Patents

Literature

45results about How to "Improve ball effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

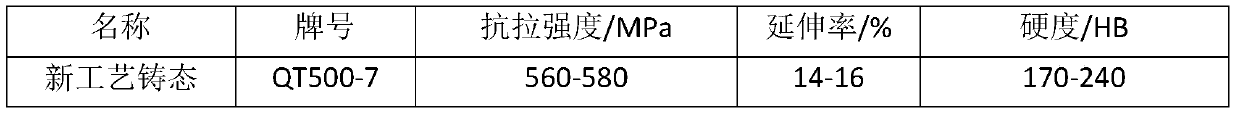

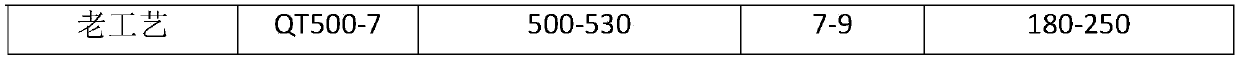

Casting process of nodular cast iron planet carrier

The invention relates to a casting process of a nodular cast iron planet carrier, which comprises the following procedures of modeling, iron melt melting, spheroidizing, modifying, casting and stress relieving and annealing. The design of a casting system adopts a step casting method which takes consideration of both bottom casting and top casting to improve the finished product rate of castings, and also adopts technical schemes of placing chill iron at the position of thick walls, adding Sn element in the iron melt, optimizing, spheroidizing, modifying, casting and the like, so that the produced planet carrier not only meets the high demands on property, but also achieves great improvement in production cost and efficiency.

Owner:JIANGSU HONGDE SPECIAL PARTS CO LTD

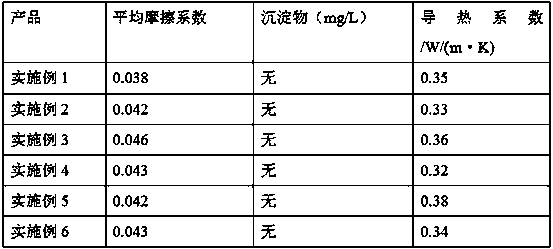

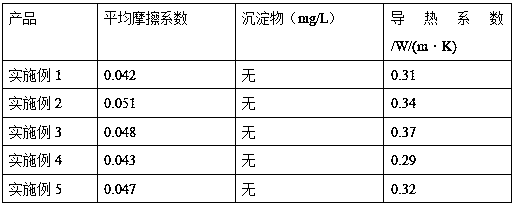

High thermal conductivity lubricating oil and preparation method thereof

ActiveCN108587755AGood compatibilityImprove stabilityCarbon compoundsLubricant compositionPolyethylene glycolBoron nitride

The invention discloses a high thermal conductivity lubricating oil and a preparation method thereof. The lubricating oil is prepared from the following raw materials, in parts by weight: 100-150 parts of basic oil, 1-3 parts of modified graphene, 0.1-0.5 part of yttrium oxide, 0.1-0.5 part of boron nitride, 1-3 parts of polyethylene glycol dehydroabietate ester, 0.5-1.5 parts of succinate sulfonated hydrogenated castor oil, 1-2 parts of diglycolamide oleate borate, 0.5-1.5 parts of defoaming agent, 0.5-1.5 parts of lubricating agent and 0.5-1.5 parts of anti-oxidant. The lubricating oil provided by the invention has the excellent compatibility and stability, is low in friction coefficient and high in heat conductivity coefficient, has the good protection effect on mechanical parts, prolongs the service life of the mechanical parts, and has the good economic benefits and social benefits.

Owner:南宁隆腾科技有限公司

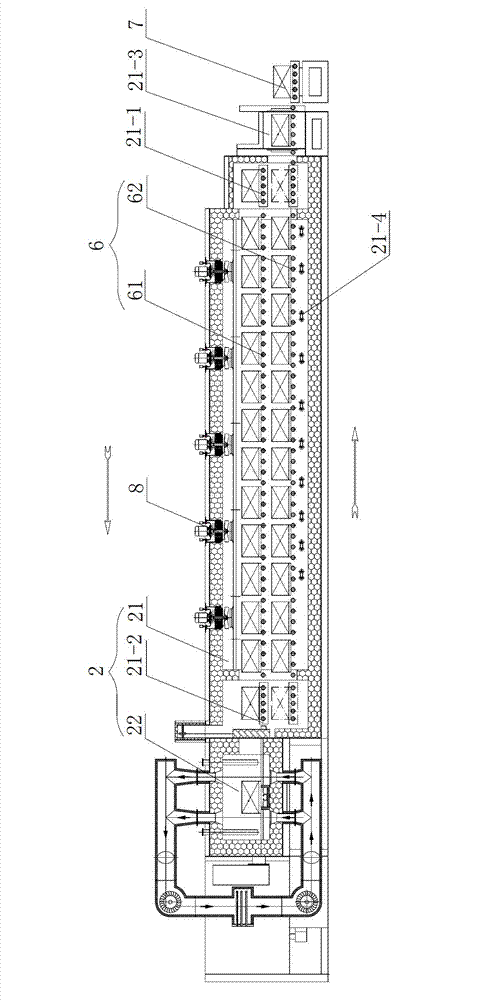

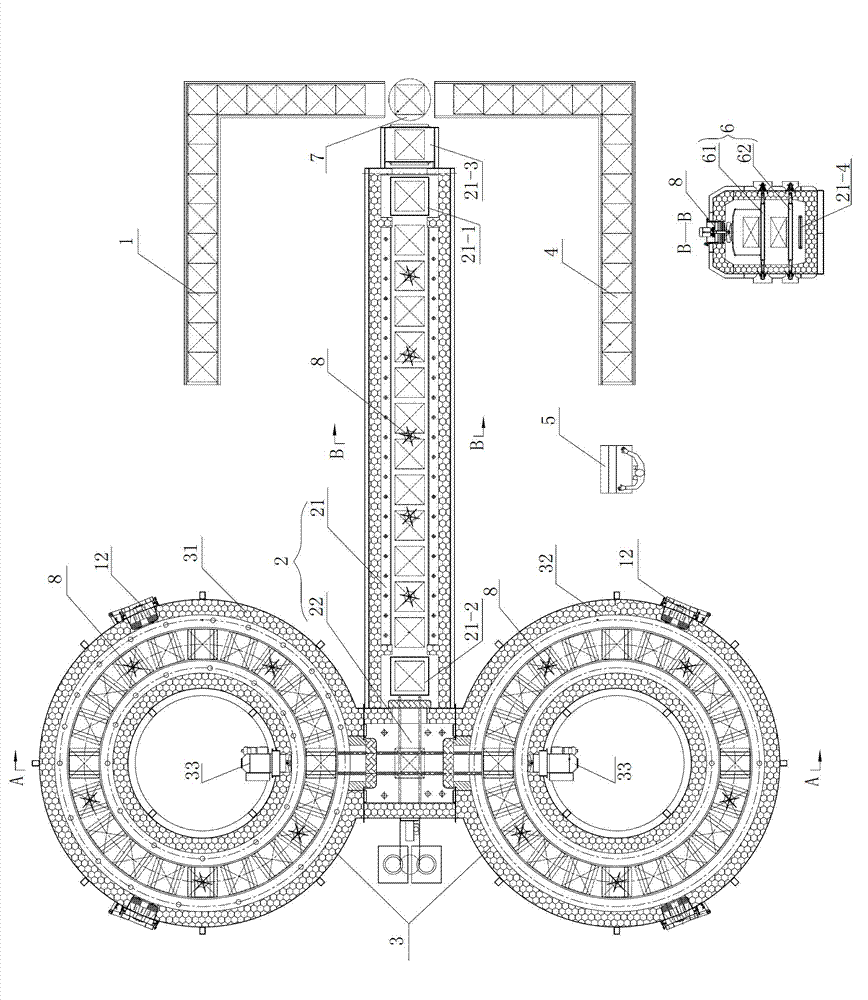

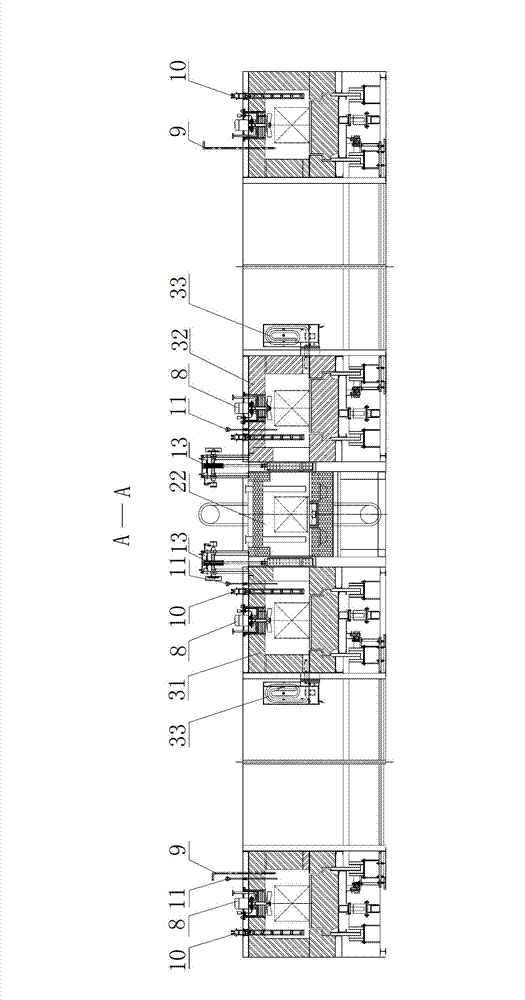

Roller-type spheroidizing annealing production line and isothermal spheroidizing annealing method

ActiveCN103074471AAvoid crackingAvoid defects such as deformationComputer control systemProduction line

The invention relates to a roller-type spheroidizing annealing production line and an isothermal spheroidizing annealing method using the roller-type spheroidizing annealing production line. The roller-type spheroidizing annealing production line sequentially comprises a roller-type feeding table, a cooling device, a heating device, a roller-type discharging table and an upper computer control system, wherein the cooling device comprises a roller-type quick cooling furnace and a forced quick cooling chamber at the tail end of the roller-type quick cooling furnace; a workpiece conveying device is arranged inside the roller-type quick cooling furnace; and the workpiece conveying device has a double-layer structure and comprises an upper cold workpiece feeding device and a lower hot workpiece discharging device. The isothermal spheroidizing annealing method comprises the following steps: feeding, exchanging heat of a cold workpiece and a hot workpiece in the furnace, austenitizing the workpieces, performing isothermal treatment, cooling and outputting the workpieces, discharging and the like. The isothermal spheroidizing annealing method is wide in application, can be applied to spheroidizing annealing treatment of parts or raw materials on a large scale as well as isothermal normalizing treatment of the parts; and the roller-type spheroidizing annealing production line has the advantages of energy conservation, environment friendliness, small floor area, high production efficiency and the like.

Owner:HEPHAES HEAT TREATMENT SYST JIANGSU

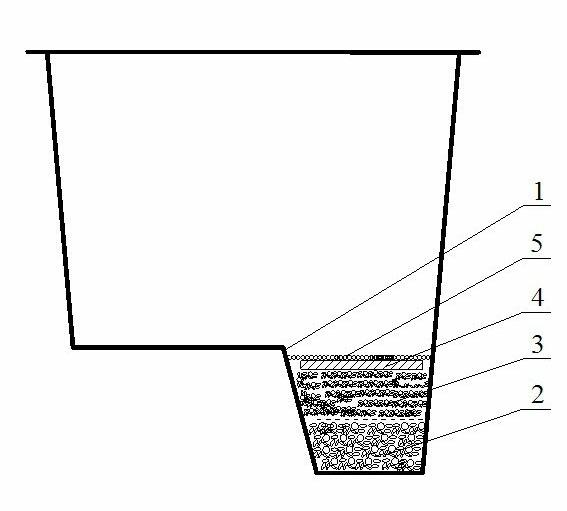

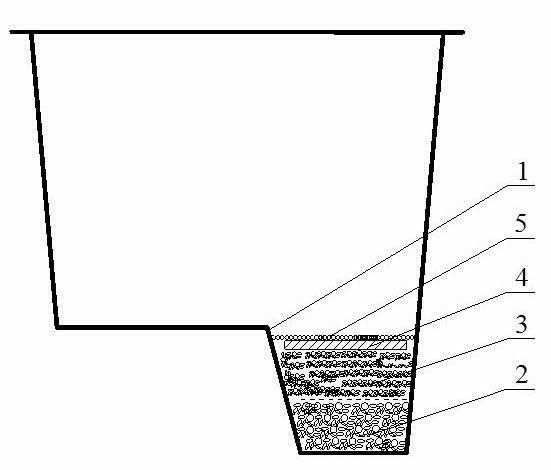

Spheroidizing treatment technology by rush-in method

The invention relates to a spheroidizing treatment technology by rush-in method, comprising the following steps: adding a nodulizer and an inoculant successively in a ladle pit or a dam; using a ductile iron plate to cover the nodulizer and the inoculant; scattering a covering agent on the ductile iron plate; dumping molten iron into the ladle; scattering a slag collecting agent after the spheroidizing reacts sufficiently, and removing the slag. By covering the nodulizer and the inoculant with the ductile iron plate and the covering agent successively, the covering agent containing perlite expands rapidly under the condition of instantaneous high-temperature to form a protective layer, so that the temperature of the spheroidizing reaction is reduced, the time of the spheroidizing reaction is prolonged and the spheroidization effect is improved.

Owner:JIANGLING MOTORS

Modified graphene and application thereof in lubricating oil

The invention discloses modified graphene and application thereof in lubricating oil. The modified graphene is modified by virtue of coco fatty acid diethanol amide, octaphenyl caged sesquisiloxane and a rare-earth coupling agent. The modified graphene is applied to the lubricating oil, and the lubricating oil is prepared from the following raw materials in parts by weight: 100 to 150 parts of basic oil, 0.5 to 2 parts of modified graphene, 0.1 to 0.5 part of silicon carbide, 1 to 3 parts of polysiloxane aminoester acrylate, 0.5 to 2 parts of succinate sulfonated hydrogenated castor oil, 1 to3 parts of oleic acid diethanolamide borate, 0.5 to 1.5 parts of defoaming agent and 1 to 2 parts of antioxidant. The lubricating oil has excellent compatibility and stability, low friction coefficient, high heat conduction coefficient and good effect for protecting mechanical parts, and can prolong the service life of the mechanical parts.

Owner:钦州市窑宝坭兴陶艺有限公司

Preparation method of low-magnesium nodulizer

The invention relates to a preparation method of a low-magnesium nodulizer, and the preparation method belongs to the technical field of nodular cast iron. The preparation method takes magnesium powder, yttrium powder, cerium powder and calcium powder as raw materials, and prepares the low-magnesium nodulizer; the magnesium is a basic graphite spheroidizing element, the chemical property of magnesium is active, the desulfurization and deoxygenation capacity is high, the generated sulfide and oxide are high in melting points, low in density and prone to float out of molten iron to be removed, the spheroidizing capacity of rare earth elements such as yttrium and cerium is high, the added rare earth elements such as yttrium and cerium can play a good auxiliary spheroidizing role, the added yttrium and cerium elements can reduce the adding amount of magnesium and possible black slag defects, and a stable spheroidizing effect can be achieved even if the sulfur content of molten base iron ishigh; and by adding calcium into the molten iron, the effects of deoxidizing, desulfurizing and improving the surface tension of the molten iron can be achieved, the adding amount of main spheroidizing elements can be reduced, and the spheroidizing effect is enhanced.

Owner:陈红喜

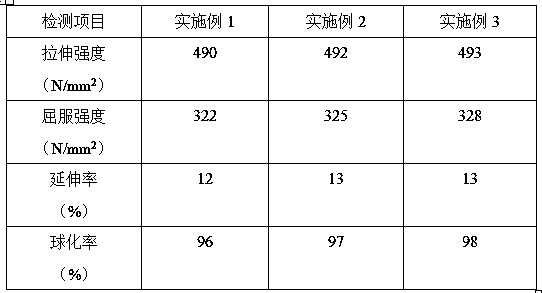

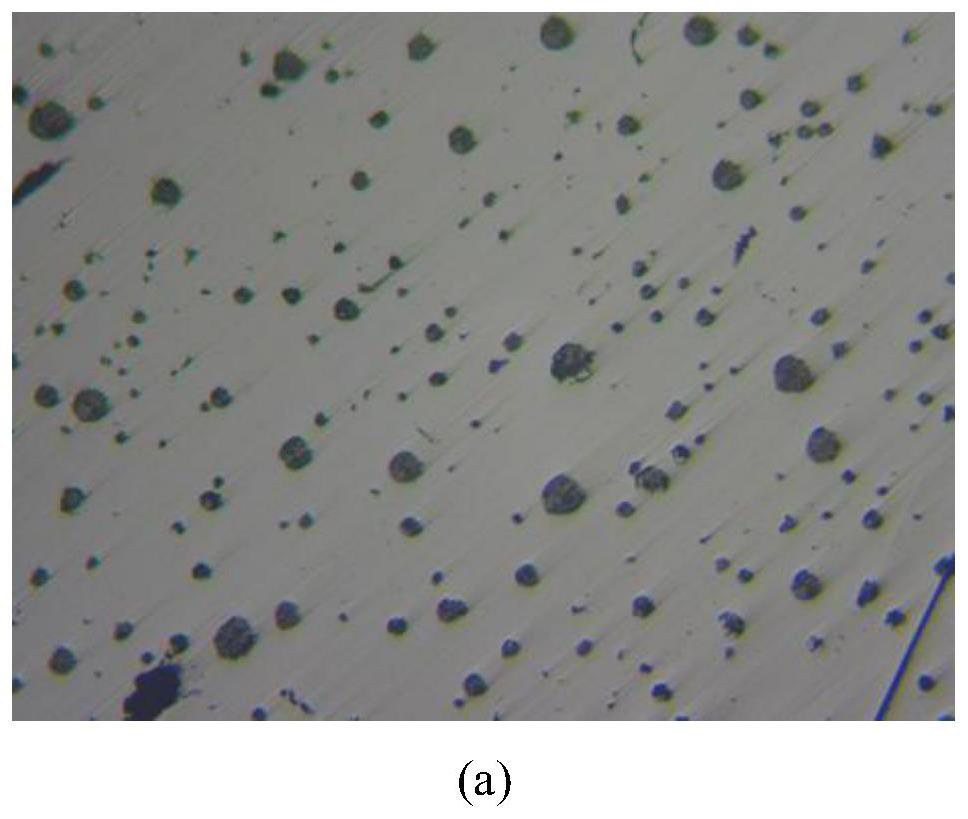

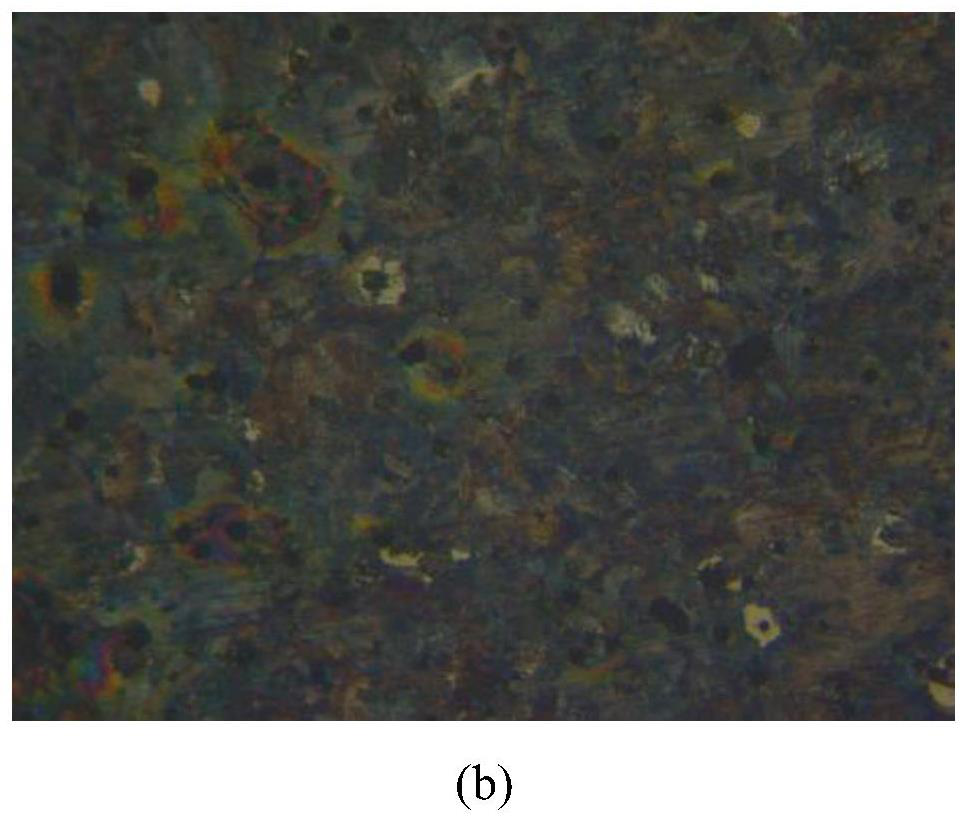

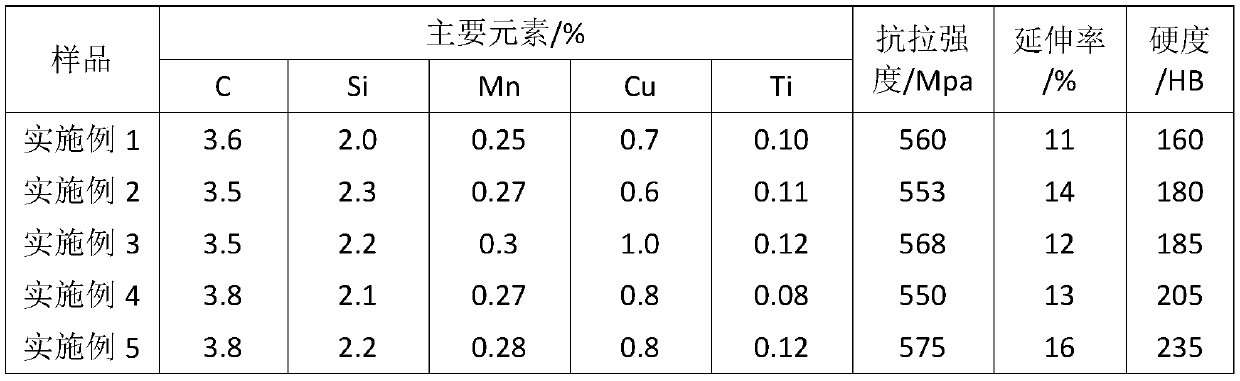

Preparation method of high-strength and high-tenacity nodular cast iron

ActiveCN108624806AGood composition uniformityImprove uniformityProcess efficiency improvementDuctile ironImpurity

The invention discloses a preparation method of high-strength and high-tenacity nodular cast iron. The high-strength and high-tenacity nodular cast iron is prepared from, by mass, 3.6%-3.8% of C, 3.5%-3.8% of Si, 0.4%-0.6% of Mn, 0.01%-0.04% of Sn, 0.4%-0.6% of Ni, 0.3%-0.4% of Ti, 0.04%-0.01% of Sb, 0.02%-0.04% of RE, 0.16%-0.2% of P, no more than 0.02% of S, and the balance Fe and inevitable impurities. The tensile strength of the nodular cast iron is 1050-1180 MPa, the yield strength of the nodular cast iron is 780-820 MPa, the ductility of the nodular cast iron is 15%-16%, the nodularity of the nodular cast iron is 95%, and all properties of the nodular cast iron are excellent.

Owner:佛山市高明康得球铁有限公司

High-fluidity environment-friendly ultrahigh-performance concrete and preparation method thereof

InactiveCN111423180AGood ball effectReduce heat of hydrationEnvironmental resource managementCrack resistance

The invention discloses high-fluidity environment-friendly ultrahigh-performance concrete. The concrete is prepared by mixing low-heat Portland cement, fly ash microspheres, silica fume, fine sand, quartz powder, a water reducing agent, water and steel fibers according to a certain ratio. Pollution is produced during production of cement; however, waste fly ash microbeads of a thermal power plantare adopted to replace a part of cement in the invention, so pollution reduction and environmental protection are realized, and the obtained ultrahigh-performance concrete has very good working performance, relatively small shrinkage and relatively good crack resistance, and is convenient to construct; and compared with existing ultrahigh-performance concrete with the same water-binder ratio, glue-sand ratio and steel fiber mixing amount, the ultrahigh-performance concrete has the advantages that working performance is greatly improved, and the problem of poor working performance of the existing ultrahigh-performance concrete can be solved, so the ultrahigh-performance concrete has good economic benefits and environmental protection benefits and is suitable for large-scale popularization and application.

Owner:福州市宇心建材科技有限公司

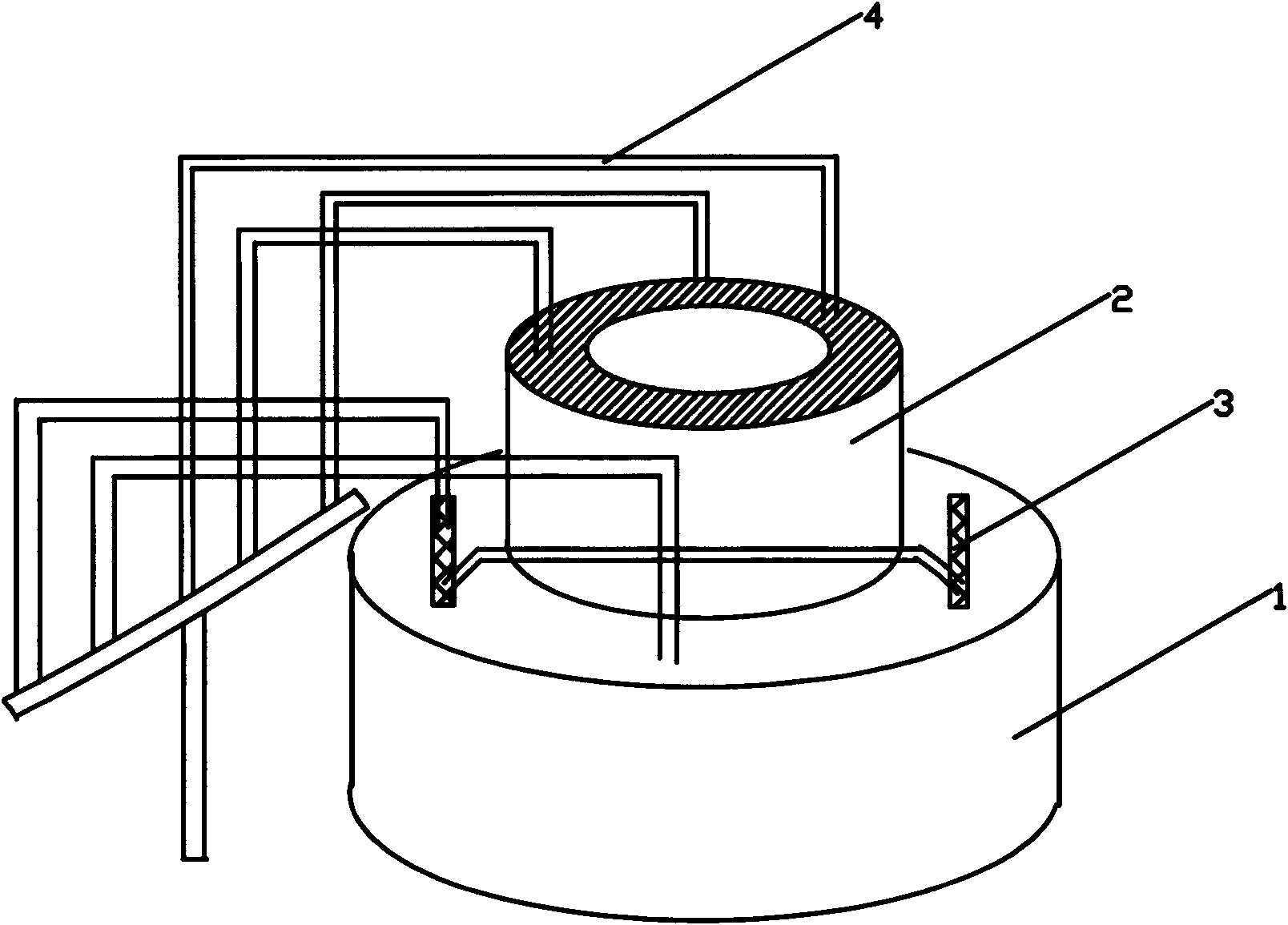

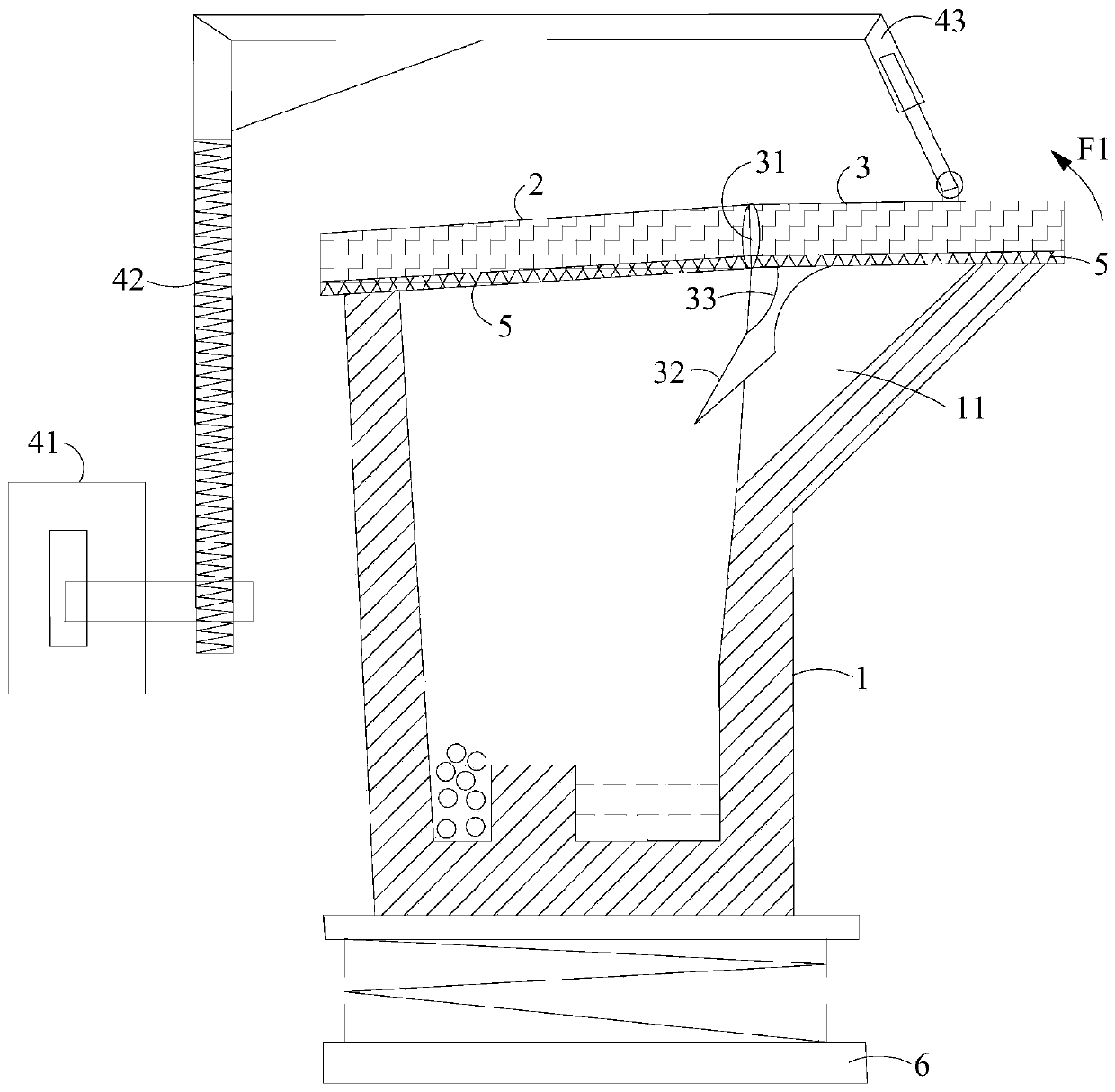

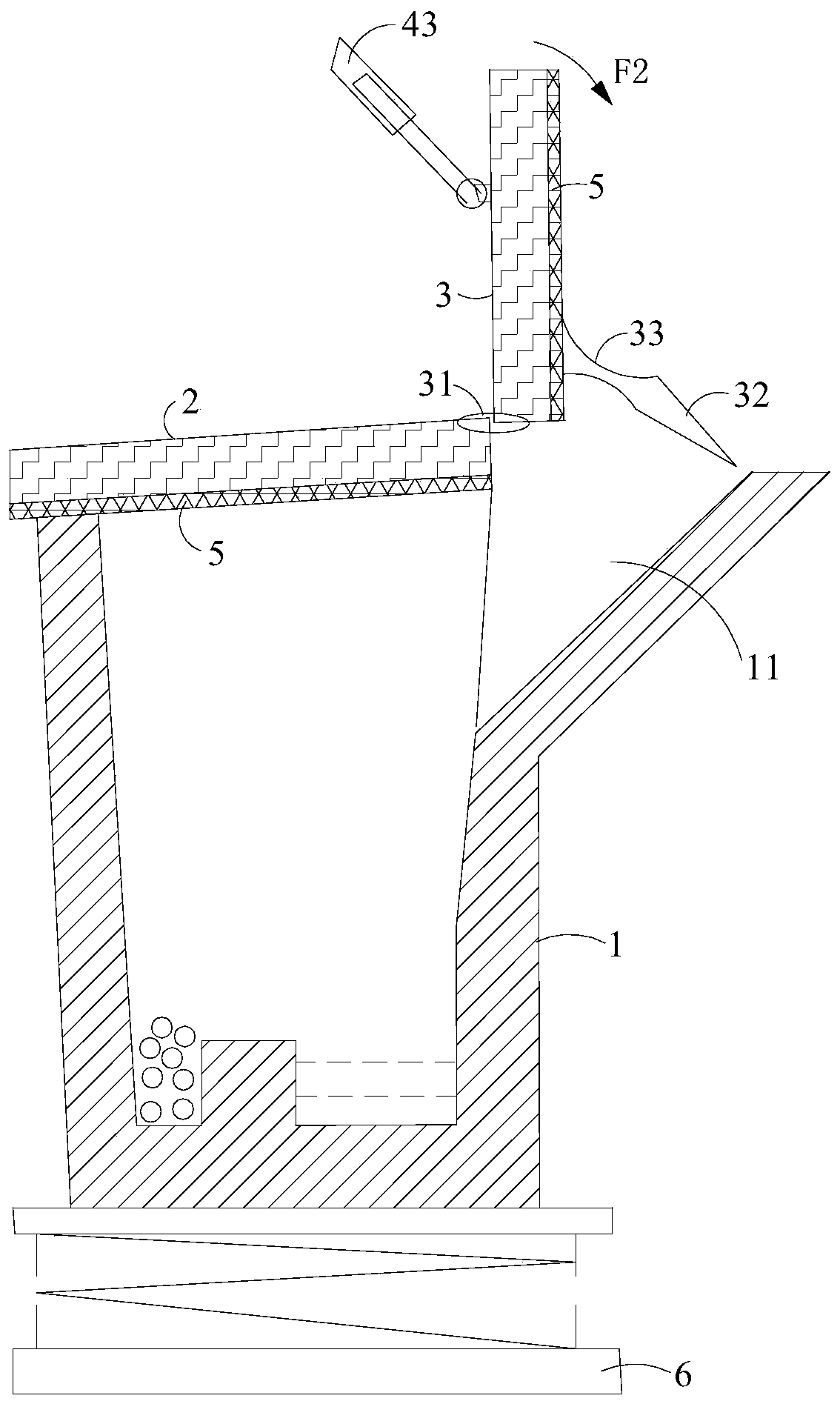

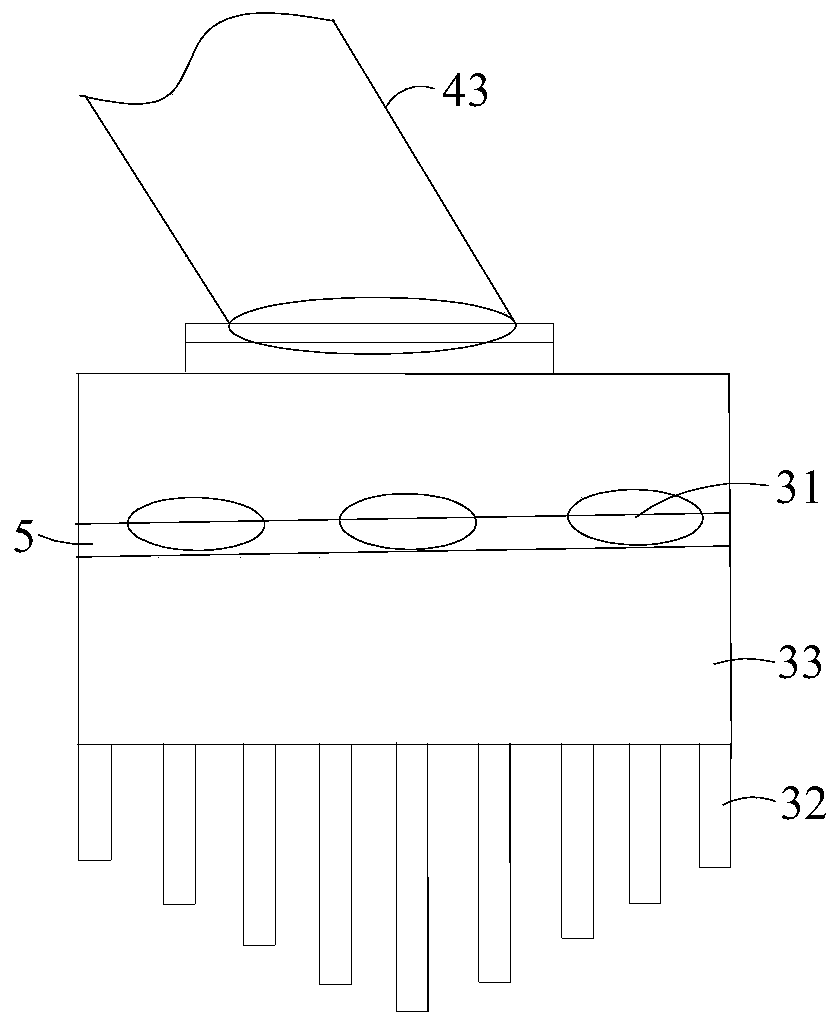

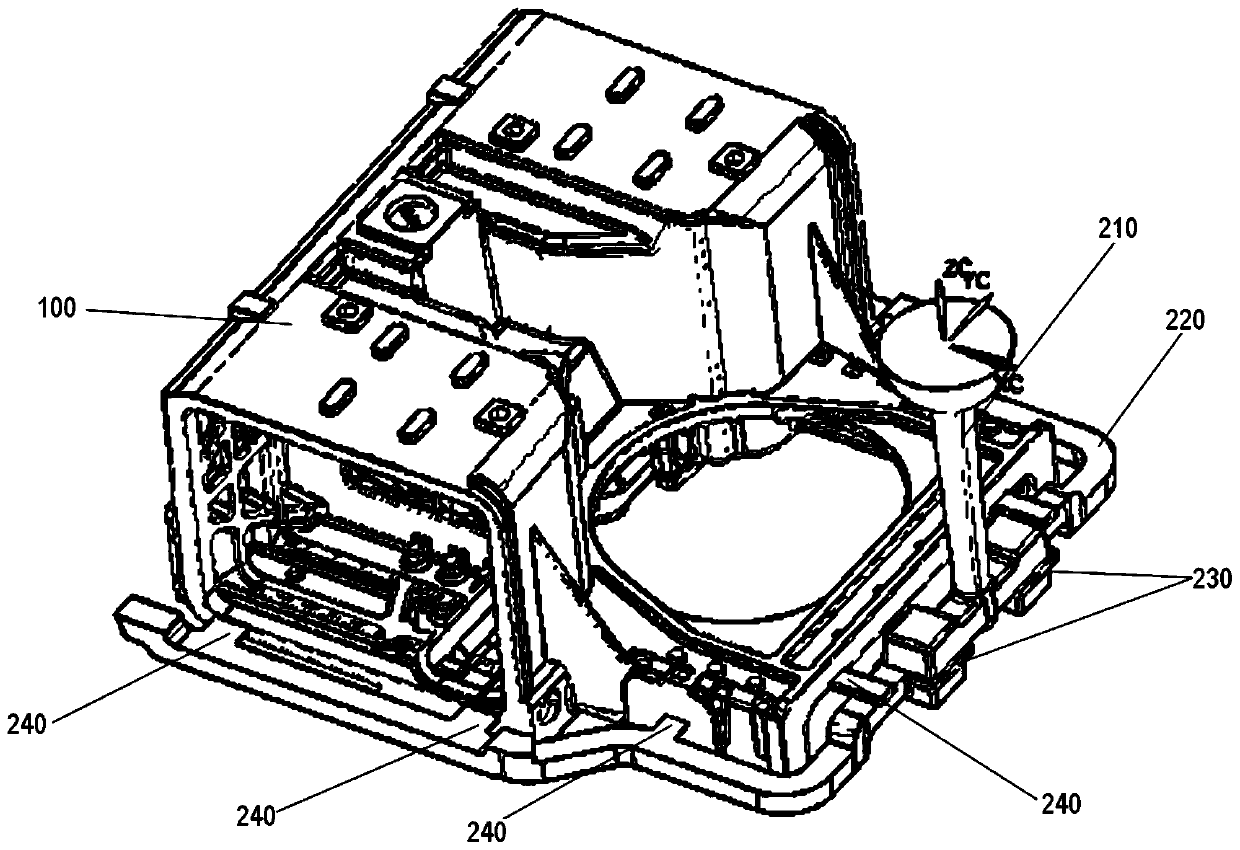

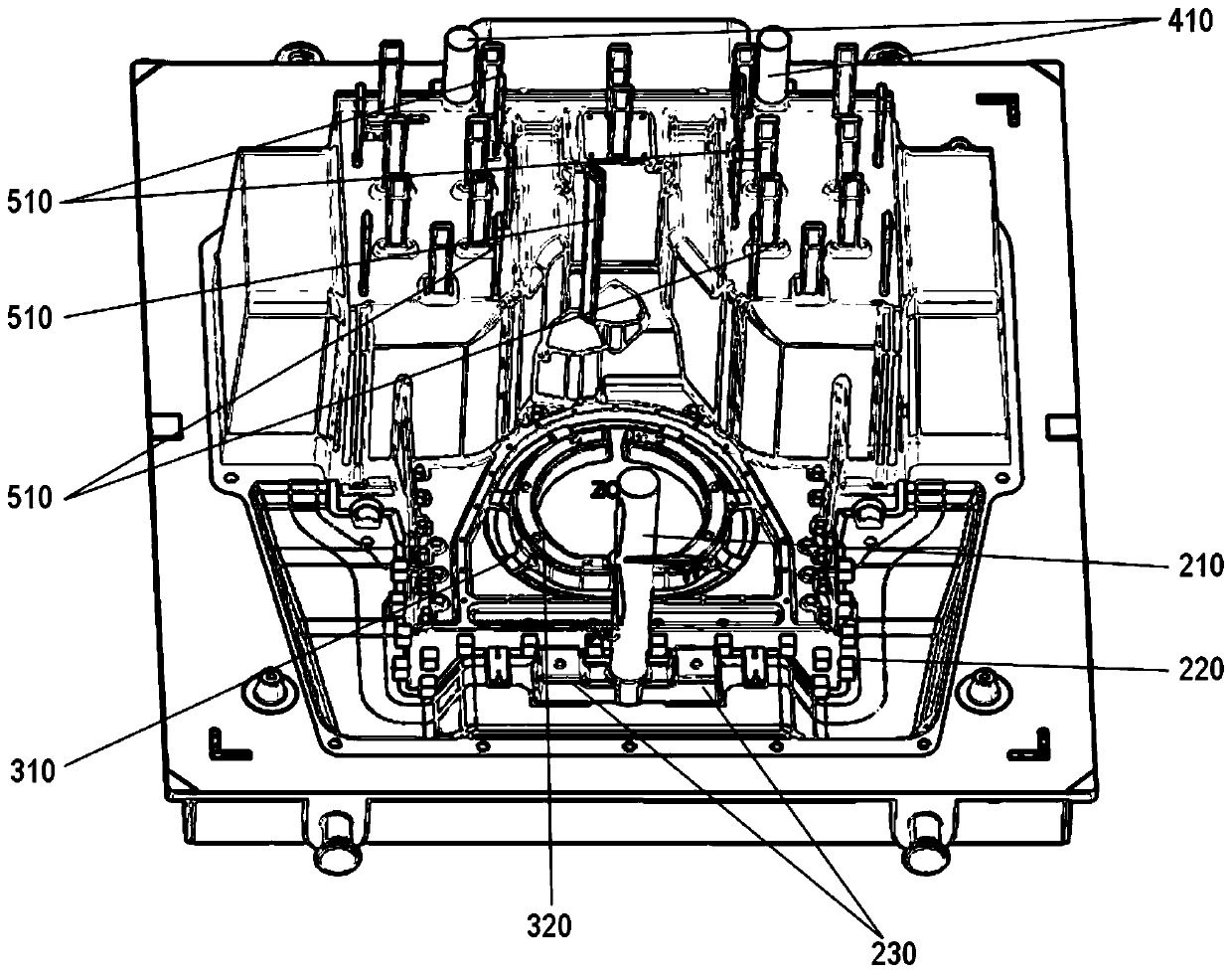

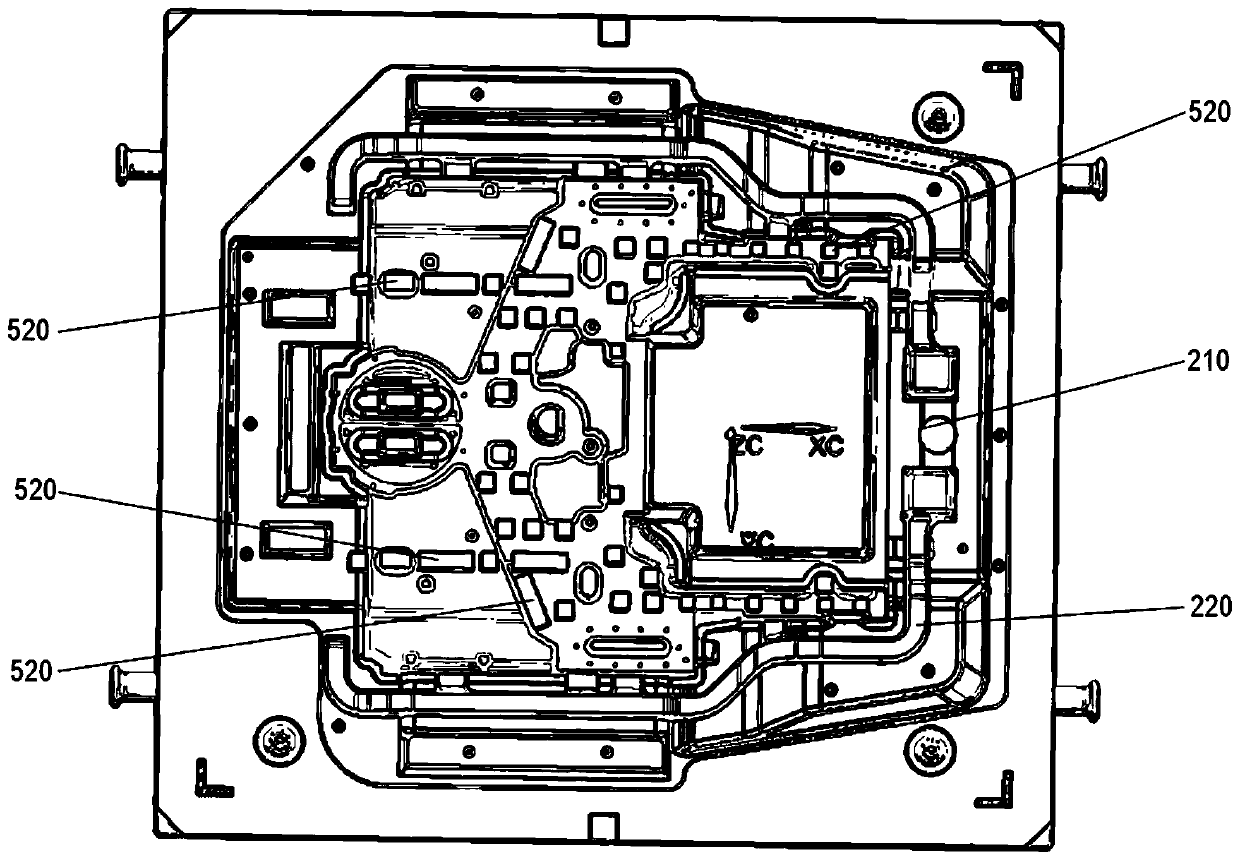

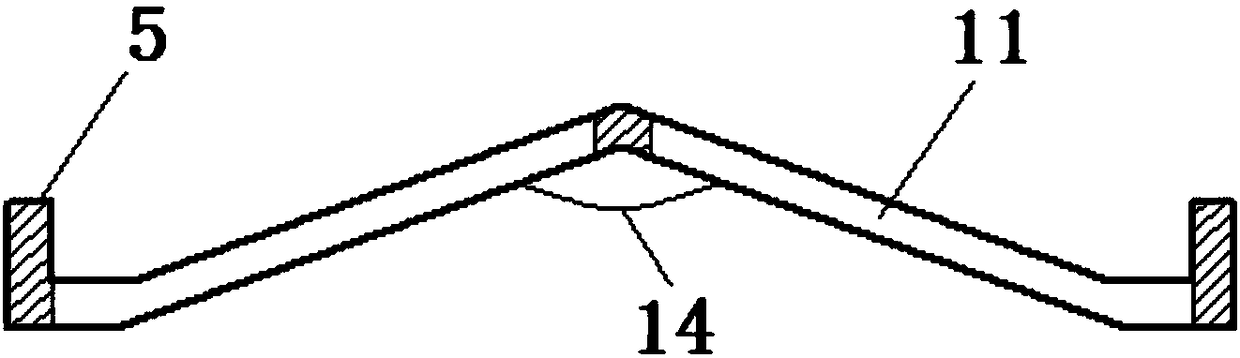

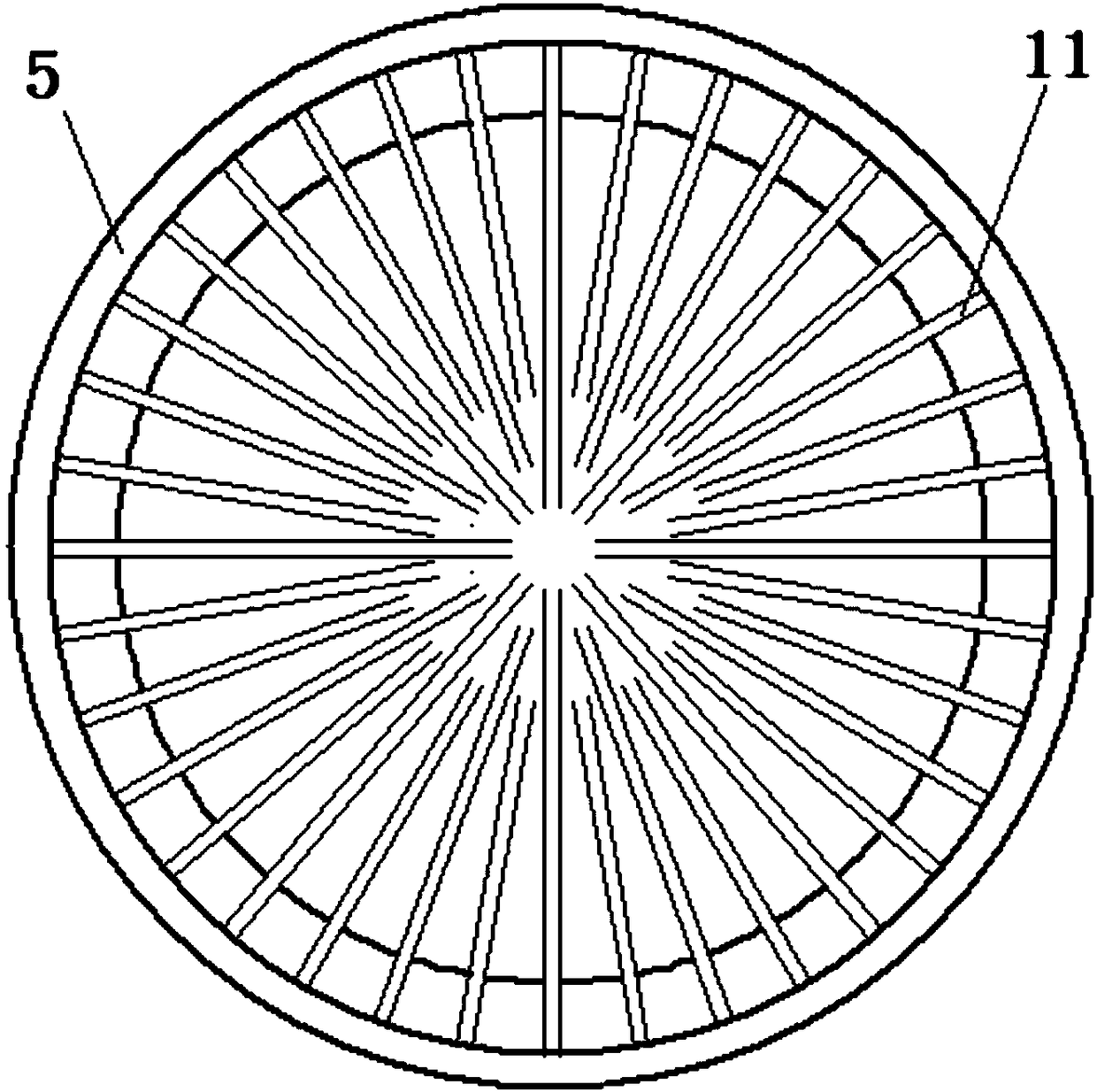

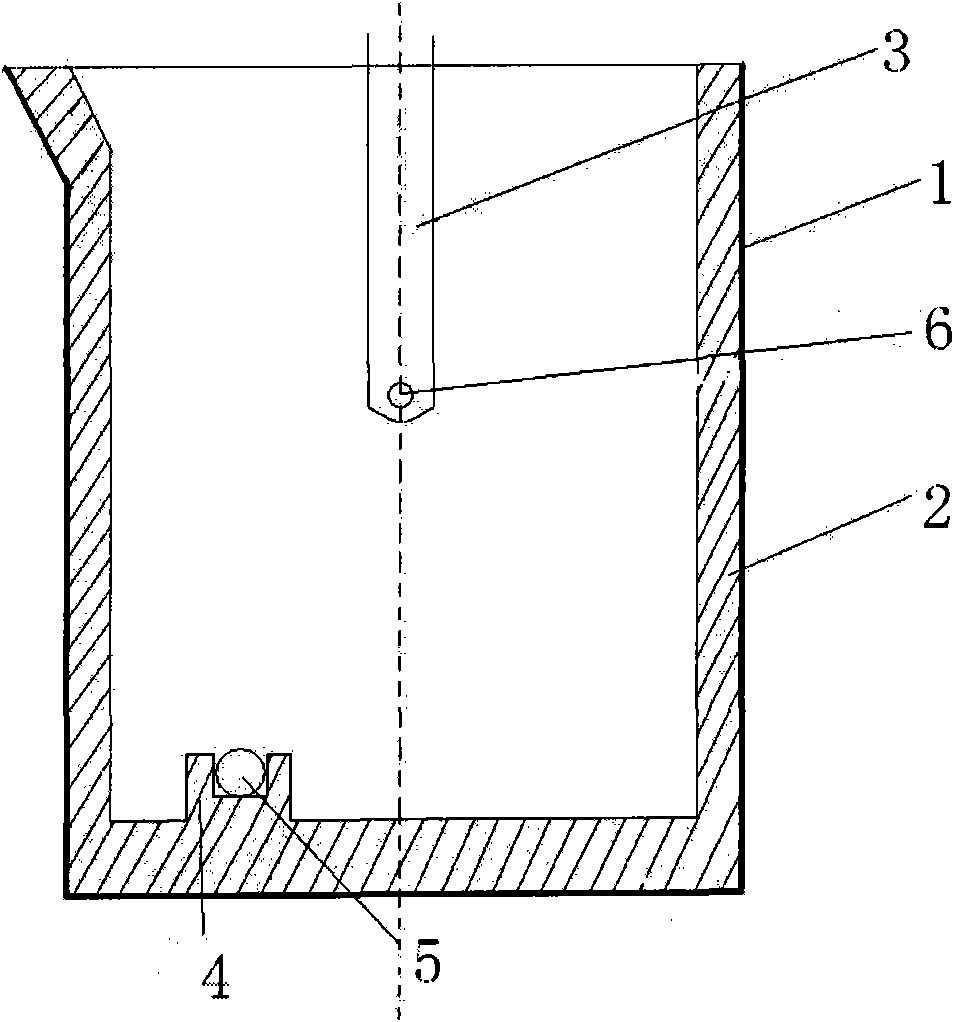

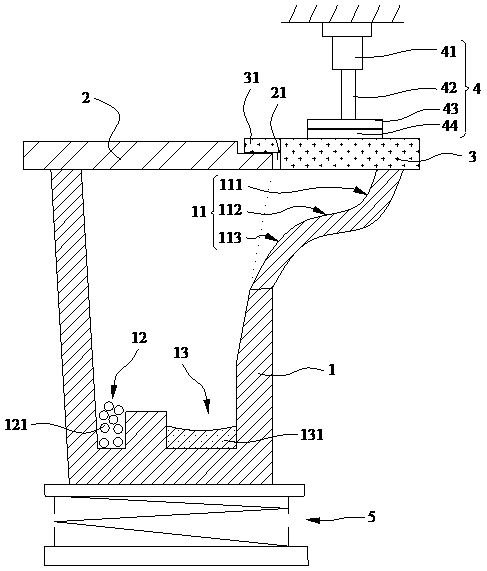

Spheroidizing device and working method thereof

ActiveCN109719262AImprove insulation effectImprove ball effectMelt-holding vesselsEngineeringMechanical engineering

The invention belongs to the field of casting equipment and in particular relates to a spheroidizing device and a working method thereof. The spheroidizing device comprises a ladle body and spheroidizing ladle head covers covering the top and an inlet / outlet of the ladle body, wherein each spheroidizing ladle head cover comprises a cover body covering the top of the ladle body, a cover cap covering the inlet / outlet of the ladle body and a driving mechanism suitable for driving the cover cap to move so as to open the inlet / outlet of the ladle body, so that molten iron enters the ladle body or flows out of ladle body is being poured.

Owner:CHANGZHOU INST OF LIGHT IND TECH

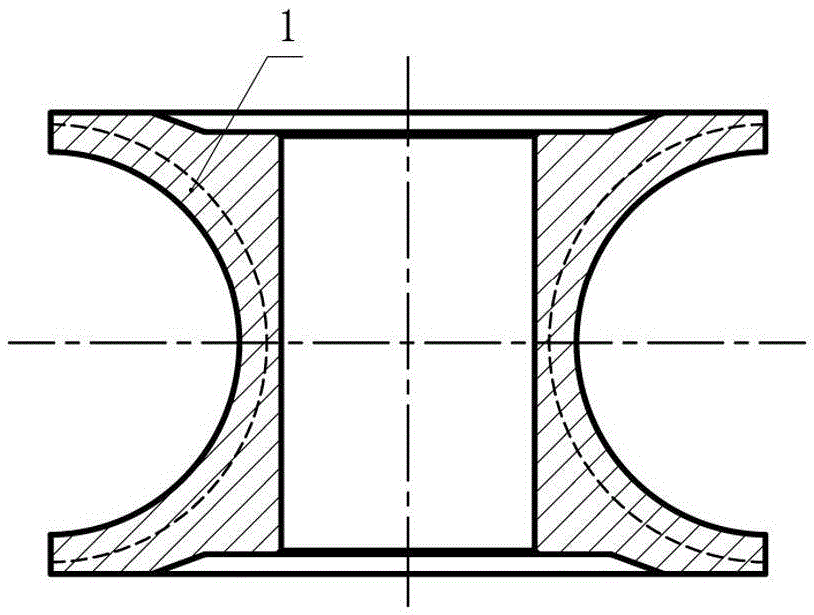

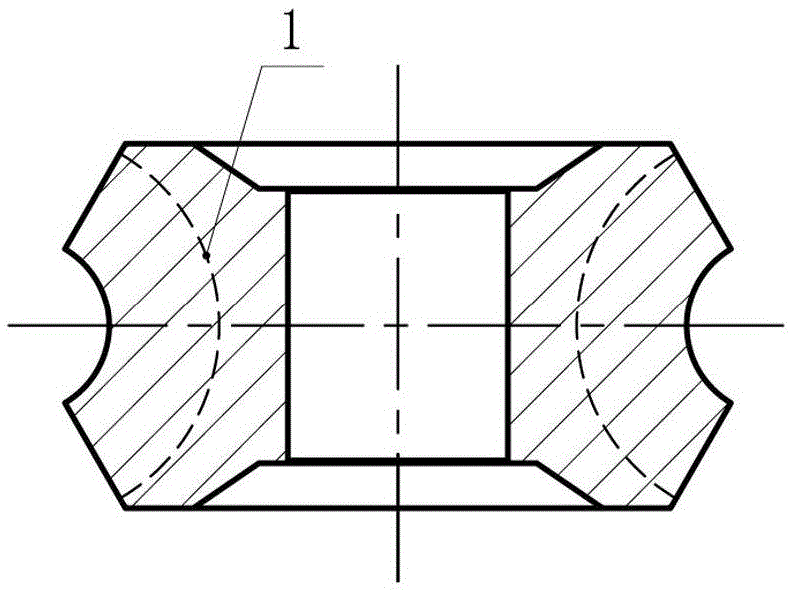

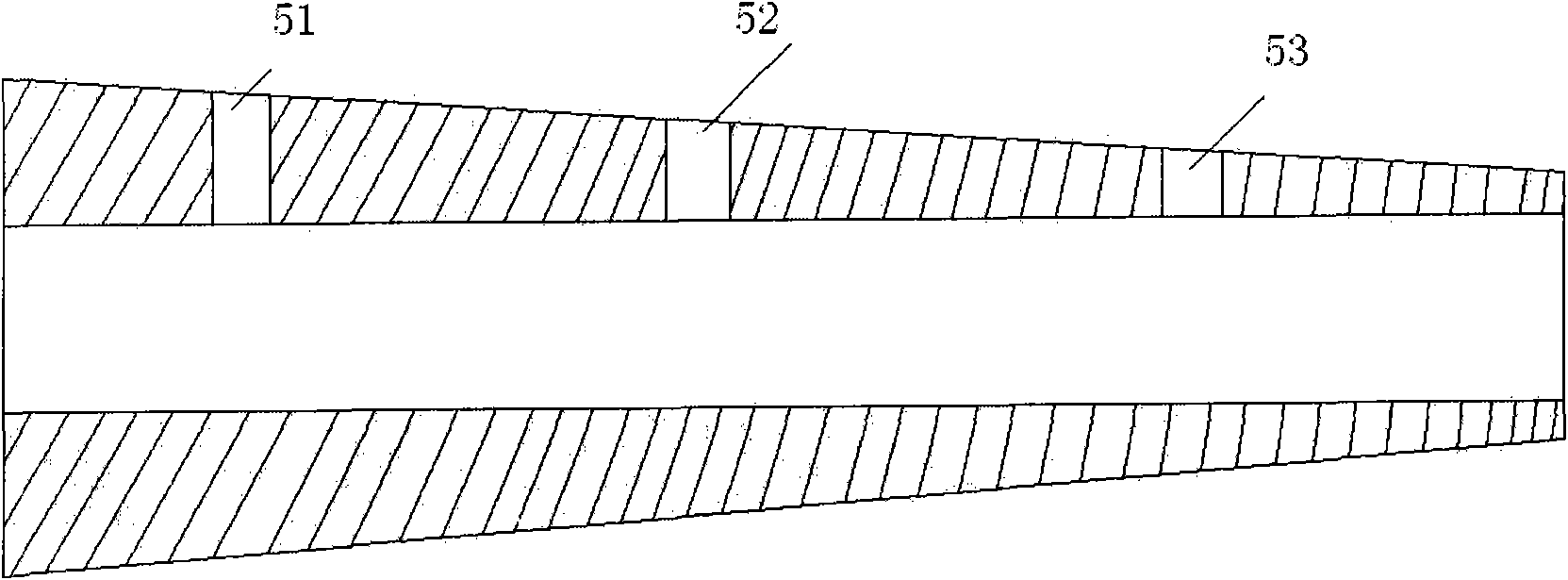

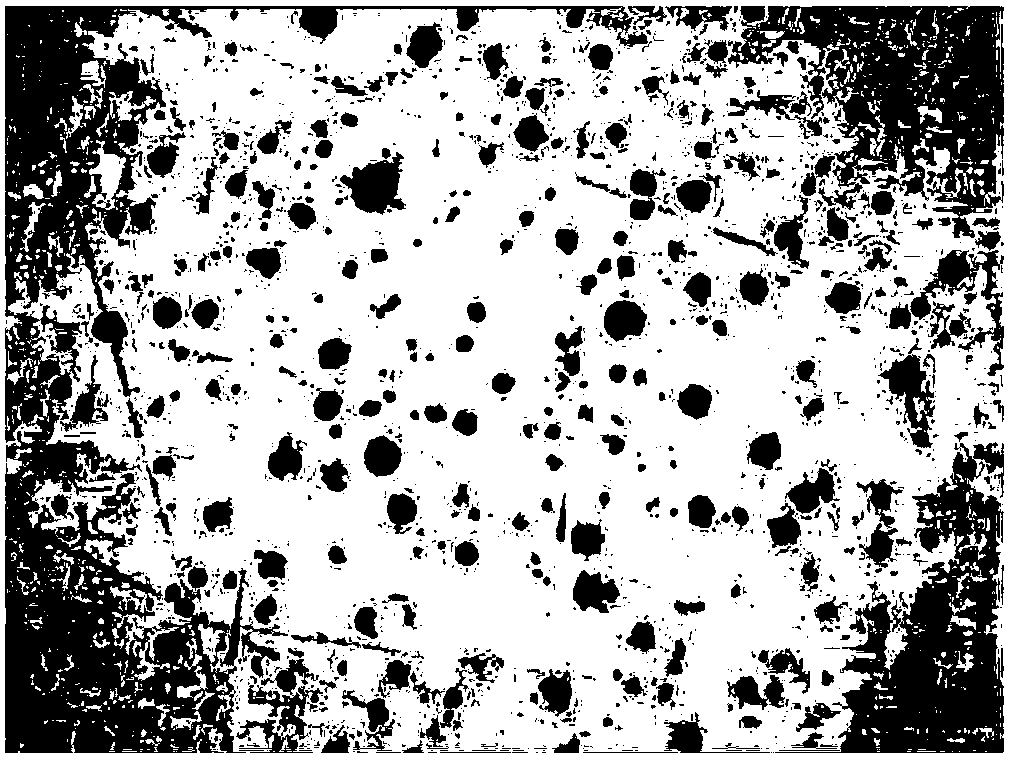

Composite particle reinforced roller of hot-rolling seamless steel pipe sizing mill or reducing mill and preparation method thereof

ActiveCN105618485AImprove ball effectImprove comprehensive mechanical propertiesFurnace typesRollsQuenchingSizing

The invention discloses a composite particle reinforced roller of a hot-rolling seamless steel pipe sizing mill or reducing mill and a preparation method thereof. Composite particles are composed of hardening particles, active wetting agents and matrix reinforcing agents. The composite particle reinforced roller of the sizing mill or reducing mill is cast after nodular cast iron matrix molten metal is reinforced; and the high-strength and high-toughness composite particle reinforced roller is obtained by conducting isothermal quenching and machining on the roller. The composite particle reinforced roller is resistant to abrasion and impact; the service life of the roller is prolonged by over two times; the production cost is lowered; the production efficiency of a steel pipe production enterprise is improved, and economic benefits of the steel pipe production enterprise are increased.

Owner:SHANDONG SIFANG STEEL PIPE EQUIP MFG

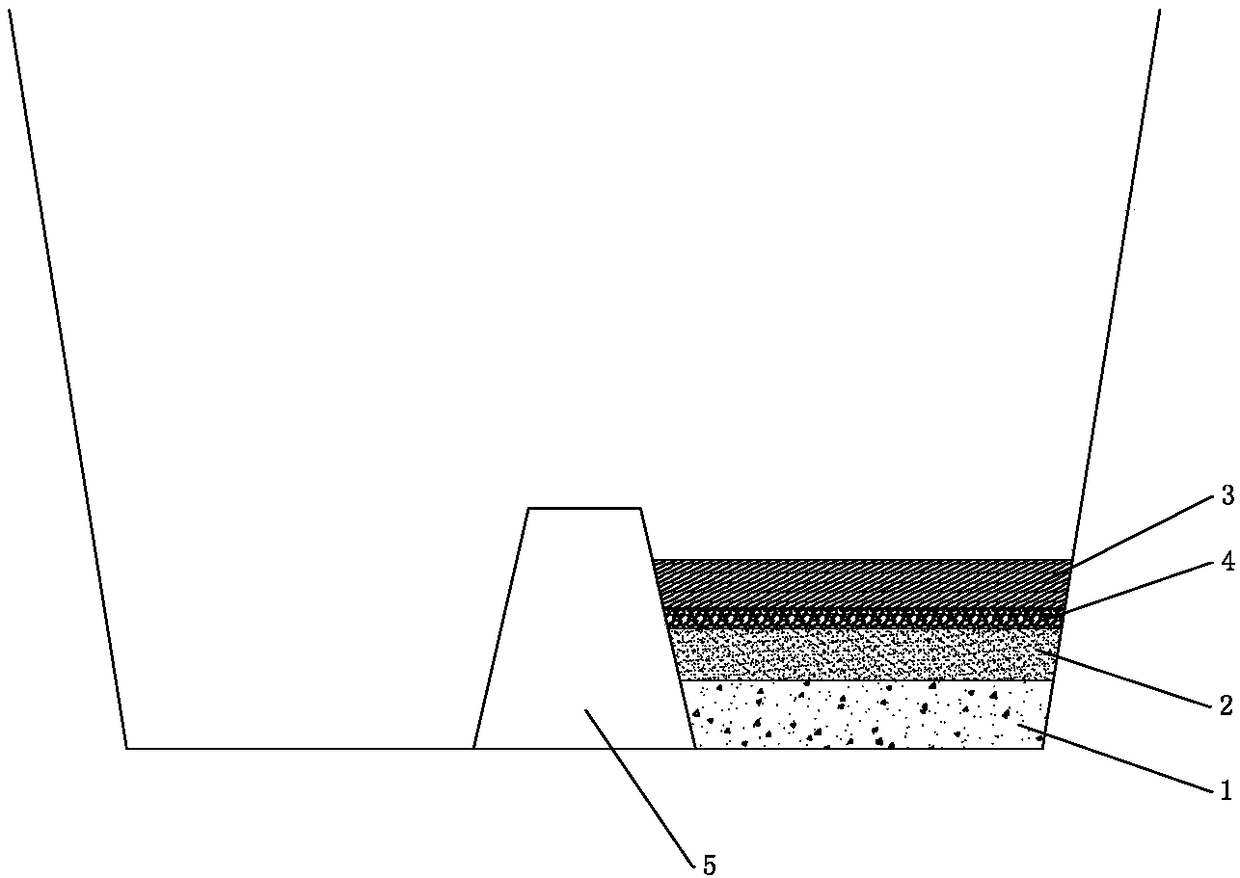

Casting method of high-powered engine box casting

PendingCN111451444AQuality improvementImprove yieldFoundry mouldsFoundry coresTemperature controlIndustrial engineering

The invention discloses a casting method of a high-powered engine box casting. The casting method comprises the steps of preparing moulding sand, performing modeling and core making to obtain a sand mould, preparing pouring iron liquid, taking pig iron, foundry returns and waste steel as raw materials to be fed into a smelting furnace to be smelted, carrying out in-package inoculation and spheroidization on the smelted iron liquid, carrying out stream inoculation before tapping, then carrying out tapping, pouring the iron liquid into the sand mould, carrying out stream inoculation, adopting acold iron riser process for feeding and temperature control, forming a casting after pouring is finished, and carrying out treatment on the formed casting. The obtained casting is good in quality, andquality problems of core clamping, shrinkage, cracks and the like are not prone to happening.

Owner:宜宾普什联动科技有限公司 +1

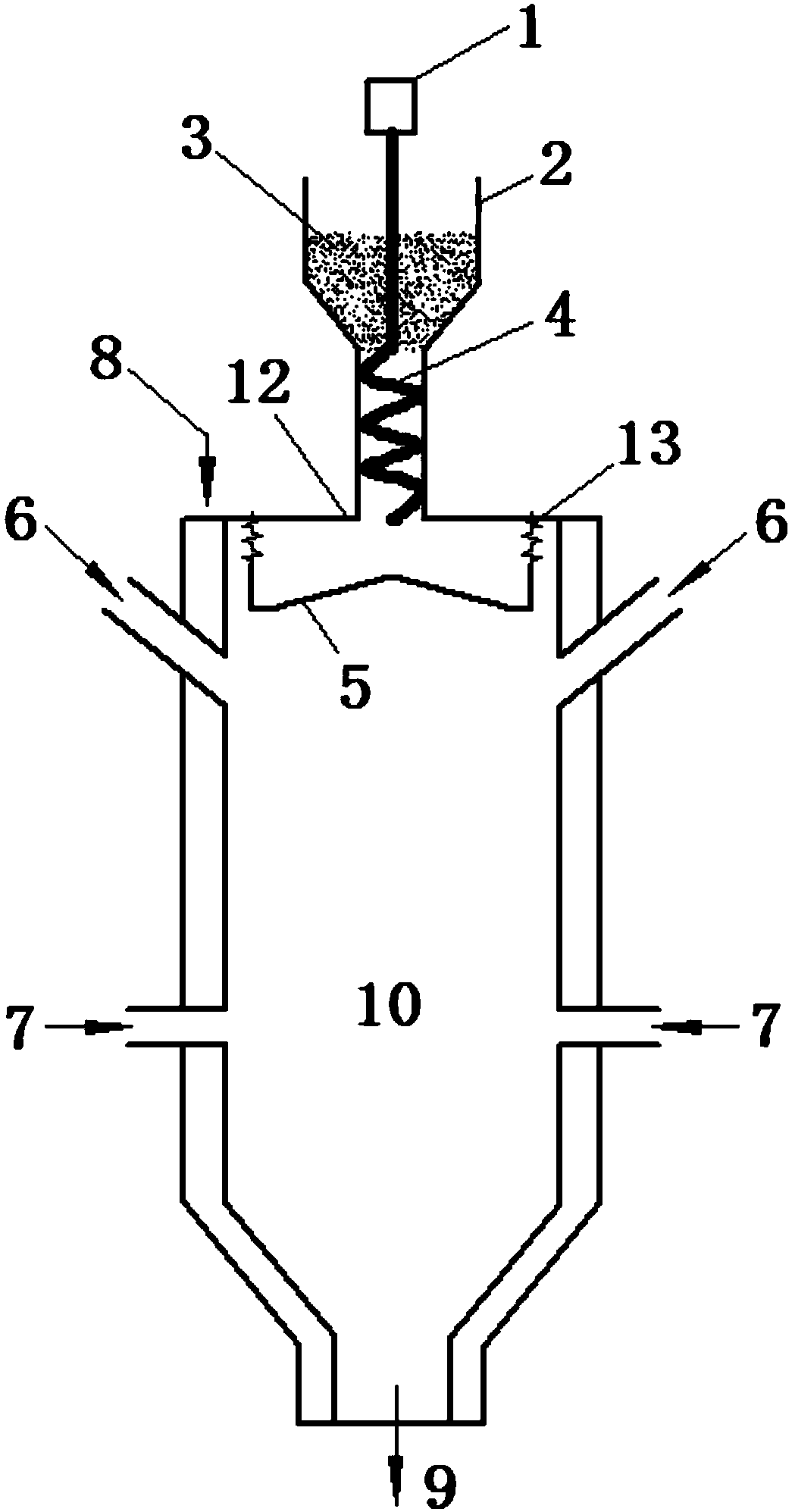

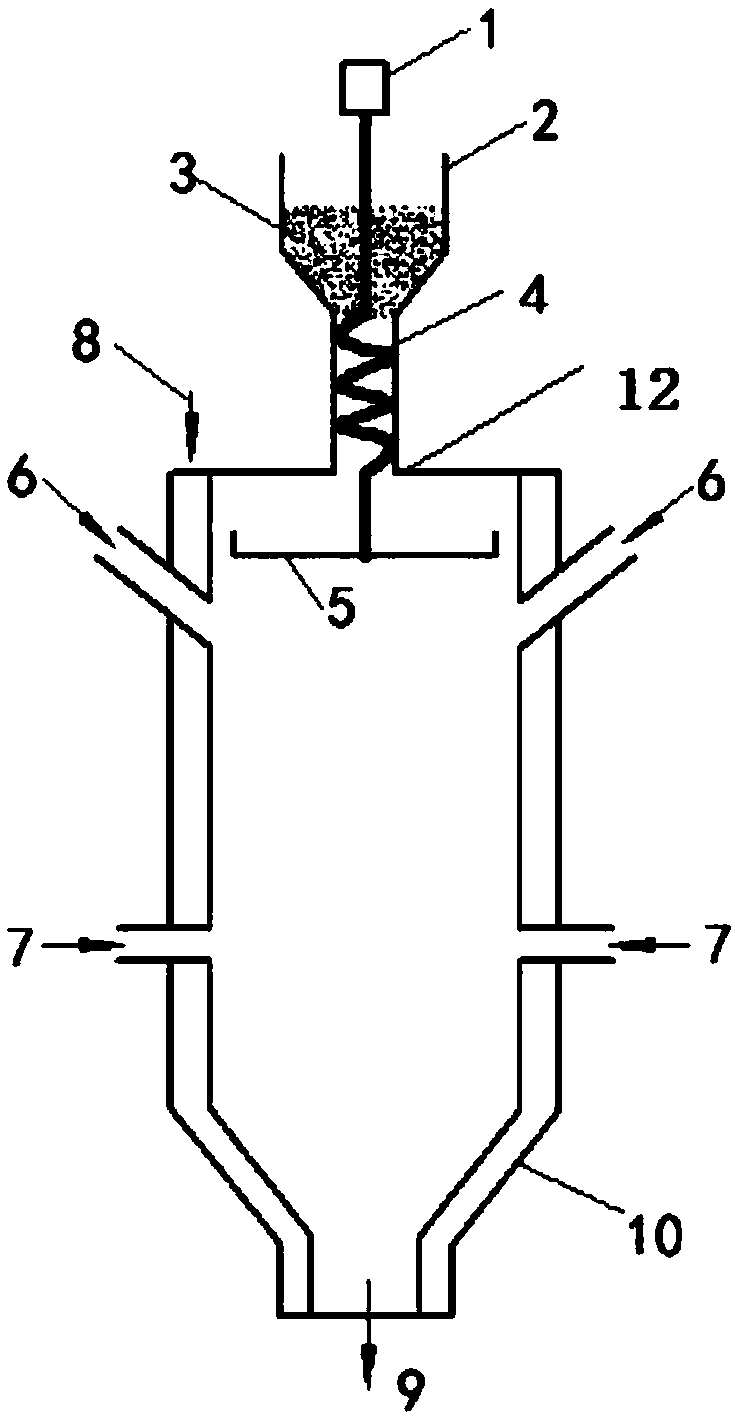

Efficient high-frequency vibration divergent plasma powder spheroidizing device and method and application thereof

ActiveCN108273992ALow costEvenly heatedTransportation and packagingMetal-working apparatusMetallurgyProduct gas

The invention discloses an efficient high-frequency vibration divergent plasma powder spheroidizing device and an application method thereof. The device comprises a high-frequency vibration device, apowder dispersion conic disc and a powder spheroidizing device. The powder dispersion conic disc and the high-frequency vibration device are connected and arranged in the powder spheroidizing device,and the vibration frequency of the powder dispersion conic disc is the same as that of the high-frequency vibration device. The vibration frequency of the high-frequency vibration device is adjusted and controlled by controlling the powder feeding amount and the powder feeding speed of a conveying device, powder is dispersed uniformly and efficiently through combination with the powder dispersionconic disc, whole equipment forms a whole by adjusting the temperature and gas flow of a spheroidizing chamber, each piece of powder can be uniformly heated easily in the spheroidizing chamber in thefree falling body process, and the powder spheroidizing effect is improved. The problems that in an existing plasma powder spheroidizing method, powder is input disorderedly in a concentrated manner and is prone to being united, nonuniform in heating and low in spheroidizing efficiency are fundamentally solved, the efficient high-frequency vibration divergent plasma powder spheroidizing device islow in manufacturing cost, and large-scale and batched production can be really achieved.

Owner:HUNAN UNIV OF TECH

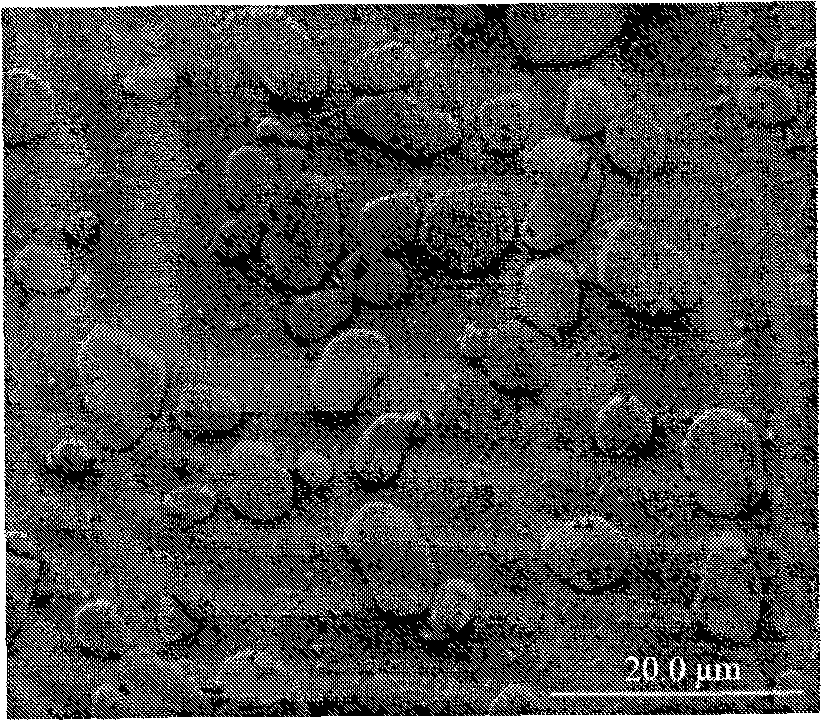

Melting process method for eliminating reverse chill phenomenon of nodular cast iron

The invention discloses a melting process method for eliminating a reverse chill phenomenon of nodular cast iron. Raw materials are strictly required, and pig iron, scrap steel, carburant, silicon carbide, nodulizer, inoculant and in-flow inoculant are selected. The melting process method comprises the following steps of performing charging and melting, performing hardening and tempering, performing molten iron pretreatment, performing spheroidizing inoculation, performing pouring inoculation and performing casting unpacking. According to the melting process method for eliminating the reversechill phenomenon of the nodular cast iron, the reverse chill phenomenon is solved through three aspects of selection of the raw materials, guarantee of the contents of c and s, improvement of the solubility of rare earth and inoculation treatment, the percent of pass of products is improved, and the economic benefit of enterprises is improved.

Owner:江苏力源金河铸造有限公司

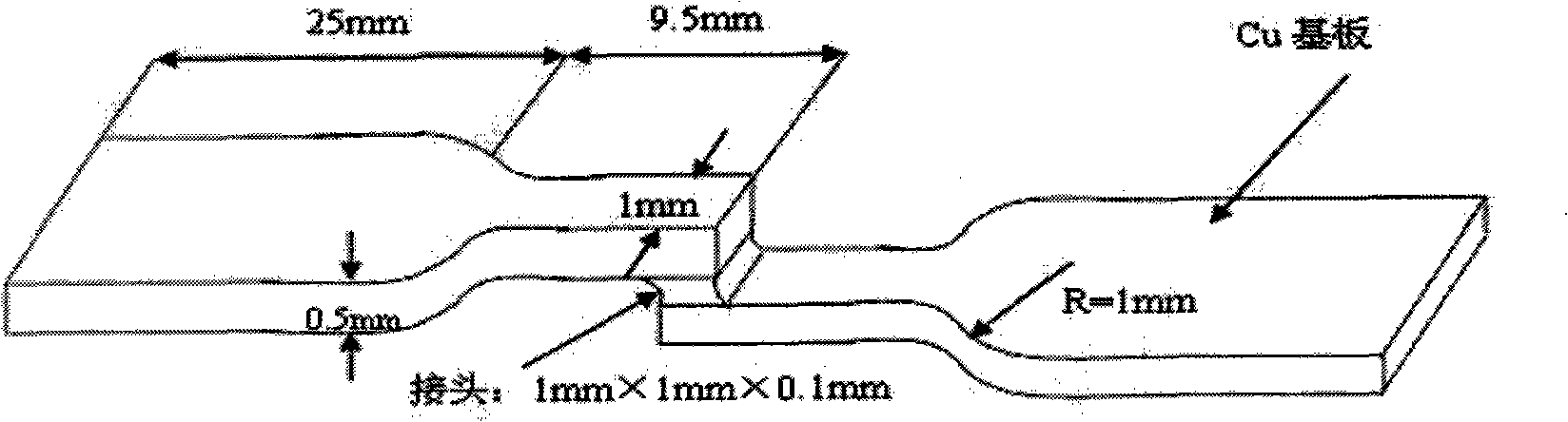

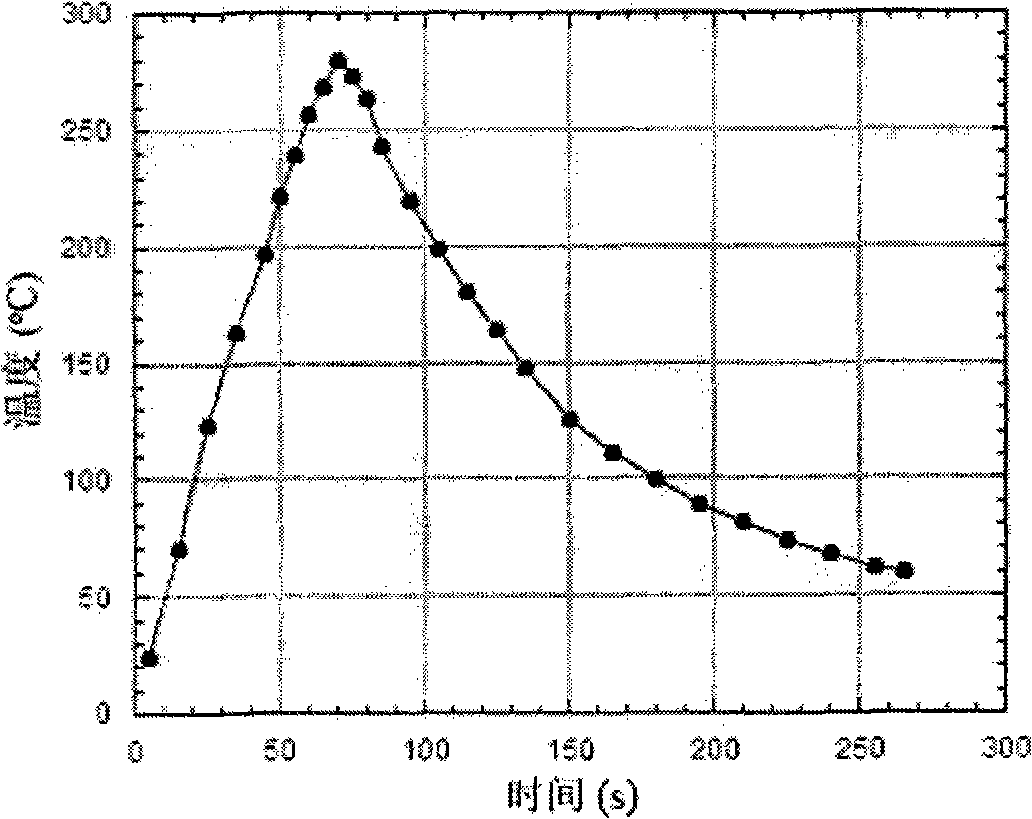

Endogenetic Cu6Sn5 granule reinforced leadless compound solder alloy and manufacture method thereof

InactiveCN101323059AEvenly distributedImprove ball effectWelding/cutting media/materialsSoldering mediaParticulatesLithium chloride

The invention relates to an endogenous Cu6Sn5 particulate reinforced tin and silver based lead-free composite solder alloy and the preparation method, belonging to the technical field of manufacturing lead-free solder for electronic assembly in the microelectronic industry. The composite solder prepared by a traditional endogenous method has uneven distribution of the endogenous particles, and the technology and mechanical property of solder are influenced. The composite solder of the invention is composed of Cu6Sn5 reinforced particles and the eutectic alloy of Sn-3.5Ag; the volume percentages of the two components are respectively 20 percent and 80 percent. The invention is characterized in that potassium chloride and lithium chloride are mixed and melted according to the weight percentage of 1.3:1, and then poured on the eutectic alloy of Sn-3.5Ag; when the eutectic alloy of Sn-3.5Ag is melted, Cu and Sn particles are added; the mixture is preserved at the temperature of 450 DEG C, stirred and staying silently; then the mixture is rapidly cooled to room temperature at a rate of 20, 2, 0.6 or 0.1 DEG C / sec; the complex solder of the invention is obtained by removing mixed salt. The complex solder of the invention has the advantages of low cost, convenient smelting, and good mechanical property and creep resistance.

Owner:BEIJING UNIV OF TECH

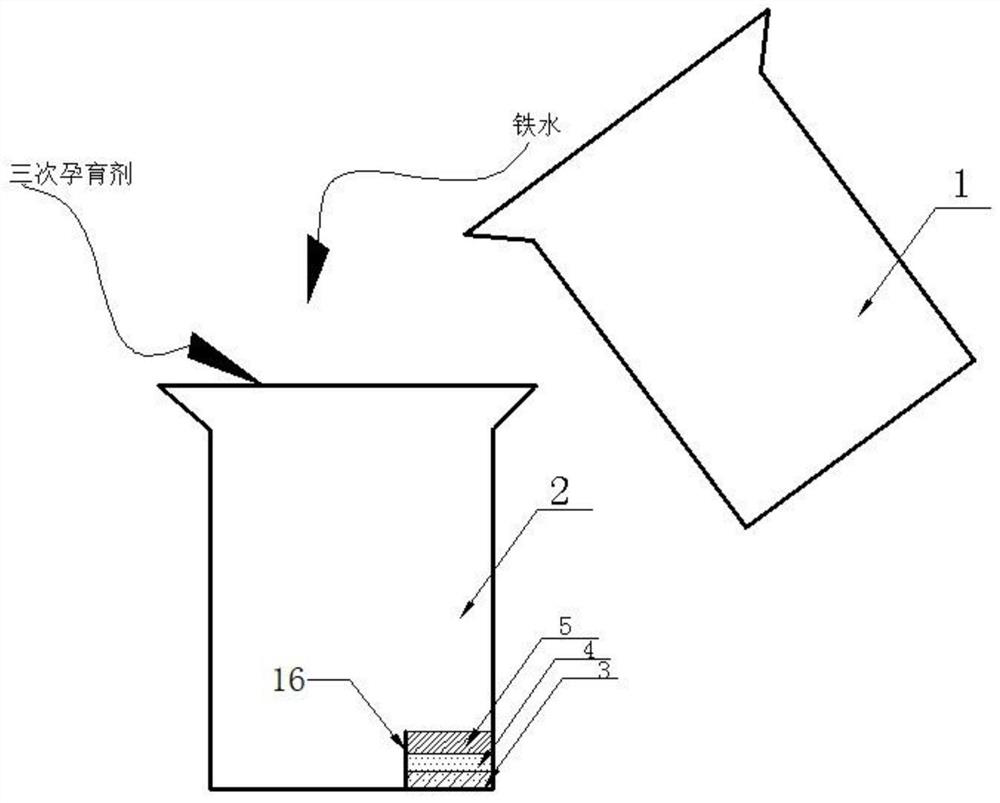

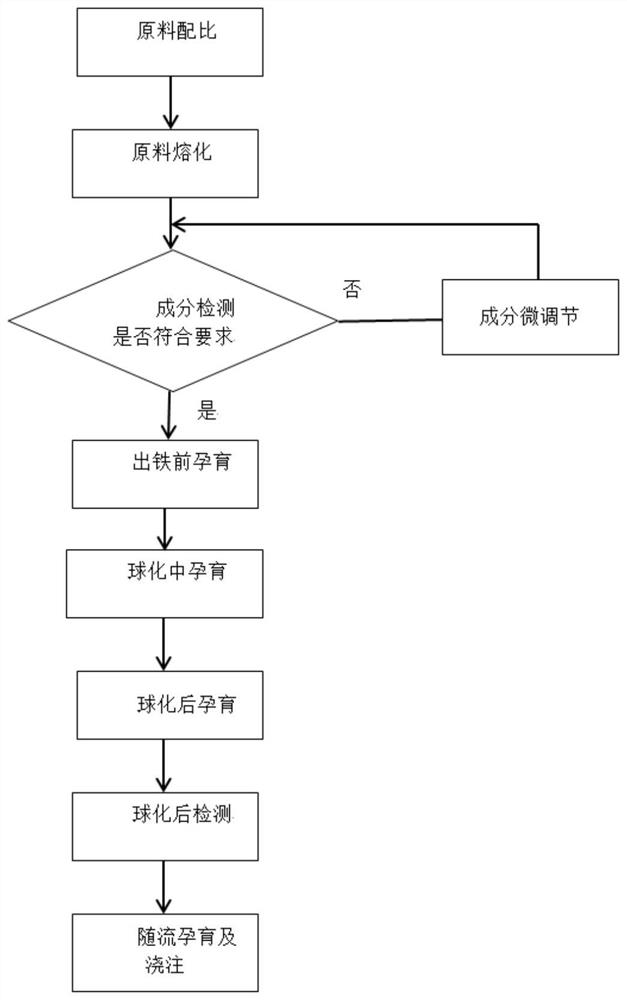

Novel spheroidizing inoculation treatment method

ActiveCN113523205AAvoid high temperature bakingEasy to pull the ropeProcess efficiency improvementDuctile ironGraphite morphology

The invention discloses a novel spheroidizing inoculation treatment method which comprises the following steps: selecting two hot metal ladles as a transfer ladle and a spheroidizing ladle respectively; after the components of the molten iron in the furnace are qualified, overheating the molten iron to 1480-1500 DEG C, discharging the molten iron into the transfer ladle, pouring out a required weight, and adding a primary inoculant into the transfer ladle, wherein a spheroidizing agent and a secondary nucleating agent are preset in the spheroidizing bag; transporting the transfer ladle and the spheroidizing ladle to a pouring site, lifting the transfer ladle to measure the weight and the temperature, rapidly pouring the molten iron into the spheroidizing ladle when the temperature of the molten iron ranges from 1400 DEG C to 1460 DEG C, and adding a third-time inoculant into the spheroidizing ladle while the molten iron is poured into the spheroidizing ladle; and during pouring, adding a nucleating agent for four times along with the molten iron. According to the method, by adopting a ladle-to-ladle spheroidizing inoculation treatment process and controlling the adding amount of the inoculant every time reasonably, the inoculation treatment effect is obviously improved, the spheroidizing effect is more ideal, the number of graphite is large, the graphite form is good, the mechanical property and the metallographic structure are stable, and finally qualified large ductile iron castings can be stably produced.

Owner:武汉武重铸锻有限公司

Spheroidisation reaction package for producing ductile cast iron and spheroidisation method therefor

InactiveCN101579732AImprove absorption rateImprove ball effectMelt-holding vesselsContact timeEngineering

The invention discloses a spheroidisation reaction package for producing ductile cast iron and a spheroidisation method therefor, belonging to the field of casting. The reaction package is composed of a package body, a package wall and a rotatable fishhook; wherein, the fishhook is connected with the package body by a bolt; the reaction package is characterized in that a convex plate with a groove is arranged at the bottom part of the package body, the convex plate is located at one side of the center of the package bottom; a reaction tube is arranged in the groove, three small air holes are arranged on tube wall of the reaction tube and are on a straight line. When the reaction tube is filled with nodularizers, under the heat effect of molten iron, the thinnest part of the tube wall of the reaction tube begins to melt; with the gradual melting of the tube wall, the nodularizers sequentially enter the molten iron to facilitate the nodularization reaction to be carried out under controllable conditions; as passivation magnesium serves as the nodularizers, thus putting off the reaction time between the magnesium and the molten iron, lengthening the contact time between magnesium vapor and the molten iron, improving absorptivity of the molten iron and increasing nodularization effect of magnesium.

Owner:SHANGHAI INST OF TECH

Plasma powder balling device and method and application thereof

ActiveCN108188389ALow costImprove ball effectTransportation and packagingMetal-working apparatusFree fallingMetallurgy

The invention discloses a centrifugal divergent plasma powder balling device. The device comprises an automatic powder feeding device, a powder dispersing device and a powder balling device body; thepowder dispersing device and the automatic powder feeding device are connected in the powder balling device body; the powder feeding amount and the powder feeding speed of the automatic powder feedingdevice are controlled, and the powder dispersing device is also used, so that powder is uniformly dispersed; the temperature and gas flow of a balling chamber are adjusted, so that the whole device is formed into a whole, the powder can be uniformly heated in the free falling process in the balling chamber, and the powder balling effect is improved. The problems that according to existing plasmapowder balling methods, powder is centralized and input disorderly, likely to conglobate and not heated evenly, and the balling efficiency is low are fundamentally solved; the plasma powder balling device is low in manufacturing cost, and can achieve large-scale and batch production in a real sense.

Owner:HUNAN UNIV OF TECH

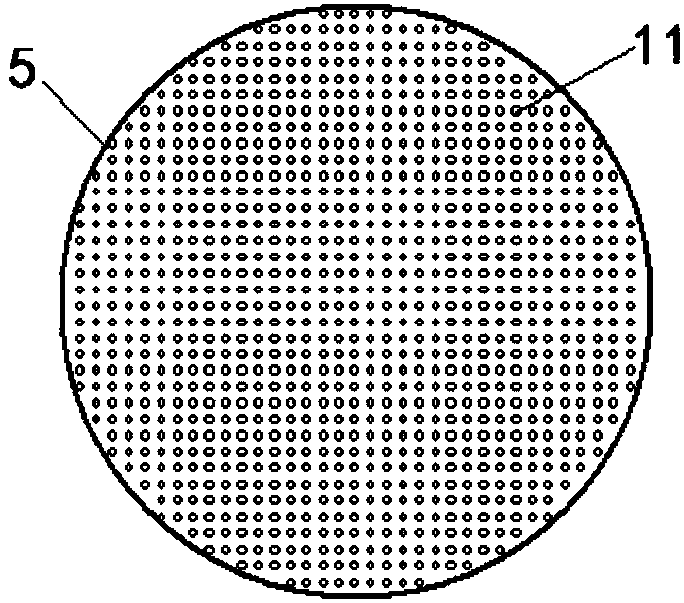

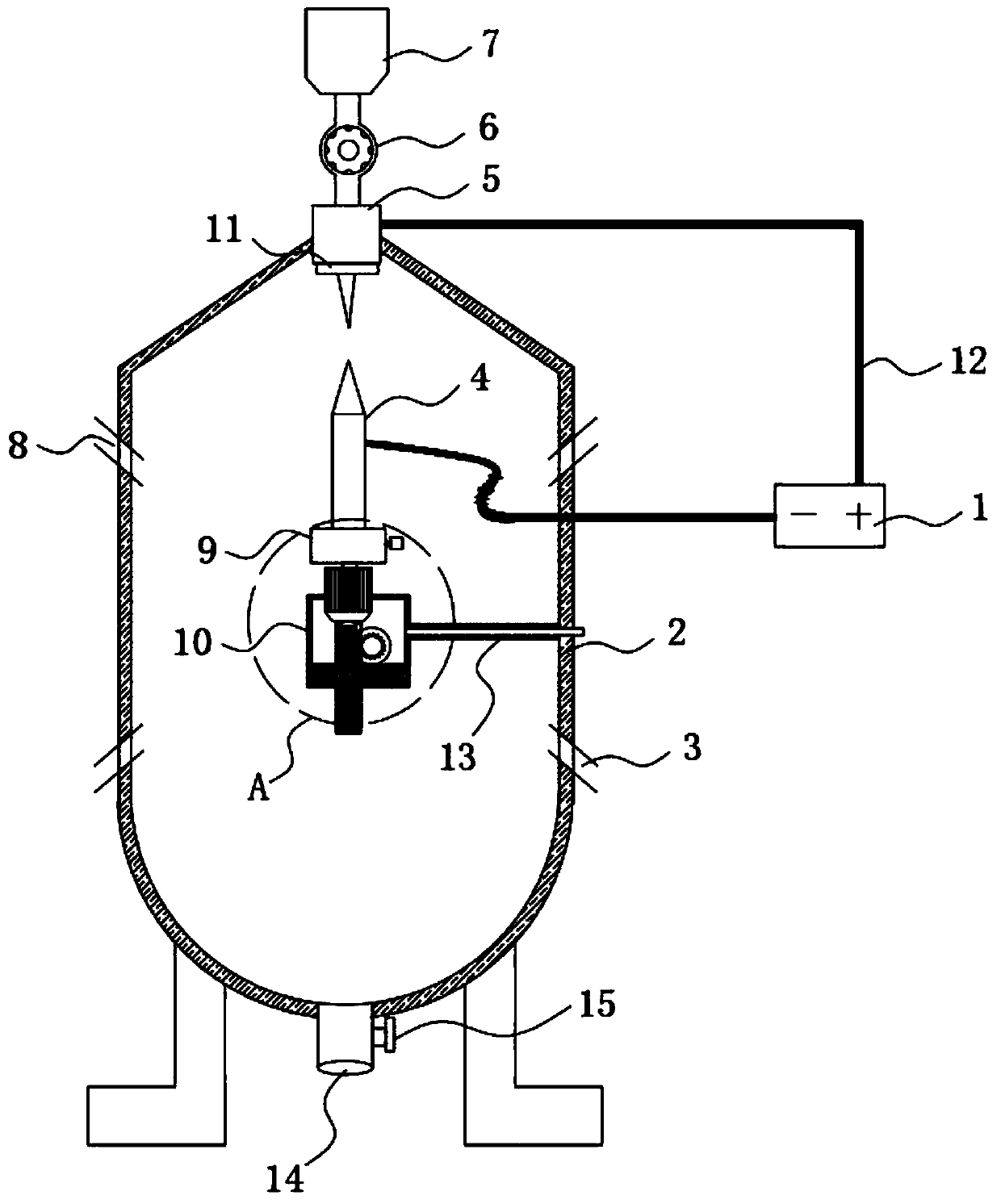

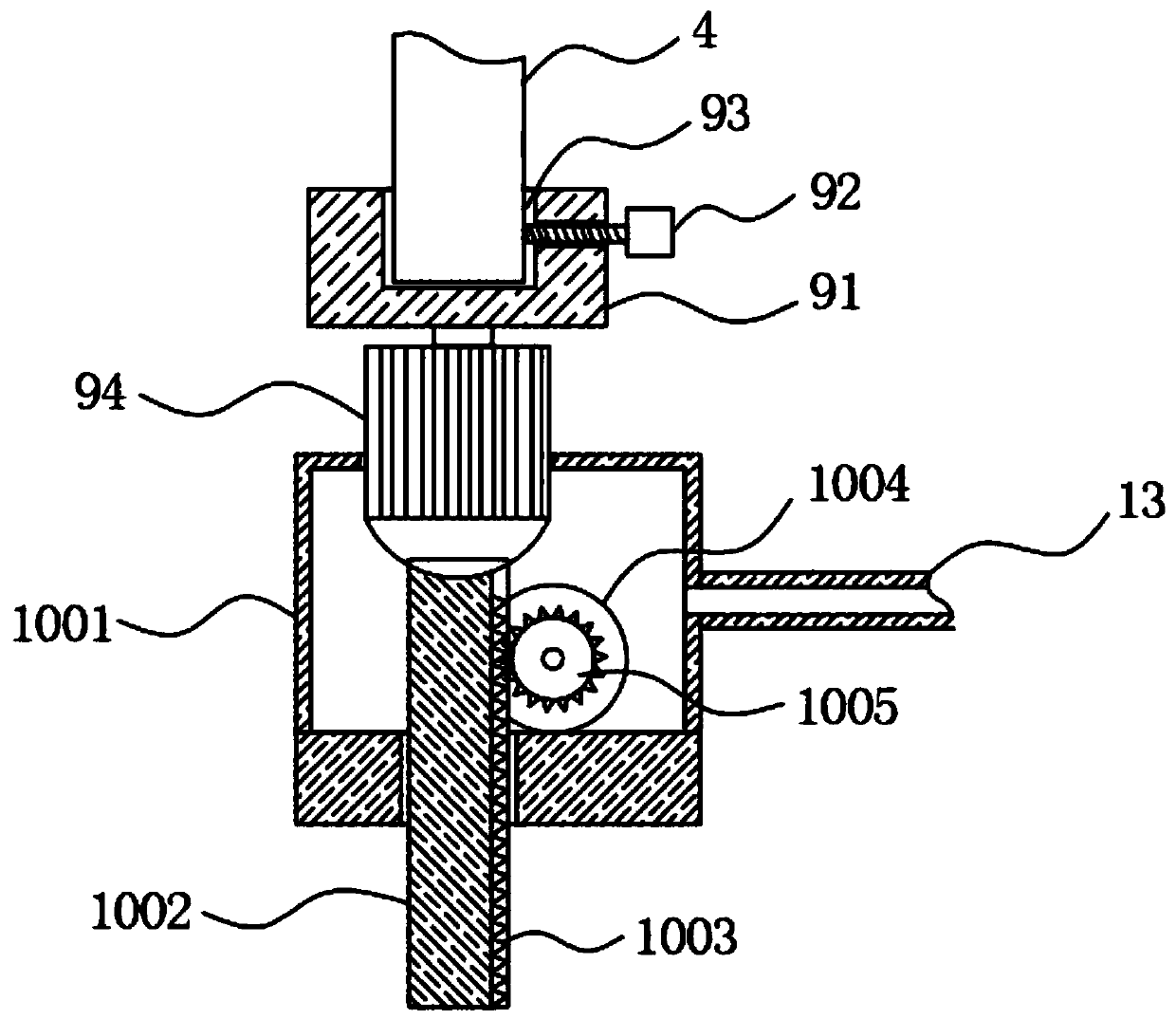

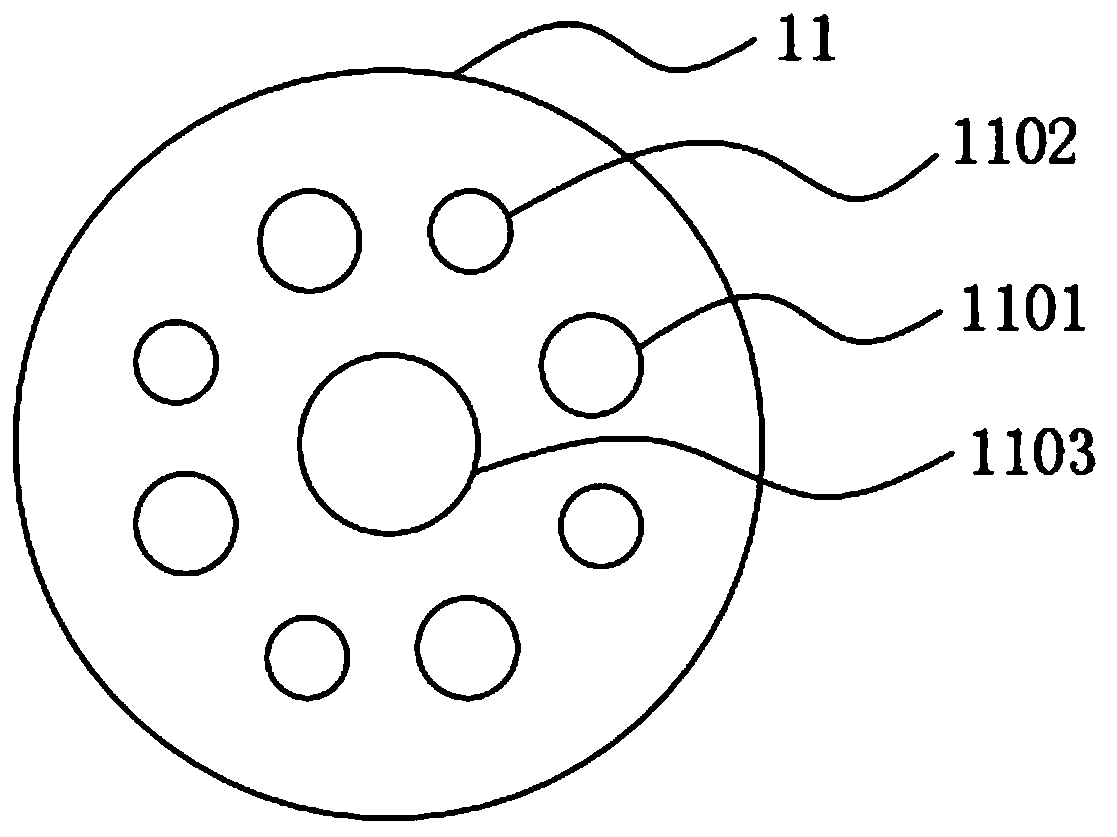

Plasma-arc nodulizing device and method for iron-based intermediate alloy powder

The invention discloses a plasma-arc nodulizing device for iron-based intermediate alloy powder. The plasma-arc nodulizing device and method for the iron-based intermediate alloy powder comprises an atmospheric reaction cavity and a plasma-arc power supply. A plasma-arc spray gun is fixedly mounted at the top of the atmospheric reaction cavity. The upper portion of the plasma-arc spray gun communicates with a powder delivery mechanism. A porous powder-dispersion outlet plate is mounted at the lower end of the plasma-arc spray gun. A lifting mechanism is fixedly connected to the inner wall of the atmospheric reaction cavity through a hollow supporting plate. A rotary clamping mechanism is mounted at the upper end of the lifting mechanism. A conical carbon bar is vertically upwards mounted on the upper portion of the rotary clamping mechanism. The positive electrode of the plasma-arc power supply is connected with the plasma-arc spray gun through a wire, and the negative electrode of theplasma-arc power supply is connected with the conical carbon bar through a wire. By the adoption of the plasma-arc nodulizing device for the iron-based intermediate alloy powder, the problem of electric-arc electrodes for plasma-arc power nodulizing is effectively solved, and the phenomenon of instable plasma arcs caused by losses of the conical carbon bar is avoided. The powder nodulizing effectis improved.

Owner:ANHUI CHUNGU 3D PRINTING INTELLIGENT EQUIP IND TECH RES INST CO LTD

Degradated-spheroidization-resisting composite inoculant and preparation technology of composite inoculant

The invention discloses a degradated-spheroidization-resisting composite inoculant. The composite inoculant comprises the following components of, by mass percent, 55-65% of Si, 1.0-2.0% of Ca, 4.0-6.0% of Ba, 0.5-2.0% of Mg, 0.1-1.5% of RE, 1.5max% of Al and the balance Fe. According to the degradated-spheroidization-resisting composite inoculant, the nodularization effect can be improved, graphite nodules are refined, the quantity of the graphite nodules is increased, the roundness of the graphite nodules is improved, the graphite nodules are distributed uniformly, the degradated spheroidization is lowered, the effective inoculation time is prolonged, and the mechanical properties of nodular iron castings are further improved, the production cost is lowered, and the quality of nodular cast iron is improved.

Owner:南京浦江合金材料股份有限公司

Spheroidizing and inoculating process for spheroidal graphite cast iron

The invention discloses a spheroidizing and inoculating process for spheroidal graphite cast iron. The spheroidizing and inoculating process comprises the following steps that materials are prepared,wherein the total amount of a required nodulizing agent and a nucleating agent is determined according to the total amount of molten iron, and the nodulizing agent and the nucleating agent are dried;alloy is loaded into a ladle, wherein the nodulizing agent, the part of the nucleating agent and a covering agent are sequentially loaded into the ladle; spheroidizing is carried out, wherein part ofthe molten iron is quickly poured into the ladle, and the rest of the nucleating agent and the remaining molten iron are added when the spheroidization reaction approaches the tail sound; and the treatment is finished, wherein slagging is carried out after the spheroidizing treatment is finished, and floating silicon is added to inoculate and cover a heat preservation agent to be lifted to a pouring site after slagging. According to the spheroidizing and inoculating process, the molten iron is poured into the ladle twice, most of the molten iron is mixed with the nodulizing agent first, so that the molten iron poured into the ladle in advance is fully reacted with the nodulizing agent, then the rest molten iron is poured, and therefore the spheroidization effect can be effectively improved. The invention is applied to the field of casting.

Owner:湖南精量重工科技有限公司

Si-Mg-Fe alloy nodularizer

The invention relates to a silicon-magnesium ferroalloy nodulizer, which is characterized in that the nodulizer comprises the following compositions by weight percentage: 5 to 15 percent of magnesium, 37 to 52 percent of silicon, and the balance being iron. The nodulizer can give full play to the advantages of various spheroidizing elements, improve the spheroidizing effect, and meet the demands of different production conditions and different structural castings by adjusting the content of the spheroidizing elements, has stable reaction, is easy to operate, and makes spheroidization stable. Simultaneously, due to increased crystal nucleus, the grain size of the castings is finer, so that the nodulizer not only has the enhancing function but also can reduce the chilling tendency.

Owner:大连核心铸造技术工程研究所

Low-temperature-resistance high-toughness as-cast ductile iron, and production method and application thereof

The invention discloses low-temperature-resistance high-toughness as-cast ductile iron, which comprises the following chemical ingredients in percentage by weight: 3.4 to 3.6 percent of C, 2.0 to 2.3 percent of Si, at most 0.2 percent of Mn, at most 0.02 percent of P, at most 0.01 percent of S, 0.035 to 0.05 percent of Mg residue, 0.015 to 0.025 percent of sigma Re residue, 0.05 to 0.1 percent ofSr, 0.15 to 0.25 percent of Ni, 0.10 to 0.15 percent of Ti and the balance Fe. The invention also discloses a production method and application of the low-temperature-resistance high-toughness as-cast ductile iron to the preparation of wind-power generator accessories, automobile accessories, boat accessories and petrochemical engineering. The low-temperature-resistance high-toughness as-cast ductile iron produced by the method provided by the invention can reach each technical index of QT400-18L of GB / T1348-2009 in the cast state, the graphitizing annealing heat treatment is avoided, the energy consumption is reduced, and meanwhile, the low-temperature-resistance high-toughness as-cast ductile iron has the outstanding advantages of stable quality and the like, and the operation is simpleand convenient.

Owner:四川海工科技有限公司

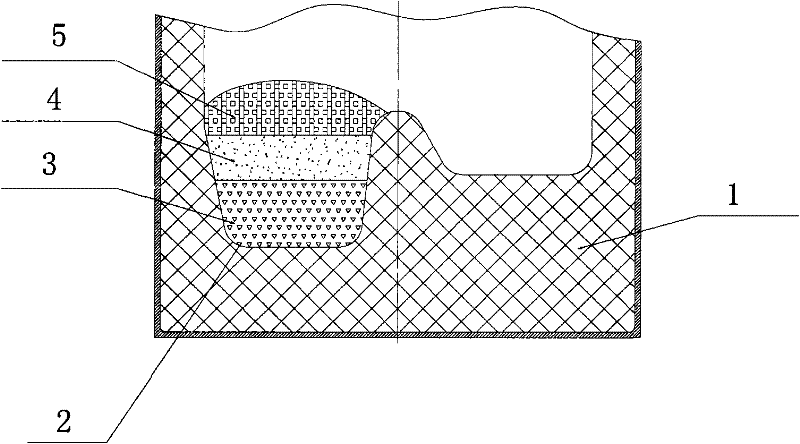

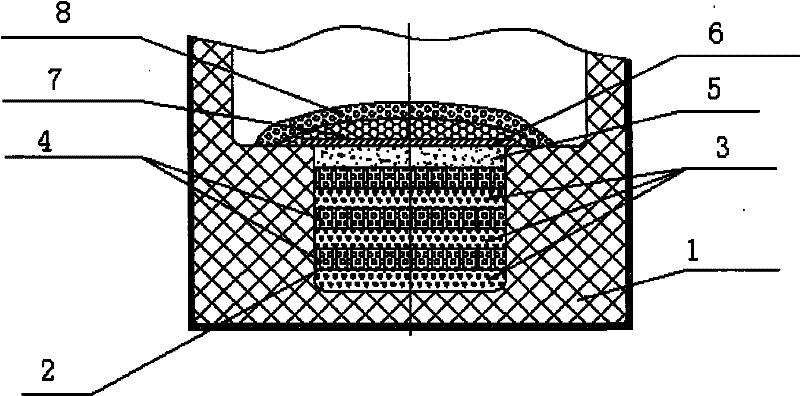

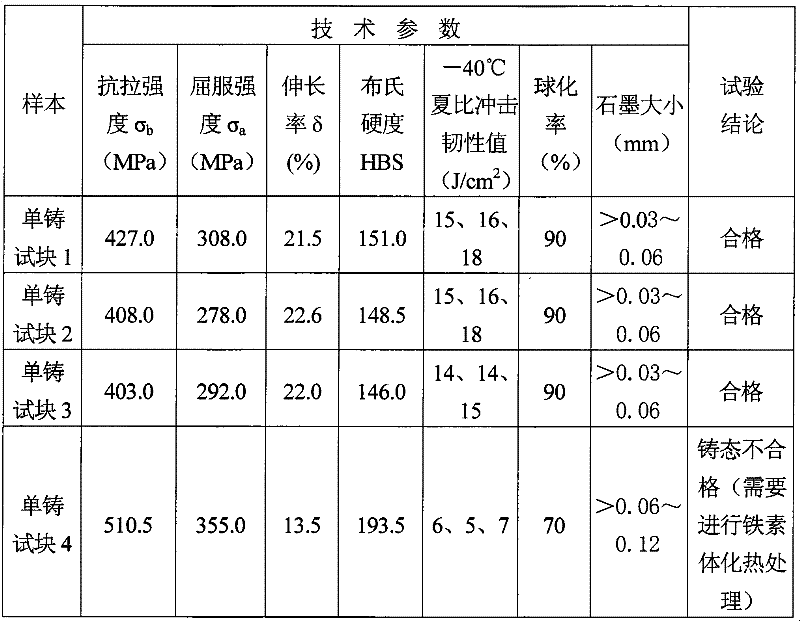

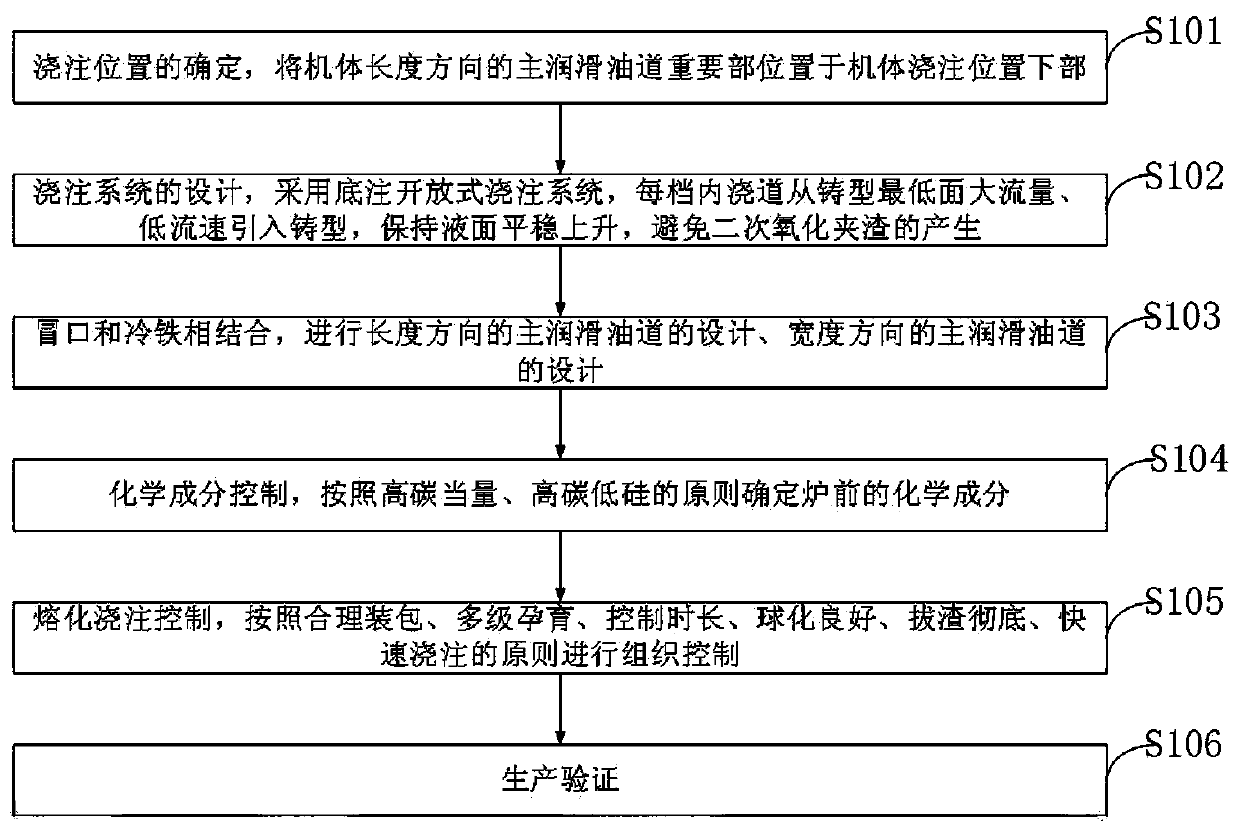

Method for forming main lubricating oil passage of nodular cast iron diesel engine body and application

The invention belongs to the technical field of cast iron casting, and discloses a method for forming a main lubricating oil passage of a nodular cast iron diesel engine body and application. A bottom-pouring open-type gating system with a filter device is adopted to purify molten iron, a feeding head is arranged at the thermal center part of the main lubricating oil passage, and cold iron is usedin cooperation to balance the temperature field of nodular cast iron; and the stokehold chemical composition, reasonable charging, multi-stage inoculation, duration control, good nodularization, thorough slagging-off and fast pouring parameters are determined according to the principles of high carbon equivalent and high carbon and low silicon, and internal compaction of the thick and large thermal center part is performed to eliminate shrinkage and slag inclusion inside the main lubricating oil passage of the engine body. The method is beneficial to realizing the basic balance of the temperature field of the nodular cast iron. The method guarantees the high quality of the molten iron, realizes the internal compaction of the thick and large thermal center part, eliminates the quality risks of shrinkage and slag inclusion defects inside the main lubricating oil passage of the engine body, and overcomes the shrinkage casting defect of the main lubricating oil passage of the complicatednodular cast iron diesel engine body.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

Intelligent spheroidizing device for metal part forging

InactiveCN110640129AShorten the opening and closing timeImprove insulation effectMolten metal pouring equipmentsProcess engineeringMolten steel

The invention belongs to the technical field of forging, and particularly relates to an intelligent spheroidizing device for metal part forging. The intelligent spheroidizing device comprises a pot-shaped bag body provided with a spout, a cover body covering the top of the pot-shaped bag body, a cap covering the spout and a drive mechanism located above the cap. The drive mechanism drives the capto move upwards to be separated from the spout so as to open the spout, and therefore molten steel enters or is poured out of the pot-shaped bag body through the spout. The automation degree is improved, the opening and closing time of the spout is shortened, the insulating effect of the pot-shaped bag body is improved, the spheroidizing effect is improved, then it is guaranteed that the initial structure of a steel blank is more uniform, and the forging quality can be improved easily.

Owner:苏师大半导体材料与设备研究院(邳州)有限公司

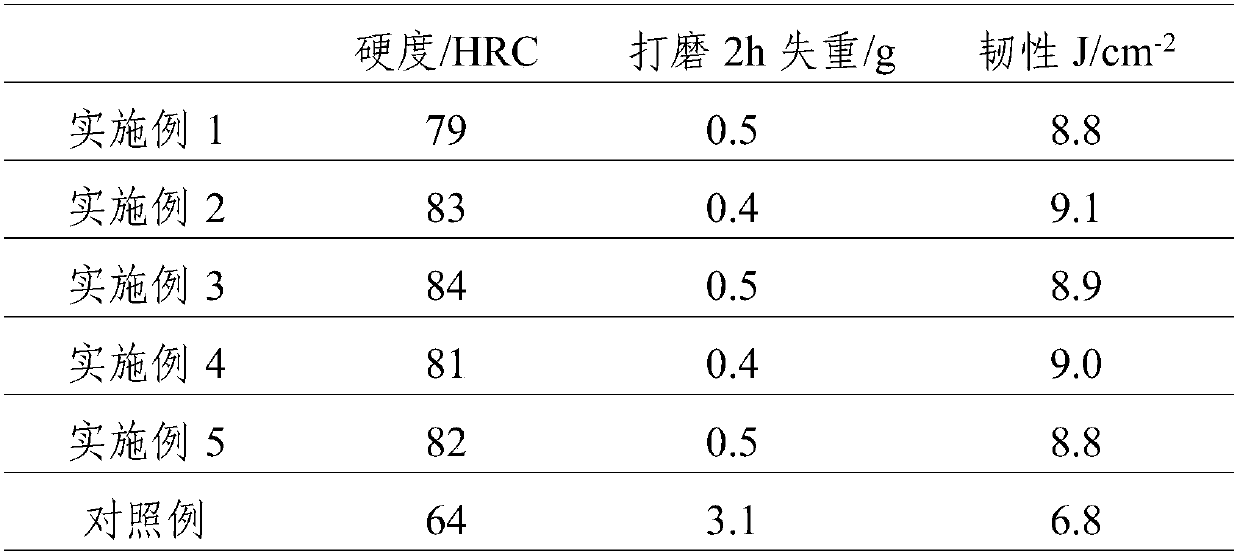

High-quality wear resisting ball and preparation process thereof

InactiveCN107723586AAvoid disadvantagesQuality improvementProcess efficiency improvementGrain treatmentsHardnessCorrosion

The invention relates to the technical field of wear resisting balls, in particular to a high-quality wear resisting ball and a preparation process thereof. The high-quality wear resisting ball comprises the following elements in percentage: 2.6-3.5% of C, 1.5-2.4% of Si, 0.4-0.9% of Mn, 1.5-2.0% of Cr, 0.003-0.01% of Nd, 0.005-0.01% of Te, 0.05-0.1% of Cu, 0.001-0.005% of B, 0.1-0.5% of Zn, 0.01-0.04% of Sr, P not more than 0.05%, S not more than 0.05%, and the balance of Fe. The wear resisting ball effectively makes up the defects of low hardness and easy corrosion in a traditional wear resisting ball to a certain extent.

Owner:NINGGUO ZHENGXING WEAR RESISTANT MATERIALS

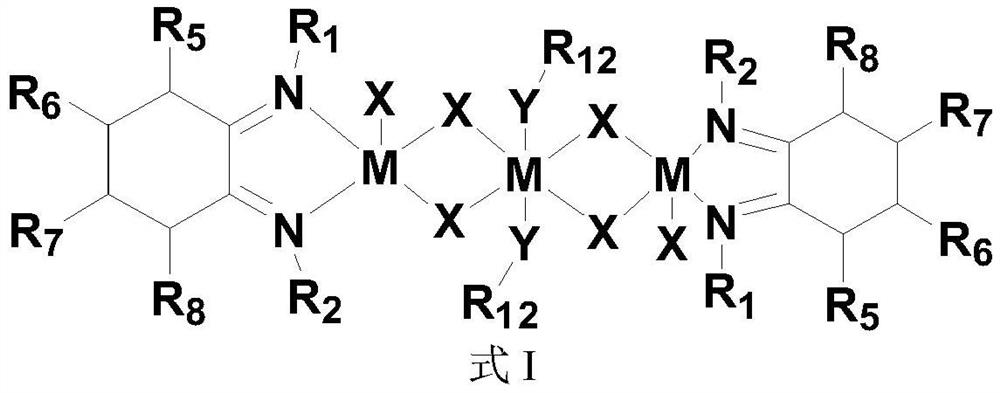

Preparation method of copolymer of olefin and unsaturated carboxylic acid

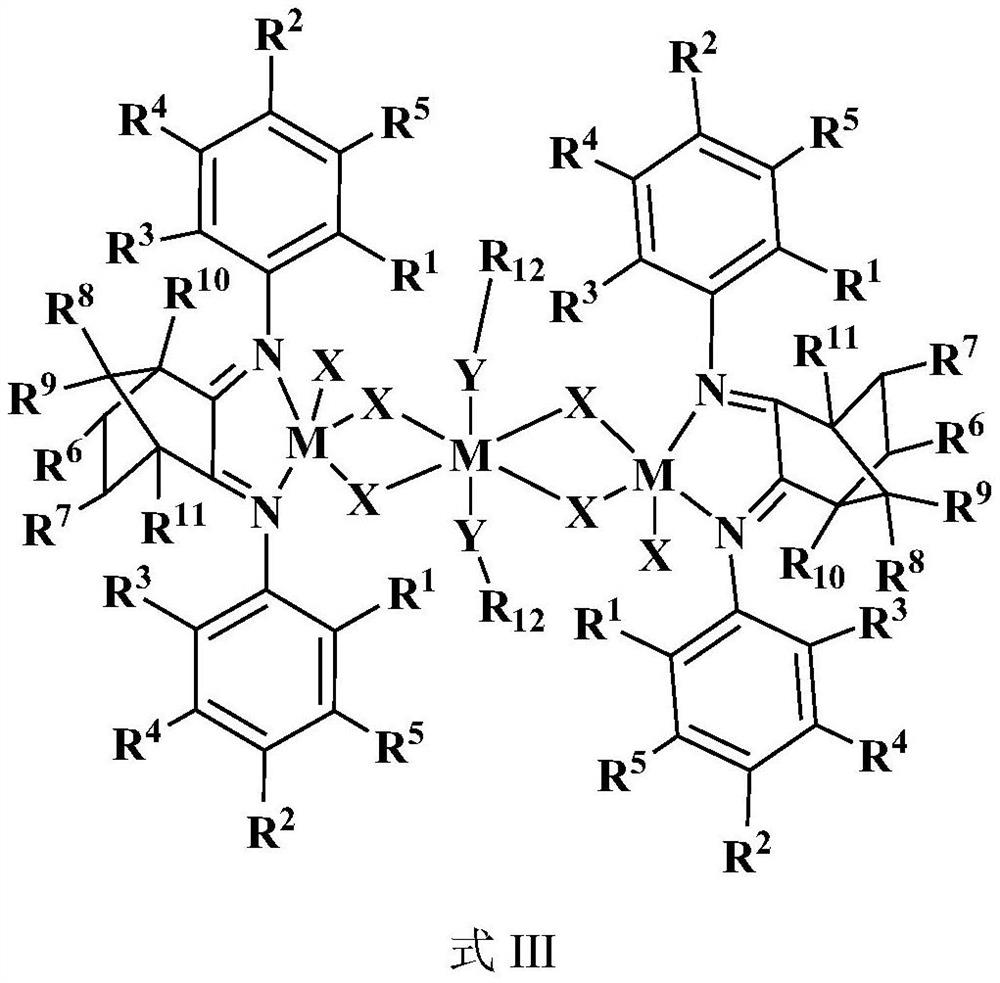

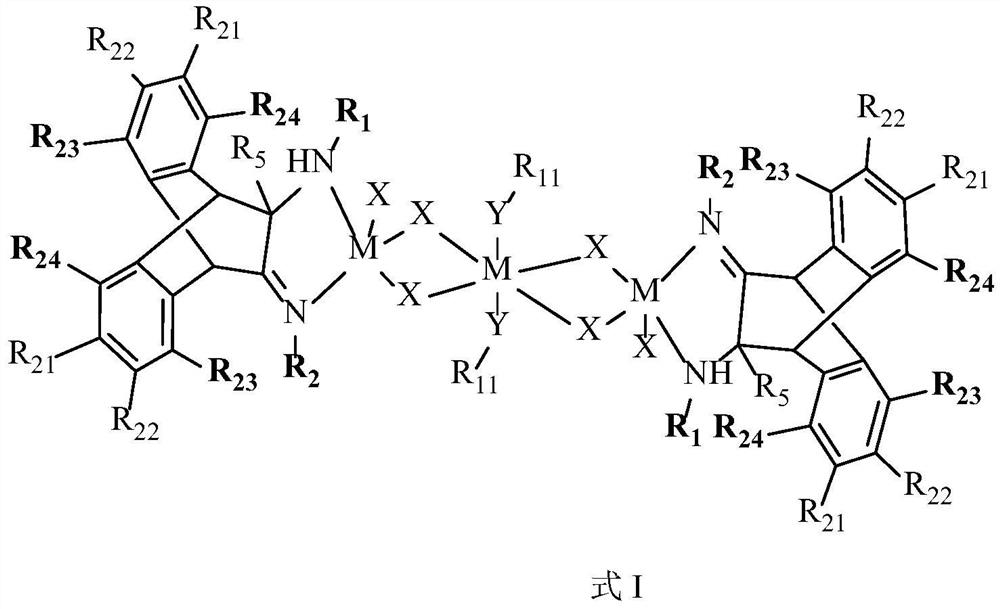

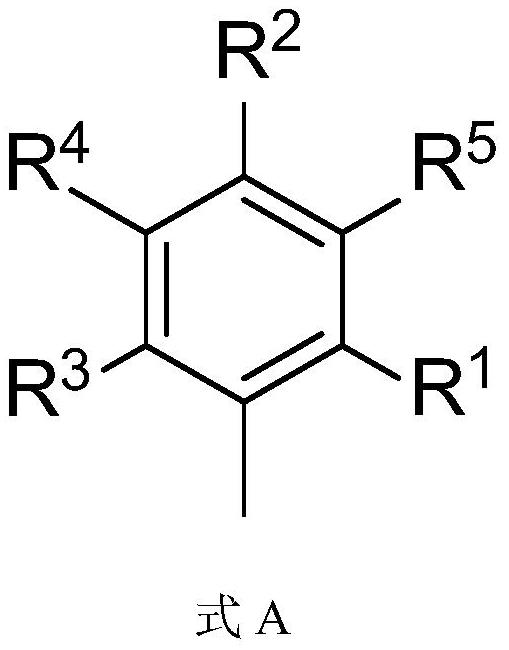

The invention relates to a preparation method of a copolymer of olefin and unsaturated carboxylic acid and the copolymer prepared by the method. The method comprises the step of polymerizing olefin and unsaturated carboxylic acid in the presence of a catalyst, an improver, an optional chain transfer agent and an improver, wherein the used catalyst comprises a diimine metal complex as shown in a formula I which is described in the specification. The spherical and / or sphere-like polymer prepared by the preparation method has a good prospect in industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

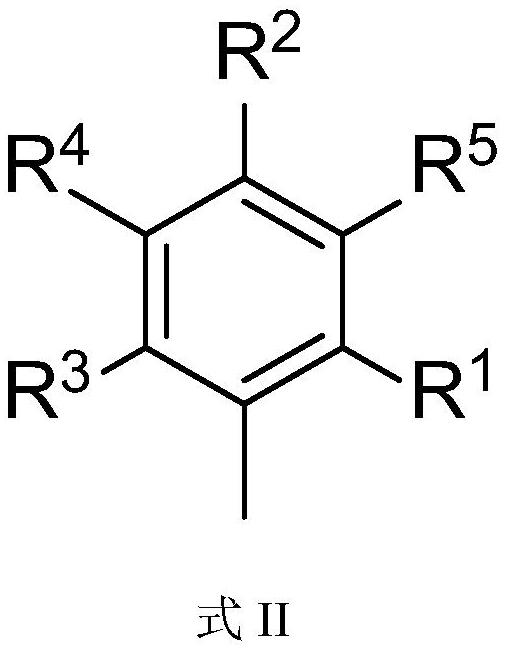

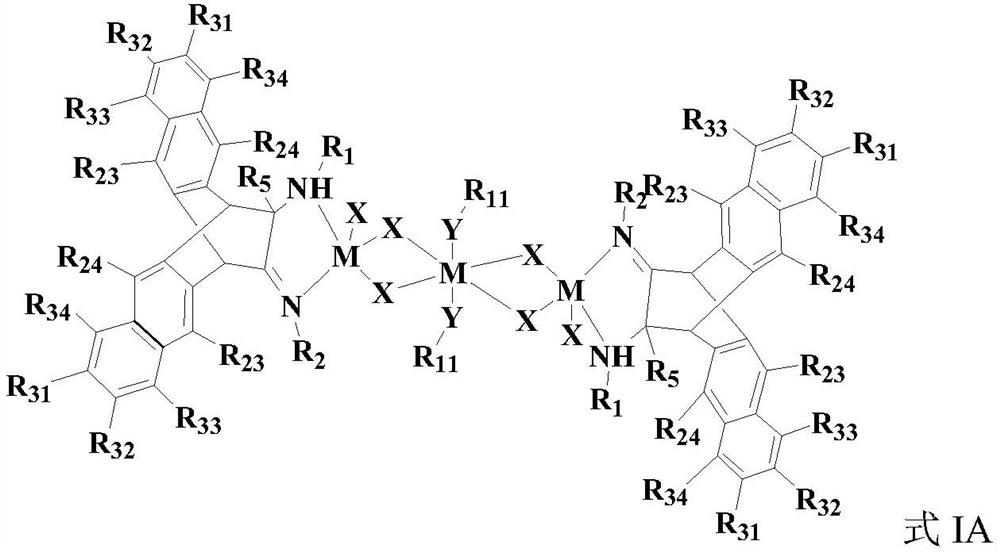

Copolymer containing polar group and preparation method and application thereof

The invention relates to a preparation method of a polar group-containing copolymer and the polar group-containing copolymer prepared by the method. The preparation method of the polar group-containing copolymer comprises the following step: carrying out polymerization reaction on olefin and olefin alcohol in the presence of a catalyst, an improver and an optional chain transfer agent, wherein the used catalyst comprises an amino imine complex as shown in a formula I. The spherical and / or sphere-like polymer prepared by the preparation method has a good prospect in industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

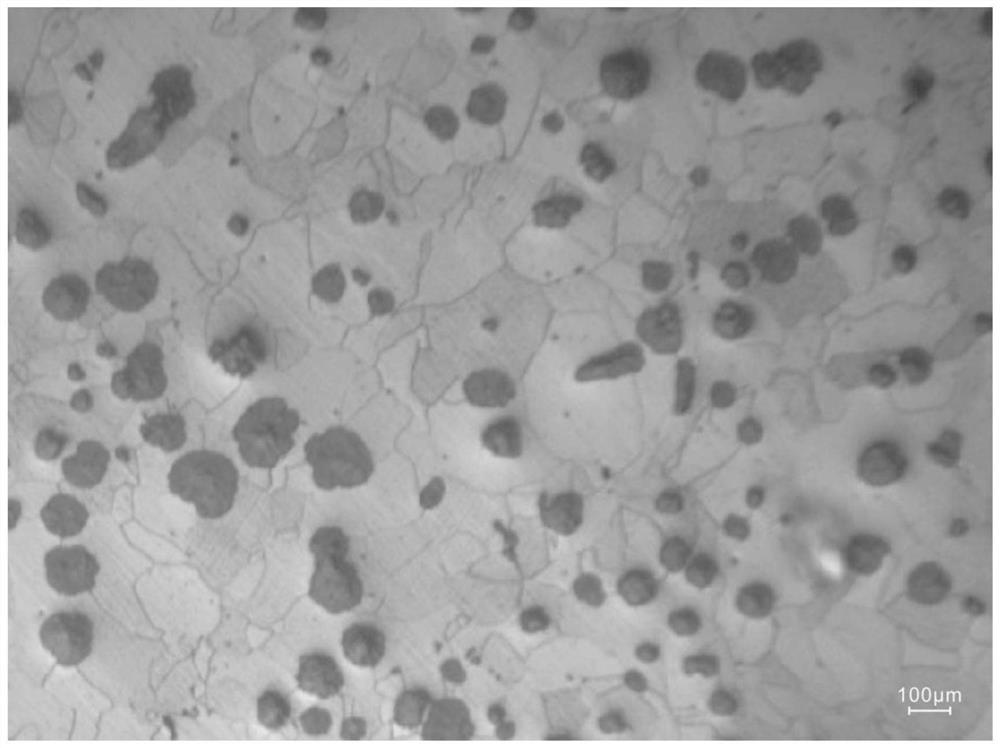

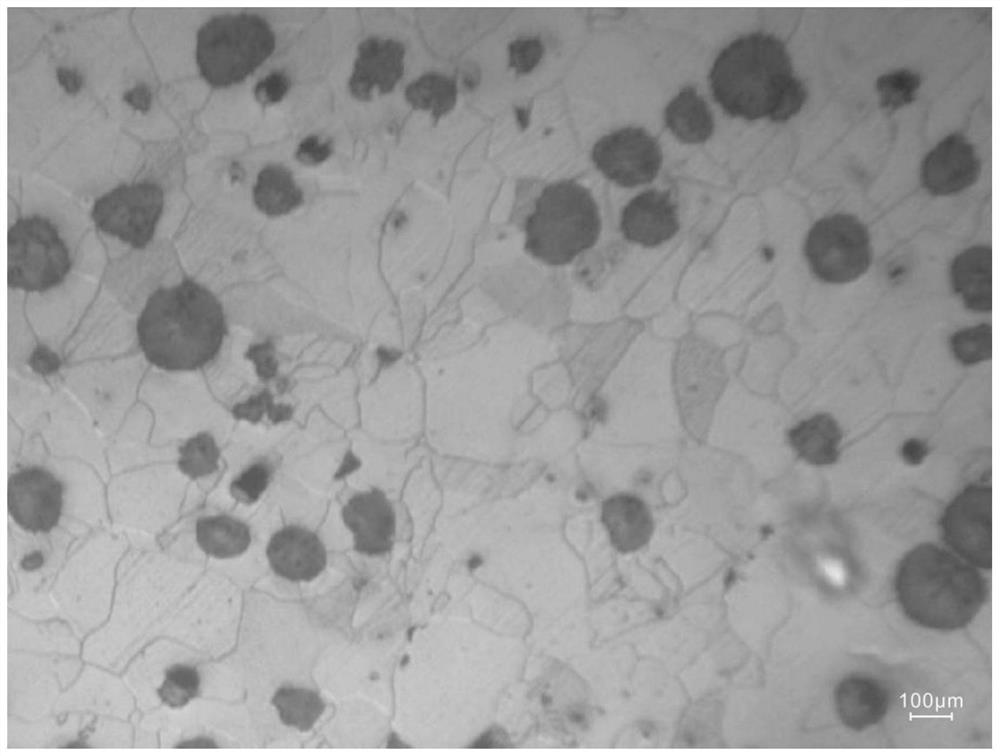

Preparation method of large-tonnage nodular cast iron casting

PendingCN114790501AImprove accuracyProlong dissolution timeProcess efficiency improvementDuctile ironMechanical property

According to the preparation method of the large-tonnage nodular iron casting, the number of balls is large, spheroidization is uniform, spheroidal graphite distortion is small, and the deformation amount of the casting in a casting state is small. The preparation method creatively adopts a ladle-to-ladle spheroidization to adjust the temperature so that the temperature can be controlled, and a four-time composite inoculation block technology is adopted; the number of large-tonnage ductile iron graphite nodules in a cast state is remarkably increased, and finally it can be guaranteed that the number of cast nodules is large, spheroidizing is uniform, deformity is avoided, and the mechanical property is guaranteed; meanwhile, the compacted blocky inoculant is adopted to inoculate the molten iron before and after spheroidizing, slow-release inoculation is achieved through multiple times of slow release, the molten iron fully exists in a temperature and concentration fluctuation area, and therefore the graphite nodules are numerous, round and uniform; according to the method, the spheroidal graphite can be stably obtained, the distortion is small, and the high elastic modulus can be obtained, so that the deformation of a casting in an as-cast state is reduced.

Owner:武汉武重铸锻有限公司

High Strength Gas Cylinder Head and Its Production Technology

ActiveCN108715974BImprove organizationQuality improvementFurnace typesHeat treatment furnacesGas cylinderDuctile iron

The invention discloses a high-strength fuel gas cylinder cover and a production technology thereof. The production technology comprises the following steps that step (1), furnace burdening is prepared, low-S nodular cast iron pig iron and pure carbon waste steel are selected, a medium-frequency induction electric furnace is adopted for smelting, wherein the smelting temperature is controlled to be 1500-1550 DEG C, argon is blown into molten iron, the blowing depth is 20-40% at the depth of the furnace, the blowing time is 5-8 minutes, and then the molten iron is discharged; step (2), spheroidizing and first inoculation treatment are carried out, and a pour over method is adopted; step (3), pouring and a second inoculation treatment are carried out, the pouring temperature of the molten iron is not lower than 1400 DEG C, the second inoculation is carried out by adopting a second nucleating agent during the pouring, and the second inoculation is a metal-stream instantaneous inoculation;step (4), after the pouring is completed, the waste heat of a casting is used for carrying out heat treatment until the room temperature is reached. The technology is reasonable in design, the heat treatment process of the technology is omitted, so that the production cost is reduced, environmental pollution is reduced; and the mechanical property of the fuel gas cylinder cover obtained by the technology is improved correspondingly.

Owner:宁波力古机械制造有限公司

Rare earth silicon and magnesium nodulizer

A rare-earth silicon-magnesium nodulizer is characterized in that the nodulizer comprises the following components by weight percentages: 25-35% of cerium in light rare-earth silicon magnesium, 37-52% of yttrium in heavy rare earth; 15-25% of silicon and 5-15% of magnesium. The rare-earth silicon-magnesium nodulizer further contains neodymium accounting for 5-8% of the total weight. In the rare-earth silicon and magnesium, the cerium in the light rare-earth silicon and magnesium and the yttrium in the heavy rare earth have obvious effect on graphite nodulizing. Firstly, the boiling point of the rare-earth silicon magnesium is higher than that of the magnesium, thus molten iron does not churn and splash when the rare-earth silicon magnesium is added to the molten iron; secondly, cerium-yttrium based rare-earth silicon magnesium has stronger desulfurization and deoxidation capacity than the magnesium, and the generated compounds such as sulfidized rare earth, oxide rare earth and the like have high melting point and good stability; and thirdly, the rare-earth silicon magnesium and nodulizing interference silicon magnesium in the molten iron can form a stable compound, thus the rare earth containing nodulizer has stronger anti-interference capacity than a magnesium nodulizer.

Owner:大连核心铸造技术工程研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com