High-strength and high-tenacity nodular cast iron and working roll of wide thick plate

A technology of nodular cast iron and high toughness, which is applied in the field of hot-rolled wide and thick plate work rolls. It can solve the problems of affecting the strength and toughness of materials, affecting the bonding strength of grain boundaries, and not being suitable for high-load and high-impact load rolls, etc., to achieve enhanced quenching performance, Increased rapid cooling and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

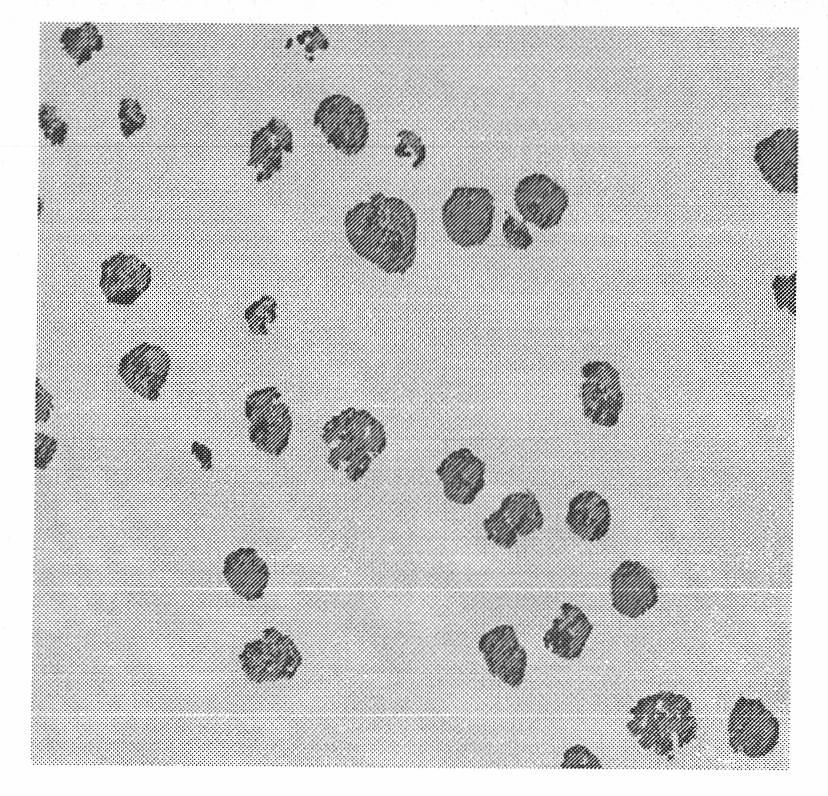

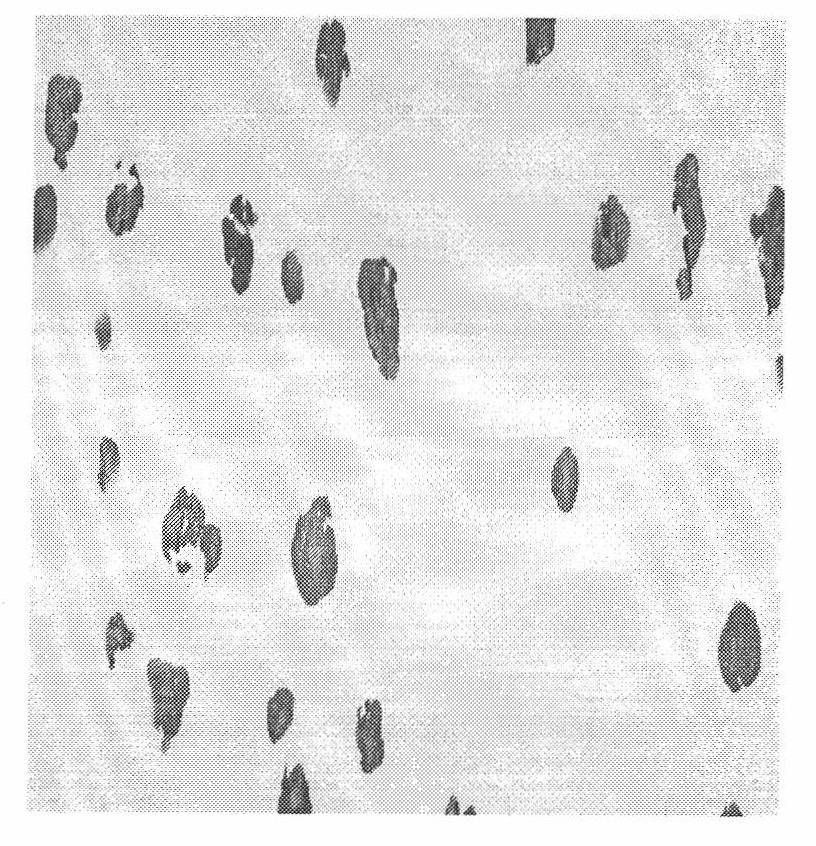

Embodiment 1

[0022] Embodiment 1: In the intermediate frequency electric furnace according to the design composition, add pig iron, scrap steel and corresponding, smelt and obtain the former molten iron of nodular cast iron, control composition is (wt%): C3.4, Si1.35, Mn0.65, P≤0.063, S≤0.027, Cu0.73, Mo0.28, Sb0.0021, and the rest are Fe and impurity elements. When the temperature of the original molten iron reaches about 1455°C, iron is tapped, and 0.16% pure magnesium per ton of molten iron is added to the ladle when the iron is tapped. Add yttrium-based heavy rare earth magnesium (brand DY-3) into the spheroidization method. After spheroidization, the molten iron is expected to increase Si by 0.5wt%, and then add a composite inoculant measured by pure Si and 0.8wt% of the molten iron weight into the ladle for inoculation. The inoculant consists of yttrium-based long-acting inoculant (brand YFY-1) and FeSi75Al10.5-A, and the two are added at a ratio of 4:6. The final composition is (wt%...

Embodiment 2

[0023] Embodiment 2: Add pig iron, steel scrap and corresponding alloy materials in the intermediate frequency electric furnace, smelt to obtain the original molten iron of ductile iron, the original molten iron composition is (wt%): C3.3, Si1.31, Mn0.68, P≤0.059, S≤0.024, Cu0.75, Mo0.27, Sb0.0019, the rest are Fe and impurity elements, tap iron at 1455°C, add 0.18% pure magnesium / ton molten iron into the ladle, add yttrium-based heavy rare earth magnesium (grade DY-3) Spheroidization by flushing method. After spheroidization, the molten iron is expected to increase Si by 0.6%. After spheroidization, add a compound inoculant measured by pure Si and 0.85% of the weight of the molten iron into the ladle for inoculation. The composite inoculant consists of yttrium-based long-acting inoculant (brand YFY-1) and FeSi75Al10.5-A, and the two are added at a ratio of 4:6. The final composition that obtains ductile iron is (wt%): C3.24, Si2.56, Mn0.65, P≤0.052, S≤0.006, Cu0.71, Mo0.26, M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com