How to make the metal grille on the back

A backside metal and manufacturing method technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, electrical components, etc., can solve problems such as rough side walls of metal grids, avoid high-temperature baking, easy to fall off, and improve yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

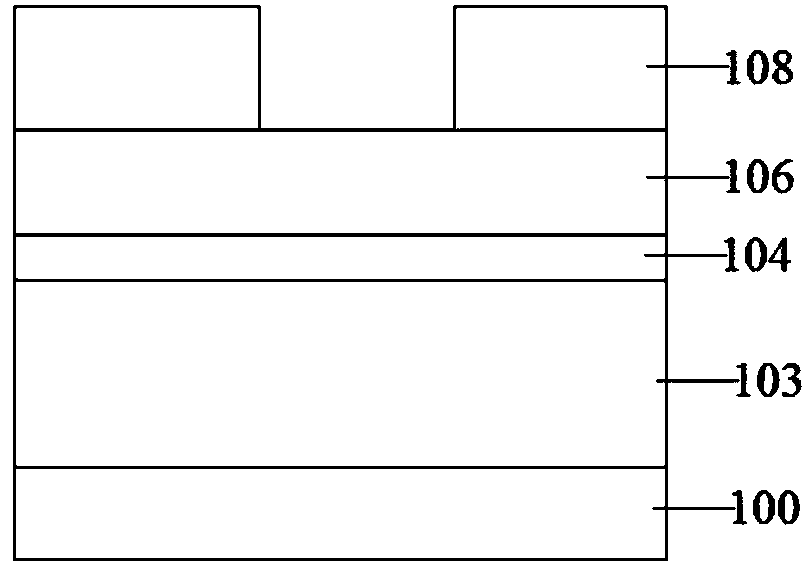

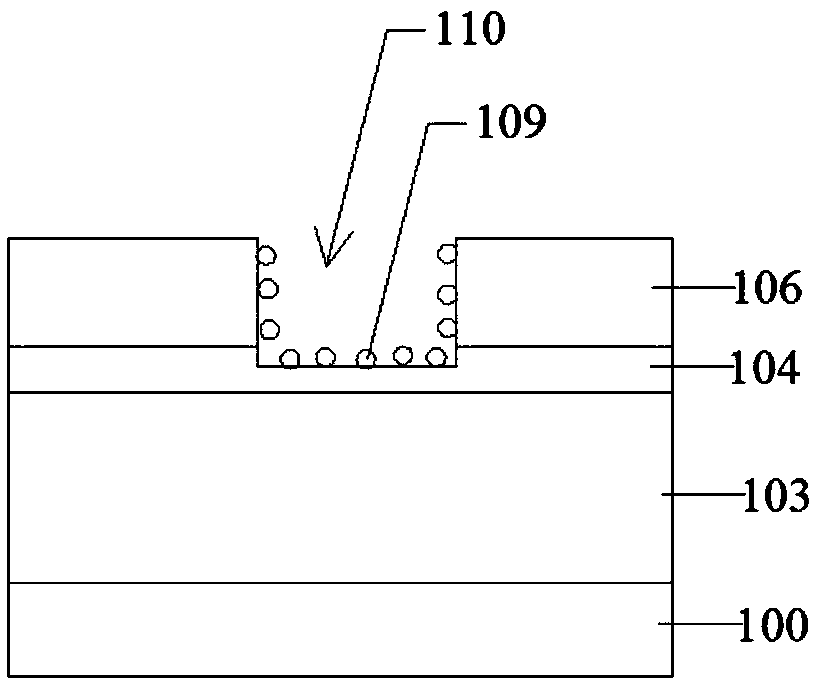

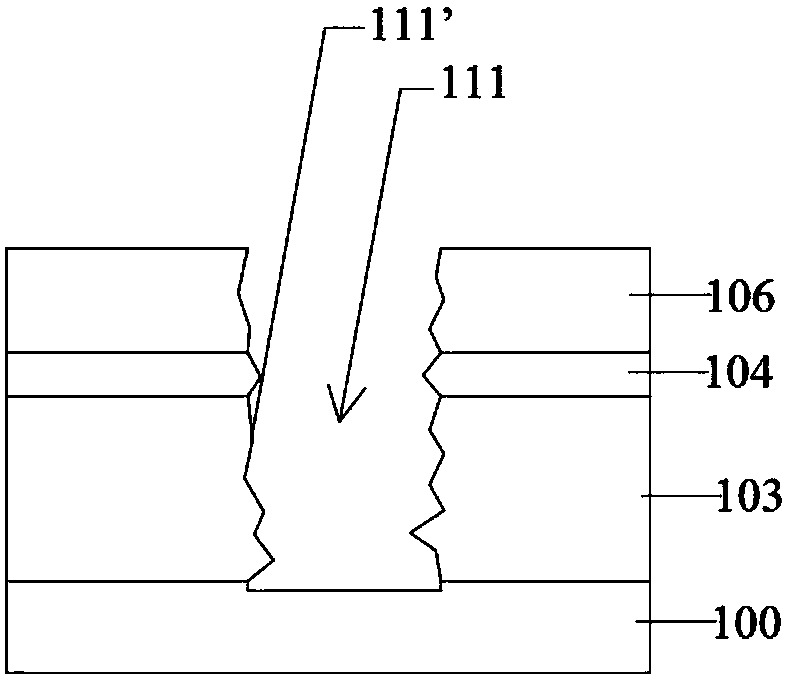

[0050] It has been mentioned in the background art that the sidewalls of the etched metal grid on the semiconductor substrate are so rough that the yield of the semiconductor device is affected by the existing process. After in-depth research, the applicant found that this is due to the formation of a polymer composed of titanium fluoride and carbon-containing compounds in the process of etching the hard mask layer 106 and part of the titanium nitride protective layer 104 with a fluorine-containing gas. 109 (eg figure 2 As shown), the polymer 109 adheres to the bottom and sidewalls of the first trench 110, and it is difficult to completely remove the polymer 109 even after wet cleaning. In this way, when the photoelectric signal transmission layer 103 is subsequently etched, due to the barrier of the polymer 109, the etched sidewall 111' of the second trench is very rough, that is, the sidewall of the metal grid is very rough. , thereby affecting the yield of semiconductor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com