High-toughness weather-resistant steel plate with yield strength of 550MPa and preparation method of high-toughness weather-resistant steel plate

A yield strength and high toughness technology, applied in the field of steel materials and their manufacturing, can solve the problems of increasing the difficulty of steelmaking production and increasing the manufacturing cost, and achieve the effects of excellent cold forming performance, excellent welding performance, and easy forming and processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

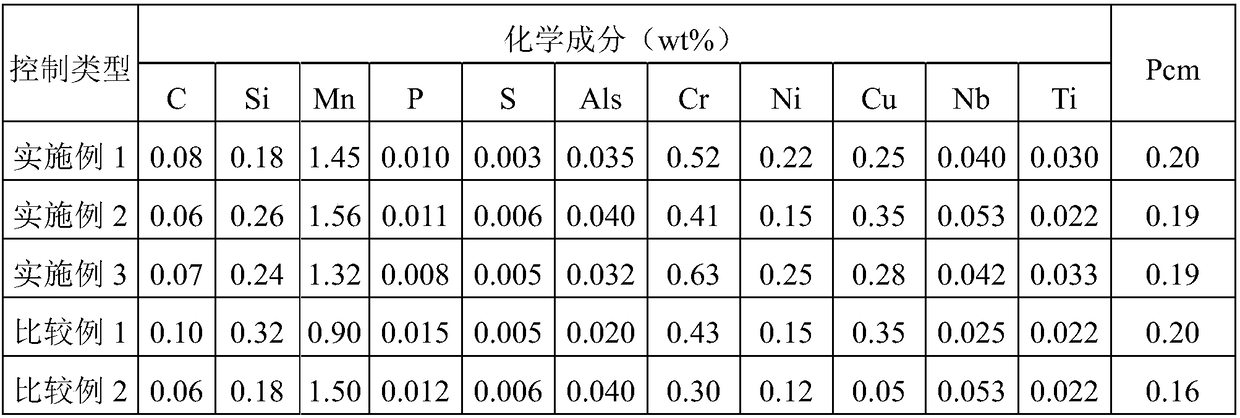

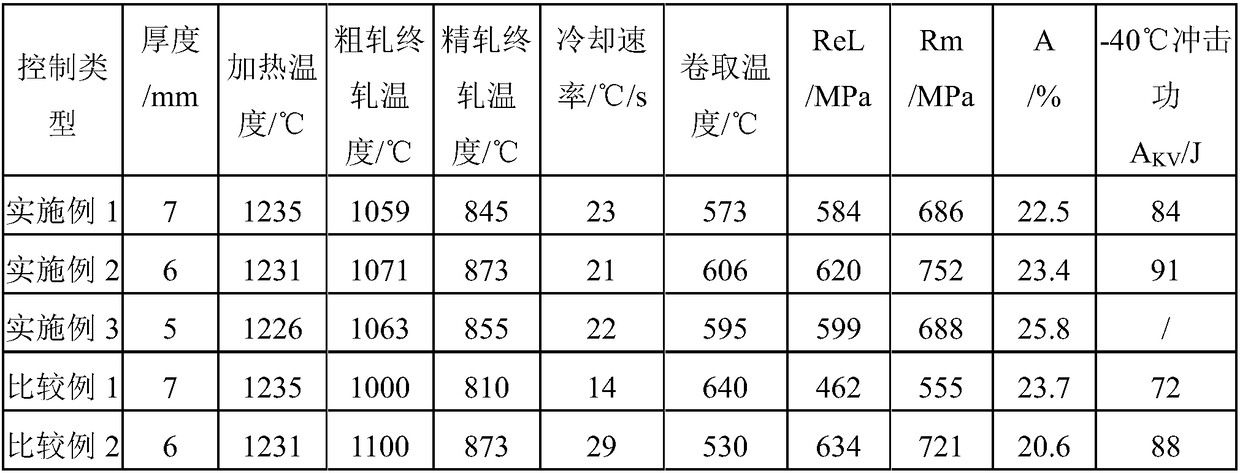

[0024] The technical solutions of the present invention will be further described below through specific examples.

[0025] The invention provides a high-toughness weather-resistant steel plate with a yield strength of 550 MPa and a manufacturing method thereof. The chemical composition meets the weight percentage (wt%): C: 0.05-0.10%; Si: 0.10%-0.40%; Mn: 1.20-1.70%; P: ≤0.012%; S: ≤0.008%; Cr: 0.40~0.80%; Ni: 0.15~0.40%; Cu: 0.25~0.40%; Als: 0.015~0.040%; Nb: 0.030~0.070%; Ti: 0.010 ~0.040%; and at the same time meet the following welding cold crack sensitivity coefficient Pcm requirements, Pcm=C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B≤0.20% ; The rest are Fe and unavoidable impurity elements.

[0026] The invention is produced by a hot continuous rolling process, and the process flow includes: deep desulfurization of molten iron pretreatment → composite blowing at the top and bottom of a converter → external refining → continuous casting → slab heating → hot continuous rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com