Non-stop maintenance method for flame path of petroleum coke calcining furnace

A petroleum coke and calcining furnace technology, applied in chemical instruments and methods, furnaces, furnace types, etc., can solve the problems of time-consuming, high maintenance cost, labor consumption, etc., to avoid high-temperature baking, improve safety, and improve efficiency. The effect of using space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Further, the preparation method of the silicon carbide prefabricated block includes the following steps: selecting raw materials according to particle size requirements, proportioning ingredients and mixing, kneading with a mixer, injection molding, drying, degreasing, and sintering. The maximum temperature after firing is controlled at 1400-1500°C, which is higher than the maximum temperature of 1300°C in the fire channel.

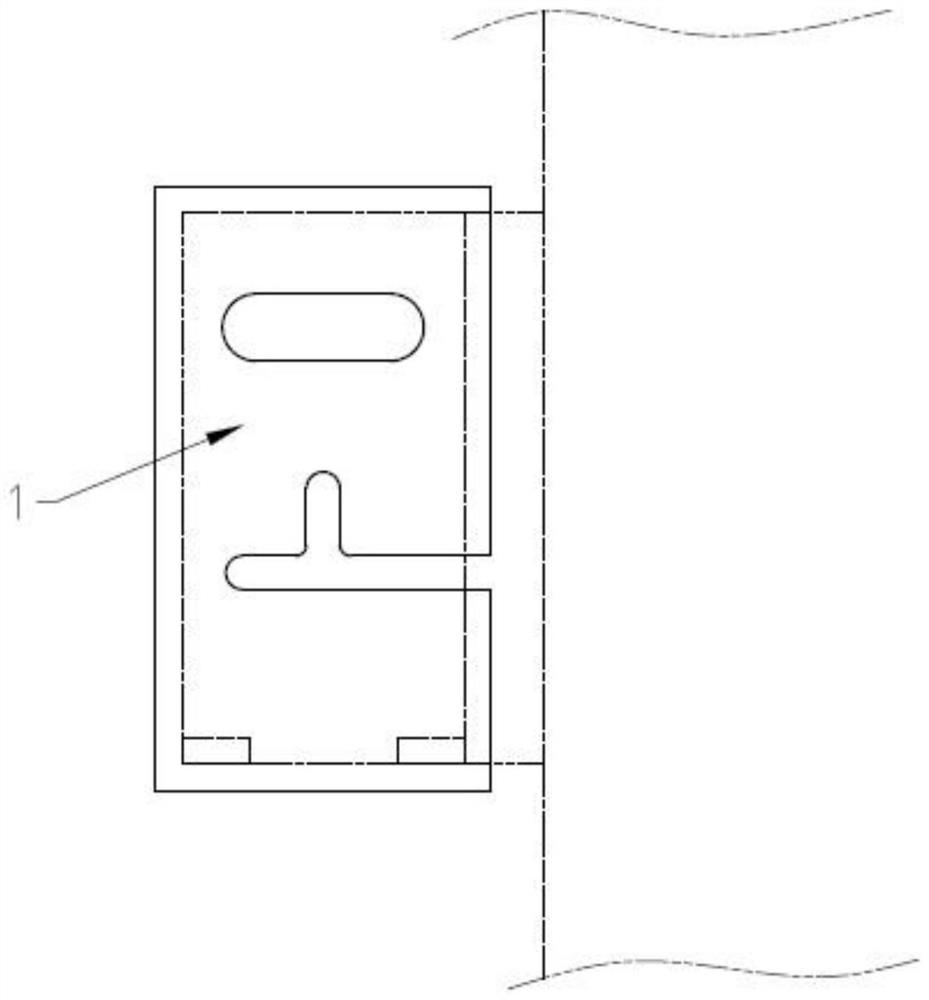

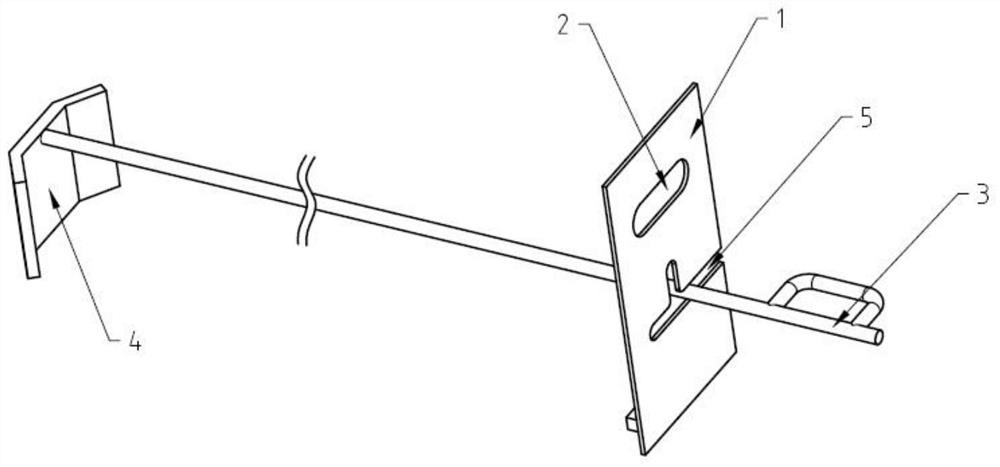

[0053] see Figure 2-Figure 5 , the fire baffle 1 used in the above-mentioned maintenance method is a rectangular structure, the size is larger than the fire channel, and it is made of refractory material. The fire viewing window 2 is embedded above it for observing the movement of the hook 3 and the hook plate 4, and a track is set below The slot 5 is open at one end of the track slot 5 for the hook 3 to pass through.

[0054] Further, the track groove 5 includes a transverse track groove 51 and a vertical track groove 52. The upper end of the ve...

Embodiment 1

[0061] This embodiment is aimed at the situation that the damage to the fire channel is relatively light and the leakage of material is less.

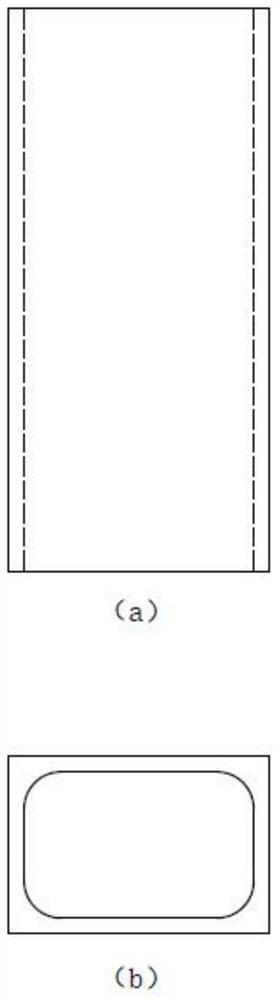

[0062] Step 1: Making silicon carbide prefabricated blocks. Get the following raw materials in parts by weight: 38 parts of silicon carbide particle size sand, 42 parts of silicon dioxide, 2 parts of kaolin, 8 parts of metal silicon powder, 5 parts of kyanite, 2 parts of polyvinyl alcohol, 2 parts of sodium silicate, three parts Sodium polyphosphate 2 parts. Then select raw materials according to particle size requirements, mix ingredients in proportion, knead in a mixer, injection molding, drying, degreasing, and sintering. The maximum temperature after firing is controlled at 1400-1500°C, which is higher than the maximum temperature of 1300°C in the fire channel. The shape of the silicon carbide prefabricated block is shown in figure 1 As shown, the cross-sectional size is 250mm*170mm, the length is 0.8m, and the thickness is 15mm...

Embodiment 2

[0070] This embodiment is aimed at the general damage of the fire channel, and it is necessary to scrape off the scattered and leaked materials.

[0071] Step 1: Making silicon carbide prefabricated blocks. Take the following raw materials in parts by weight: 47 parts of silicon carbide particle size sand, 35 parts of silicon dioxide, 3 parts of kaolin, 8 parts of metal silicon powder, 7 parts of kyanite, 3 parts of polyvinyl alcohol, 3 parts of carboxymethyl cellulose , 3 parts of silica sol. Then select raw materials according to particle size requirements, mix ingredients in proportion, knead in a mixer, injection molding, drying, degreasing, and sintering. The maximum temperature after firing is controlled at 1400-1500°C, which is higher than the maximum temperature of 1300°C in the fire channel. The shape of the silicon carbide prefabricated block is shown in figure 1 As shown, the cross-sectional size is 250mm*170mm, the length is 1m, and the thickness is 16mm. The p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com