A modular combined high-power high-frequency switching power supply and a work flow thereof

A high-frequency switching power supply and module combination technology, applied in the power supply field, can solve problems such as increased investment cost, heavy equipment load, power supply damage, etc., to ensure normal production, solve maintenance steps, and save costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

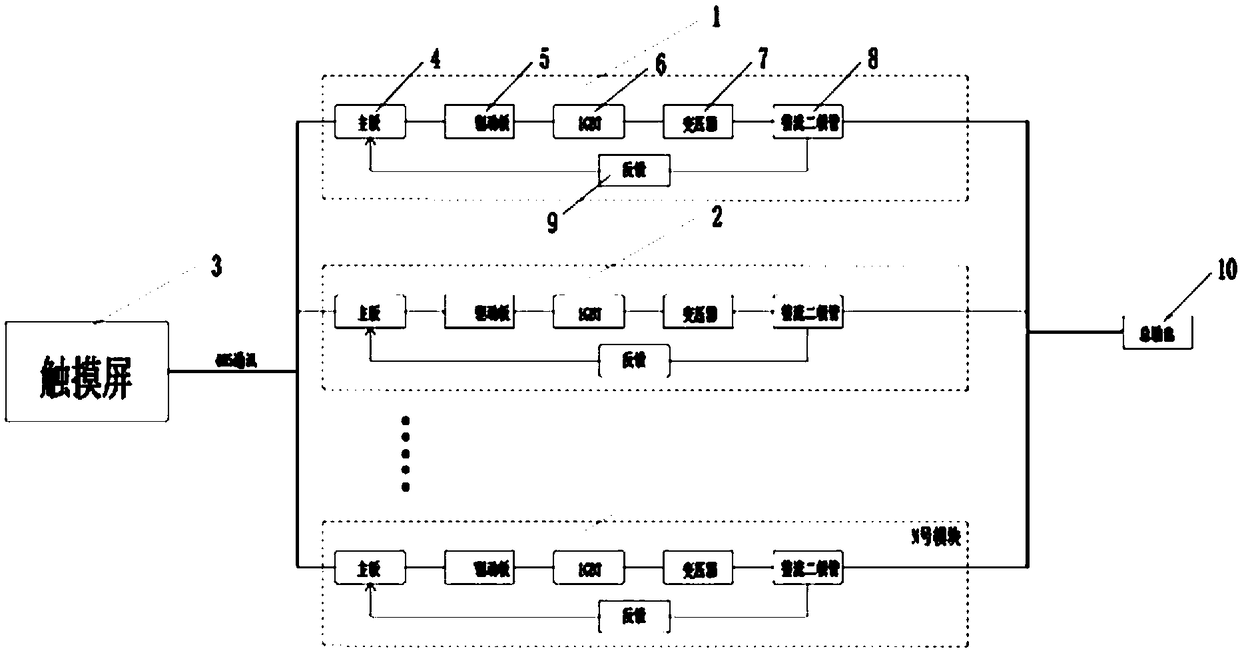

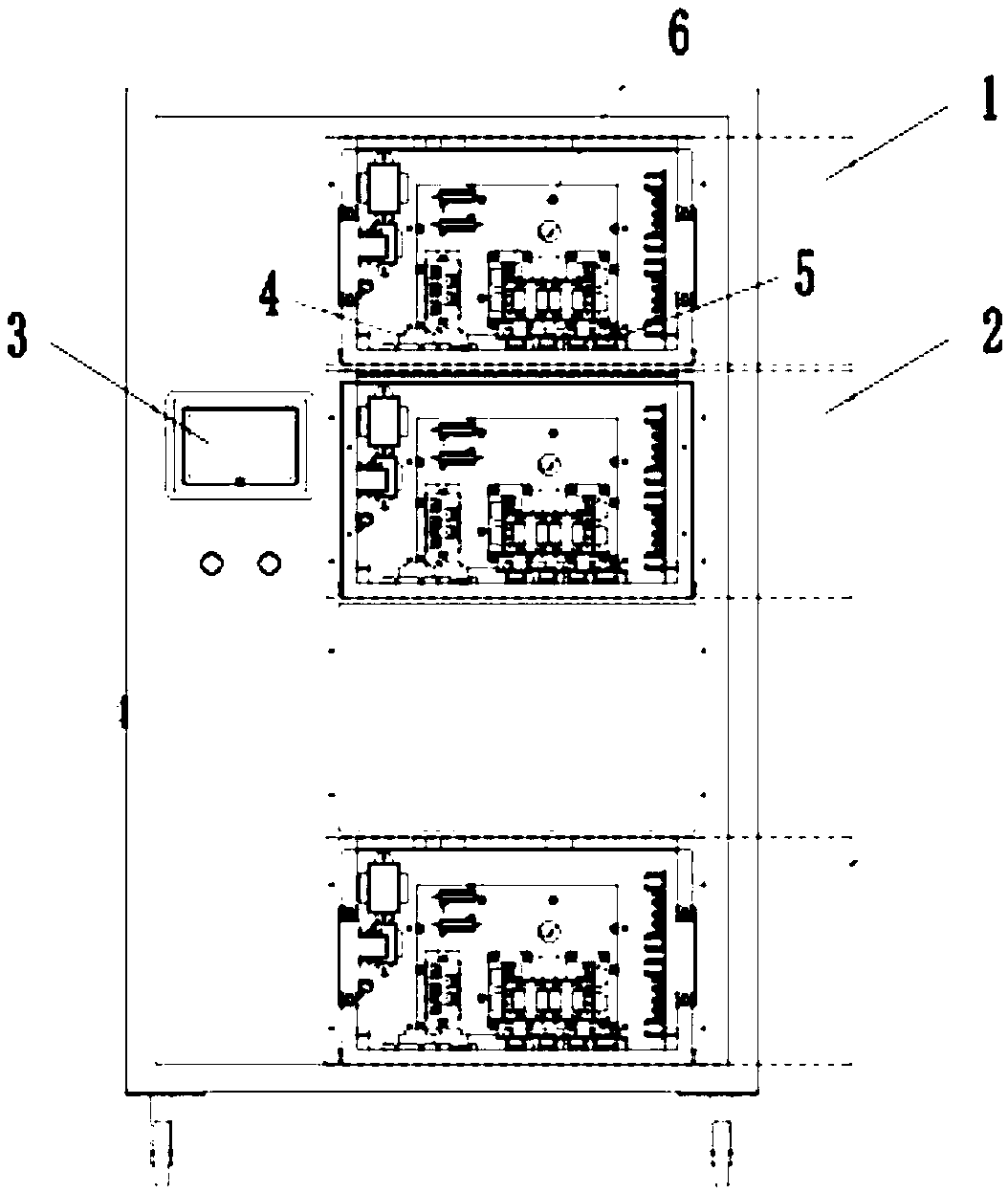

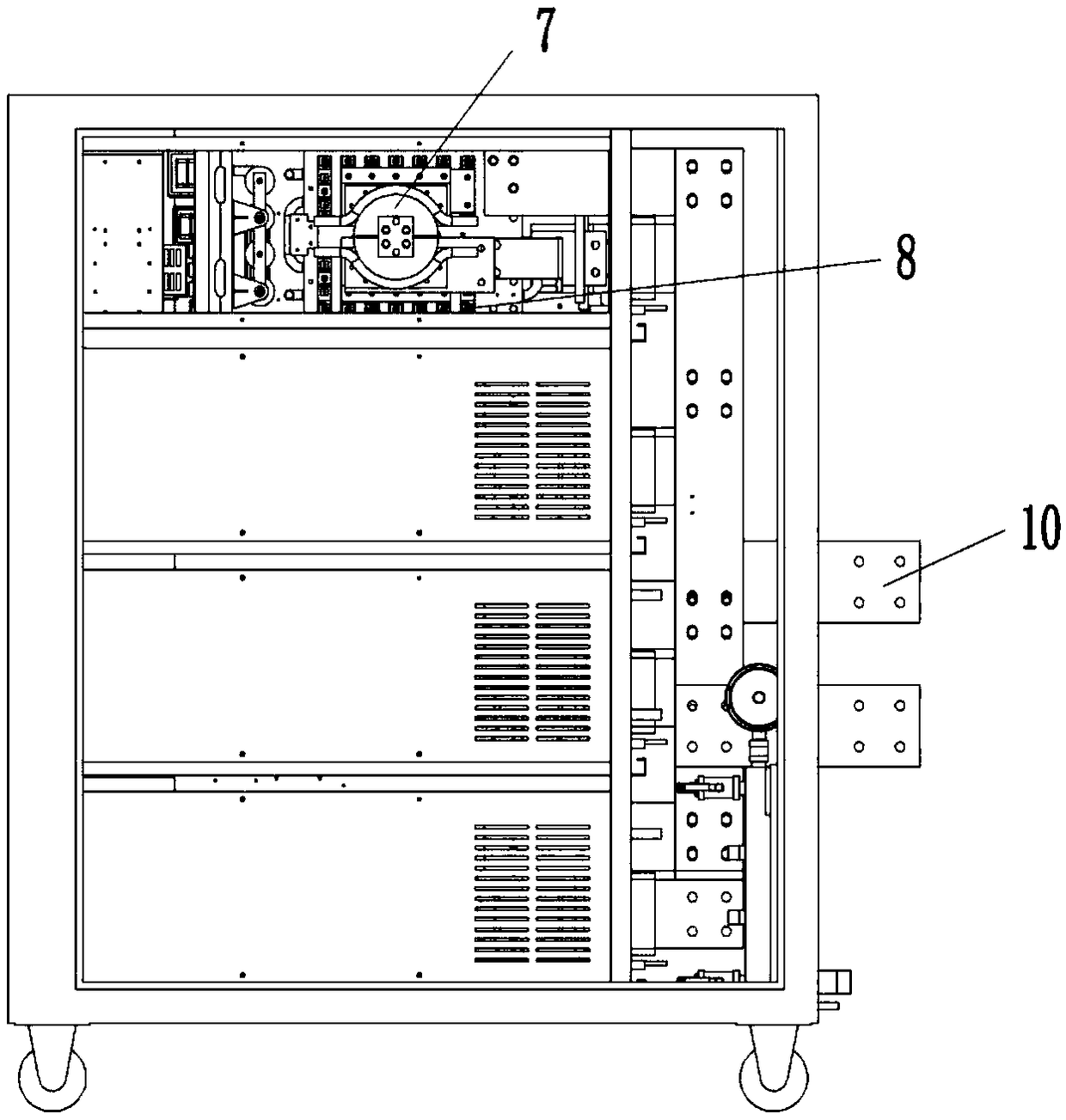

[0025] A modular high-power high-frequency switching power supply, including a touch screen 3, a total output unit 10 and multiple modules, the module includes a main board 4, a driver board 5, an insulated gate bipolar transistor 6, a transformer 7, a rectifier diode 8 and a feedback In the module 9 , the touch screen 3 is connected with the main board 4 of the module, the drive board 5 drives the insulated gate bipolar transistor 6 , and the rectifier diode 8 is connected with the total output part 10 . The touch screen 3 adopts a liquid crystal display touch screen, which has good stability and low failure rate. The main board 4 is connected to the drive board 5 and the feedback module 9 respectively, the IGBT 6 is connected to the drive board 5 and the transformer 7 respectively, the transformer 7 is also connected to the rectifier diode 8 , and the rectifier diode 8 is connected to the feedback module 9 .

[0026] The working process of the modular high-power high-frequen...

Embodiment 2

[0029] A modular high-power high-frequency switching power supply, including a touch screen 3, a total output unit 10, a first module 1 and a second module 2, the module includes a main board 4, a driving board 5, an insulated gate bipolar transistor 6, and a transformer 7 , rectifier diode 8 and feedback module 9, the touch screen 3 is connected with the main board 4 of the module through 485 bus and MODBUS protocol, the driver board 5 drives the insulated gate bipolar transistor 6, and the rectifier diode 8 is connected with the total output unit 10. The transformer 7 adopts a three-phase transformer.

[0030] The working process of the modular high-power high-frequency switching power supply, the specific steps are as follows:

[0031] (1) The user sets the total output current through the touch screen, and automatically and evenly distributes the output current value of each module. After the main board of each module receives the control signal from the touch screen, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com