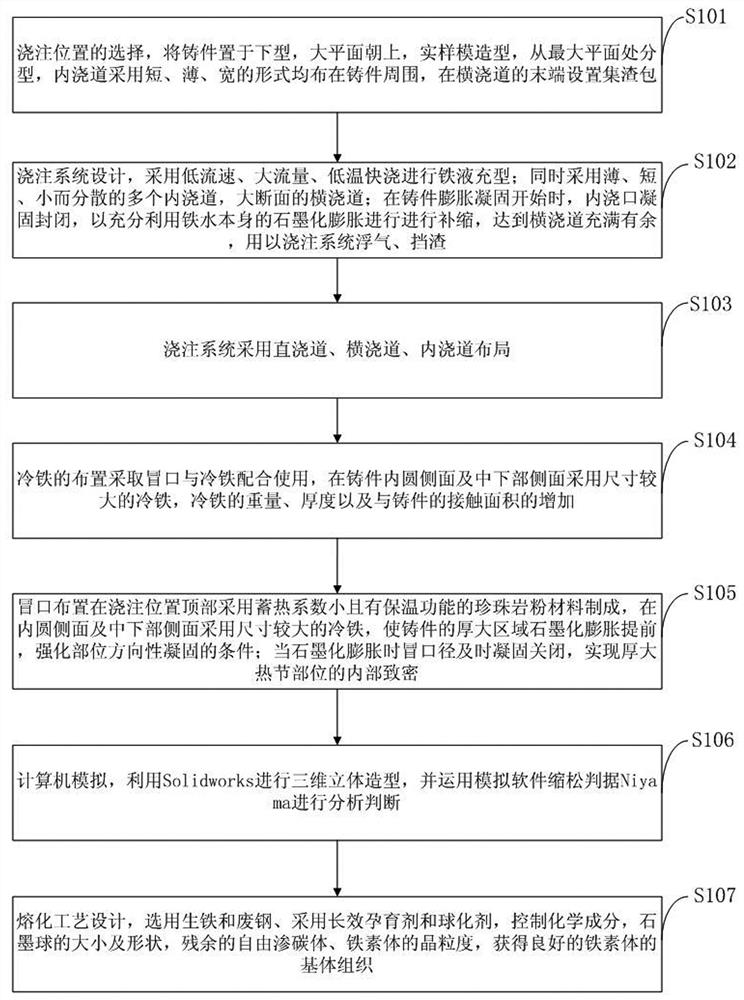

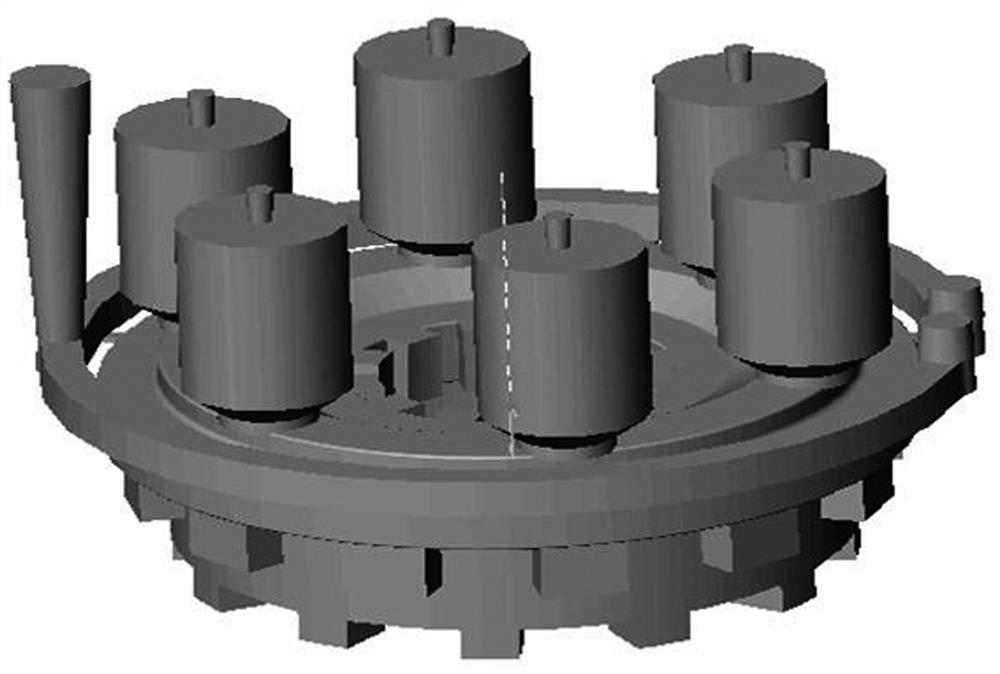

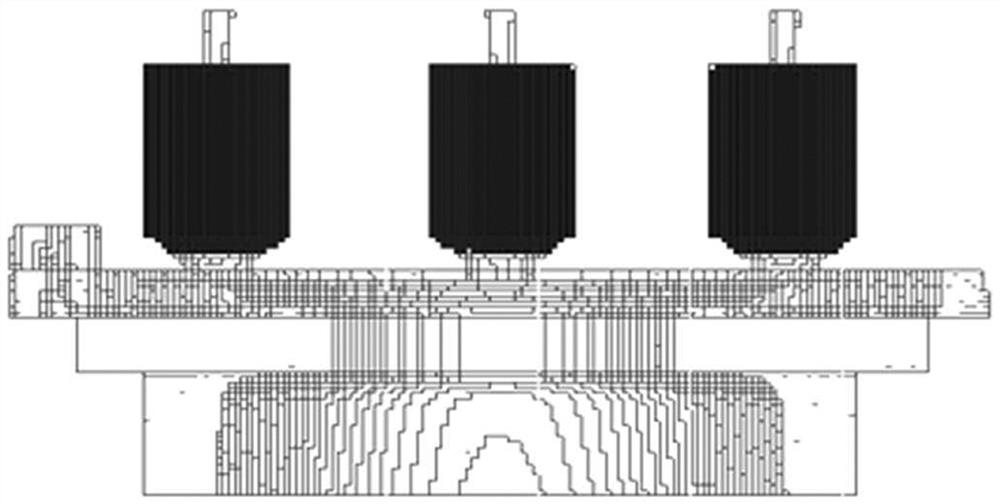

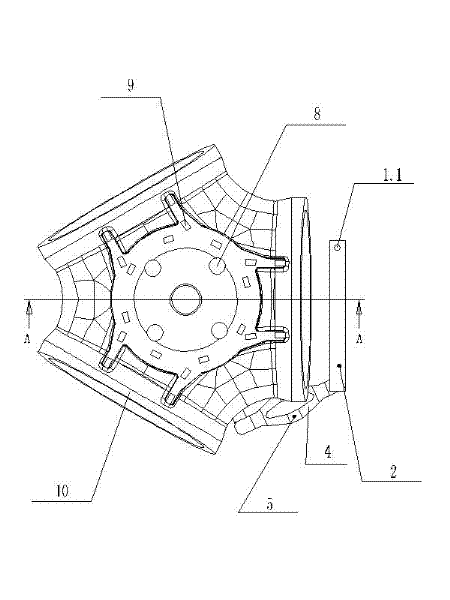

Forming method for medium-high-speed high-power diesel nodular cast iron flywheel

PendingCN111940680AImprove feeding capacityImprove feeding efficiencyFoundry mouldsFoundry coresDieselingDuctile iron

The invention belongs to the technical field of cast iron casting, and discloses a forming method for a medium-high-speed high-power diesel nodular cast iron flywheel. The forming method comprises thesteps: a pouring position is selected, a casting placed in a lower mold, a large plane faces upwards, molding is conducted through a real sample mold, parting is conducted from the maximum plane, andingates are uniformly distributed around the casting in a short, thin and wide form, and a slag collecting ladle is arranged at the tail end of a cross gate; and then through pouring system design, pouring system layout, chiller arrangement, riser arrangement, computer simulation and final melting process design, pig iron and scrap steel are selected, a long-acting inoculant and a nodulizing agent are adopted, chemical components, the size and shape of graphite nodules and the grain size of residual free cementite and ferrite are controlled, and a good ferrite matrix structure is obtained. According to the forming method, the mechanical performance requirements of a medium-high-speed high-power diesel nodular cast iron flywheel iron casting can be effectively met, and casting defects suchas slag inclusion, shrinkage porosity, coarse defect structures and graphite floating are not found.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

Wheel hub of wind turbine generator system (WTGS)

The invention discloses a wheel hub of a WTGS, and the wheel hub is characterized by comprising by weight: 3.80%-3.90% of carbon, 1.8%-2.3% of silicon, less than or equal to 0.3% of manganese, less than or equal to 0.02% of phosphor, 0.01%-0.015% of sulfur, 0.04%-0.06% of magnesium, 0.02%-0.08% of tin, 0.015%-0.025% of rare earth, and the balance iron, with the carbon equivalent controlled within 4.40-4.66. Without the surface defects of dispersed shrinkage, shrinkage cavity, inclusion, pore, sand inclusion, sand hole and the like, the wheel hub of a WTGS in the invention has a low manufacturing cost, and can effectively control shrinkage and obtain proportional solidification without putting a cold iron.

Owner:宁波日星铸业有限公司

Control method for increasing the number of graphite nodules in solid solution strengthened ferritic ductile iron with thick and large section

ActiveCN109402491BEnsure consistencyStable and reliable gating systemProcess efficiency improvementPerformance indexDuctile iron

The invention discloses a control method for increasing the number of graphite nodules by solid solution strengthening ferrite nodular cast iron with a thick and large cross section, which comprises the following steps: selecting materials: 50-70 percent of pig iron and 30-50 percent of scrap steel; smelting: adding the materials into an electric furnace for smelting, wherein the tapping temperature of the molten iron is 1420-1450 DEG C; spheroidizing: adding a spheroidizing agent, adding a covering agent on the spheroidizing agent, and then spheroidizing, wherein the spheroidizing temperatureis 1420-1450 DEG C; inoculating: adding a silicon-aluminum-calcium-barium type inoculant during a primary inoculation, and respectively adding the inoculant on the surface of the covering agent and the other side of a ladle dam before tapping, wherein the distribution proportion is 50 percent; adding a trace amount of alloy Sb along with the flow of the molten iron during casting, wherein the adding amount of the alloy Sb is 0.003-0.005% of the total amount of the molten iron, molding, casting and cooling: ensuring that the casting opening temperature is controlled to be <= 300 DEG C, and thecasting is obtained by air cooling after the casting is opened. The control method has the advantages of obtaining higher number of the graphite nodules, ensuring a metallographic structure and goodconsistency of performance indexes, thereby improving the quality of the castings and prolonging the service life.

Owner:宁波日星铸业有限公司

Short-process manufacturing method for producing casting for wind power generation equipment

The invention provides a short-process manufacture method for producing a casting for wind power generation equipment and relates to manufacture of cast iron alloy. The manufacture method is a short-process manufacture process for producing the thick-large-section casting used for the wind power generation equipment. The short-process manufacture method comprises the steps that molten iron obtained through sintering of iron ore and blast furnace smelting reduction is poured into a medium-frequency induction electric furnace after being subjected to dephosphorization and desulfuration treatment, and scrap steel and foundry returns are added for continued smelting, meanwhile the components of the molten iron are adjusted; then spheroidization and inoculation treatment is conducted; and finally forming is conducted through casting, and the thick-large-section casting used for the wind power generation equipment is produced and obtained. According to the short-process manufacture method, the short-process process is adopted, so that the production efficiency is improved. A cupola furnace is replaced by the medium-frequency induction electric furnace, so that impurities in the molten iron and the temperature in the molten iron are precisely controlled, and the functions of environmental protection, energy saving and consumption reducing are further achieved. A cored wire is used for all dephosphorization, desulfuration and spheroidization, so that the treatment is fast in effect and high in efficiency, and the amount of graphite nodules are effectively increased, and accordingly the high-quality thick-large-section casting used for the wind power generation equipment is obtained.

Owner:匡永刚

Preparation method of solid-solution-strengthened ferritic nodular cast iron for thick and large pieces

InactiveCN110760739ALight in massSimple preparation processProcess efficiency improvementSolid solution strengtheningDuctile iron

The invention discloses a preparation method of solid-solution-strengthened ferritic nodular cast iron for thick and large pieces. The preparation method includes the following steps that (1) pig ironand scrap steel are heated to 1460 DEG C-1520 DEG C to be melted, and the content of the C element is adjusted to 3.0%-4.0% by adding a carburant; (2) molten iron is nodulized by using a covering nodulizing method, the amount of a nodulizing agent added is 1.0%-2.0% of the weight of the original molten iron, and metal elements of Ce and Sb are added while nodulizing is carried out; (3) when a nodulizing incubation bag is prepared and the nodulizing agent is tight, a 75SiFe inoculant with the particle size of 3-8 mm uniformly covers the upper part of the nodulizing agent; (4) 0.04%-0.1% of TiCand TiN mixed nano-powder is added, and a Bi alloy with the weight being 0.004%-0.008% of the weight of the original molten iron is added; (5) metal-stream inoculation is carried out during pouring;and (6) the strengthened ferritic nodular cast iron is obtained after the molten iron is cooled. According to the preparation method of the solid-solution-strengthened ferritic nodular cast iron for the thick and large pieces, after the incubation is completed, the TiC and TiN nano-powder and the Bi element are added, so that the tensile strength and elongation of the nodular cast iron are increased; and the preparation process of the preparation method is simple, the overall weight of the thick and large pieces can be reduced, the cost is low, and industrial production is easy to implement.

Owner:JIANGSU XIHUA FOUNDRY CO LTD

Ductile cast iron as well as ductile cast iron piston and casting process thereof

ActiveCN102912214BReduce shrinkage and shrinkage defectsImprove product qualityFoundry mouldsFoundry coresDuctile ironCasting defect

The invention discloses a ductile cast iron as well as a ductile cast iron piston and a casting process thereof. The ductile cast iron comprises the following components in percentage by weight: 3.50-3.60 percent of C, 1.90-2.10 percent of Si, greater than 0.50 percent and not more than 0.60 percent of Mn, greater than 0 percent and not more than 0.030 percent of P, greater than 0 percent and not more than 0.01 percent of S, 0.50-0.60 percent of Cu, 0.010-0.030 percent of RE, 0.030-0.050 percent of Mg and the balance of Fe. The ductile cast iron piston is produced by the ductile cast iron. The ductile cast iron piston is produced by coating thin-layer molding sand on a roughly-formed iron mold inner cavity. The filling, solidifying and cooling steps of a casting are finished under one perfect condition by reasonably controlling the quality and the wall thickness of the iron mold and the thickness of the coating sand layer, so that the factors for generating casting defects are eliminated to the maximum extent and further the quality of the casting is greatly improved.

Owner:GUANGDONG ZHONGTIAN CHUANGZHAN DUCTILE IRON CO LTD

Pipe die powder for centrifugally casting nodular cast iron pipe and preparation process thereof

The invention discloses pipe die powder for centrifugally casting a nodular cast iron pipe and a preparation process thereof. The pipe die powder comprises the following components in percent by mass: 60-65 percent of Si, 1.5-2.0 percent of Ca, 2.0-3.0 percent of Ba, 1.4-1.6 percent of Mn, 1.0-1.5 percent of Mg, 1.0-2.0 percent of Zr, 0.7-1.5 percent of Al and the balance of Fe; and the granularities of pipe die powder comprise less than 1.5 percent of 80 mu, 25-30 percent of 100-120 mu, 40-50 percent of 140-180 mu, 25-30 percent of 200-300 mu and less than 2.5 percent of more than 300 mu. The preparation process comprises the following steps of: preparing, melting, pouring, cooling, crushing, milling, proportioning granularities and packaging in vacuum. The pipe die powder has the advantages of uniform components, consistent melting points and reasonable granulometric class, and is beneficial to the prolonging of the service life of a pipe die of the nodular cast iron pipe, the reduction of a series of casting defects of cockles, poor nodulizing, surface cracks and the like of the nodular cast iron pipe, the improvement of the quality of the nodular cast iron pipe and the yield, and the lowering of the production cost.

Owner:YUZHOU HENGLILAI ALLOY CO LTD

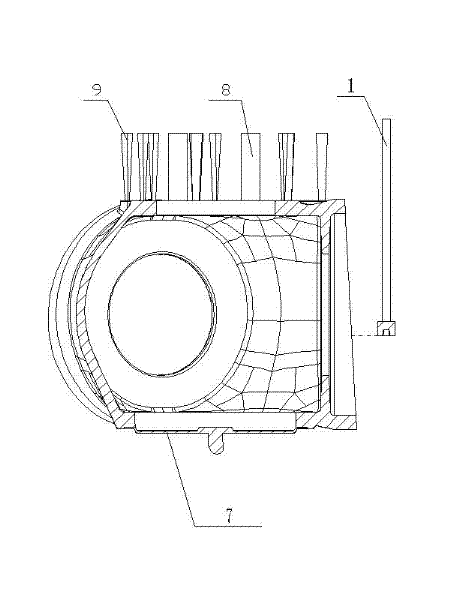

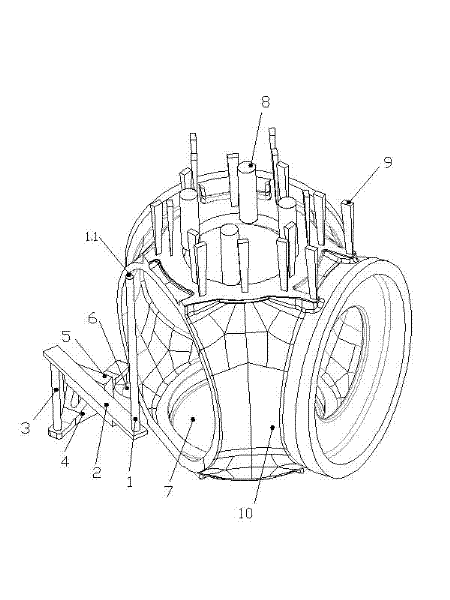

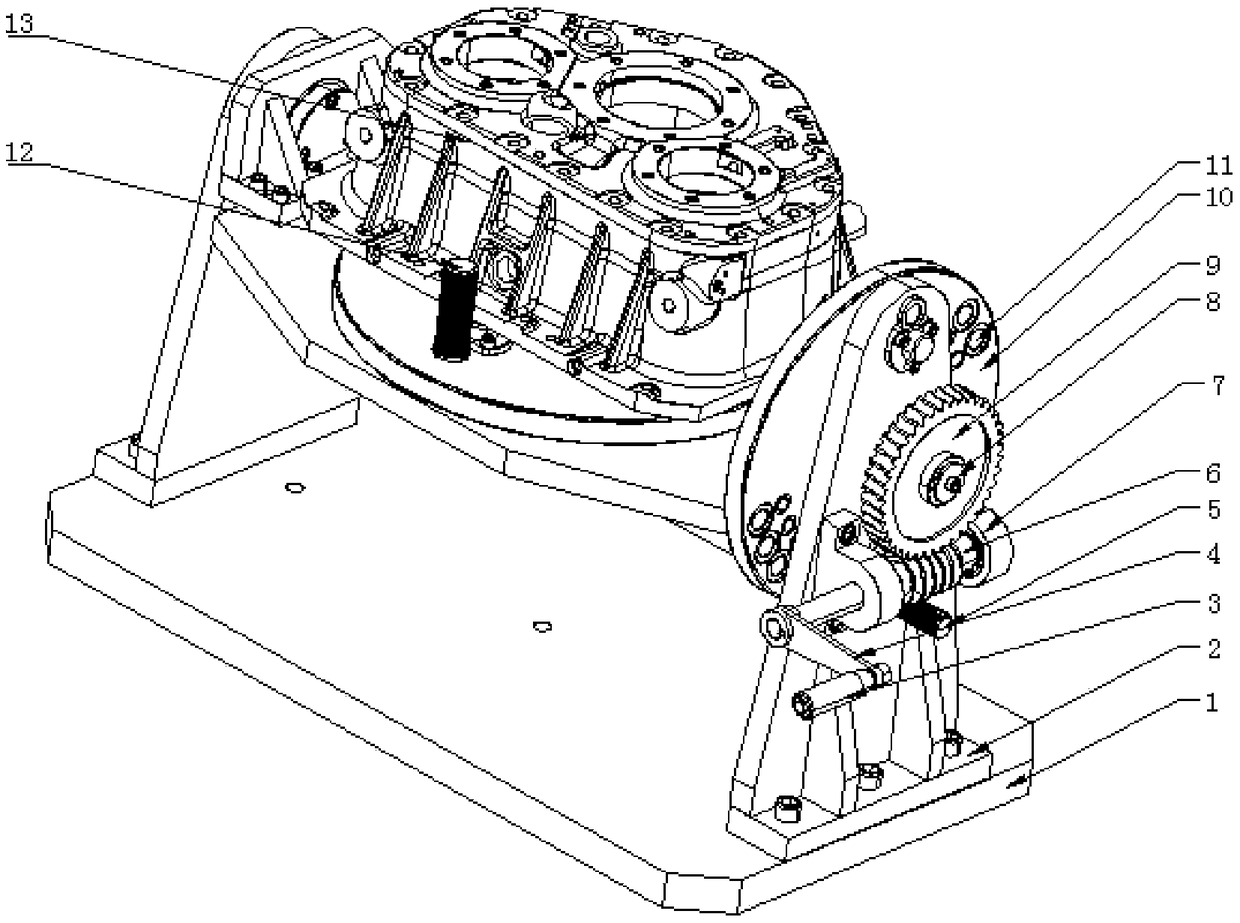

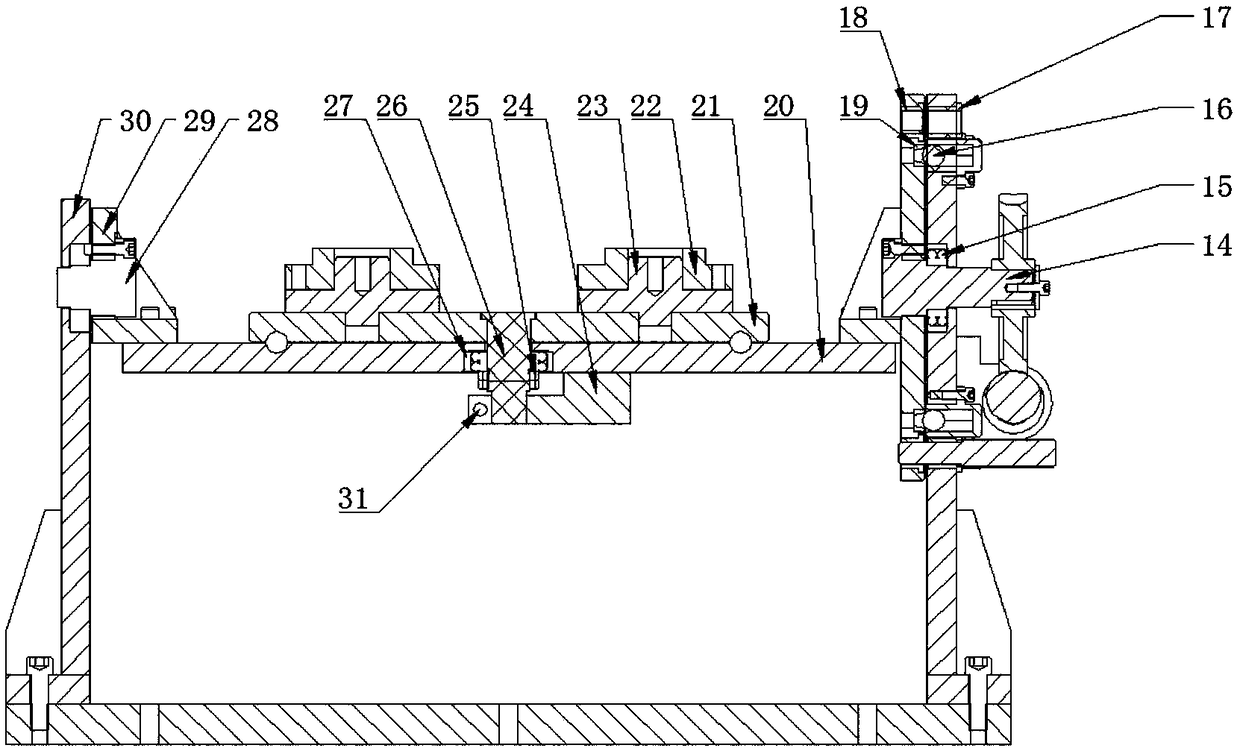

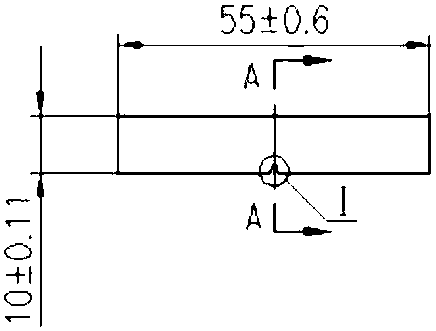

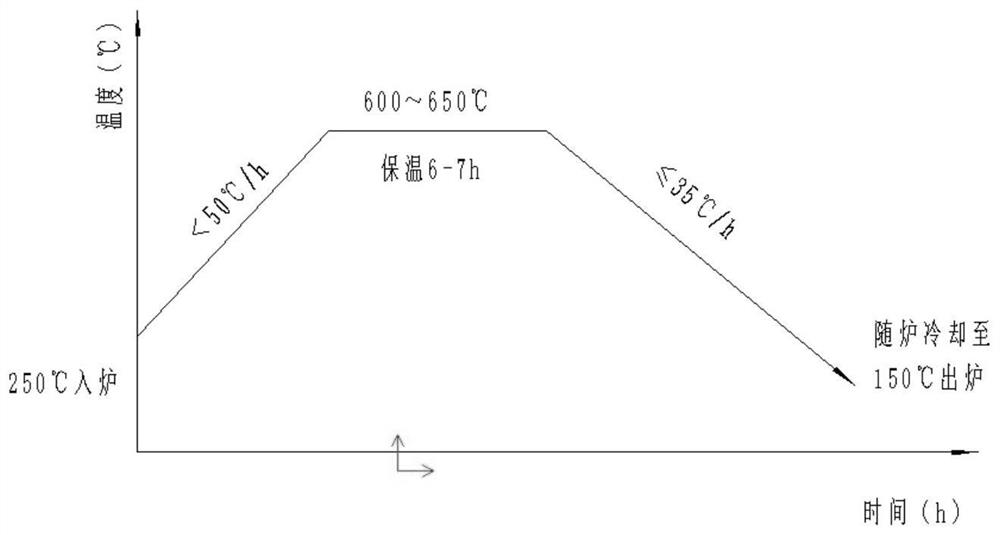

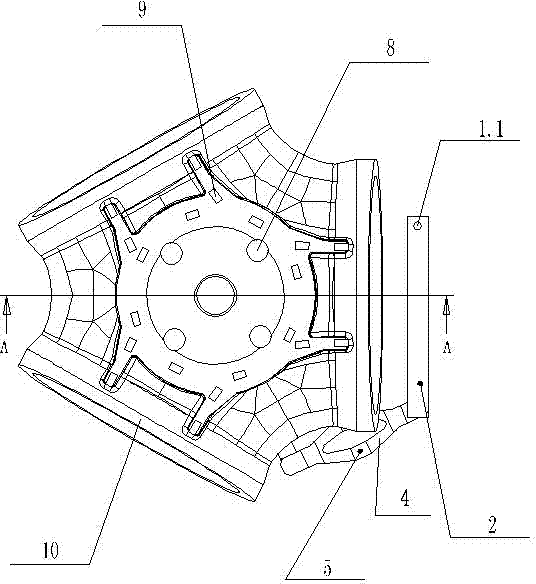

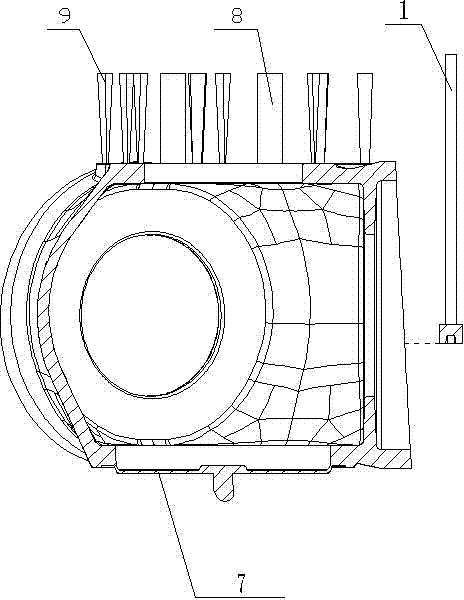

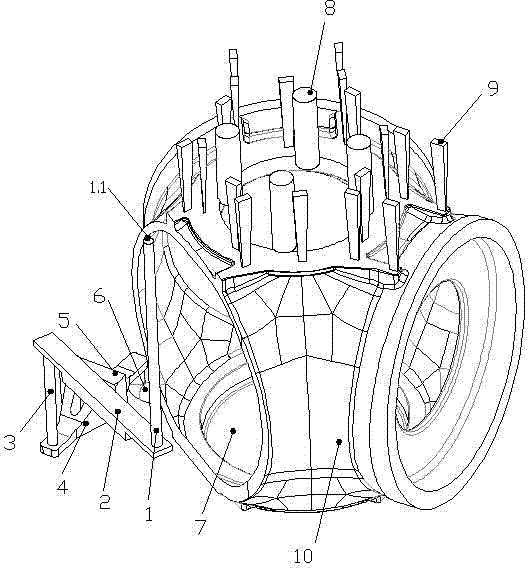

Manufacturing and installing-clamping tool and manufacturing technology of ultralow-temperature subway transmission box

InactiveCN108500572AAchieve multiple positioningReduce the clamping processLarge fixed membersManufacturing technologyVertical plane

The invention discloses a manufacturing and installing-clamping tool and a manufacturing technology of an ultralow-temperature subway transmission box. The problem that a machining and installing-clamping procedure of an oil passage hole of a subway transmission box are complex is solved, the installing-clamping procedure can be reduced by the manufacturing and installing-clamping tool and the manufacturing technology of the ultralow-temperature subway transmission box, the production efficiency is improved, and meanwhile, the positioning of the workpiece is accurate, and the error can be reduced. According to the technical scheme, the tool comprises a horizontal rotating disc which is fixedly connected with the subway transmission box, the horizontal rotating disc is rotatably connected with a rotating bottom plate so as to drive the subway transmission box to realize longitudinal turnover; the rotating bottom plate is connected with a transverse turnover mechanism, and the transverseturnover mechanism drives the rotating bottom plate to rotate so as to realize transverse turnover of the subway transmission box; and the transverse turnover mechanism comprises a vertical directional rotating disc which is fixedly connected with the rotating bottom plate, and the vertical directional rotating disc is driven by the rotating device to rotate inside a vertical plane.

Owner:山东鑫昊精密机械股份有限公司 +1

A kind of high-strength ductile iron Qt900-6 and preparation method thereof

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

A kind of high-strength and high-toughness cast qt700-10 and its production method

ActiveCN106811676BIncrease the number ofReduce oxidation burnProcess efficiency improvementHigh intensityDuctile iron

The invention belongs to the field of casting technologies and new materials and particularly relates to a high-strength high-tenacity cast-state QT700-10 and a production method thereof. Compared with ductile iron produced in the prior art, the high-strength high-tenacity cast-state QT700-10 has high strength and a high elongation rate, heat treatment is not needed, heavy metal, such as, Ni and Mo are not added in production, the tensile strength Rm in the cast state is larger than or equal to 700 MPa, the elongation rate A is larger than or equal to 10%, compared with the standard brand QT 450-10, the lowest tensile strength is improved by 55% under the same elongation rate; and compared with the standard brand QT 700-2, the lowest elongation rate is improved by four times under the same tensile strength. The high-strength high-tenacity cast-state QT700-10 can meet requirements of automobile ductile iron castings with high requirements for safety and comprehensive mechanical properties.

Owner:山东汇金股份有限公司

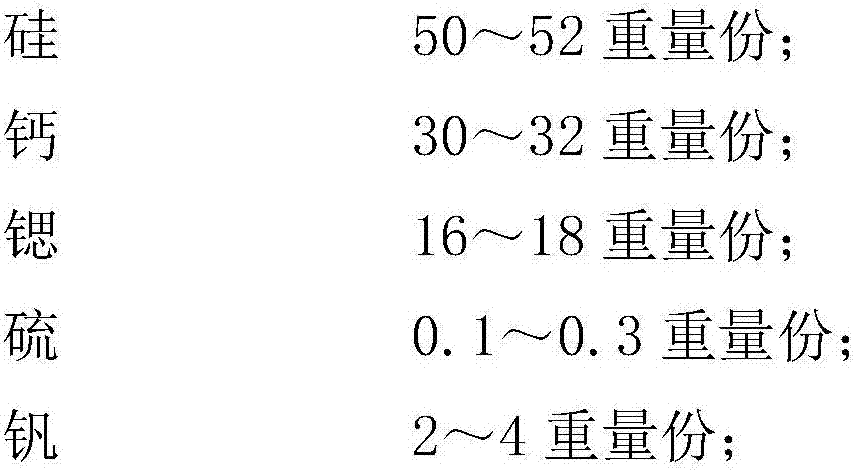

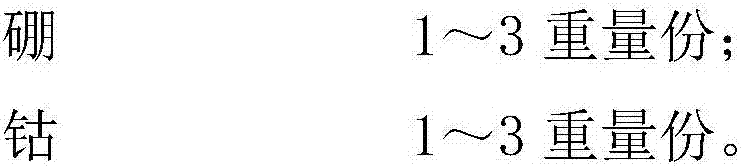

Pipe powder for ductile iron

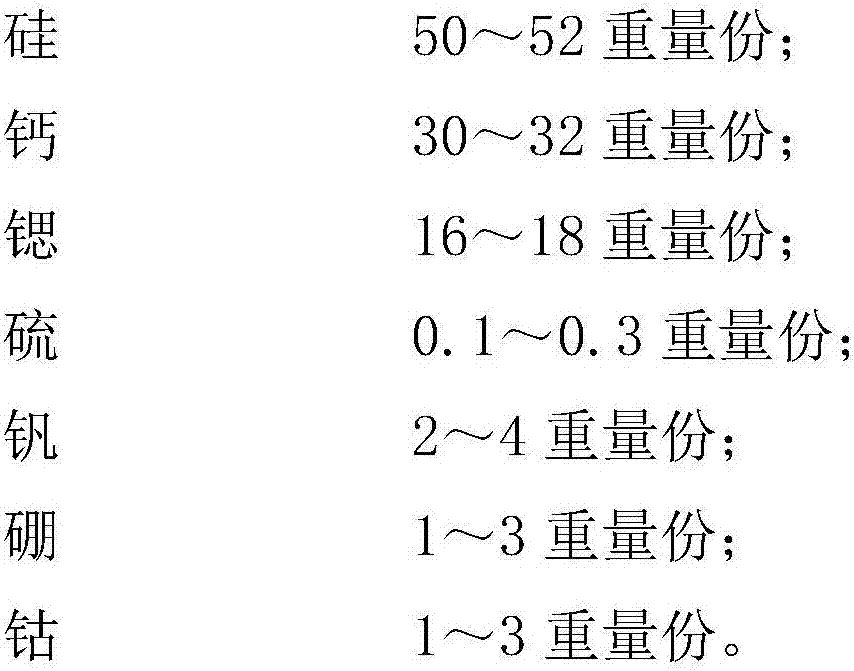

InactiveCN107321931AHigh nodularityIncrease the number of graphite ballsFoundry mouldsFoundry coresIndiumCobalt

This case discloses a pipe mold powder for ductile iron, including the following materials by weight: 50-52 parts by weight of silicon, 30-32 parts by weight of calcium, 16-18 parts by weight of strontium, and 0.1-0.3 parts by weight of sulfur , 2 to 4 parts by weight of vanadium, 1 to 3 parts by weight of boron, 1 to 3 parts by weight of cobalt, 0.5 to 1.5 parts by weight of barium sulfide, 0.05 to 0.1 parts by weight of iron sulfide, and 0.05 to 0.1 parts by weight of platinum , 0.05-0.1 parts by weight of indium and 0.005-0.01 parts by weight of tungsten oxide. In this case, through the improvement and optimization of the formula of pipe mold powder for ductile iron, a variety of elements with synergistic effects were introduced, which effectively improved the nodularization rate and number of graphite balls of the pipe mold powder, and reduced the number of pores on the surface of ductile iron pipes and the number of pinholes. At the same time, the formula reduces the use of precious metals, which not only reduces production costs, but also reduces damage to the environment.

Owner:苏州楚博生物技术有限公司

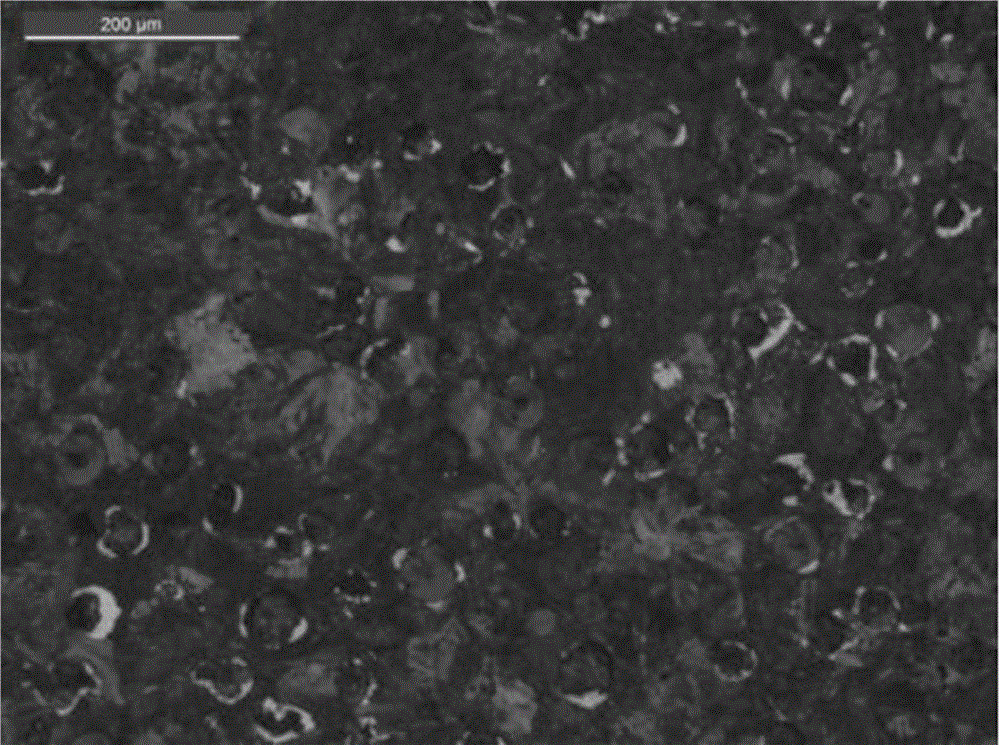

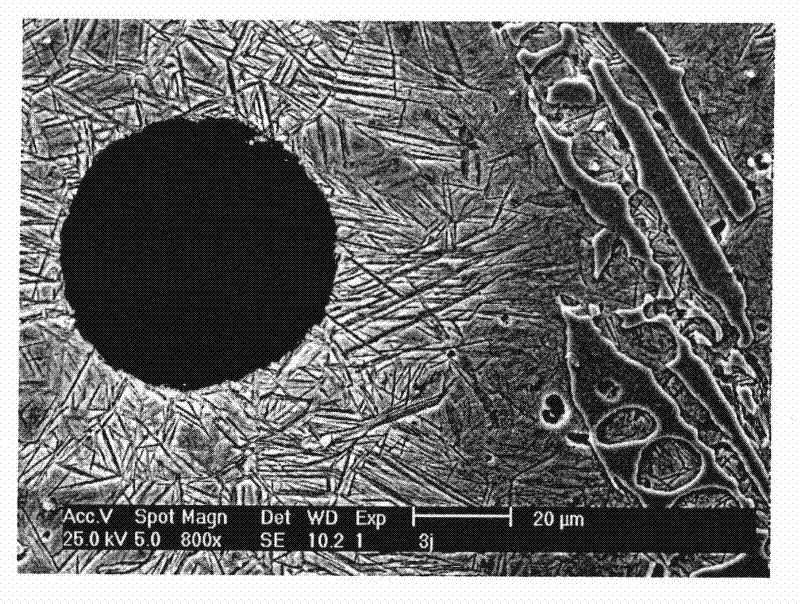

Carbide-containing ausferrite spheroidal graphite cast iron grinding ball and manufacturing method thereof

The invention discloses a carbide-containing ausferrite spheroidal graphite cast iron grinding ball and a manufacturing method thereof, relating to a cast iron alloy containing spheroidal graphite. The grinding ball comprises the following chemical elements in percentage by mass: 3.3 to 3.7 percent of C, 2.4 to 3.3 percent of Si, 2.5 to 3.6 percent of Mn, 0.6 to 1.5 percent of Cr, less than 0.08 percent of P, less than 0.025 percent of S, 0.03 to 0.05 percent of Mg, 0.02 to 0.04 percent of Re and the balance of Fe. The preparation method of the grinding ball comprises the following steps of: (1) raw material preparation and smelting; (2) spheroidization and inoculation; and (3) isothermal quenching heat treatment. In the invention, a certain quantity of carbides and graphite balls are formed in a grinding ball casting-state structure by utilizing a sand lined metal casting technology; and an ausferrite base body with excellent comprehensive mechanical property is obtained by adopting an isothermal quenching technology; and as a certain quantity of carbides are distributed in the ausferrite base body, the carbide-containing ausferrite spheroidal graphite cast iron grinding ball has high wear resistance and toughness.

Owner:HEBEI UNIV OF TECH +1

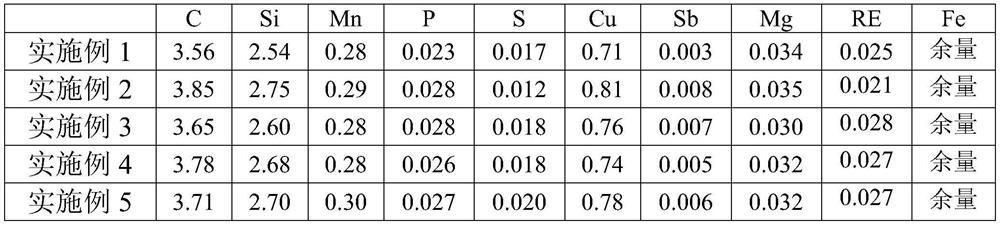

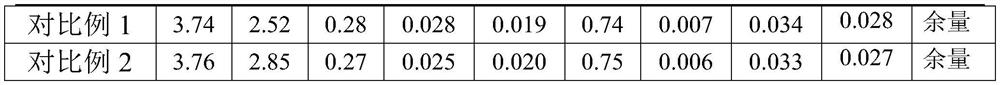

Nodular cast iron and preparation method thereof

PendingCN114058936AIncrease the number of graphite ballsImprove fatigue resistancePearliteDuctile iron

The invention relates to nodular cast iron and a preparation method thereof. The nodular cast iron comprises the following components in percentage by mass: 3.5 wt%-3.9 wt% of C, 2.5 wt%-2.8 wt% of Si, 0.7 wt%-0.85 wt% of Cu, 0.001 wt%-0.01 wt% of Sb, 0.03 wt%-0.06 wt% of Mg, 0.01 wt%-0.03 wt% of RE, less than or equal to 0.3 wt% of Mn, less than or equal to 0.03 wt% of P, less than or equal to 0.02 wt% of S and the balance of Fe. The nodular cast iron contains the components in a specific ratio, and all the components are coordinated and matched, so that the anti-fatigue performance of the nodular cast iron is improved, and the nodular cast iron has a high nodulizing grade and a large number of pearlites.

Owner:FAW JIEFANG AUTOMOTIVE CO

A production process of qt500-12 ductile iron casting

The invention discloses a production process of a QT500-12 spheroidal graphite iron casting. The production process comprises the following steps: A, raw material selection: selecting 60-80 parts of scrap steel, 20-40 parts of scrap returns, 2.5-3.5 parts of a carburant, 0.4-1.0 part of 75# ferrosilicon, 0.3-0.6 part of copper, 1-1.2 parts of a spheroidizing agent, 0.8-1.2 parts of a 75# ferrosilicon inoculant and 0.2-0.4 part of a silicon-strontium inoculant; B, weighing; C, smelting; D, spheroidizing; E, secondary inoculation; and F, pouring. The overall performances of the QT500-12 spheroidal graphite iron casting produced by using the production process are improved, and the tensile strength is larger than or equal to 500Mpa on the premise that the elongation percentage is larger than or equal to 12%; the consistency of a matrix structure of the spheroidal graphite iron casting is also realized, and the local function of the spheroidal graphite iron casting is prevented from being deteriorated; and the weight of the spheroidal graphite iron casting is reduced on the premise that the elongation percentage and tensile strength indexes of the spheroidal graphite iron casting reach standards, so that the lightweight of the spheroidal graphite iron casting is realized.

Owner:山东力嘉轻量化科技有限公司

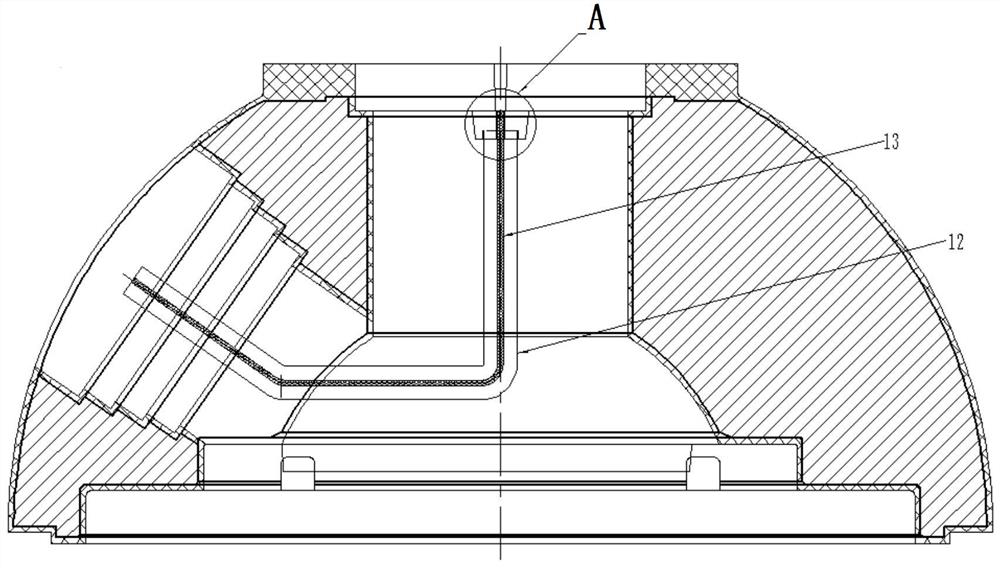

Method for forming large-section nodular cast iron shielding hemispherical casting

ActiveCN113118381AAvoid formingImprove inner qualityCasting safety devicesFoundry mouldsMold fillingSlag

The invention belongs to the technical field of cast iron casting, and provides a method for forming a large-section nodular cast iron shielding hemisphere casting. The method comprises the following steps of performing low-temperature, rapid and stable mold filling on molten iron by selecting a bottom pouring, filtering and open pouring system, and forming the nodular cast iron shielding hemisphere casting by adopting high-carbon low-silicon, heavy rare earth nodulizing and multi-stage inoculation strengthening. The requirements of part forming technical files are effectively met, and the quality problems of shrinkage porosity, shrinkage cavity, slag inclusion, inclusion, graphite floating, air holes and the like are not found.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

Method for preparing megawatt wind power high-strength high-toughness and low-temperature spheroidal iron casting

Owner:JIANGSU JIXIN WIND ENERGY TECH

Wheel hub of wind turbine generator system (WTGS)

Owner:宁波日星铸业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com