Pipe powder for ductile iron

A technology of ductile iron and pipe mold powder, which is applied in the direction of casting mould, mold composition, casting molding equipment, etc., can solve the problem that various additives cannot play a synergistic effect, the number of ductile iron pipe casting defects increases, and the performance of pipe mold powder is unstable and other problems, to achieve the effect of improving the spheroidization rate, reducing environmental damage, reducing the number of pores and pinholes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

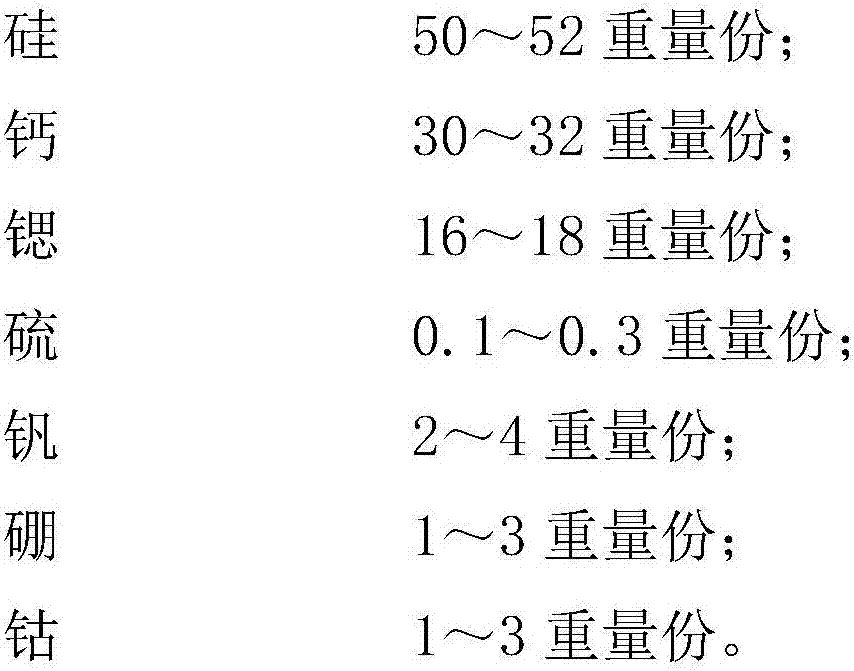

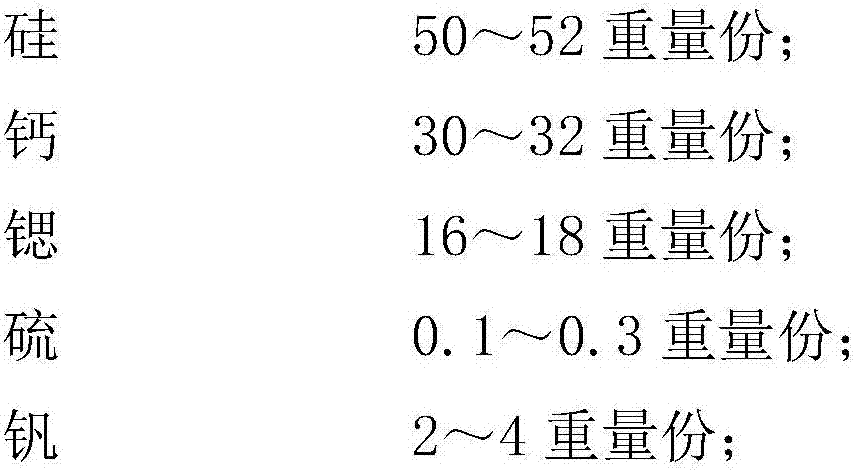

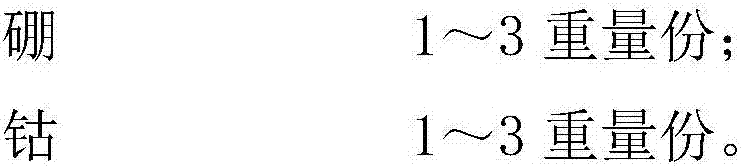

[0014] The present case proposes the pipe mold powder for ductile iron of an embodiment, including the following materials by weight:

[0015]

[0016]

[0017] As another embodiment of the present application, it further includes 0.5-1.5 parts by weight of barium sulfide and 0.05-0.1 parts by weight of iron sulfide. Barium sulfide and iron sulfide can synergistically inhibit the formation of iron carbide, reduce the whitening tendency of cast iron pipes, and simultaneously increase the nodularization rate and the number of graphite nodules. But in order to play a better synergistic effect with other components, the addition of barium sulfide and iron sulfide should be limited.

[0018] As yet another embodiment of the present application, 0.05-0.1 parts by weight of platinum is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com