Roller-type spheroidizing annealing production line and isothermal spheroidizing annealing method

An isothermal spheroidizing annealing and spheroidizing annealing technology, which is applied in the warm spheroidizing annealing production line and the field of warm spheroidizing annealing, can solve the problems of high labor intensity, increased production cost, and time occupation, so as to reduce the labor intensity of workers and prevent the surface Oxidative decarburization, effect of reducing heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

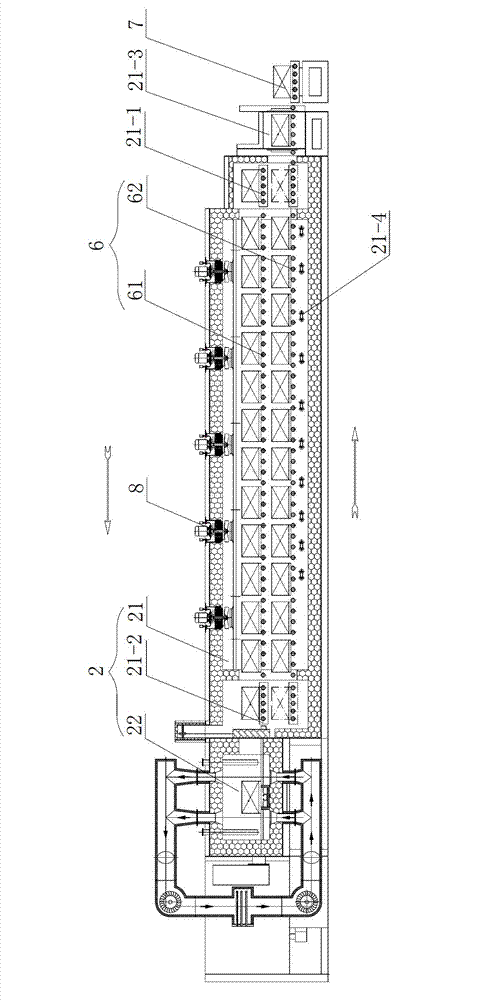

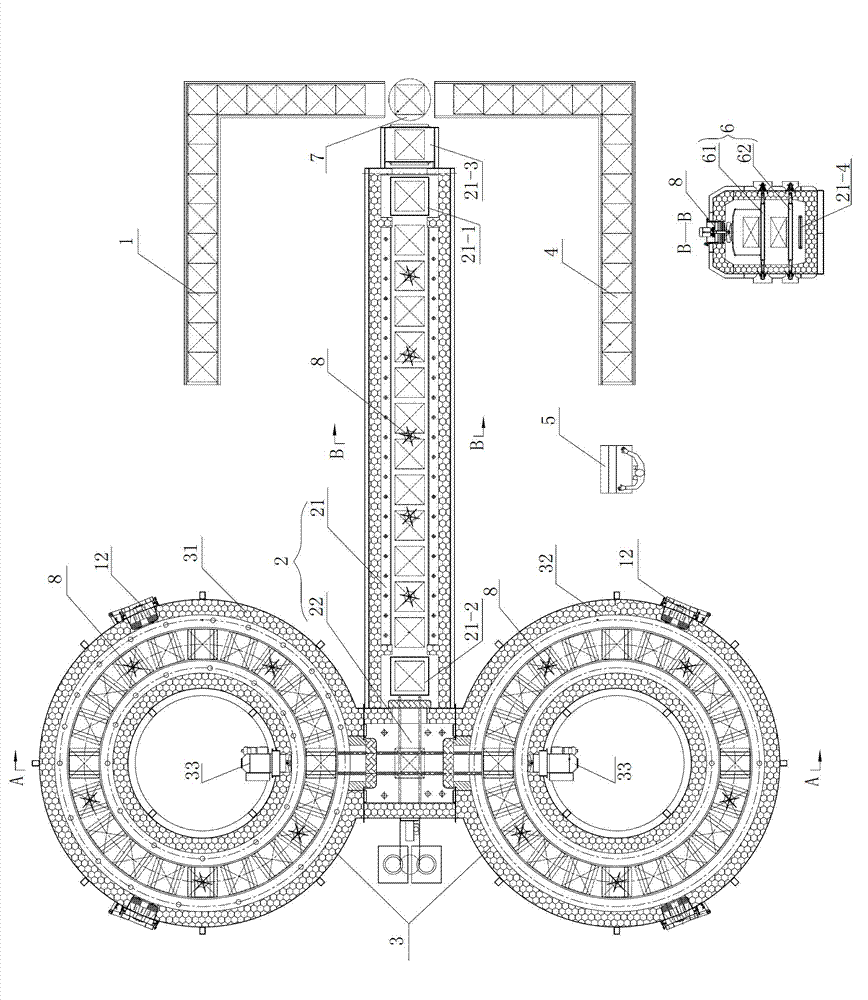

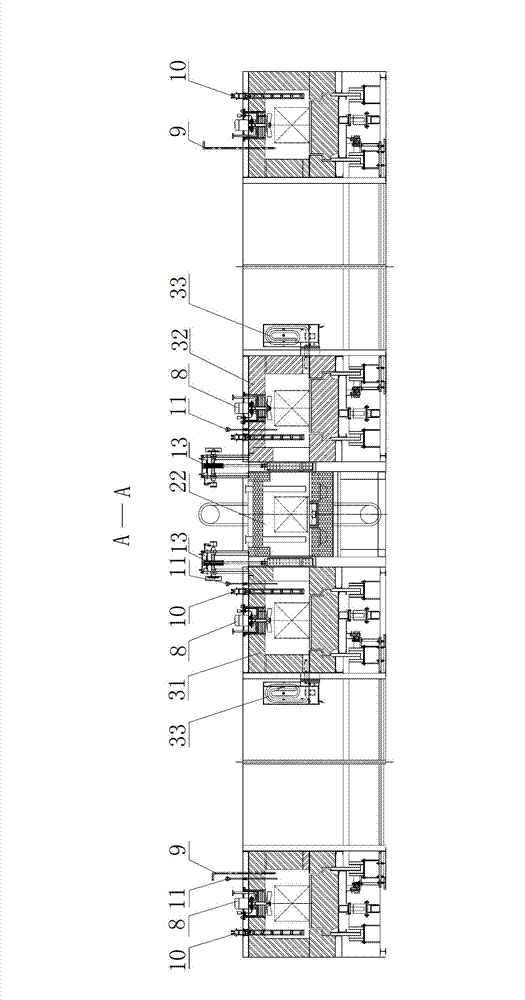

[0041] See Figure 1 to Figure 3 , the present invention successively comprises a roller-type feeding platform 1, a cooling device 2, a heating device 3, a roller-type unloading platform 4 and an upper computer control system 5 for controlling the entire assembly line; the cooling device 2 comprises a roller-type rapid cooling furnace 21 and the forced quick cooling chamber 22 positioned at the end of the roller-type quick-cooling furnace 2, the roller-type quick-cooling furnace 21 is provided with a workpiece transfer device 6, and the workpiece transfer device 6 is a double-layer structure, including an upper layer cold workpiece input device 61 and Lower layer thermal workpiece output device 62 . The front and rear lifting platforms 21-1 and rear lifting platforms 21-2 are respectively provided at the front and rear ends of the roller-type fast cooling furnace 21. The front end of the front lifting platform 21-1 is also provided with a vacuum air lock chamber 21-3, and a va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com