Novel spheroidizing inoculation treatment method

A technology of nodular inoculation and treatment method, which is applied in the field of casting, can solve the problems such as the inconspicuous production effect of ductile iron castings, and achieve the effect of improving effect, high safety, stable mechanical properties and metallographic structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

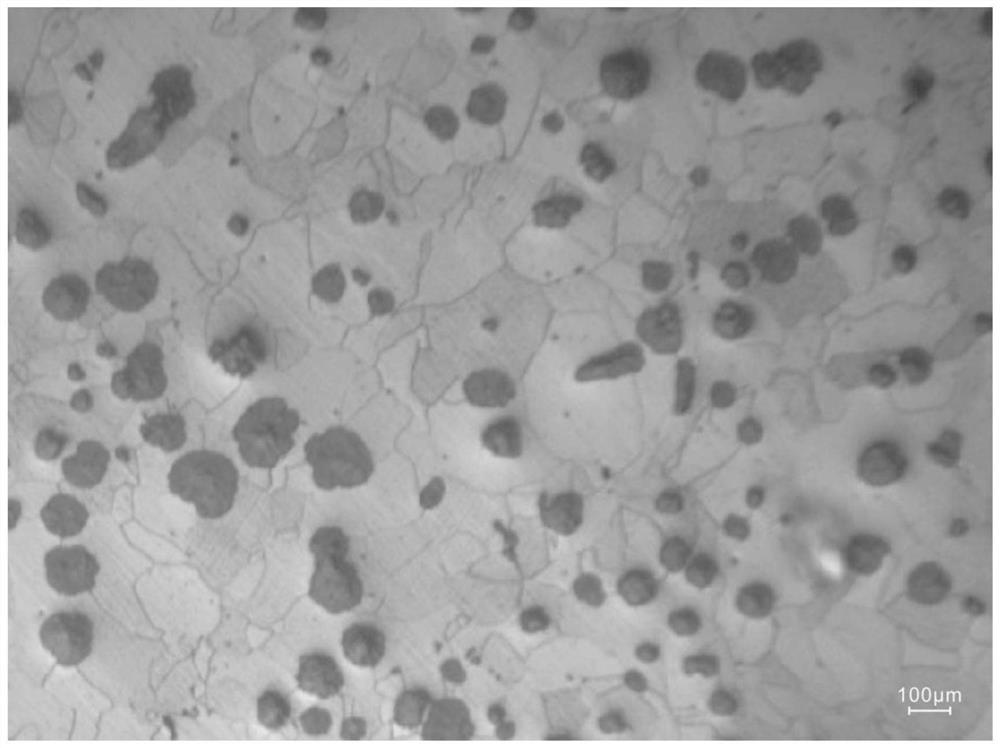

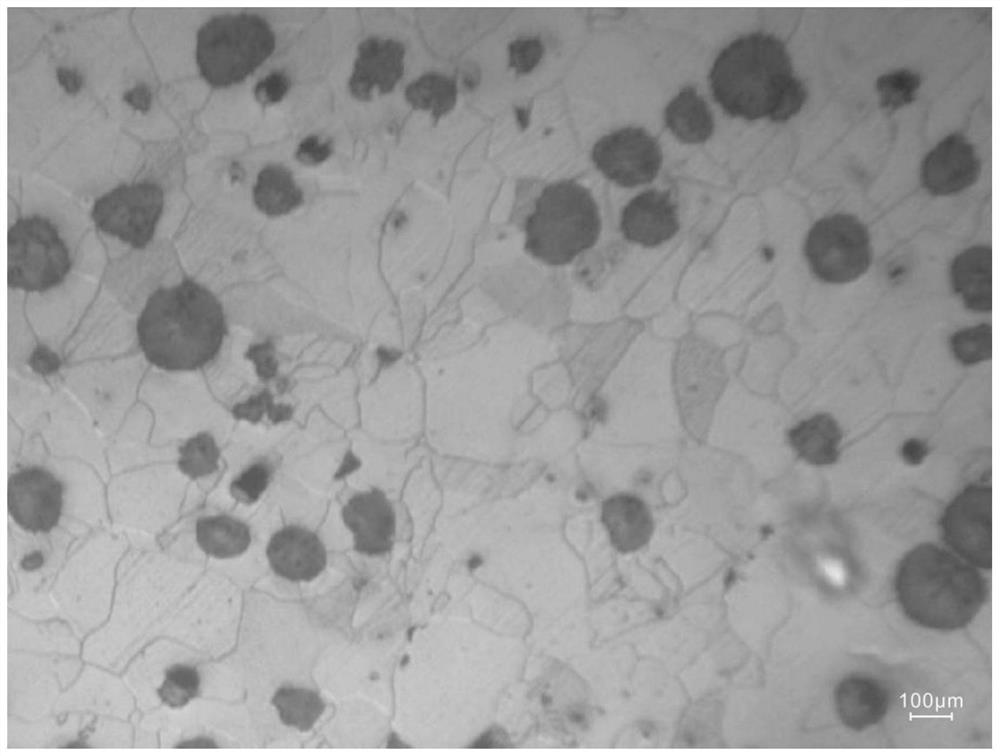

[0062] The above-mentioned spheroidizing inoculation method is used to produce shell ductile iron castings with an average wall thickness of more than 60mm and a thickness of 170mm at the thickest part. The net weight of the castings is 39t (upper shell) and 48t (lower shell), and multiple pieces are produced continuously. The casting number The order is 1-2, 1-1, 2-2, 2-1, 3-2 and 3-1. The castings are respectively equipped with 40mm attached casting test blocks and 70mm attached casting test blocks. The corresponding metallographic structure and mechanical properties As shown in Table 1.

[0063] The added amount of the nodulizer is 1.1%, the added amount of the primary inoculant is 0.2%, the added amount of the secondary inoculant is 0.4%, the added amount of the secondary inoculant is 0.4%, and the added amount of the secondary inoculant is 0.4%. The amount of inoculant added is 0.07%,

[0064] Use 43% low-Mn stamping scrap steel and 57% Q10 pig iron for melting and smelt...

Embodiment 2

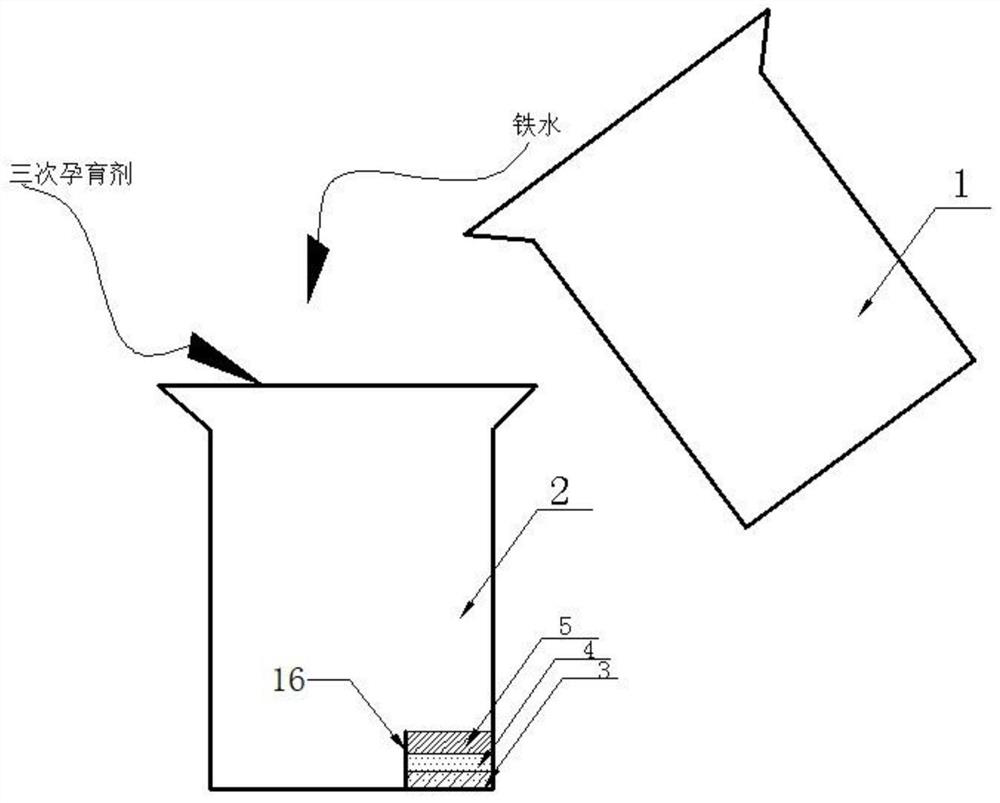

[0072] This embodiment provides a spheroidization inoculation device used in the spheroidization inoculation method to improve and ensure the inoculation effect.

[0073] like Figure 4 and Figure 5 As shown, the device for incubating with the flow includes a follower funnel 8, and a connecting rod 9 fixedly supporting the follower funnel 8, and the connecting rods 9 are two symmetrically arranged on the outer periphery of the follower funnel 8, so The connecting rod 9 is arranged parallel to the crossbeam 7 above the boom 6 of the spheroidizing bag 2; the outside of the boom 6 is provided with a vertical slideway 10, and the slideway 10 is provided with a slide block 11, Described slide block 11 is provided with electric push rod 12, and the output end of described electric push rod 12 is connected with the end of described connecting rod 9; The lower end outlet of described follower funnel 8 is provided with plug 13, and described A stay cord 14 is connected to the plug 1...

Embodiment 3

[0080] This embodiment provides a follower funnel of another structure.

[0081] like Figure 7 As shown, the top of the follower funnel 8 is cylindrical, and the bottom is a tapered discharge part. The cross section of the discharge part is an inverted trapezoidal silo structure, and an anti-sticking device is provided on the inside of the follower funnel 8. A paint layer is attached; the anti-adhesion paint is a silicon crystal porcelain paint painted on the warehouse wall, which can reduce friction and facilitate the smooth outflow of the inoculant.

[0082] Further, the connecting rod 9 is symmetrically welded to the cylindrical outer circumference of the follower funnel 8, and a reinforced transition plate is provided at the welding place to improve the connection strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com