Spheroidisation reaction package for producing ductile cast iron and spheroidisation method therefor

A technology of spheroidizing and nodular cast iron, which is applied in casting equipment, casting melt containers, manufacturing tools, etc., can solve the problems affecting the performance of nodular cast iron and prone to abnormal graphite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

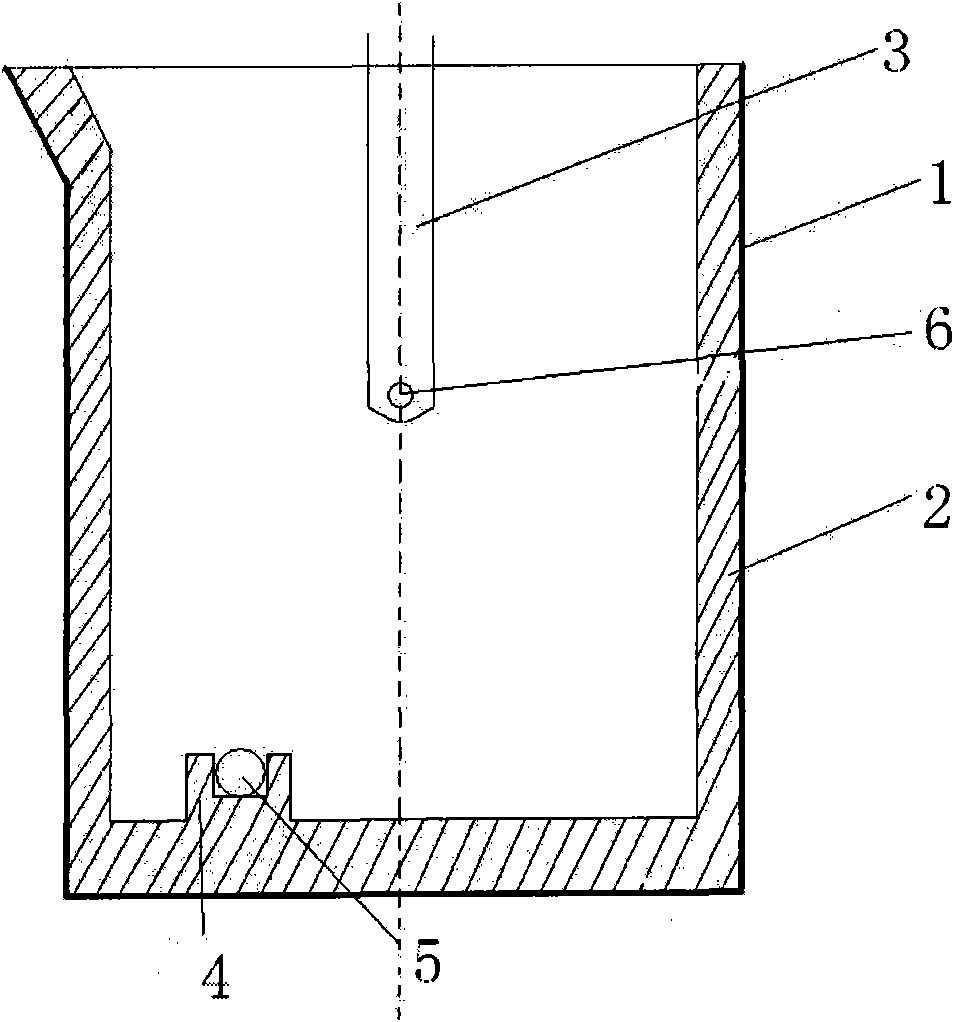

[0029] A spheroidizing treatment reaction package for producing nodular cast iron

[0030] Enclosure 1 is welded by 8mm steel plate, and enclosure wall 2 is knotted by refractory material, wherein the refractory material consists of 20% refractory mud, 5% corundum powder, 60% quartz sand and 15% water glass composition. There is a rotatable hook 3 on the upper part of the enclosure 1. The hook 3 is connected to the enclosure 1 through the bolt 6. The enclosure 1 is 1700mm high, 700mm in diameter, and the thickness of the enclosure wall 2: 80mm at the top, 120mm at the bottom, The thickness is 150mm, and there is a boss 4 with a groove at the bottom of the bag body. The boss 4 is 175mm away from the center point, the height is 120mm, the width is 150mm, the length extends to the bag wall 2, the groove width is 120mm, the depth is 80mm, and the length extending to the cladding wall 2;

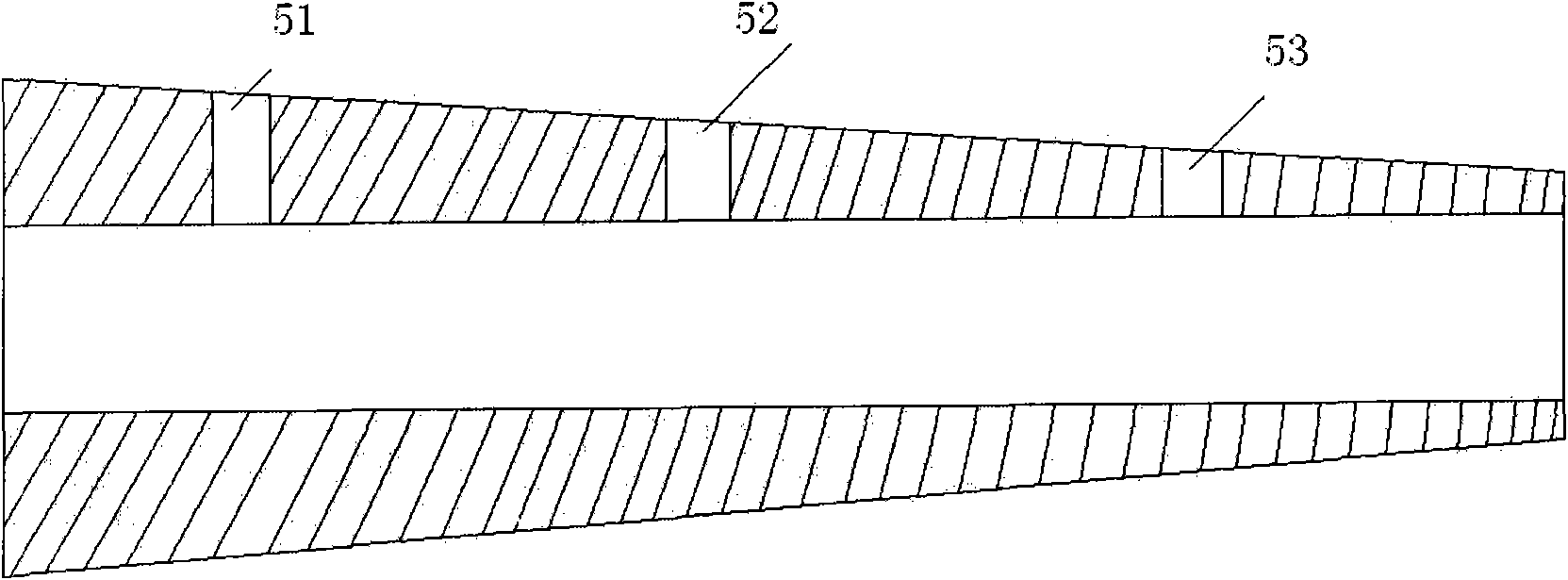

[0031] The inner diameter of the reaction tube 5 is 70 mm, the thickness of the thin-walled...

Embodiment 2

[0047] A spheroidizing treatment reaction bag for producing nodular cast iron, as in Example 1.

[0048] A spheroidizing treatment method of a spheroidizing treatment reaction package for producing nodular cast iron

[0049] (1), nodulizer passivation magnesium into the reaction tube

[0050] Spheroidizing agent passivated magnesium (magnesium content is greater than 92%, particle diameter 2mm) is packed into reaction tube 5, and loading is 1.3Kg, adds ferrosilicon powder (silicon: 55%, all the other are iron, particle every 30mm) The diameter is 2mm), the amount of addition is 30g, and then baked in an oven for 90min at a baking temperature of 120°C;

[0051] (2), the reaction tube into the spheroidization reaction bag

[0052] The step (1) is packed into the reaction tube 5 of passivated magnesium into the groove of the boss 4 at the bottom of the spheroidization reaction bag, the positions of the 3 small air holes 51, 52 and 53 are upward, and the gap between the reaction t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com