Airtight pump filling device for liquefied gas and used for chemical plant

A technology for liquefied gas and chemical plants, which is applied to the components, pumps, driving pumps, etc. of pumping devices for elastic fluids, which can solve the problem of long equipment preparation time delaying normal production, waste of liquefied gas in pipes, and backflow method requiring exhaust And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

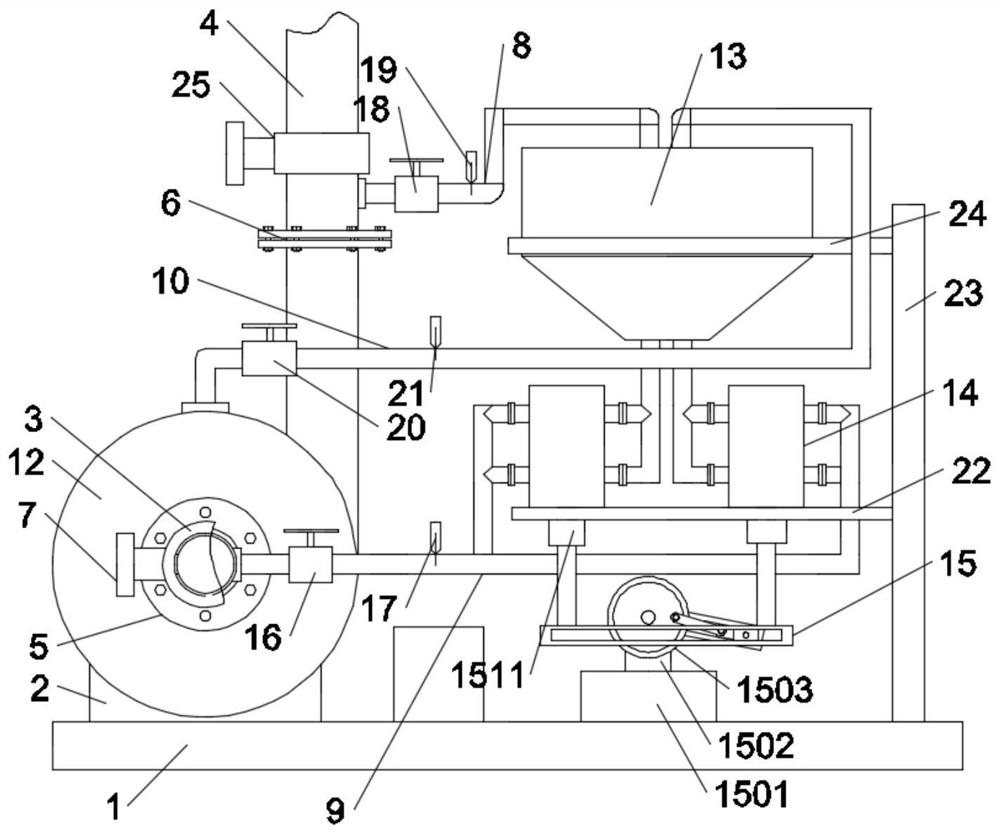

[0022] like figure 1 , figure 2 , image 3 and Figure 4 As shown, in the embodiment of the present invention, a liquefied gas sealed filling pump device for a chemical plant includes a mounting base 1, a first motor mounting base 2 is connected to the mounting base 1, and the first motor mounting base 2 A first motor 11 is installed on it, and the first motor 11 is connected with a pump body 12, and the pump body 12 is connected with a water suction pipe 3 and a water outlet pipe 4, and the water suction pipe 3 and the water outlet pipe 4 are respectively connected with first The flange connection port 5 and the second flange connection port 6, the suction pipe 3 and the water outlet pipe 4 are respectively equipped with a first solenoid valve 7 and a second solenoid valve 25, which are located at the first flange connection port 5 and the second flange connection port. The outlet pipe 4 between the electromagnetic valves 7 is connected with the first air delivery pipe 8,...

Embodiment 2

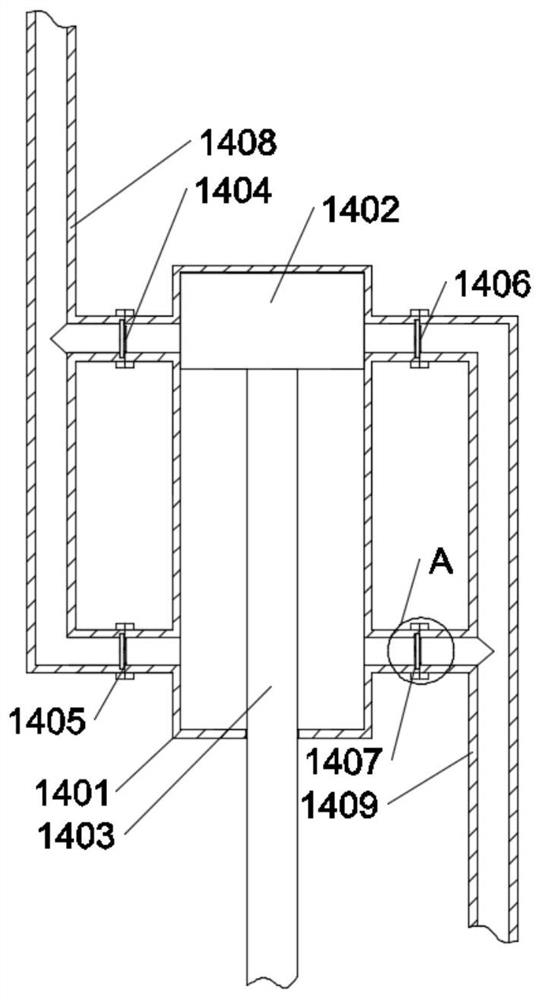

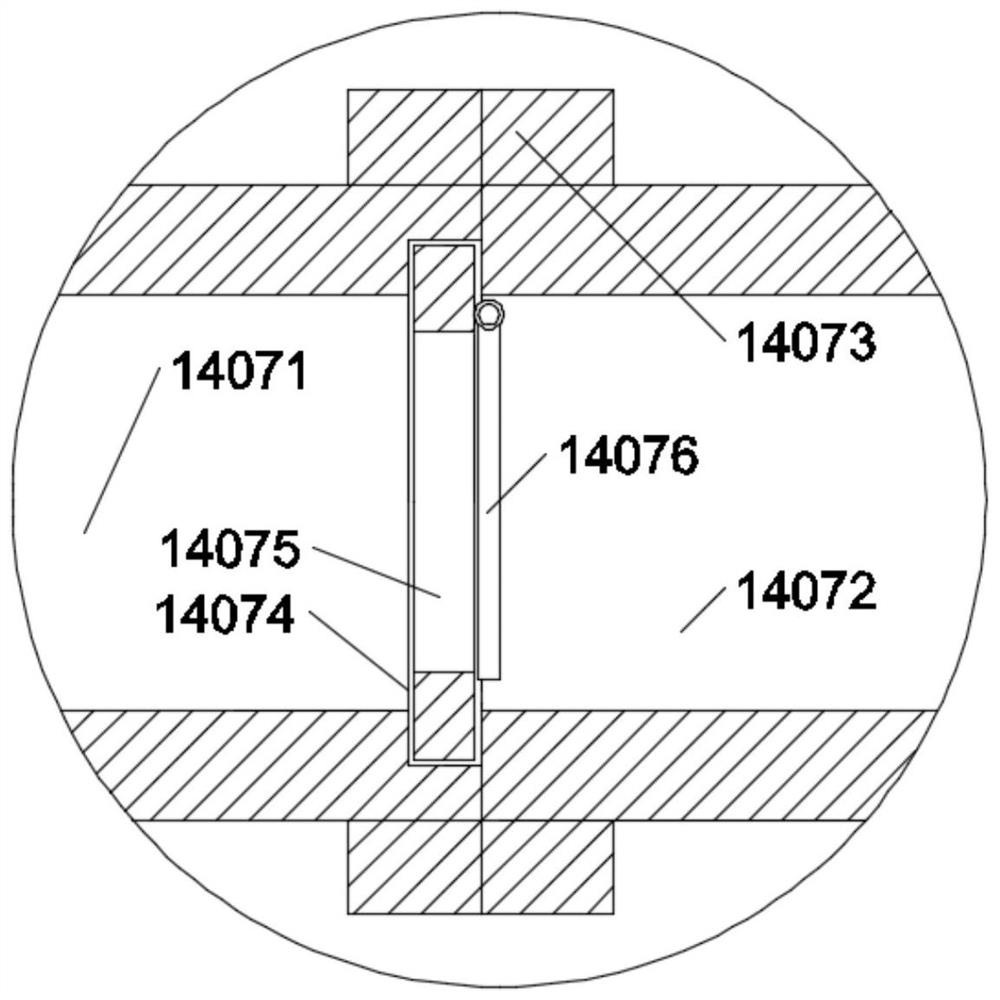

[0025] like figure 1 , figure 2 , image 3 and Figure 4 As shown, in the embodiment of the present invention, the pumping device 14 on the right side includes a hydraulic cylinder 1401, a piston 1402 is arranged inside the hydraulic cylinder 1401, and a pumping rod 1403 is connected to the piston 1402, which is located in the hydraulic cylinder 1401. A first one-way pipe valve 1404 and a second one-way pipe valve 1405 are respectively connected up and down on the left side of the cylinder 1401, and a third one-way pipe valve 1406 and a fourth one-way pipe valve 1407 are respectively connected above and below the hydraulic cylinder 1401. The first one-way pipe valve 1404 and the second one-way pipe valve 1405 communicate with a first pipe 1408, the first pipe 1408 is connected to the bottom of the storage tank 13 for barrel-shaped irrigation pump, and the third one-way pipe valve 1406 and the fourth one-way valve 1407 communicate with a second pipeline 1409 , and the secon...

Embodiment 3

[0028] like figure 1 , figure 2 , image 3 and Figure 4As shown, in the embodiment of the present invention, a third solenoid valve 16 is connected to the pipeline near the suction pipe 3 of the infusion tube 9, and a first pressure sensor 17 is also provided on the infusion tube 9, which is located on the first pressure sensor 17. A fourth solenoid valve 18 is connected to the pipeline near the position of the water outlet pipe 4 of an air delivery pipe 8, and a second pressure sensor 19 is connected to the first air delivery pipe 8 on the right side of the fourth solenoid valve 18, located at the second delivery pipe 8. A fifth solenoid valve 20 is connected to the gas pipe 10 near the pump body 12 , and a third pressure sensor 21 is connected to the second gas delivery pipe 10 on the right side of the fifth solenoid valve 20 .

[0029] In the embodiment of the present invention, when the pressure values of the first pressure sensor 17, the second pressure sensor 19 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com