Plasma powder balling device and method and application thereof

A technology of plasma and powder feeding device, applied in the field of materials, can solve the problems of difficulty in realizing large-scale, mass production, centralized and disorderly input of powder, expensive spheroidizing equipment, etc., and achieves the advantages of industrialization promotion, high production efficiency and convenient control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

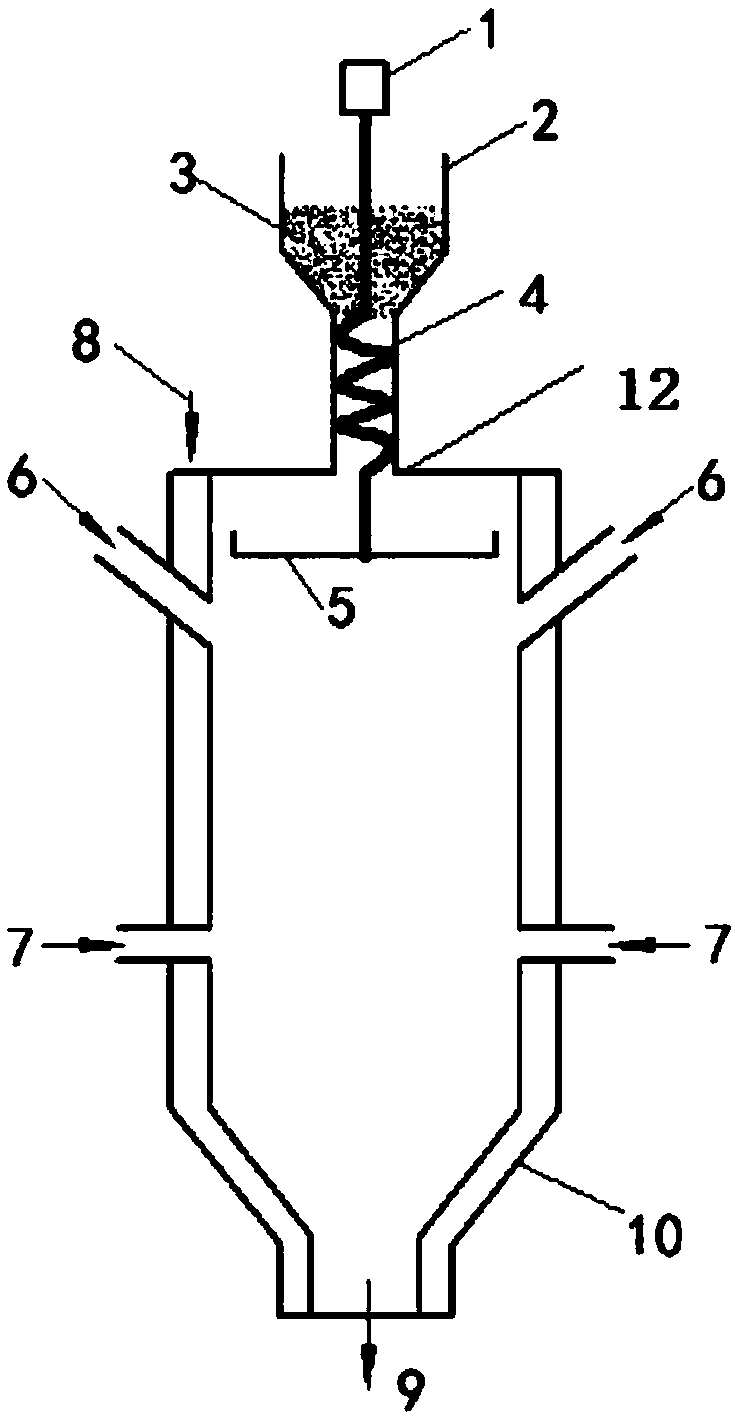

[0035] Embodiment 1 Centrifugal divergent plasma powder spheroidization device

[0036] Such as figure 1 As shown, the centrifugal divergent plasma powder spheroidization device of this embodiment includes an automatic powder feeding device, a powder dispersion device 5 and a powder spheroidization device; the powder dispersion device 5 is connected to the automatic powder feeding device and placed in the powder spheroidization device.

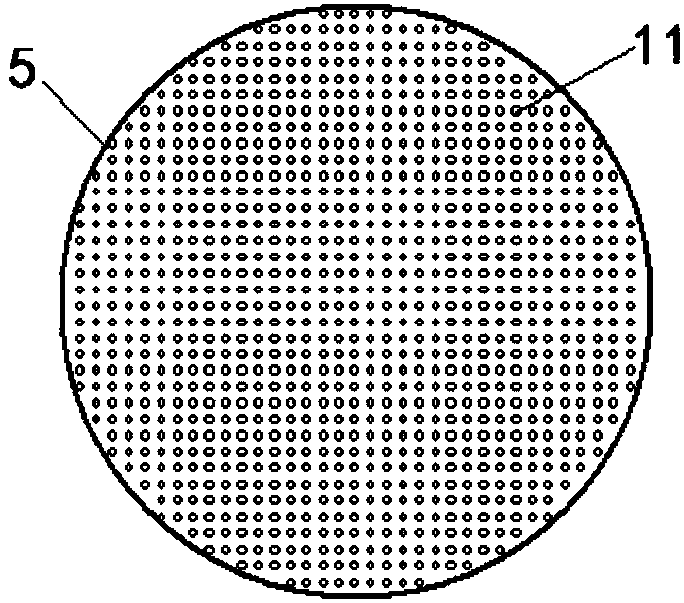

[0037] Among them, the automatic powder feeding device includes the feeding port 2 and the conveying device from top to bottom, and the conveying device passes through the inside of the feeding port 2, which is set to convey powder into the powder spheroidizing device; the conveying device includes a speed regulating motor 1 and A worm gear 4 detachably connected to the powder dispersing device at one end. The powder dispersing device 5 is a porous disc (see figure 2 ), which is set to uniformly disperse the powder; the diameter of the poro...

Embodiment 2

[0039] Embodiment 2 The usage method of centrifugal divergent plasma powder spheroidization device

[0040] This embodiment discloses the usage method of the centrifugal divergent plasma powder spheroidization device of embodiment 1, including the following steps:

[0041] S1. Add the powder with irregular shape to the feed port, and quantitatively convey the powder to the powder dispersion device through the conveying device; the powder feeding speed is 100-1000g / min, and the powder in the porous disc is input into the ball through the holes on the porous disc. The diameter of the circular hole on the porous disk in the chemical chamber is 2 to 4 times the average particle diameter of the powder to be treated, and it is 3 times in this embodiment;

[0042] S2. At the same time, the delivery pipe is fed into the plasma gas. The flow rate of the plasma gas is 2-5L / min. In this embodiment, 3L / min is selected; the pressure is 0.3-0.8MPa. In this embodiment, the pressure is 0.5MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com