Patents

Literature

34results about How to "Small expansion deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Halogen-free environmentally-friendly power cable material for wind power generation, and its preparation method

The invention discloses a halogen-free environmentally-friendly power cable material for wind power generation, and its preparation method. The cable material comprises the following raw materials, by weight, 90-110 parts of a polyolefin elastomer (POE) 8450 / American DuPont, 50-60 parts of PVC resin powder, 40-60 parts of wollastonite powder, 60-80 parts of nanometer attapulgite, 50-80 parts of ethylene-propylene-diene terpolymer rubber, 40-50 parts of nitrile butadiene rubber, 20-30 parts of nanometer pottery clay, 30-40 parts of aluminum hydroxide, 1-4 parts of precipitated white carbon black, 60-80 parts of light calcium carbonate, 3-5 parts of insoluble sulfur, 1-4 parts of triallyl isocyanurate, 3-5 parts of an antiager TPPD, 4-6 parts of dicumyl peroxide (DCP), 3-8 parts of dibasic lead phosphite, 5-7 parts of an antioxidant 1010, 2-5 parts of monoglycerin stearate and 50-70 parts of antimony trioxide. The cable material has the advantages of simple preparation method, excellent electrical property, good heat, ageing and wear resistances, small swelling deformation at a high temperature, secondary vulcanizing processing benefiting, low smoke and fire resistance, and environmental protection and safety.

Owner:苏州益普敦新材料科技有限公司

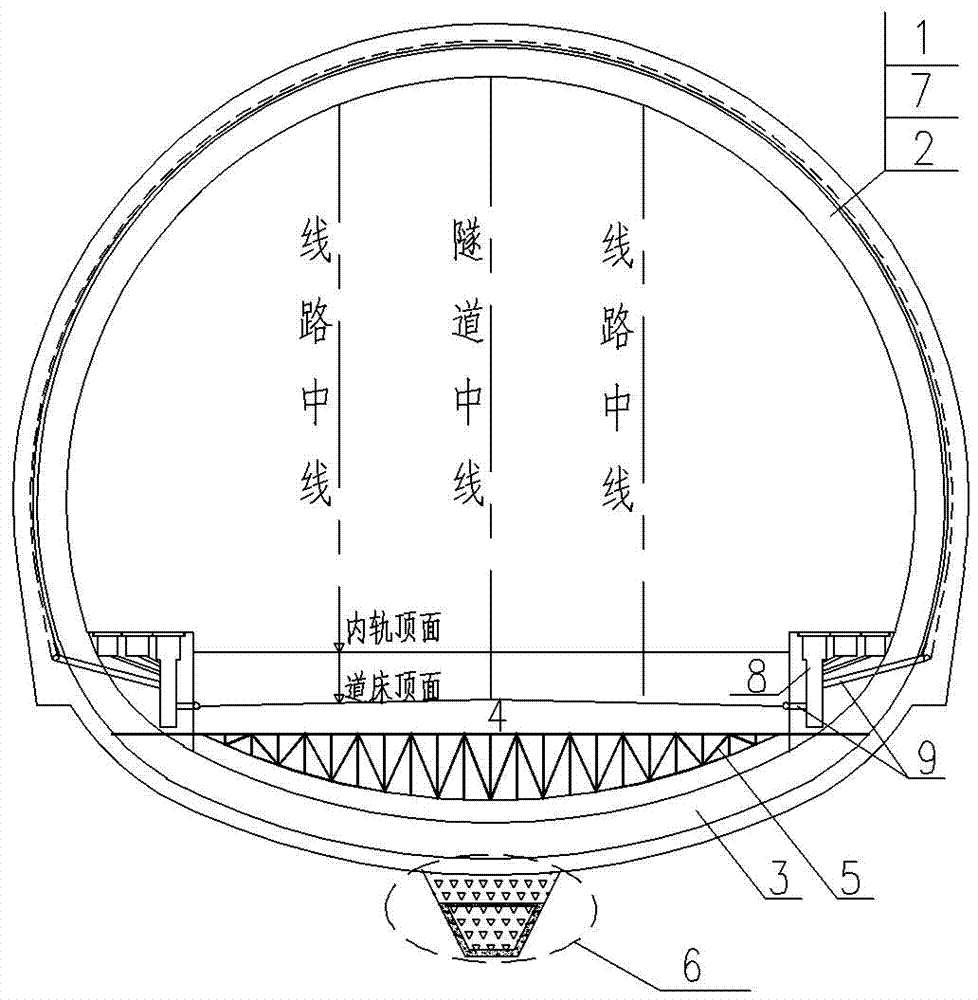

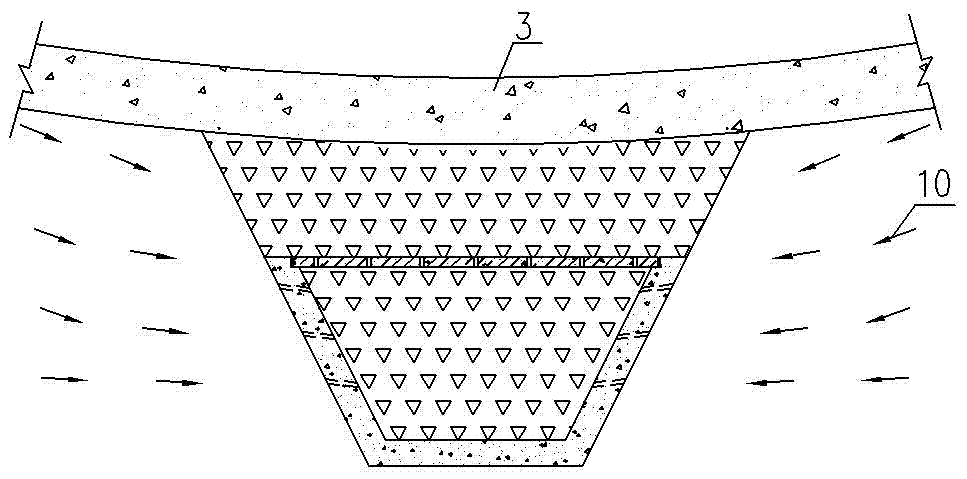

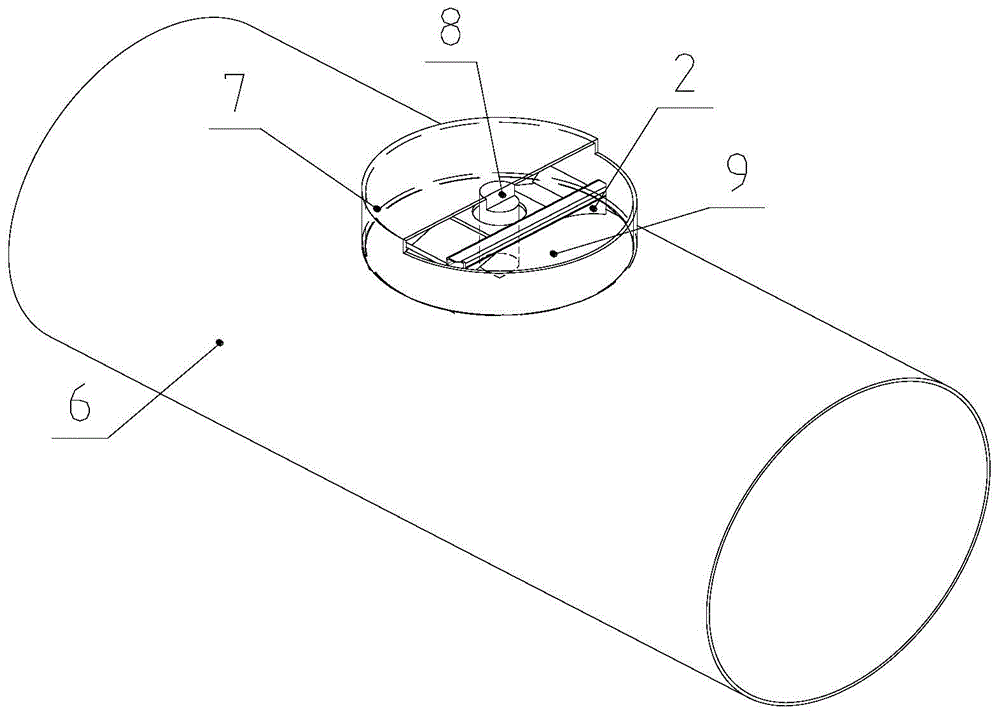

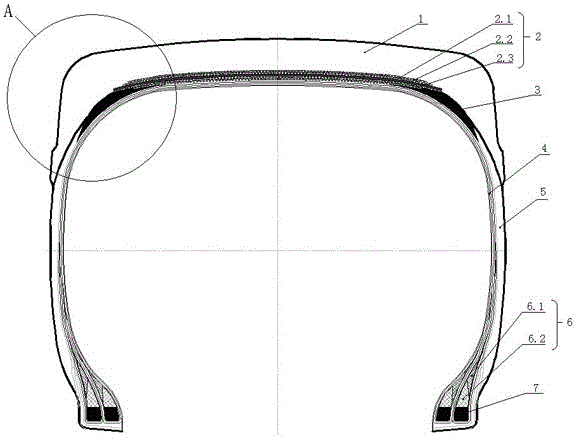

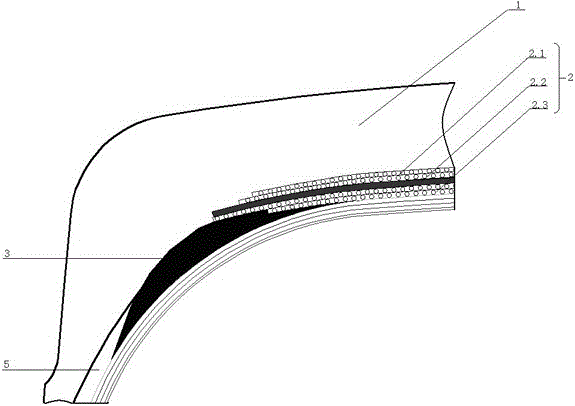

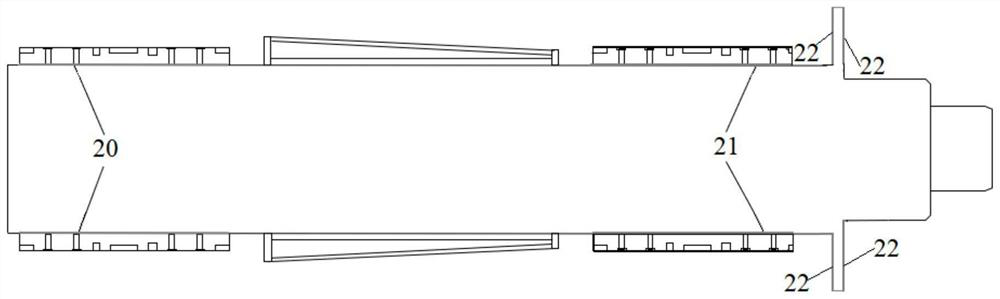

Tunnel structure for expansible stratum

PendingCN107401413ASmall expansion deformationHarm reductionUnderground chambersDrainageShotcreteReinforced concrete

The invention relates to a tunnel structure for an expansible stratum. The tunnel structure comprises a steel rack sprayed concrete primary support brace, a reinforced concrete arc wall lining, an inverted arch and inverted arch filling, wherein a reinforcing steel bar grating truss is disposed in the inverted arch filling over the inverted arch; and a central seepage trench is arranged under the inverted arch. A tunnel structure is adjusted, and tunnel inverted arch curvature is enlarged; a central water trench is replaced by the reinforcing steel bar grating truss is placed in the inverted arch filling, so bearing performance of a base structure is improved; with the arrangements of the side trench and the central seepage trench, underwater in the stratum around the tunnel and the base can be discharged; and stratum expansion deformation and damages to a tunnel lining structure by the expansion and deformation can be reduced.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Figured egg skin moon cake and its preparing method

ActiveCN1775044ASmall expansion deformationGuaranteed clarityDecorative surface effectsBakery productsVegetable oilEngineering

The present invention relates to an egg-wrapper moon cake with decorative pattern and its making method. Said making method includes the following steps: using 30-50 portions of flour, 15-25 portions of egg, 15-30 portions of sugar and 15-25 portions of vegetable oil, mixing them and making them into cake wrapper material, wrapping stuffing, placing it into mould, embossing, baking in baking oven, after the cake is cooked, taking out from mould and cooling so as to obtain the invented moon cake.

Owner:太原双合成文化传播有限公司

Method for manufacturing three-dimensional molded product and three-dimensional molded product using the same

ActiveUS20180264716A1Increase productivityImprove workabilityAdditive manufacturing apparatusInksSwelling ratioShell molding

A method for manufacturing a three-dimensional molded product capable of performing support at high accuracy using a support material having sufficient hardness and rigidity, capable of removing the support material efficiently after molding, and requiring no finishing step in manufacturing a three-dimensional molded product by an inkjet optical molding method, and a three-dimensional molded product manufactured by this method. A roughly molded product formed from a model material forming a molded product and a support material supporting the shape of the model material during molding is immersed in a washing liquid. The support material swells at a swelling ratio of 10% or more, and is thereby peeled from an interface with the model material having a swelling ratio of 1% or less. Then, the support material is easily and completely removed without applying an external force. Furthermore, a three-dimensional molded product can be manufactured with high accuracy and high efficiency.

Owner:KJ CHEM +1

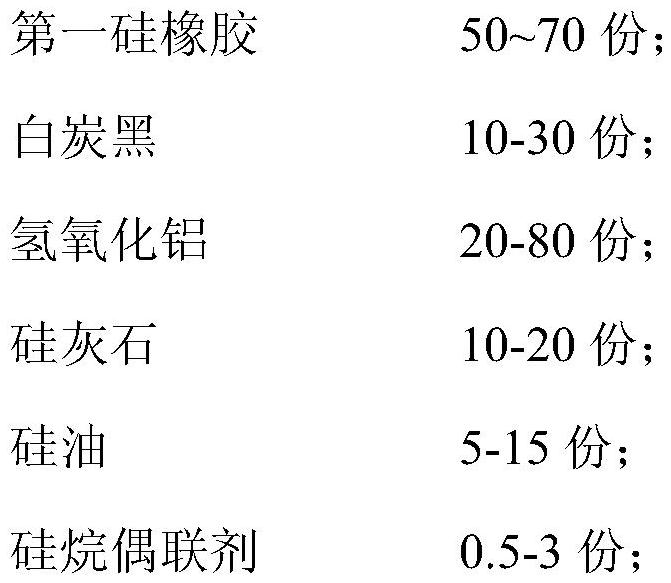

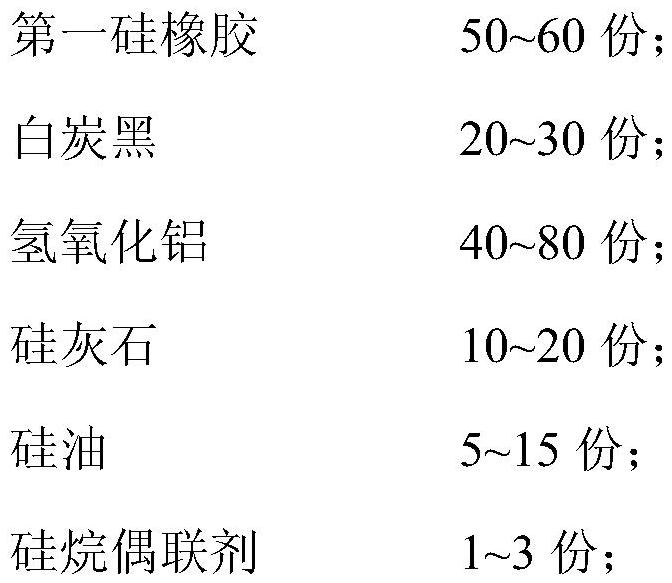

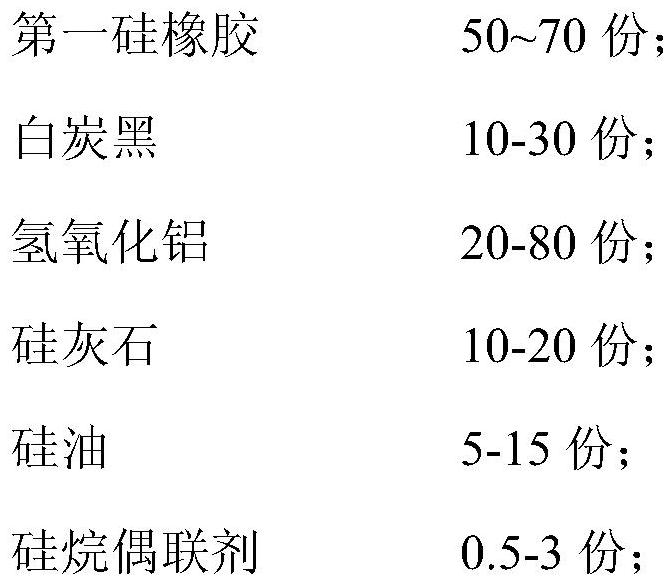

Fireproof silicone rubber material and preparation method thereof

The invention relates to the technical field of silicone rubber materials, in particular to a fireproof silicone rubber material and a preparation method thereof. Raw materials of the fireproof silicone rubber material may comprise a component A and a component B. The component A comprises first silicone rubber, white carbon black, aluminum hydroxide, wollastonite, silicone oil and a silane coupling agent; and the component B comprises second silicone rubber, magnesium oxide and boric acid. The fireproof silicone rubber material can quickly undergo a decomposition reaction when meeting high temperature or flames of 400 DEG C or above so as to release gas for oxygen isolation and flame retardance, and residues quickly form a hard shell, so expansion deformation is small, good fireproof performance, oxygen isolation performance and flame retardance are achieved, self-extinguishing can be achieved when the material is separated from a fire, and good processability and low cost are achieved; and the material can function as a fireproof layer and an oxygen barrier layer simultaneously when applied to wire and cable structures.

Owner:常州市沃科科技有限公司 +1

Fire clay for silica brick building body of industrial kiln stove

The invention discloses a fire clay for a silica brick building body of an industrial kiln stove. The fire clay contains powder materials composed of a main raw material and an auxiliary raw material and an additive, wherein fused quartz aggregate SiO2 occupying equal to or larger than 99.5% is adopted as the main raw material, silicon fume SiO2 occupying equal to or larger than 94% is adopted as the auxiliary raw material, and the additive is phosphoric acid or aluminium dihydrogen phosphate solid. The fire clay has the advantages of being very small in thermal expansion coefficient and capable of reducing expansion and deformation of the silica building body in the temperature rising process of the stove and enabling the stove to be simple to operate and safe and reliable. The fire-resisting degree of the fire clay reaches above 1730 DEG C, is high in SiO2 content and free of CaO, accordingly is high in high-temperature alkali-resistant corrodibility, and the combustion condition at the reducing atmosphere is met. The fire clay is small in granularity, high in viscosity and simple in masonry construction, can meet the requirement that the masonry mortar joint is smaller than 1.5mm, ensures masonry quality and can prolong service life of the kiln stove.

Owner:CHINA LIGHT IND INT ENG CO LTD

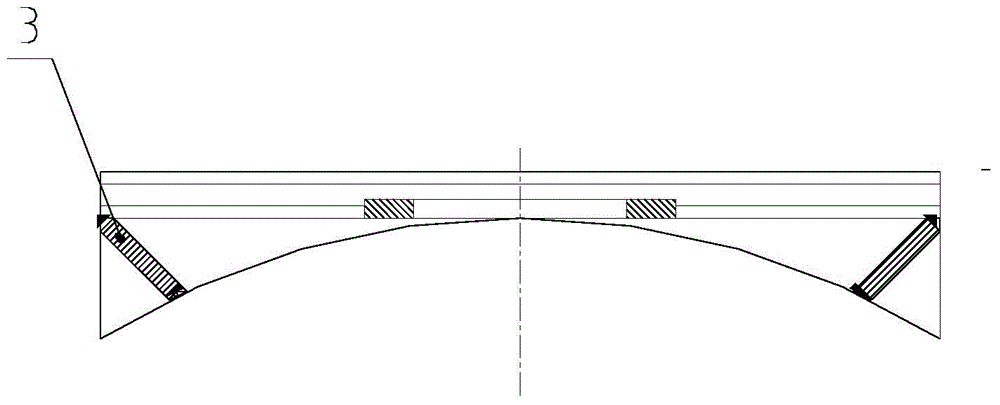

Small-diameter high-speed wheel device of unmanned system test platform fake car

PendingCN110667306AImprove cooling effectMaintain dynamic balanceHubsNon-inflatable tyresBrakeControl theory

The invention belongs to the technical field of auto parts, and discloses a small-diameter high-speed wheel device of an unmanned system test platform fake car. The device comprises a metal hub, a rubber tire encapsulating the metal hub and an axle; the metal hub is of an integrated structure and comprises a rim, a center plate, a bearing block, a brake disc and radiating rib plates; the rim and the bearing block are fixedly connected through the center plate and a plurality of the radiating rib plates; the brake disc is located at one end of the bearing block; a pair of oppositely-arranged tapered roller bearings is arranged in the bearing block; the center plate is in the shape of a circular ring, and a plurality of air duct holes are evenly distributed in the circumferential direction;and the axle is fixed to the metal hub through a shaft shoulder and locknuts. According to the device, the overall outer diameter of a wheel can be smaller than 110 mm, and the device has the good heat dissipation capability and can run at the high speed higher than or equal to 50 km / h under the heavy load.

Owner:WUHAN UNIV OF TECH +2

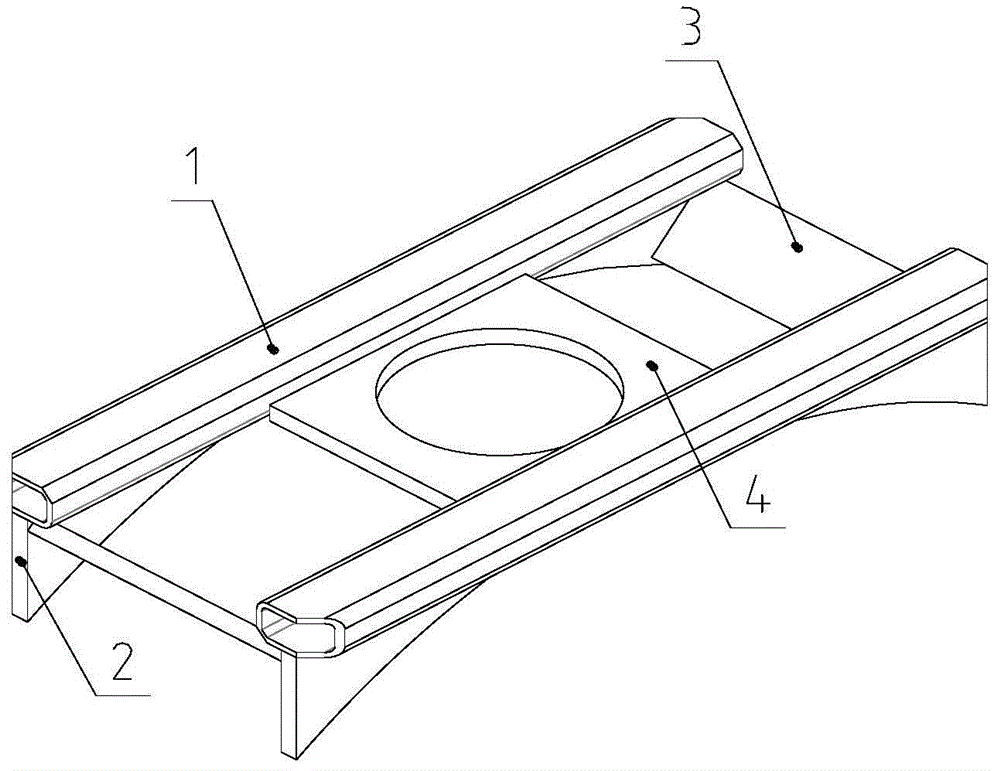

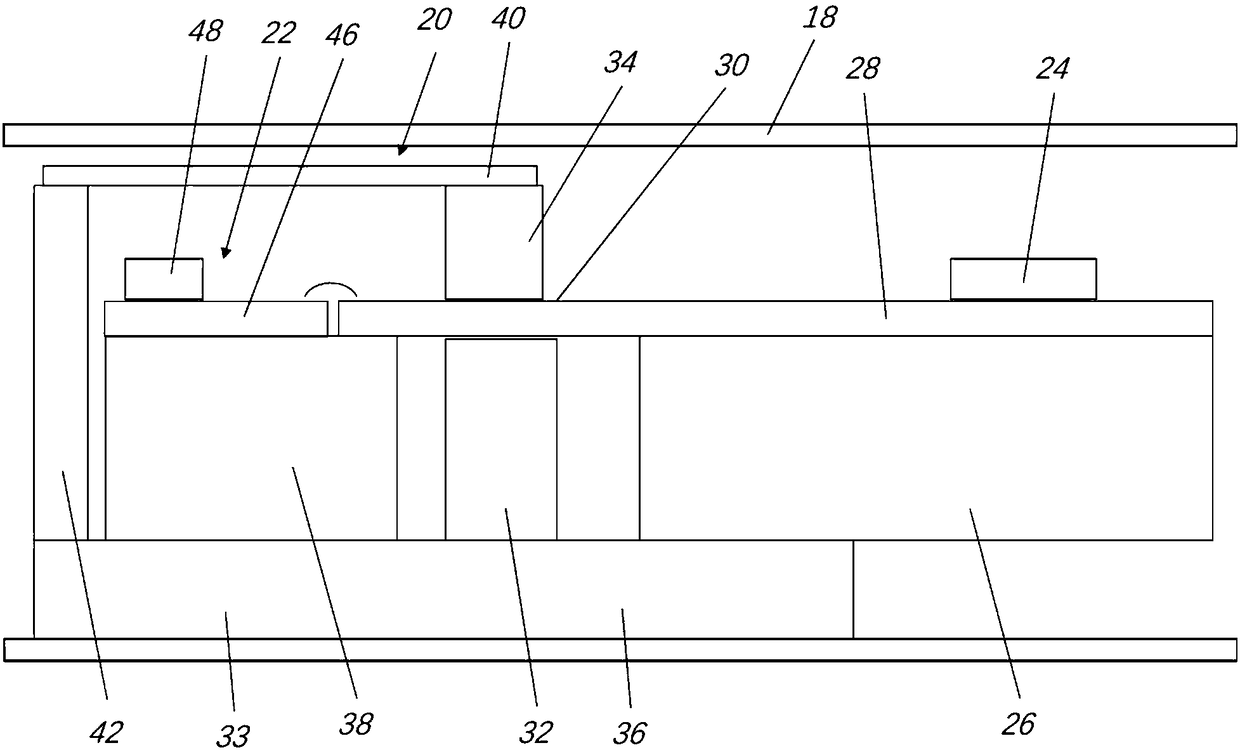

Expanding and blocking preventing device used for radial hole forming of pipeline and expanding and blocking preventing method

InactiveCN105127483AIncrease success rateDoes not affect workBoring/drilling componentsMaintainance and safety accessoriesEngineeringSaddle shape

The invention discloses an expanding and blocking preventing device used for radial hole forming of a pipeline, and belongs to the technical field of oil and gas storage and transportation safe operation. The expanding and blocking preventing device comprises parallel reinforcing ribs, a parallel double-arch rib plate, an inclined rib plate and a center positioning plate, and is characterized in that the parallel reinforcing ribs are composed of two parallel edges; the center positioning plate is round inside and square outside; the two ends of the center positioning plate and the two edges of the parallel reinforcing ribs are fixed; the parallel double-arch rib plate comprises two side faces of the same structure; the lower portions of the side faces are each of an arch-shaped structure; the radian of each arch-shaped structure is consistent with the radian of the outer diameter of the pipeline where a hole is about to be formed; the upper portions of the two side faces and the two edges of the parallel reinforcing ribs are fixed respectively; and the lower plane of the center positioning plate is tangent to the arc tops of the arch-shaped structures. The expanding and blocking preventing device is used in radial hole forming operation of the oil and gas pipeline under pressure; due to the fact that the expanding and blocking preventing device is pre-welded before hole forming, the problem that a saddle-shaped arc plate is deformed because of internal stress release in the hole forming cutting and separating process, and consequently a cylindrical cutter is expanded and blocked is solved; and the hole forming success rate is increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Multi-mining-type high-saturability steel wire-chinlon composite body OTR radial tire

InactiveCN105730150ALarge amount of sinkingReduce the anglePneumatic tyre reinforcementsTire beadMechanical engineering

The invention discloses a multi-mining-type high-saturability steel wire-chinlon composite body OTR radial tire. The multi-mining-type high-saturability steel wire-chinlon composite body OTR radial tire comprises a crown, a tire shoulder, a belted layer, tire body cord fabric, sidewall rubber and a tire bead. Shoulder pad compound is arranged at the joint part of the belted layer and the tire shoulder. Rubber cores and steel wire rings are arranged on the tire bead part. The belted layer comprises a steel wire cord fabric layer I, an insulating rubber plate and a steel wire cord fabric layer II. The insulating rubber plate is located between the steel wire cord fabric layer I and the steel wire cord fabric layer II. The rubber cores are formed by splicing upper triangular rubber core bodies and lower triangular rubber core bodies. The abrasion resistance of the OTR radial tire is about 20% higher than that of bias OTR tires, the oil saving performance of the OTR radial tire is about 13% higher than that of the bias OTR tires, the comprehensive service life of the OTR radial tire is about 50% longer than that of the bias OTR tires, and the OTR radial tire has high cost performance.

Owner:XUZHOU XUGONG TIRES

Safe self-controlled temperature type heat tracing cable

InactiveCN105924732AExcellent electrical performanceImprove wear resistanceHeating element shapesElectricityWear resistant

The invention discloses a safe self-controlled temperature type heat tracing cable which comprises a PTC core belt, an insulating layer, a metal shielding layer and a wear-resistant sheath layer, wherein the insulating layer, the metal shielding layer and the wear-resistant sheath layer covers the PTC core belt in sequence; the PTC core belt consists of two heating leads arranged in parallel and a PTC material layer covering each heating lead; diatomite is modified through cationic polyacrylamide so as to be positively charged and have good compatibility, electrical conductivity and mechanical property of improving a matrix material. The cable prepared by the invention is excellent in electrical property, good in heat resistance, aging resistance and wear resistance, small in swelling deformation, low in smoke, retardant in flame, environmentally friendly, safe and worthy of being popularized.

Owner:ANBANG ELECTRICAL GRP

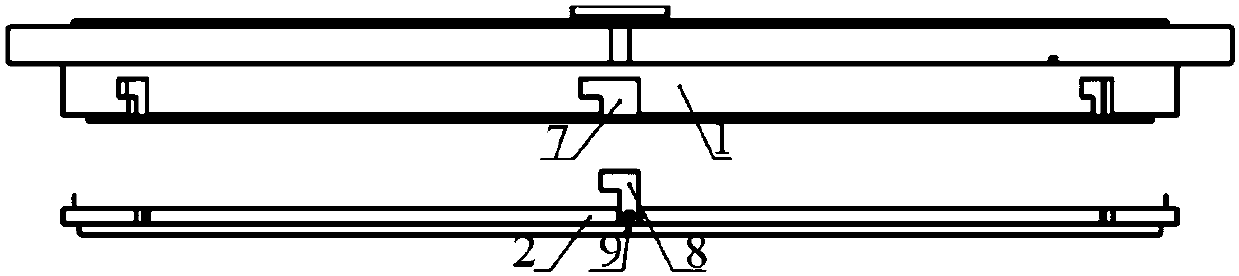

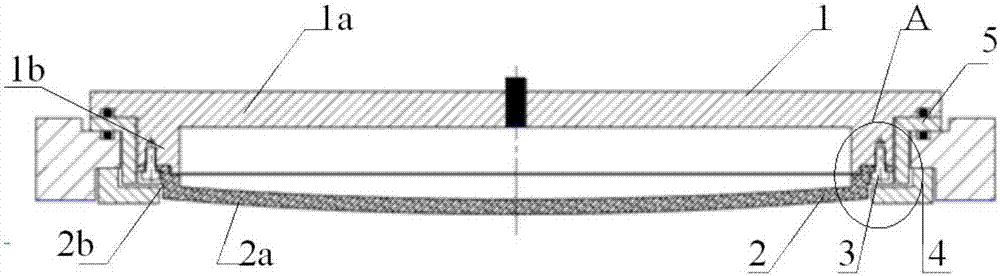

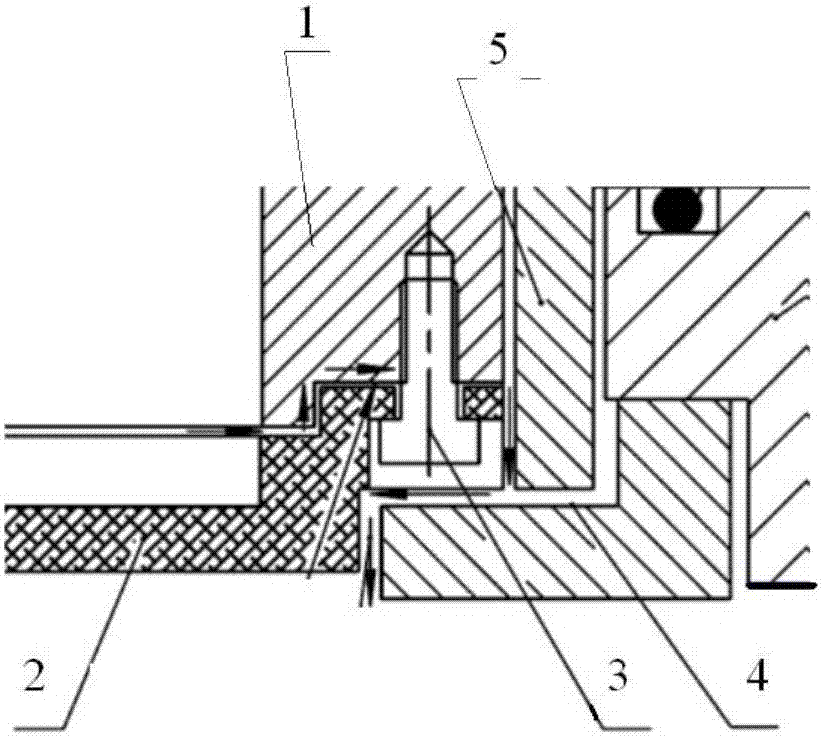

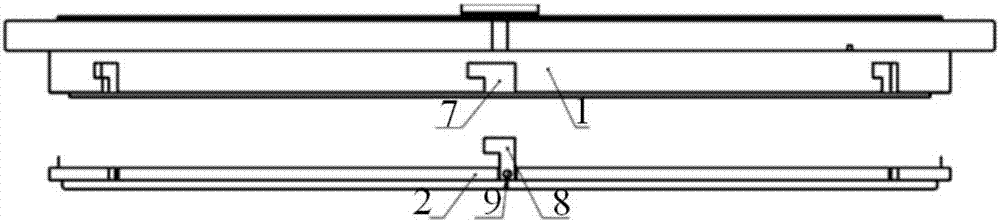

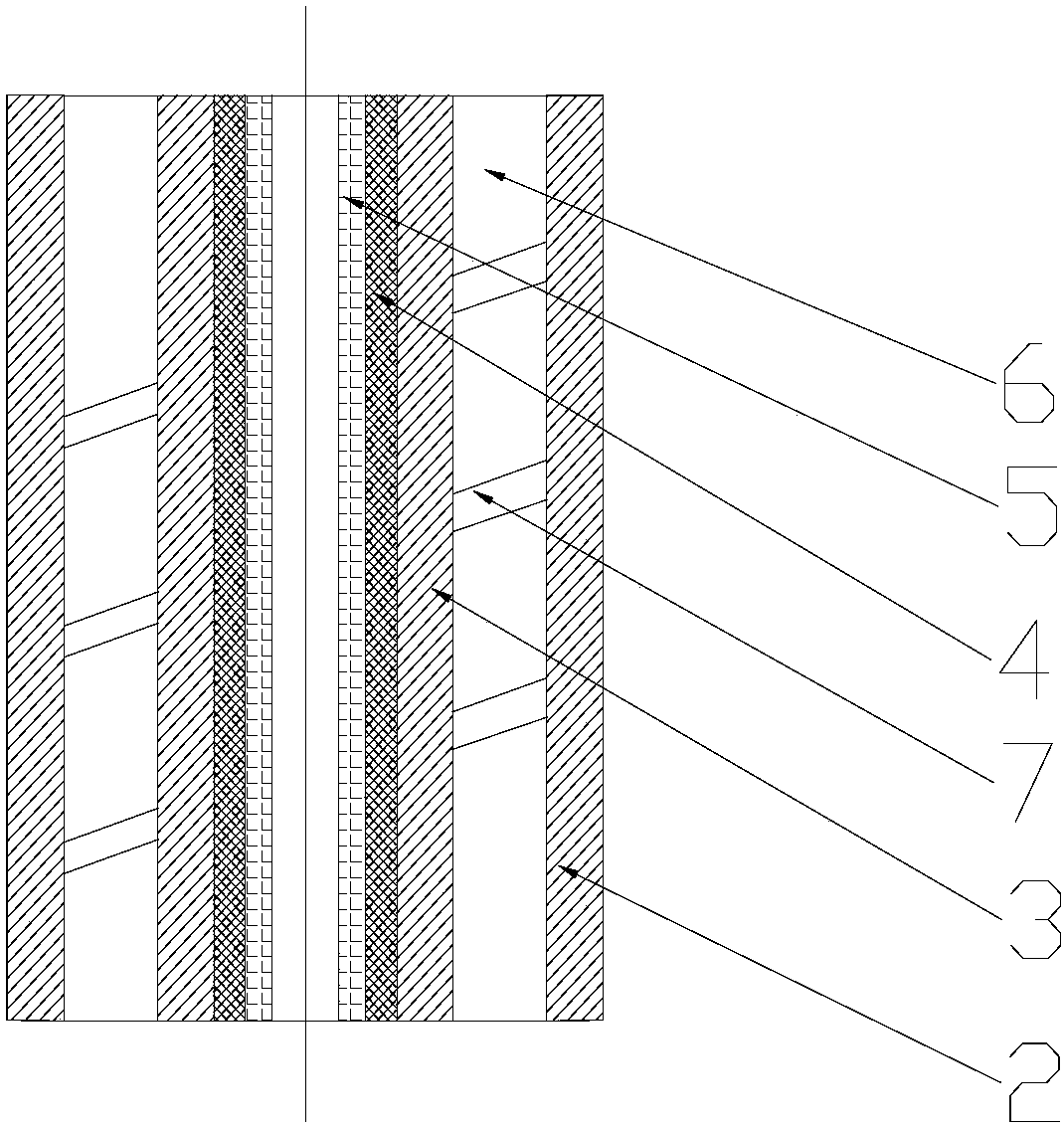

Optical module

The invention discloses an optimal module comprising a casing, a sealing shell arranged in the casing, an optoelectronic component and a circuit board. The optoelectronic component is arranged in thesealing casing, and the circuit board is electrically connected to the optoelectronic component in the sealing casing, wherein the circuit board includes a first board and a second board disposed on the surface of the first board, the thickness of the second board is smaller than that of the first board, the second board includes a high-speed link layer disposed on a surface layer and a referencelayer disposed under the surface layer, the second board extends into the sealing casing and is electrically connected to the optoelectronic component, one side wall of sealing casing comprises a carrier and an insulating plate, the second board of the circuit board passes through an opening between the carrier and the insulating plate and is sealingly connected to the carrier and the insulating plate, and the insulating plate is disposed at one side of the high-speed link layer of the second board. The optical module has good high-speed transmission performance, low cost and good air tightness.

Owner:INNOLIGHT TECHNOLOGY (SUZHOU) LTD

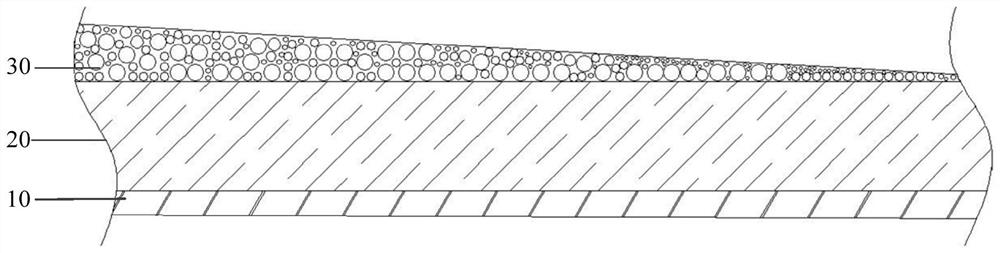

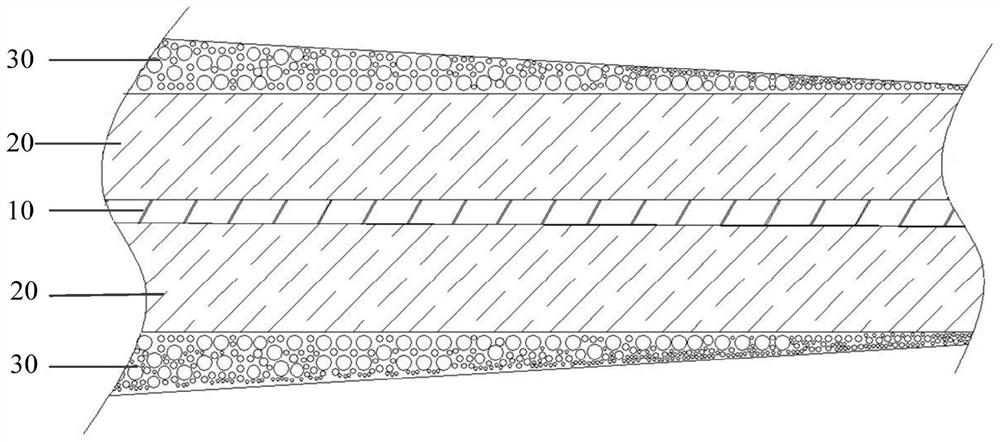

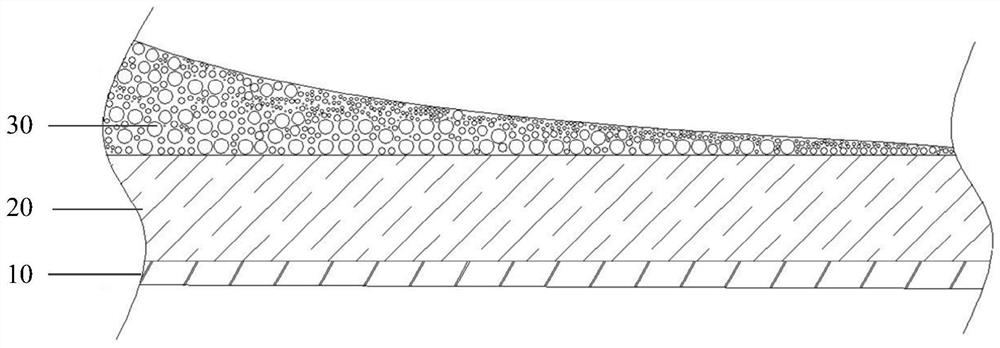

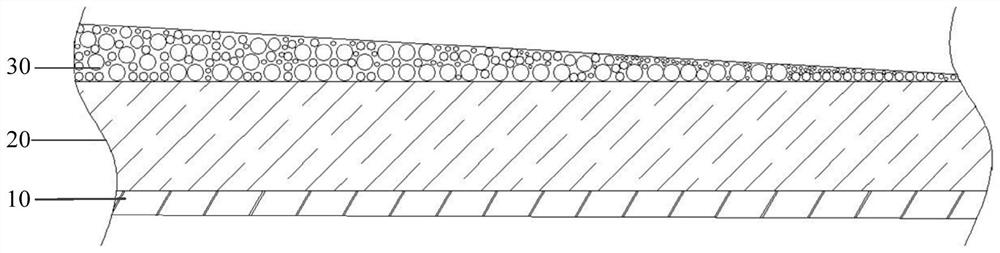

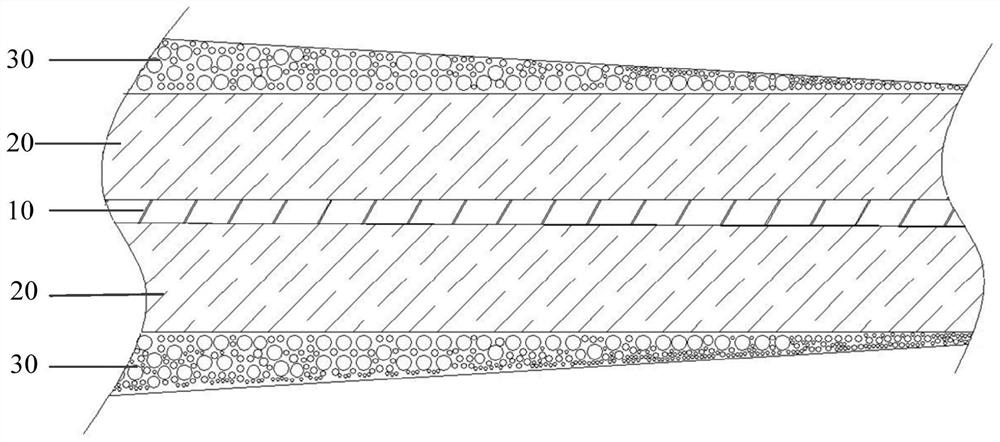

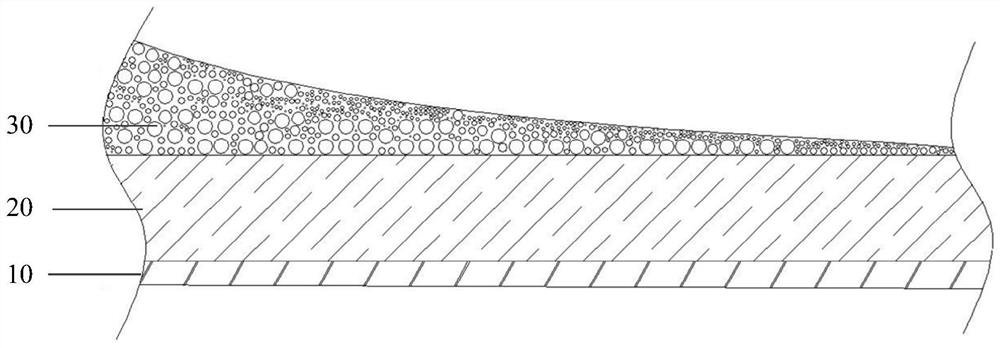

Electrode plate and battery

ActiveCN112701246ASmall expansion deformationImprove flatnessFinal product manufactureSecondary cellsBattery cellPhysics

The invention provides an electrode plate and a battery. The electrode plate comprises a current collector, the current collector comprises a first surface and a second surface which are oppositely arranged, at least one surface of the first surface and the second surface is provided with an active material layer, the side, far away from the current collector, of the active material layer is provided with a protruding point layer, the thickness of the protruding point layer decreases progressively from a first end of the current collector to a second end of the current collector, and the first end of the current collector and the second end of the current collector are two opposite ends of the current collector. According to the embodiment of the invention, the problem that a coiled electrode plate is relatively small in expansion space, so that a battery cell is easy to deform in a circulating process and the liquid storage capacity of the battery cell is relatively low can be solved.

Owner:ZHUHAI COSMX BATTERY CO LTD

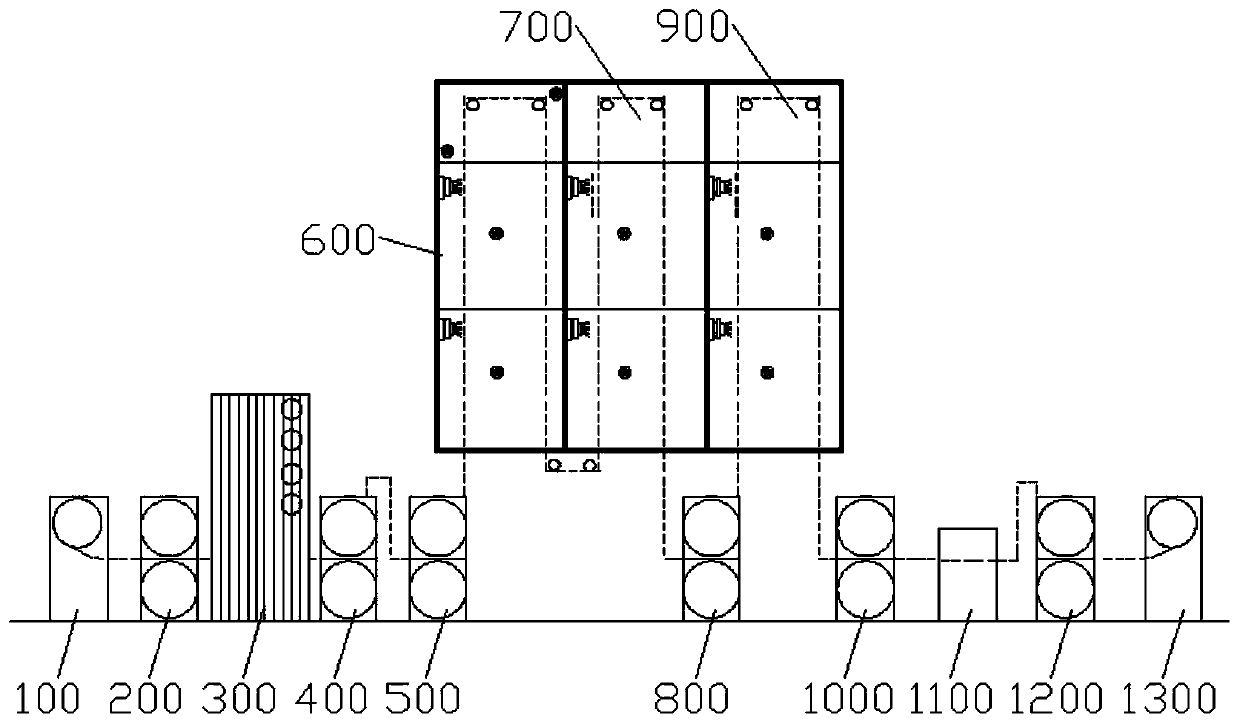

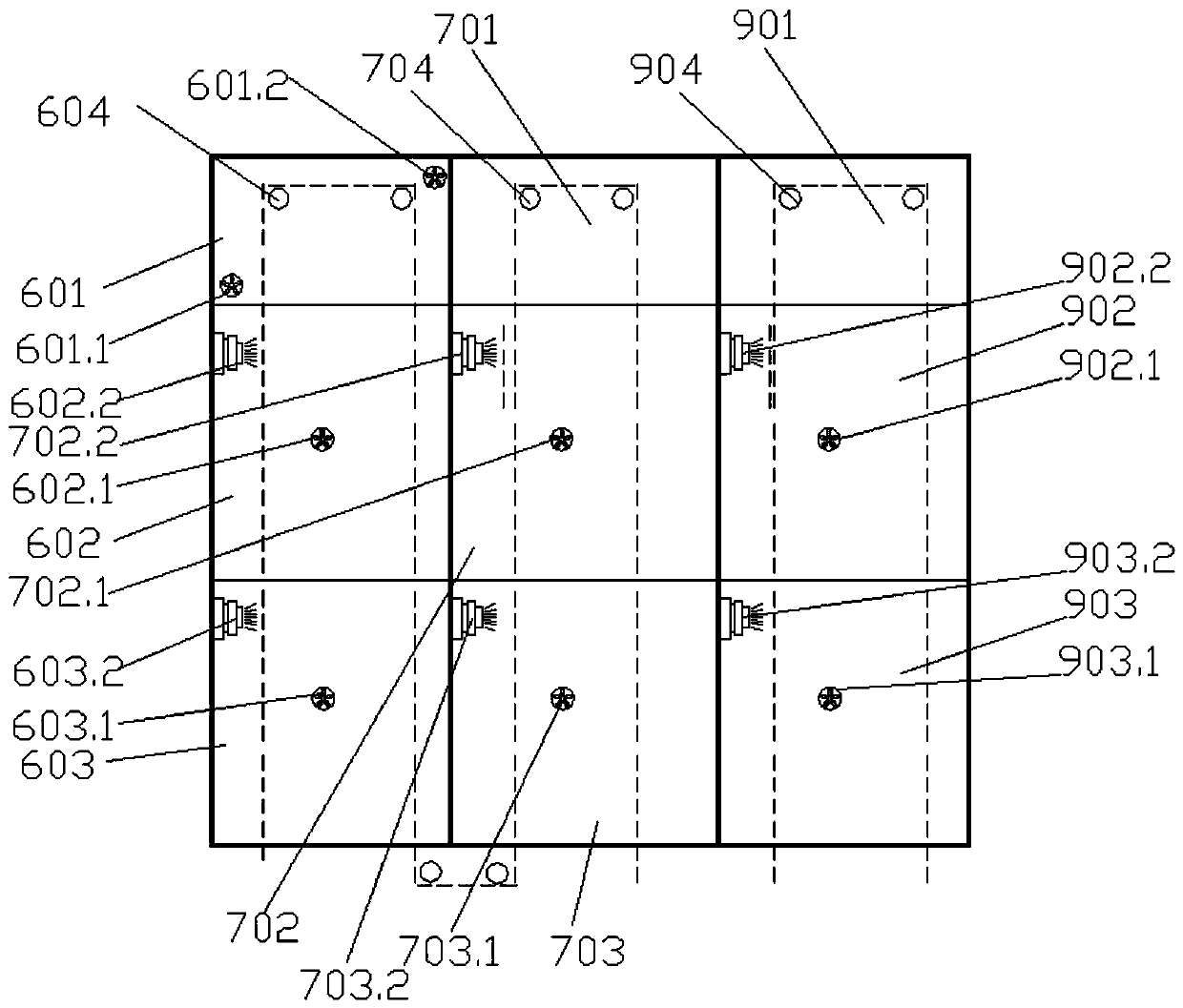

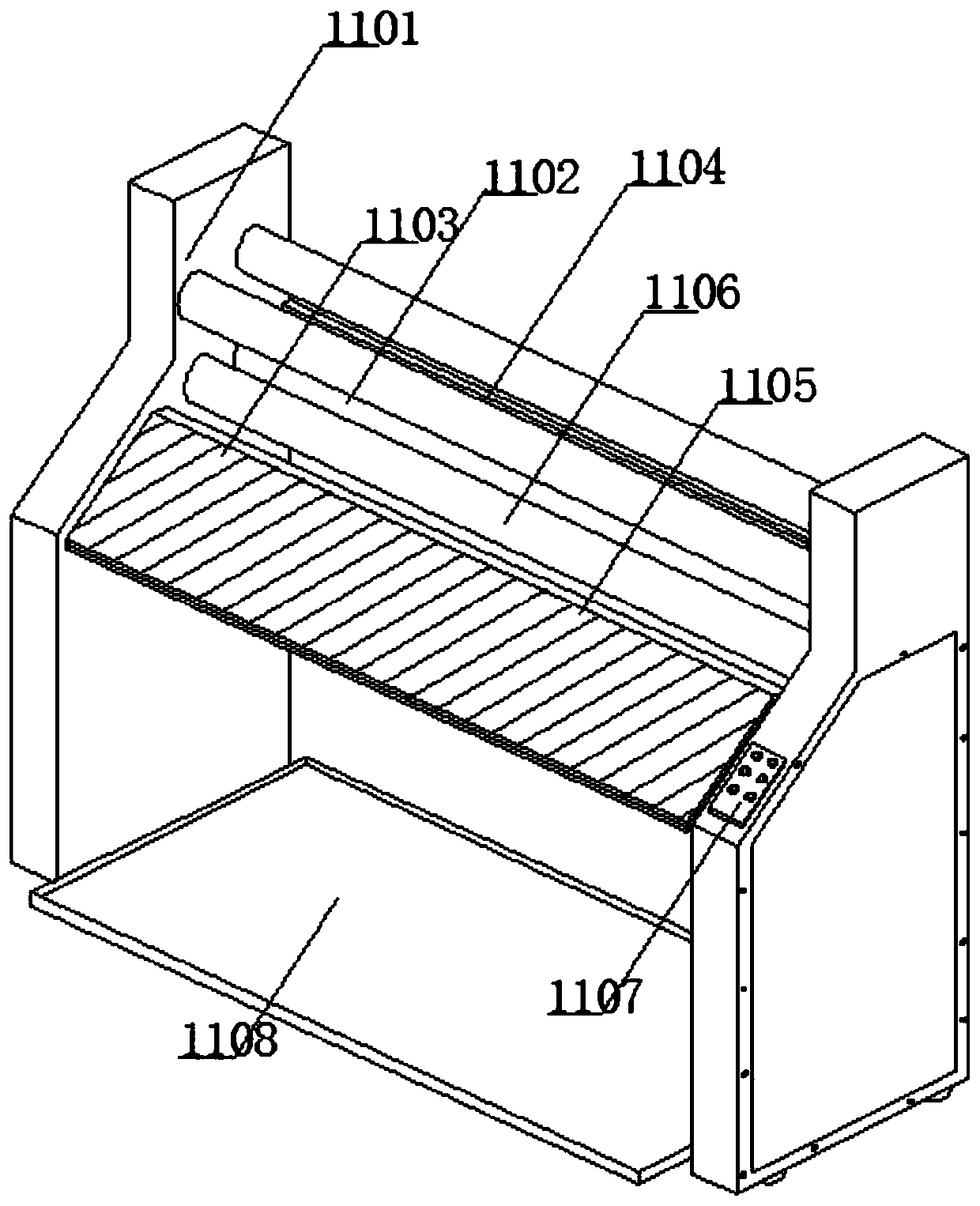

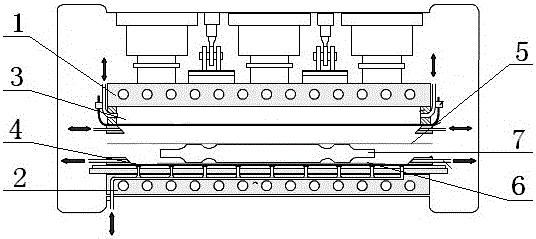

Multifunctional rubber dipping machine for preparing chinlon 6 cord fabric

PendingCN109811491AExtended service lifeStrong fatigue resistanceSucessive textile treatmentsLiquid/gas/vapor removalShrinkage rateHigh energy

The invention relates to a multifunctional rubber dipping machine for preparing a chinlon 6 cord fabric. The multifunctional rubber dipping machine is characterized in that the multifunctional rubberdipping machine comprises a system rack, the system rack sequentially comprises an unwinding device, a front traction device, a slow storage cloth device, a middle traction device, a dipping host, a front drying room, a rear drying room, a first roller set, a stretching drying room, a second roller set, a shaping device, a third roller set, and a winding device along the cord fabric from front toback. The multifunctional rubber dipping machine for preparing the chinlon 6 cord fabric has the advantages of high production efficiency, high energy utilization rate, and low product dry-heat shrinkage rate.

Owner:江阴市沙江纺织科技有限公司

Air static pressure high-speed motorized spindle based on titanium-aluminum alloy mandrel

ActiveCN114131060AReduce distortionCounteract axial force fluctuationsLarge fixed membersMaintainance and safety accessoriesAir bearingPull force

The invention relates to an air static pressure high-speed motorized spindle based on a titanium-aluminum alloy mandrel. The air static pressure high-speed motorized spindle comprises a base, a shell, the mandrel, an axial air bearing, a supporting assembly, a cooling assembly and a wedge-shaped motor assembly. The mandrel is made of titanium-aluminum alloy, and the axial air bearing is connected to the mandrel in a sleeved mode. The supporting assembly is arranged in the shell to support the mandrel, and the cooling assembly is arranged on the outer side of the supporting assembly. The wedge-shaped motor assembly comprises a stator assembly and a rotor assembly, the stator assembly is fixedly connected with the supporting assembly, and the core shaft is sleeved with the rotor assembly. The wedge-shaped motor assembly generates magnetic pulling force perpendicular to the surface of the rotor assembly under the electrified condition, and the resultant force of the magnetic pulling force is parallel to the direction where the mandrel is located. After the wedge-shaped motor assembly is powered on, magnetic pulling force perpendicular to the surface of the rotor can be generated, part of axial force fluctuation, caused by external force, of the mandrel is offset, and the bearing capacity of the axial load of the electric spindle is improved. And the heating value of the thrust plate in the rotating process can be reduced through the magnetic pulling force, and deformation of the motorized spindle is reduced.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

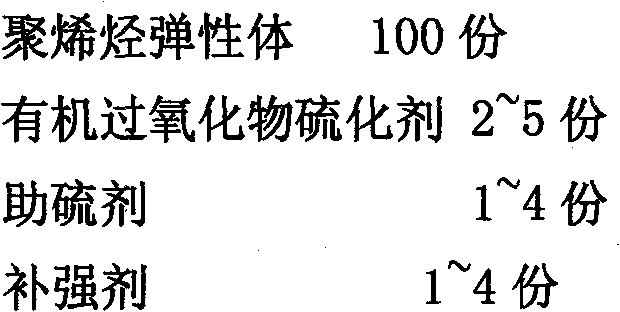

Low smoke zero halogen high-temperature (100 DEG C) and flame resistance multi-core control cable core insulation rubber

ActiveCN101845160BComprehensive technical performanceImprove electrical performanceRubber insulatorsInsulating bodiesElastomerPolyolefin

The invention discloses a low smoke zero halogen high-temperature (100 DEG C) and flame resistance multi-core control cable core insulation rubber comprising the following components by weight part: 100 parts of polyolefin elastomer (POE), 2-5 parts of organic peroxide curing agent, 1-4 parts of assistant sulfur agent and 1-4 parts of reinforcing agent. Preferentially, the POE is POE8450, the organic peroxide curing agent is dicumyl peroxide (DCP), the assistant sulfur agent is triallyl isocyanurate (TAIC), and the reinforcing agent is deposited white carbon black. The multi-core control cable core insulation rubber has good comprehensive performance, excellent electrical performance, good heat resistance, ageing resistance and wear resistance, high temperature resistance level and long service life.

Owner:JIANGSU JUYE CABLE

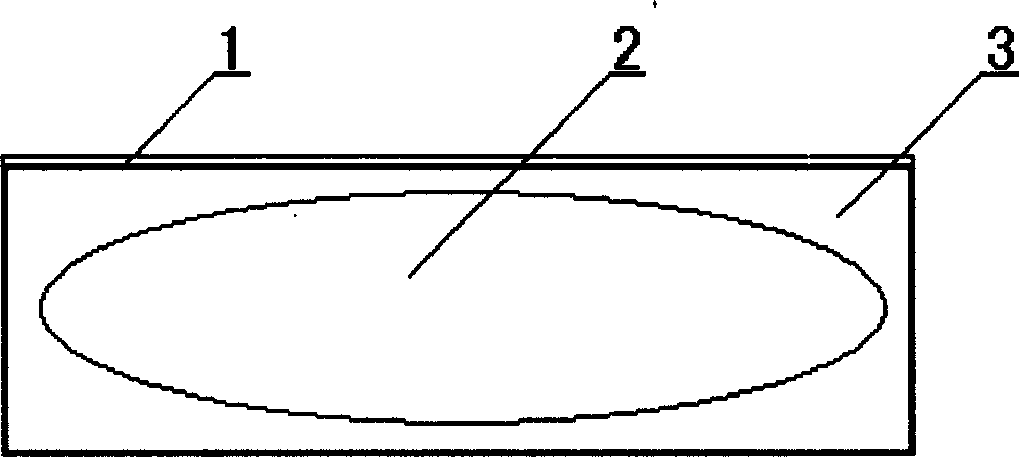

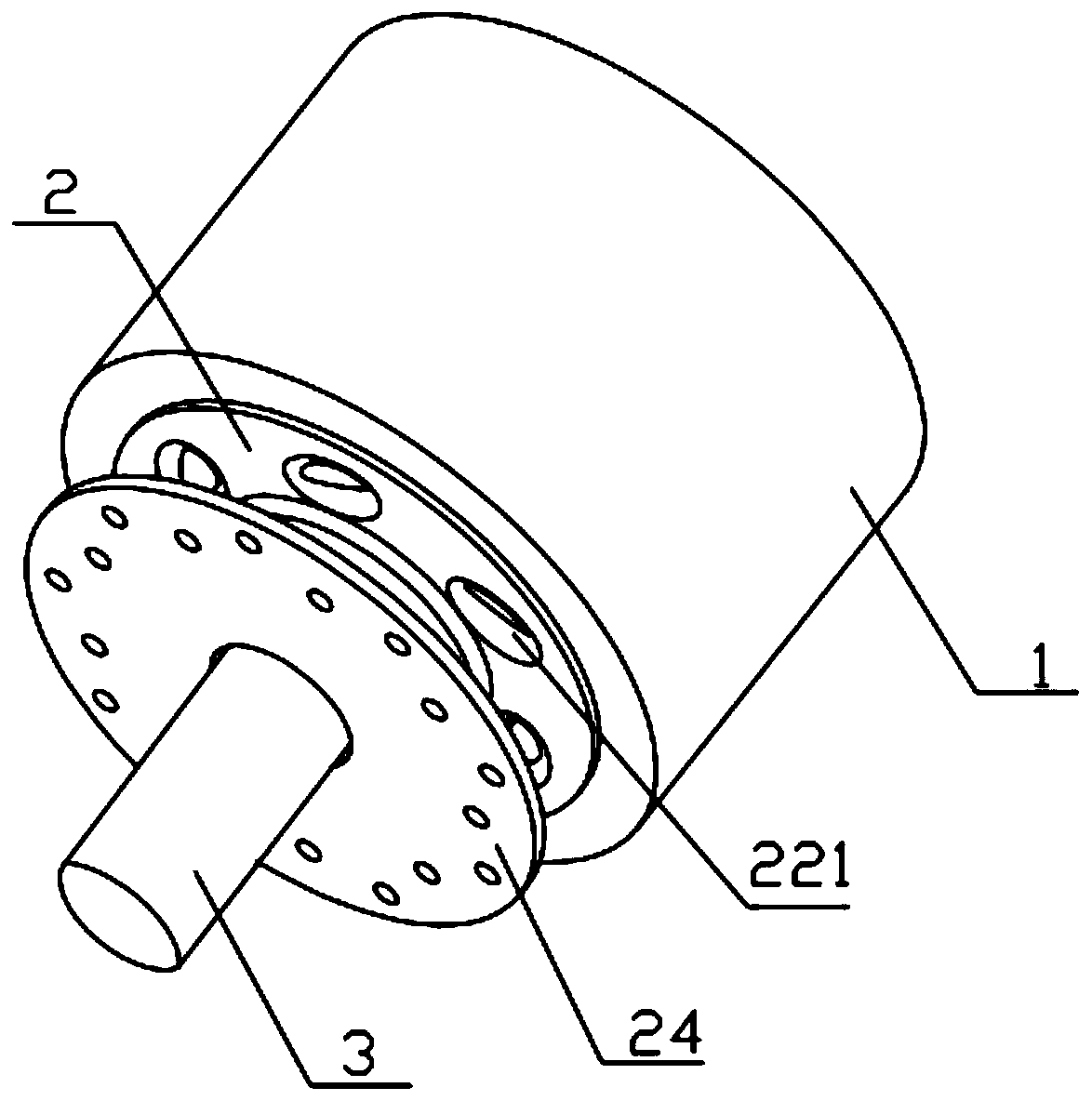

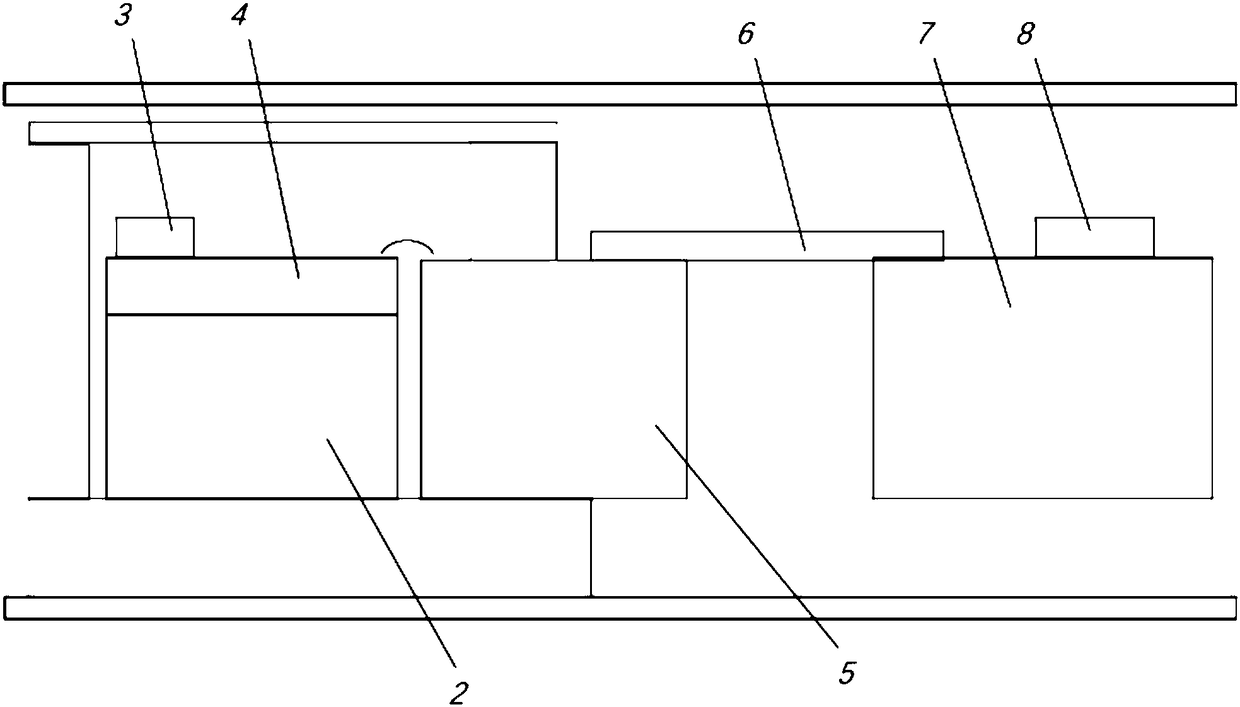

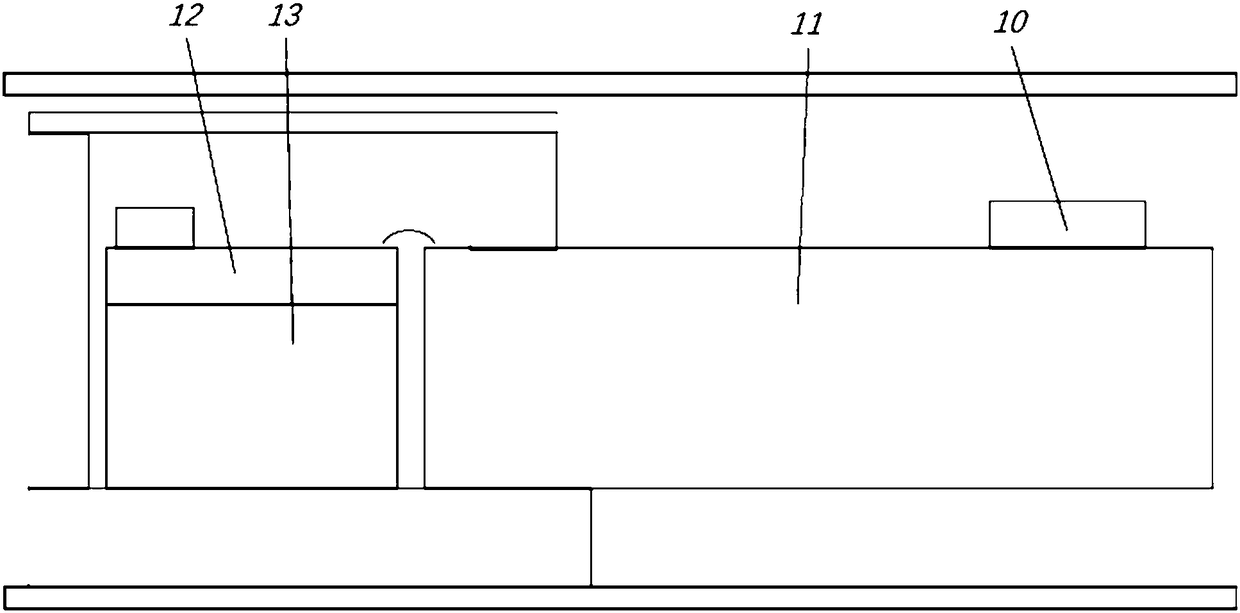

A flow equalizing device and reaction chamber

ActiveCN107090575BSmall expansion deformationReduce leakageChemical vapor deposition coatingMachining processRadio frequency

The invention provides a flow rectifier. The flow rectifier comprises a radio frequency cover and a spraying plate. The radio frequency cover comprises an upper part and a lower part which are fixedly connected into a whole. The upper part of the radio frequency cover is a first disc body, and the lower part of the radio frequency cover is a first annular connecting part. The outer diameter of the first connecting pat is smaller than the diameter of the first body. The spraying plate comprises an upper part and a lower part which are fixedly connected into a whole. The upper part of the spraying plate is a second annular connecting part, and the lower part of the spraying plate is a second disc body. The outer diameter of the second connecting part is greater than the diameter of the second body. The outer side wall of the first connecting part and the outer side wall of the second connecting part are provided with matching clamping parts in the axial direction correspondingly, so that the radio frequency cover is fixedly connected with the spraying plate. Through the flow rectifier provided by the invention, the problem of non-ideal machining processes caused by gas leakage and deformation can be effectively solved, and the flow rectifier has good conduction characteristic.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

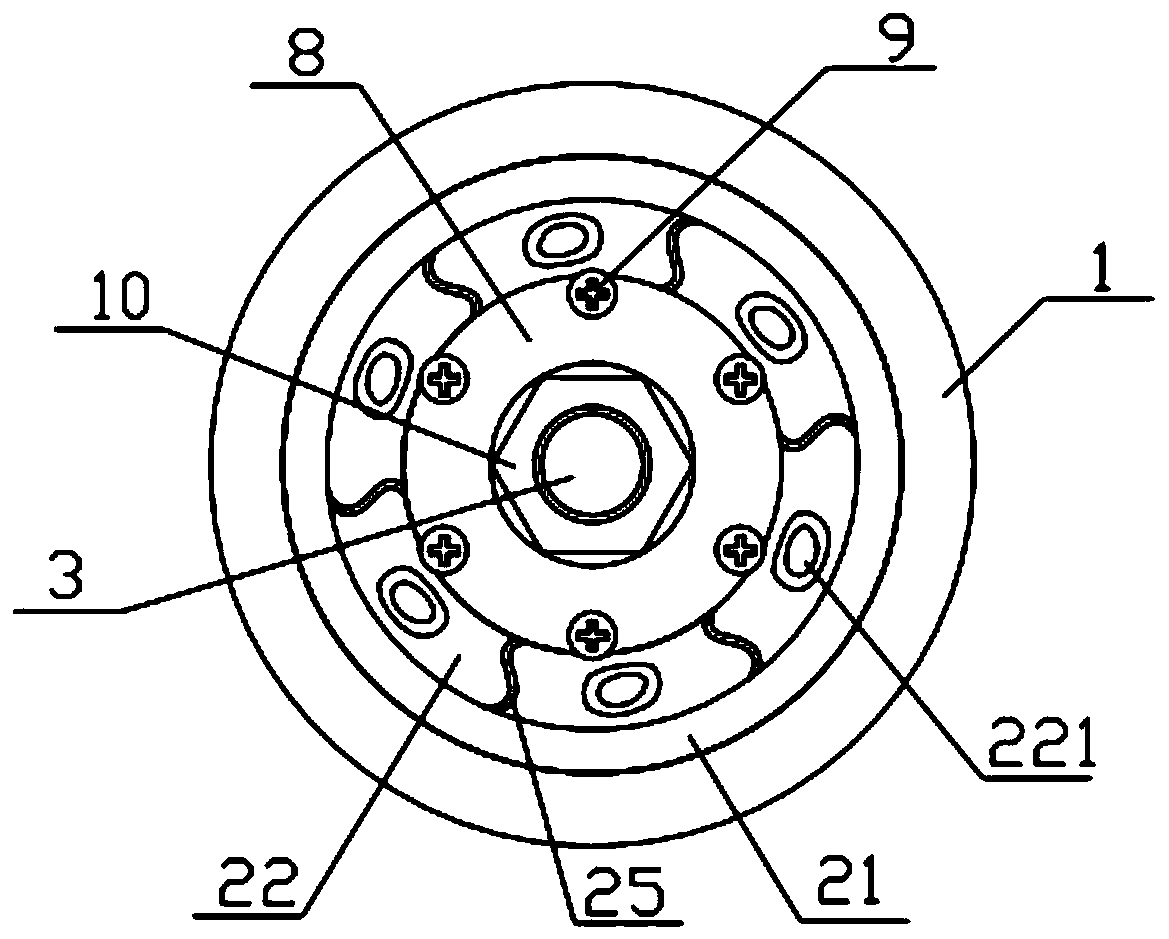

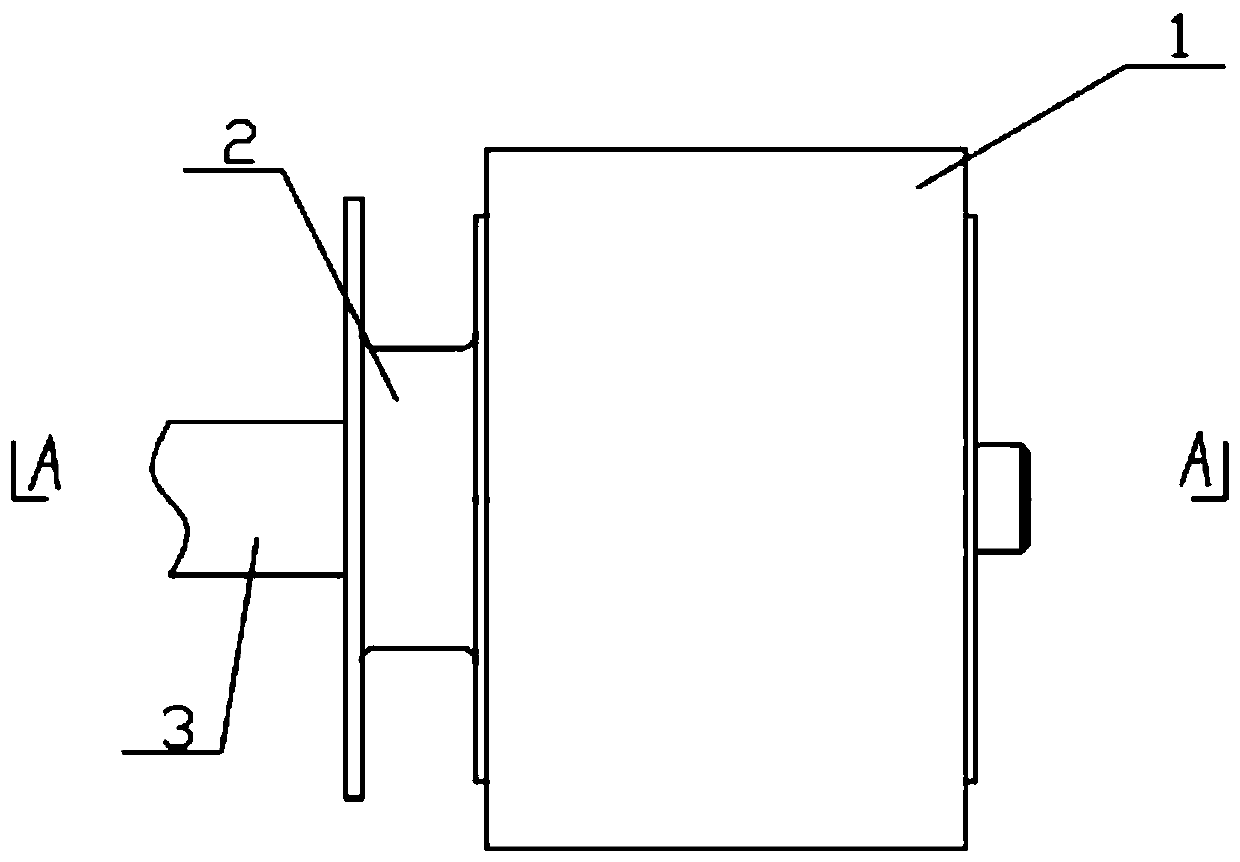

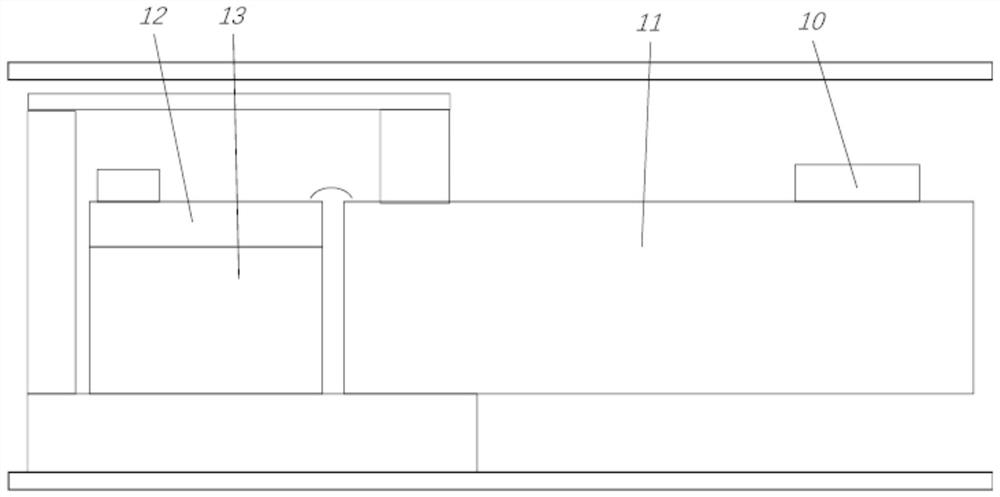

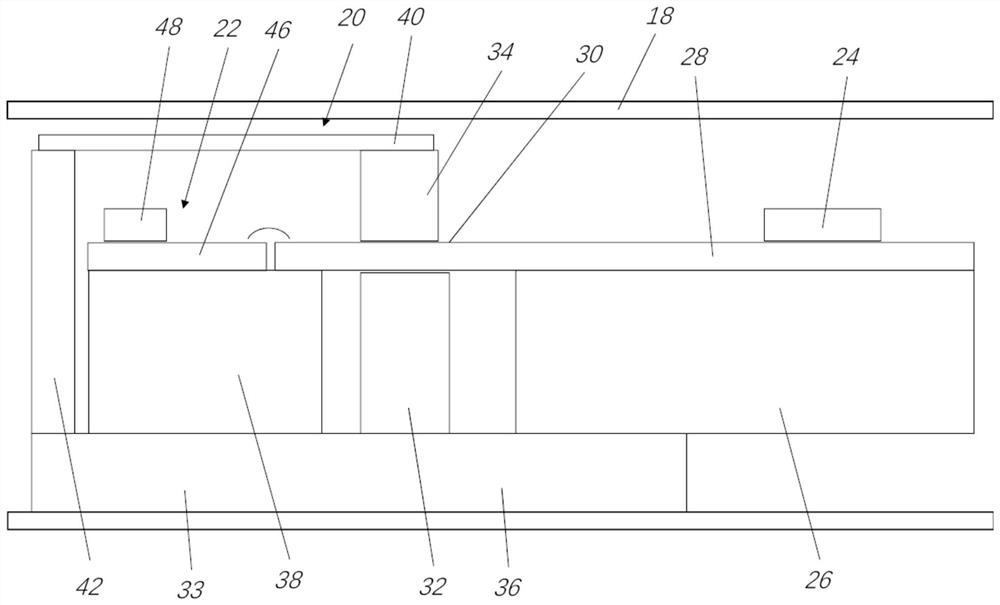

Flow rectifier and reaction cavity

ActiveCN107090575ASmall expansion deformationReduce leakageChemical vapor deposition coatingMachining processRadio frequency

The invention provides a flow rectifier. The flow rectifier comprises a radio frequency cover and a spraying plate. The radio frequency cover comprises an upper part and a lower part which are fixedly connected into a whole. The upper part of the radio frequency cover is a first disc body, and the lower part of the radio frequency cover is a first annular connecting part. The outer diameter of the first connecting pat is smaller than the diameter of the first body. The spraying plate comprises an upper part and a lower part which are fixedly connected into a whole. The upper part of the spraying plate is a second annular connecting part, and the lower part of the spraying plate is a second disc body. The outer diameter of the second connecting part is greater than the diameter of the second body. The outer side wall of the first connecting part and the outer side wall of the second connecting part are provided with matching clamping parts in the axial direction correspondingly, so that the radio frequency cover is fixedly connected with the spraying plate. Through the flow rectifier provided by the invention, the problem of non-ideal machining processes caused by gas leakage and deformation can be effectively solved, and the flow rectifier has good conduction characteristic.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

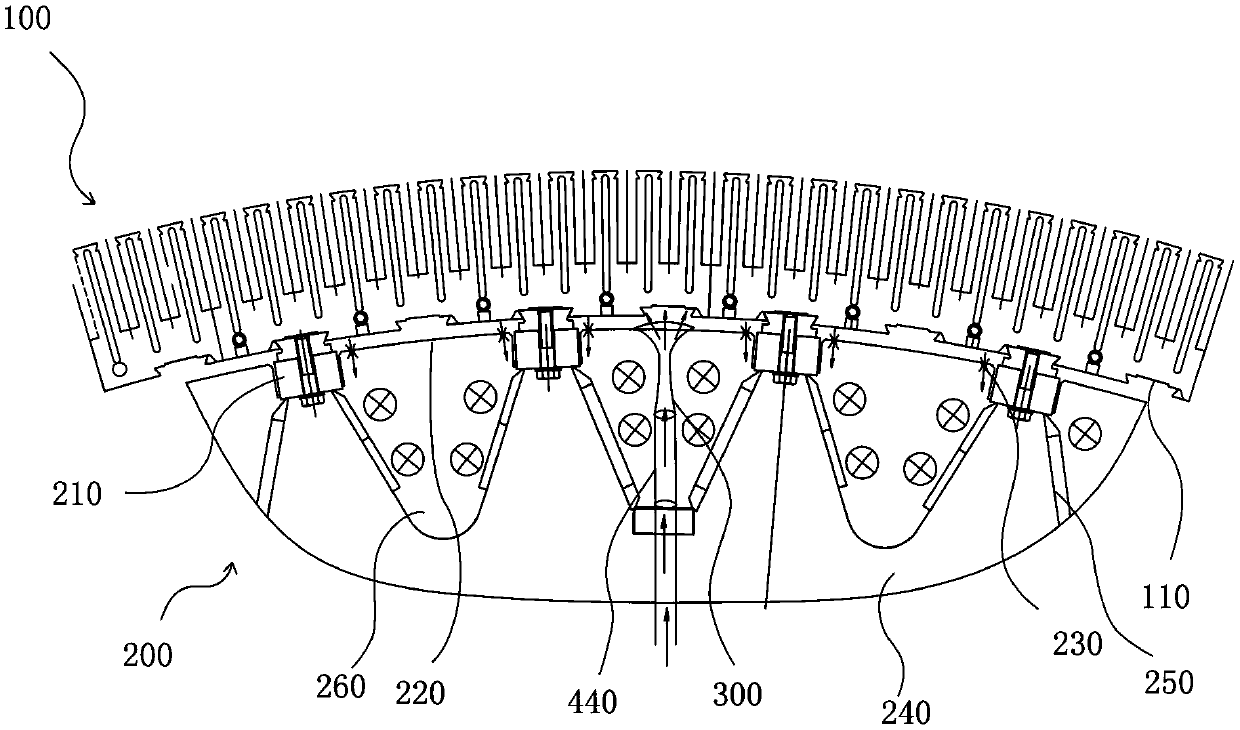

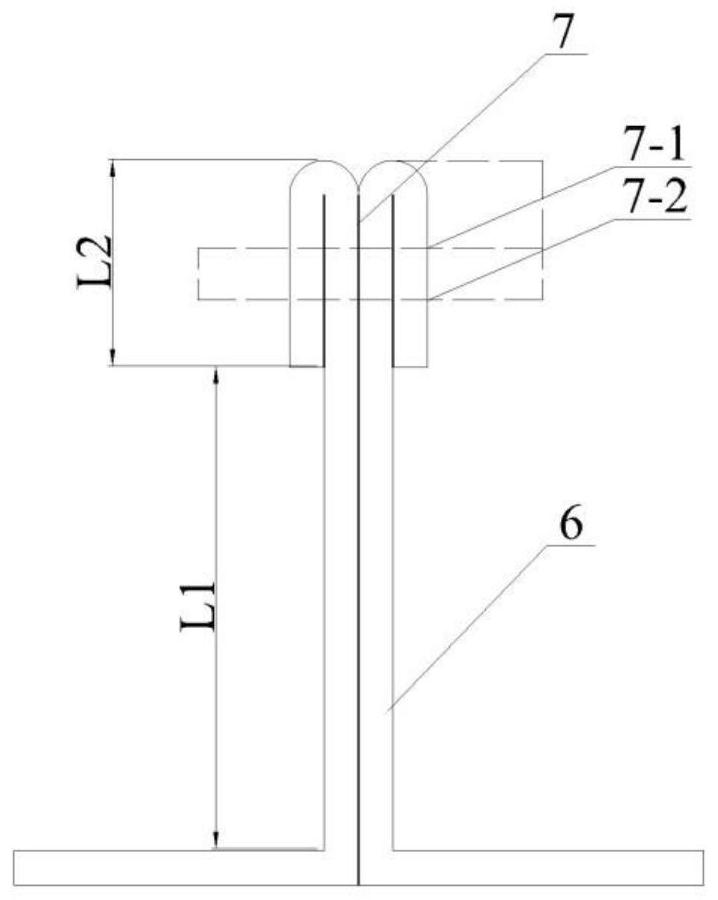

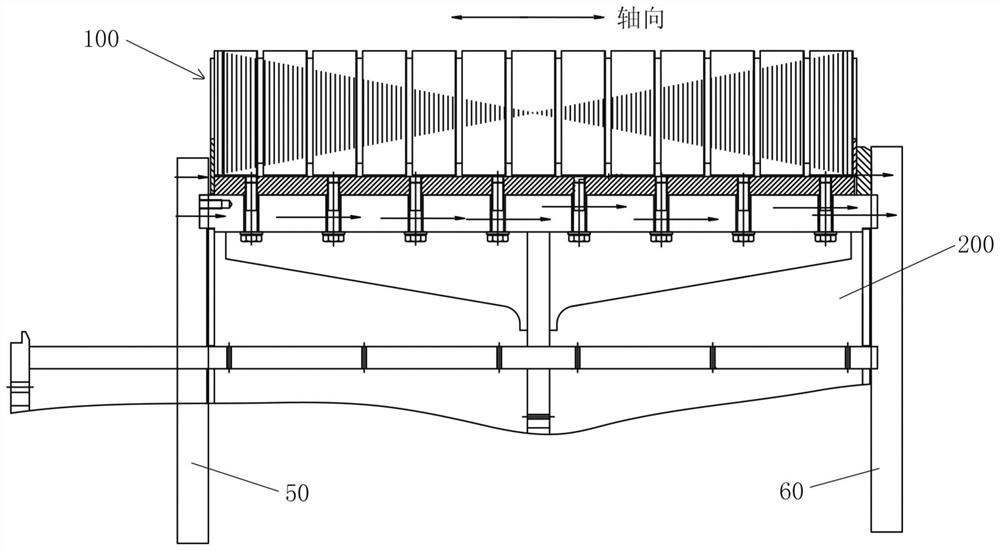

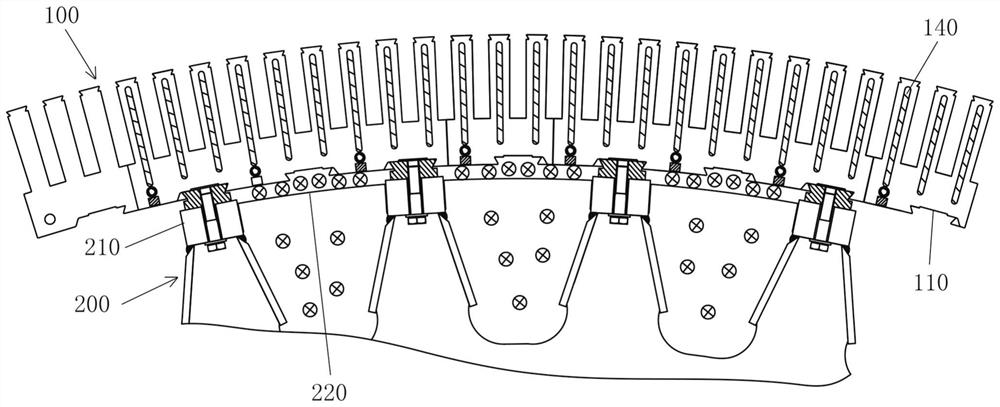

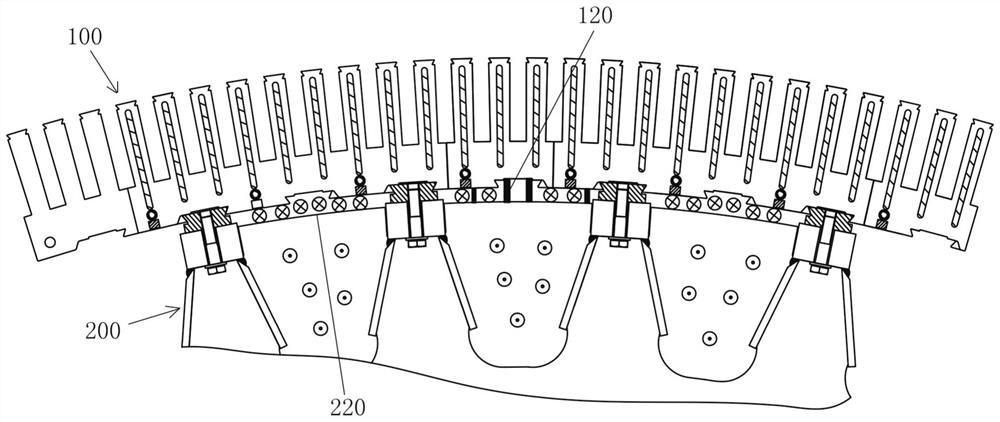

Stator assembly and motor having stator assembly

ActiveCN110635589AExtended service lifeSmall expansion deformationEngine fuctionsMagnetic circuit stationary partsCooking & bakingElectric machine

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Environment-friendly tensile high-temperature-resistant control cable material and preparation method thereof

InactiveCN102911409BReasonable formulaEasy to prepareInsulated cablesInsulated conductorsPolycaprolactoneMaterials science

The invention discloses an environment-friendly tensile high-temperature-resistant control cable material and a preparation method thereof. The cable material is composed of a mixture A and a mixture B, wherein the mixture A comprises, by weight, 30-40 parts of nitrile rubber, 20-30 parts of silicon rubber, 10-20 parts of polyacrylate, 10-20 parts of poly(styrene-butadiene-styrene), 1-3 parts of semi-reinforcing carbon black, 40-60 parts of modified nano-powder, 1-3 parts of insoluble sulfur, 1.5-2.5 parts of methyltrimethoxysilane, 1-3 parts of zinc stearate, 3-4 parts of antioxidant 1035, 1-3 parts of bi-texanol, 10-20 parts of magnesium hydroxide and 1-3 parts of dioctyl phthalate; the mixture B comprises, by weight, 30-50 parts of nitrile rubber, 20-40 parts of silicon rubber, 20-30 parts of polyacrylate, 0.3-0.5 part of poly(4-methyl-1-pentene) , 2-4 parts of antiager RD, 5-10 parts of polycaprolactone, 2-3 part of crosslinking agents TAIC, 1-3 part of chlorinated paraffin, 5-8 parts of ammonium dihydrogen phosphate and 1-3 parts of isooctyl thioglycolate dimethyl tin. The preparation method is simple, the composite formula is reasonable, the performance of the cable material is improved greatly, thermal resistance, aging resistance and wear resistance of the cable material are good, expansion deformation under high temperature is small, secondary vulcanization is facilitated, and the cable material is low-smoke, flame-retardant, environment-friendly and safe.

Owner:沛县格桑电子有限公司

A kind of polyolefin thermoplastic elastomer cable sheath material and preparation method thereof

ActiveCN103601941BImprove flame retardant performanceImprove electrical performancePlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePolyolefin

The invention discloses a polyolefin thermoplastic elastomer cable sheathing material and a preparation method thereof. The raw materials comprise a polyolefin thermoplastic elastomer, natural rubber, zinc oxide powder, nano titanium dioxide, modified nano aluminum hydroxide, a curing agent VA-7, an accelerator BF, tetraisopropyl di(dioctylphosphate) titanate, calcium stearate, catechol, an anti-dripping agent KY-G80 and chlorinated paraffin. The material provided by the invention adopts a polyolefin thermoplastic elastomer as a main material, has excellent electrical properties, good heat resistance, good aging resistance, good wear resistance, small expansion deformation under high temperature, and is conducive to secondary vulcanization processing, low-smoke, flame-retardant environment-friendly and safe; and through the modification treatment on a flame retardant nano aluminum hydroxide, the cable sheath gains greatly improved flame retardance and has obvious flame retardant effect.

Owner:STATE GRID CORP OF CHINA +1

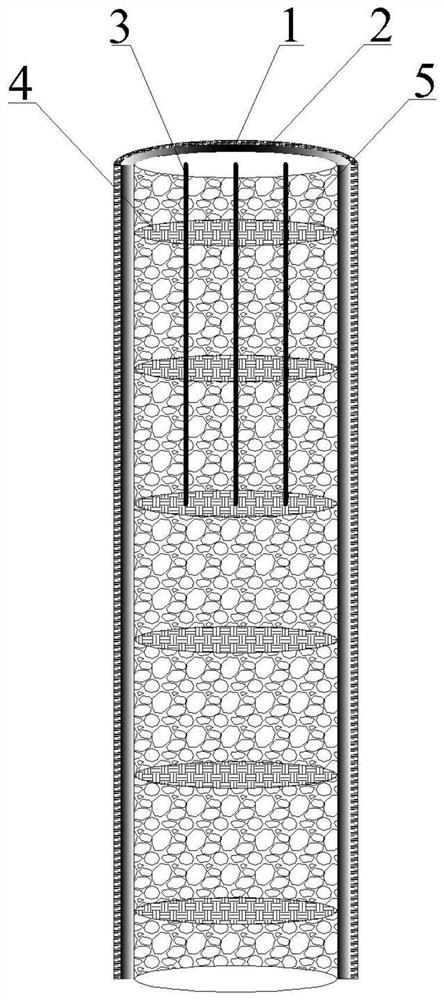

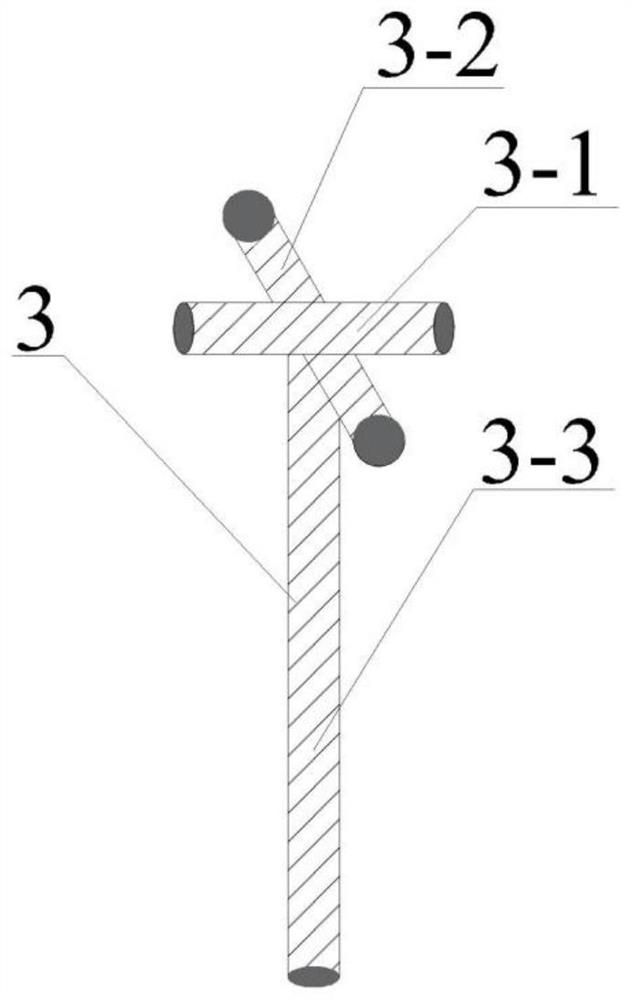

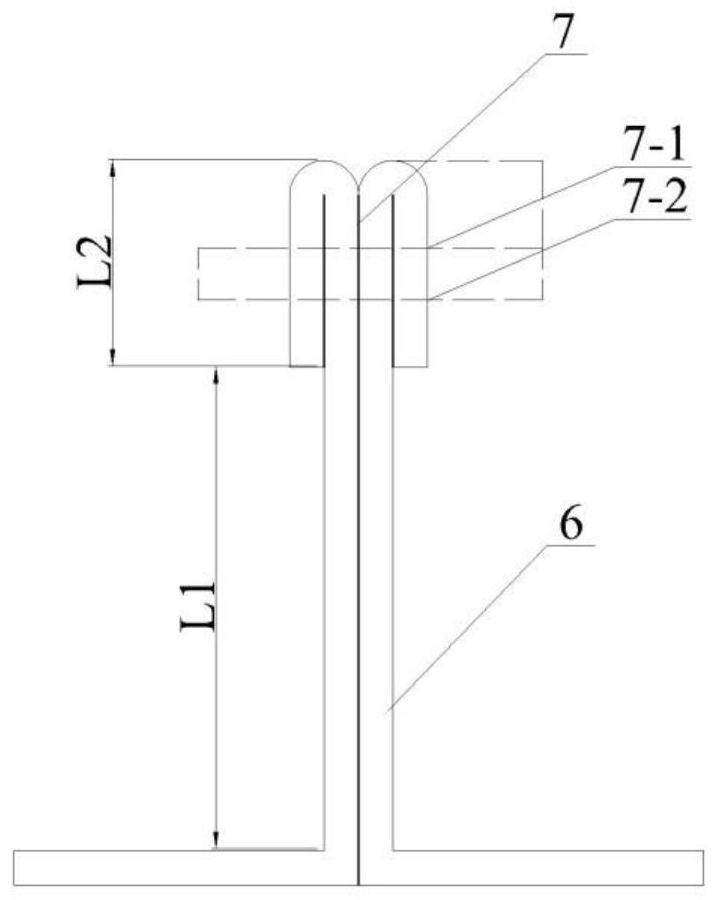

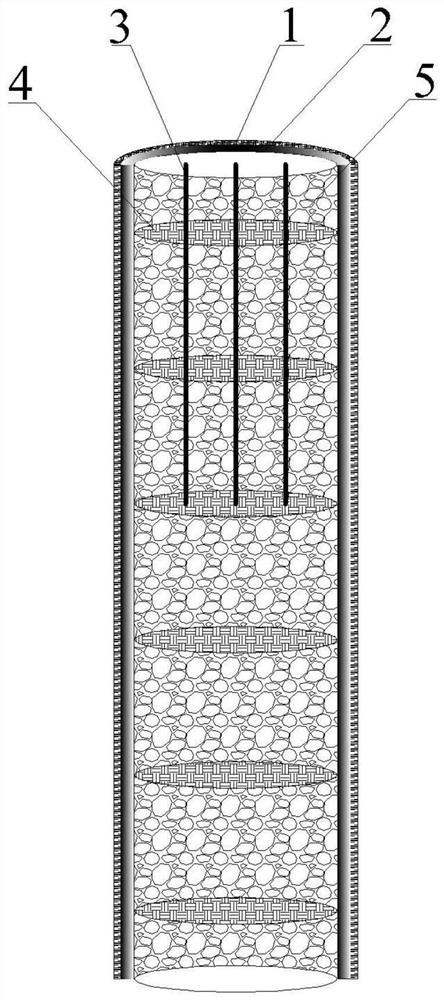

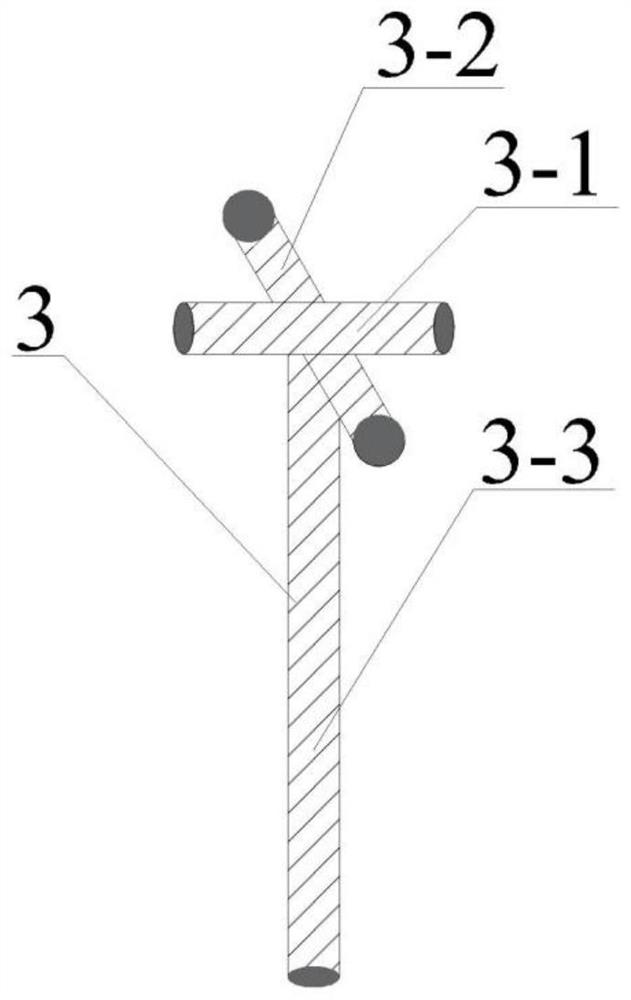

Multi-reinforced granular pile and its construction method

ActiveCN112663592BImprove carrying capacityKeep from drainingBulkheads/pilesSoil preservationStructural engineeringHollow core

The invention discloses a multi-reinforced granular material pile, which is arranged inside soft soil, and comprises hollow cylindrical vertical reinforcement and filler filled in the vertical reinforcement, and the vertical reinforcement circumferential surface in the filler is evenly arranged along the axial direction There are horizontal reinforcements, the horizontal reinforcements are placed between the fillers, and the axial reinforcements are evenly arranged along the radial direction of the vertical reinforcements. The multi-reinforced granular material pile of the present invention is more suitable for soft soil. The present invention also provides a construction method of the above-mentioned multi-reinforced granular pile.

Owner:HUBEI UNIV OF TECH

A kind of halogen-free environment-friendly power cable material for wind power generation and preparation method thereof

The invention discloses a halogen-free environmentally-friendly power cable material for wind power generation, and its preparation method. The cable material comprises the following raw materials, by weight, 90-110 parts of a polyolefin elastomer (POE) 8450 / American DuPont, 50-60 parts of PVC resin powder, 40-60 parts of wollastonite powder, 60-80 parts of nanometer attapulgite, 50-80 parts of ethylene-propylene-diene terpolymer rubber, 40-50 parts of nitrile butadiene rubber, 20-30 parts of nanometer pottery clay, 30-40 parts of aluminum hydroxide, 1-4 parts of precipitated white carbon black, 60-80 parts of light calcium carbonate, 3-5 parts of insoluble sulfur, 1-4 parts of triallyl isocyanurate, 3-5 parts of an antiager TPPD, 4-6 parts of dicumyl peroxide (DCP), 3-8 parts of dibasic lead phosphite, 5-7 parts of an antioxidant 1010, 2-5 parts of monoglycerin stearate and 50-70 parts of antimony trioxide. The cable material has the advantages of simple preparation method, excellent electrical property, good heat, ageing and wear resistances, small swelling deformation at a high temperature, secondary vulcanizing processing benefiting, low smoke and fire resistance, and environmental protection and safety.

Owner:苏州益普敦新材料科技有限公司

Multi-reinforced aggregate pile and construction method thereof

ActiveCN112663592AImprove carrying capacityKeep from drainingBulkheads/pilesSoil preservationStructural engineeringHollow core

The invention discloses a multi-reinforced aggregate pile. The multi-reinforced aggregate pile is arranged in soft soil, and comprises hollow cylindrical vertical reinforcements and fillers filled in the vertical reinforcements, horizontal reinforcements are uniformly arranged on the circumferential surfaces of the vertical reinforcements in the fillers in the axial direction, the horizontal reinforcements are placed among the fillers, and axial reinforcements are uniformly arranged in the radial direction of the vertical reinforcements. The multi-reinforced aggregate pile is more suitable for soft soil. The invention further provides a construction method of the multi-reinforced aggregate pile.

Owner:HUBEI UNIV OF TECH

Stator assembly and motor with the stator assembly

ActiveCN110635587BExtended service lifePrevent narrowingMagnetic circuit stationary partsWind energy generationCold airElectric machine

The invention provides a stator assembly and a motor with the stator assembly. The stator assembly includes a stator bracket and a stator core installed on the stator bracket, and the stator bracket includes a support shroud, formed between the support shroud of the stator bracket and the radial side surface of the stator core. There is a first axial airflow passage, and the stator assembly further includes an airflow conveying unit for supplying the first cold airflow to the first axial airflow passage, so that the cold airflow flows in the axial direction. According to the embodiment of the present invention, during the operation of the motor, a cold airflow can be introduced to the other side of the stator opposite to the air gap, so that both radial sides of the stator can be cooled at the same time, reducing the expansion and deformation of the stator core and preventing The air gap is narrowed, and at the same time, it prevents the stator from high-temperature baking of the magnetic poles, protects the magnetic poles, and prolongs the service life of the motor.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

Miscellaneous wood vacuum modified composite wooden door and its processing method

ActiveCN104400869BReduce pollutionHigh strengthWood working apparatusDoor leavesAir compressionEngineering

The invention provides a vacuum modified weedtree composite wooden door and a processing method thereof. The processing method comprises the following steps of arranging two rubber thin films between an upper thin film air cushion and a lower thin film air cushion of a double-surface thin film air cushion press, and putting a wooden door substrate between the two rubber thin films to form a workpiece to be pressed; lifting a lower pressing plate to attach to the upper surface of the workpiece to be pressed to the upper thin film air cushion, and heating the workpiece to be pressed to 95-110 DEG C for 20-40 seconds; compressing air in an upper air cushion and a lower air cushion of the double-surface thin film air cushion press under the air pumping pressure being 0.5-0.8Mpa for 300-500 seconds; meanwhile, vacuumizing a sealed cavity formed between an upper pressing plate and the lower pressing plate; releasing the pressure to obtain the vacuum modified weedtree composite wooden door. The steps of the processing method of the vacuum modified weedtree composite wooden door are scientific, reasonable and environment-friendly and can be used for processing a wooden door with a specially-shaped surface.

Owner:浙江恒峰家居有限公司

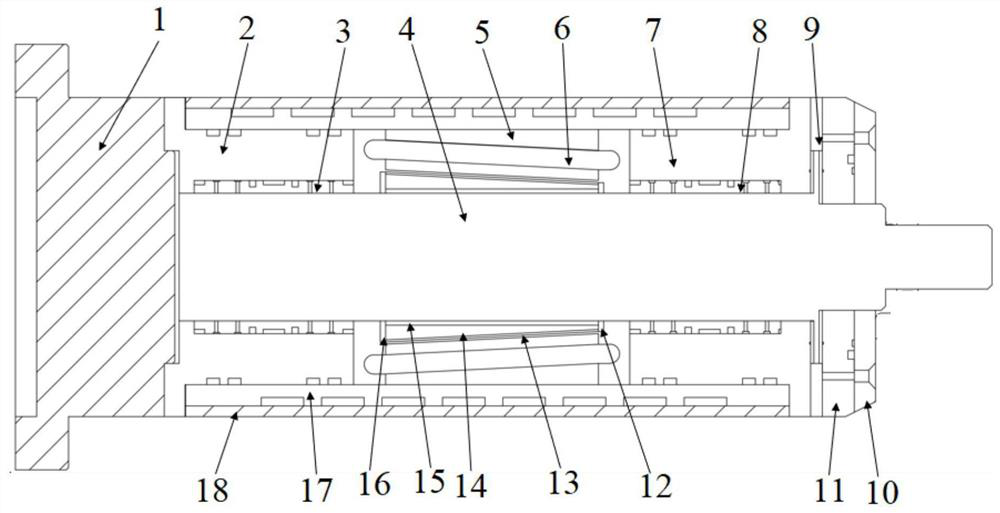

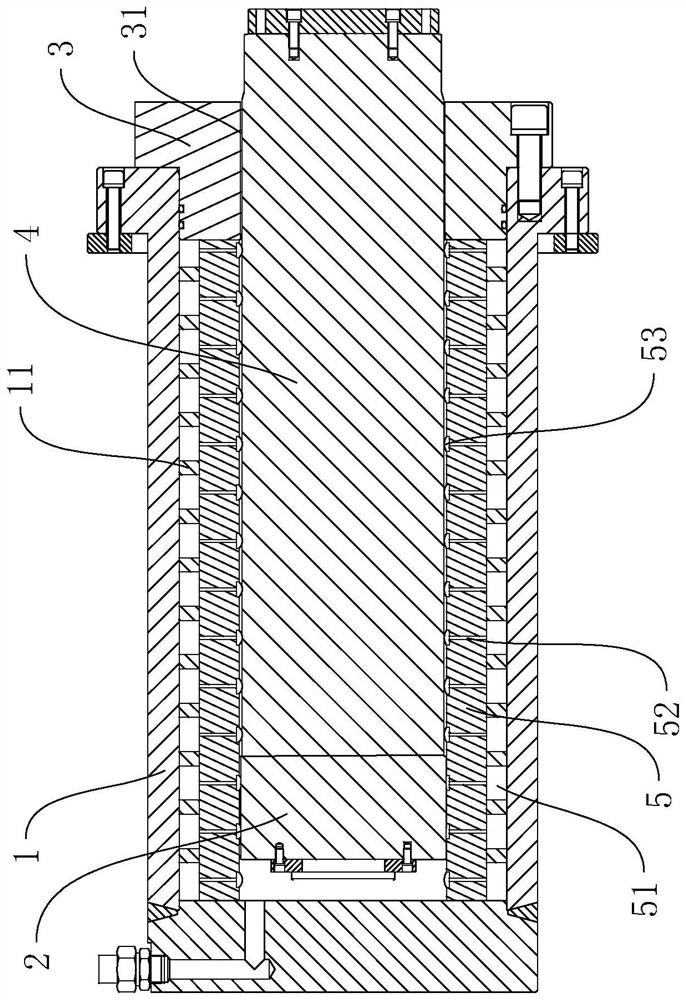

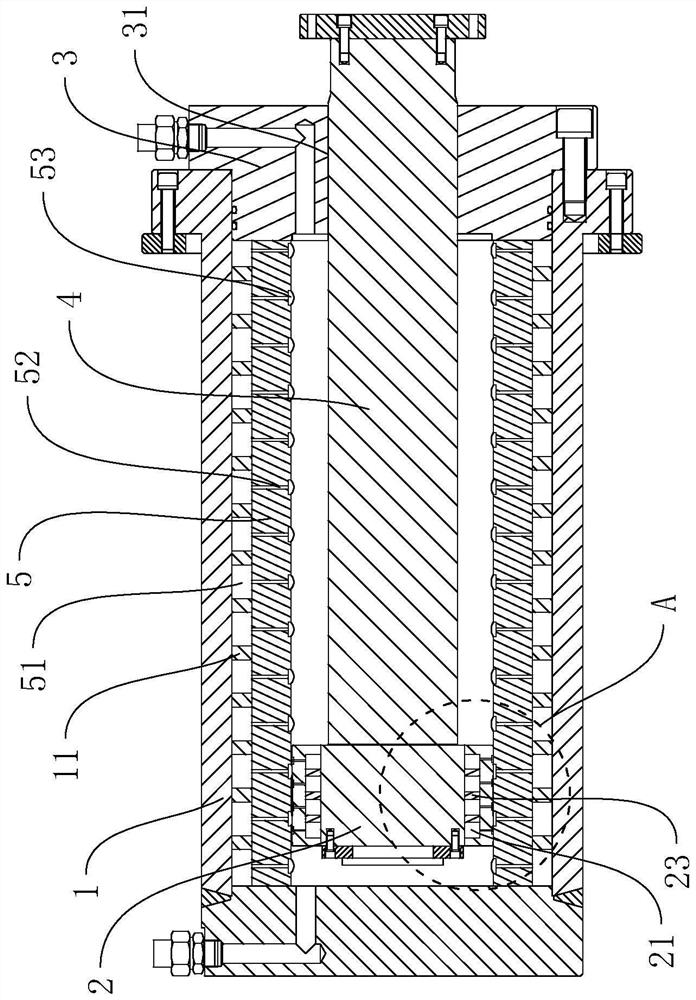

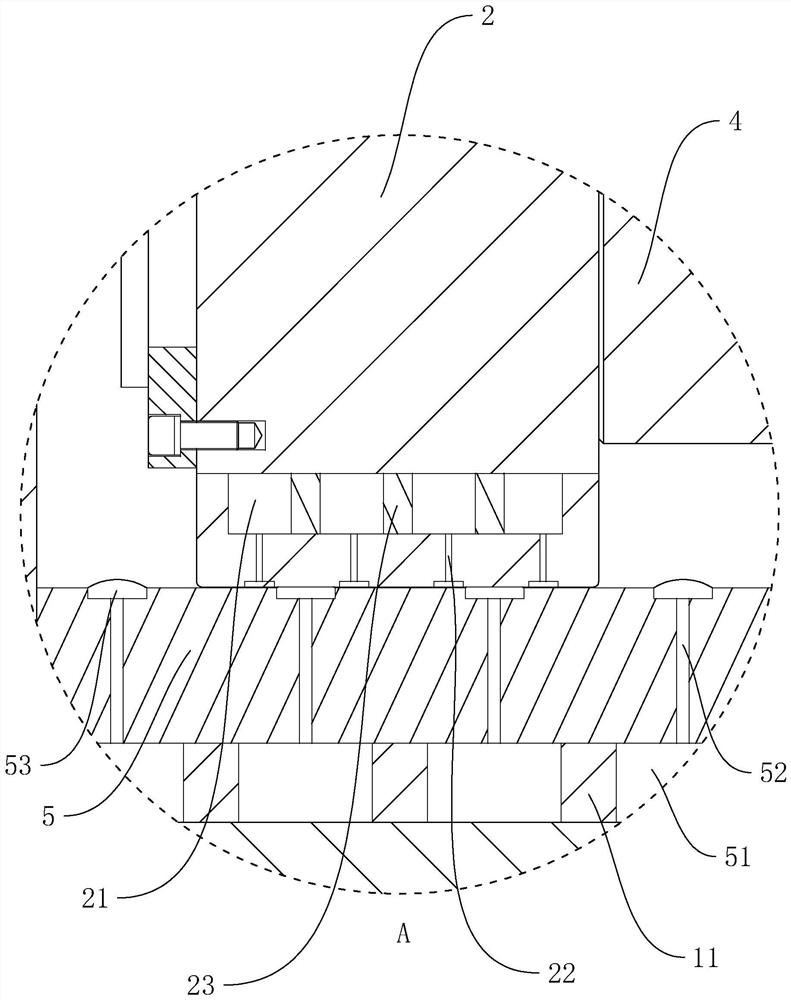

Energy-saving gap sealing type hydraulic cylinder and detection equipment applying same

ActiveCN114321084AReduce internal and external pressure differenceSmall expansion deformationFluid-pressure actuatorsHydraulic cylinderEngineering

The hydraulic cylinder comprises a cylinder barrel, a cylinder cover, a piston and a piston rod, the cylinder cover covers an opening of the cylinder barrel, a sliding opening is formed in the cylinder cover, the piston rod is connected with the piston, and one end of the piston rod penetrates through the sliding opening and extends out of the cylinder barrel; a lining is coaxially distributed in the cylinder barrel, the piston is arranged in the lining in a sliding mode, one end of the lining is connected with the inner bottom wall of the cylinder barrel in a sealed mode, the other end of the lining is connected with the cylinder cover in a sealed mode, an annular cavity is formed between the peripheral wall of the lining and the inner wall of the cylinder barrel, and a pressure balancing structure used for increasing the inner pressure of the annular cavity is arranged on the lining. The hydraulic cylinder has the effects of reducing gaps in positions such as the cylinder cover and the piston of the hydraulic cylinder, reducing liquid leakage and reducing energy consumption.

Owner:绍兴市肯特机械电子有限公司

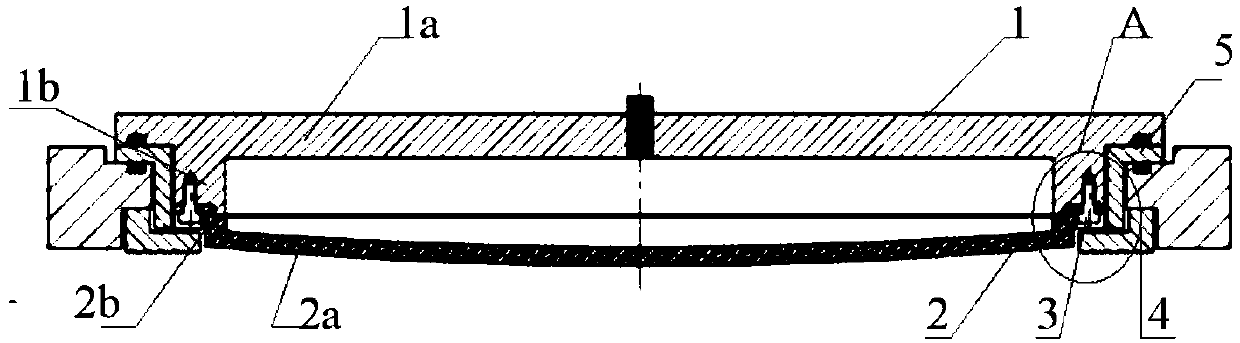

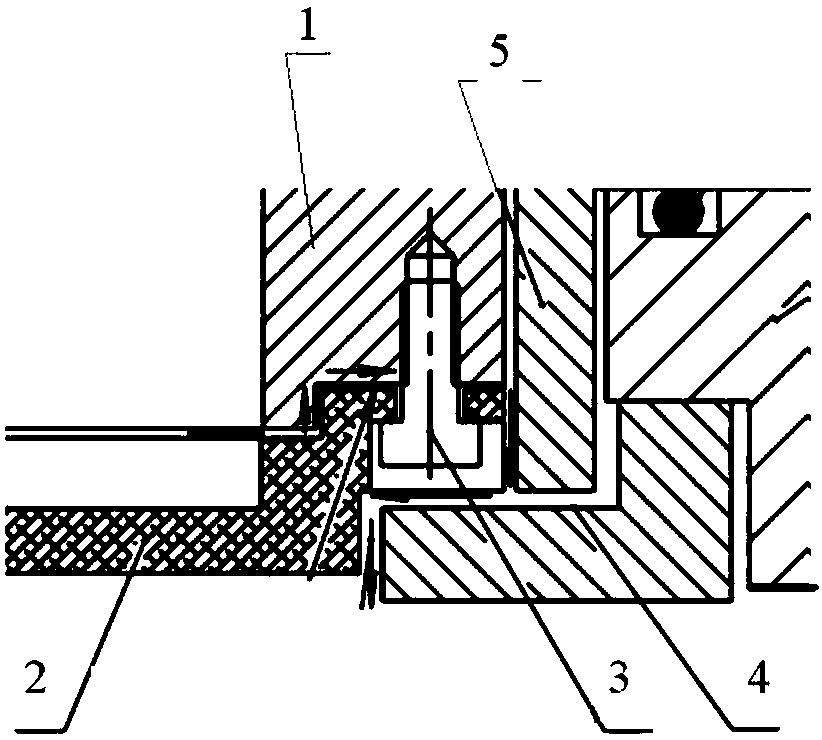

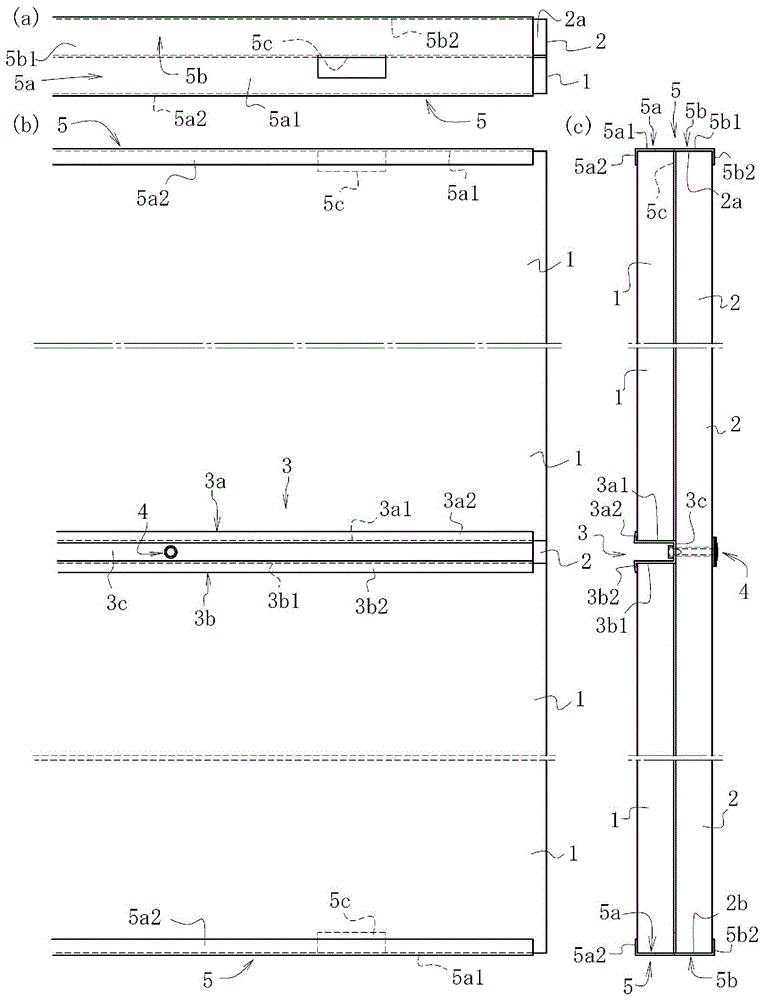

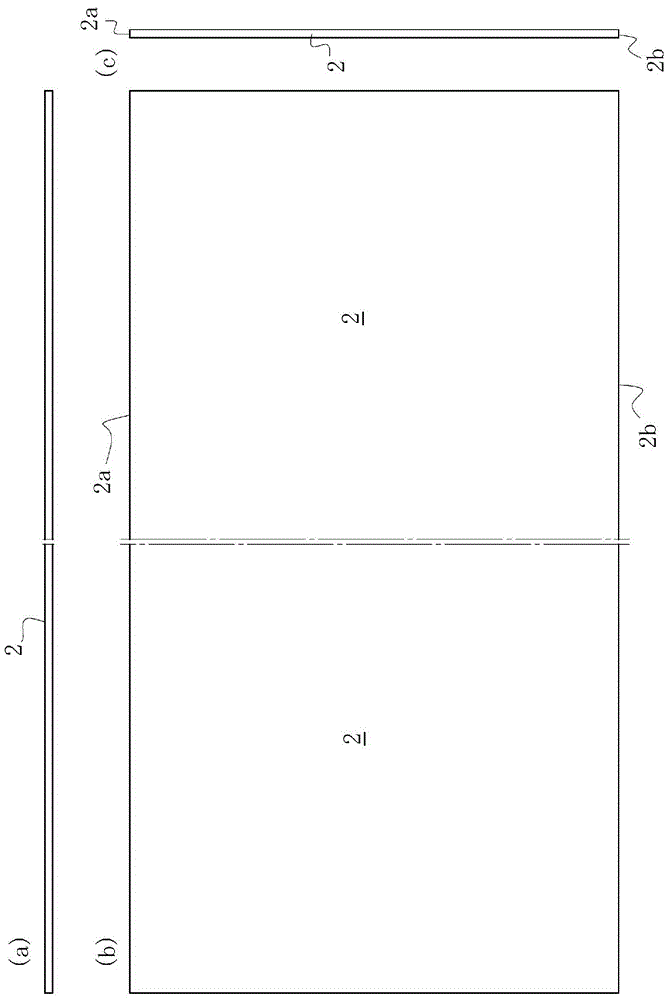

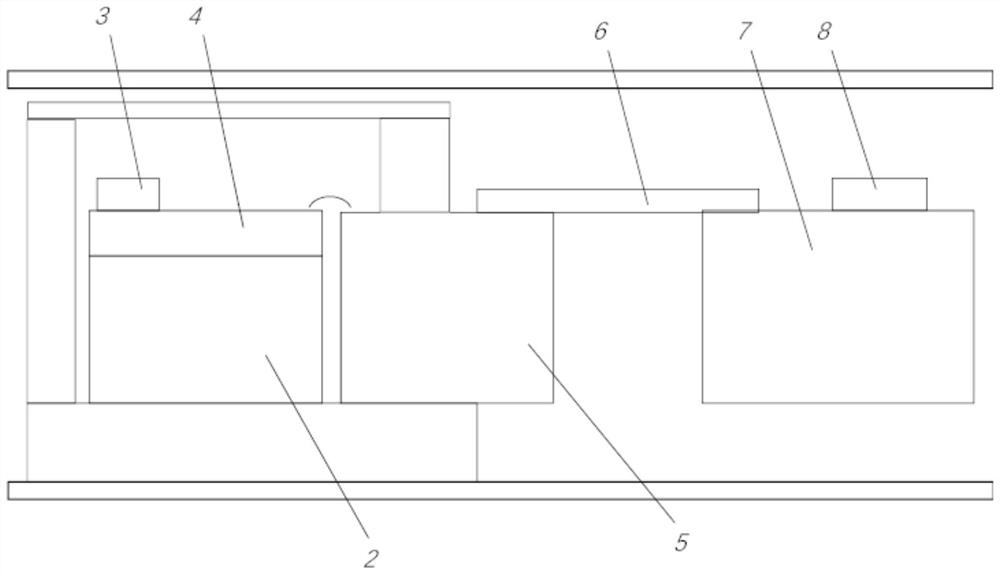

tile panel

ActiveCN104395556BAchieve installationEasy to manufactureCovering/liningsUnderground chambersVertical edgeCement board

An objective of the present invention is to provide a tile panel whereby a tile is not prone to peeling from a substrate even in a poor environment such as an atmosphere including an acidic gas. A tile panel is configured from: a cement board (2) whereupon is positioned a plurality of tiles (1, 1...); interim locking jigs (3) which are positioned in joints of the vertical tiles (1, 1...), and which further comprise lower edge locking portions (3a) which lock with the lower edges of the tiles (1, 1...) which are immediately thereabove, upper edge locking portions (3b) which lock with the upper edges of the tile (1, 1 ...) which are immediately therebelow, and attachment portions (3c) therebetween; rivet members (4) which anchor the attachment portions (3c) to the cement board (2); and vertical locking jigs (5), further comprising vertical edge locking portions (5a) which lock either the upper edges or the lower edges of either the uppermost part or the lowermost part of the plurality of tiles (1, 1...), covered locking portions (5b) which lock in a covered manner either upper part small cut ends (2a) or lower part small cut ends (2b) of the cement board (2), and locking tongue portions (5c, 5c...) which either face straight down or straight up between the vertical edge locking portions (5a) and the covered locking portions (5b), and which are inserted between either the uppermost parts or the lowermost parts of the tiles (1, 1...) and the cement board (2).

Owner:HIRO

optical module

The invention discloses an optical module, which includes a housing, a sealing shell arranged in the housing, an optoelectronic component and a circuit board, the optoelectronic component is disposed in the sealing housing, the circuit board and the photoelectric module in the sealing housing The components are electrically connected, wherein the circuit board includes a first board and a second board disposed on the surface of the first board, the thickness of the second board is smaller than the thickness of the first board, and the second board is arranged on the surface of the first board. The board includes a high-speed link layer arranged on the surface layer and a reference layer arranged below the surface layer, and the second board extends into the sealed casing to be electrically connected with the photoelectric component; one of the side walls of the sealed casing includes The carrier and the insulating board, the second board of the circuit board passes through the opening between the carrier and the insulating board and is sealed and connected with the carrier and the insulating board, and the insulating board is arranged on the high-speed chain of the second board road layer side. The optical module has good high-speed transmission performance, low cost and good airtightness.

Owner:INNOLIGHT TECHNOLOGY (SUZHOU) LTD

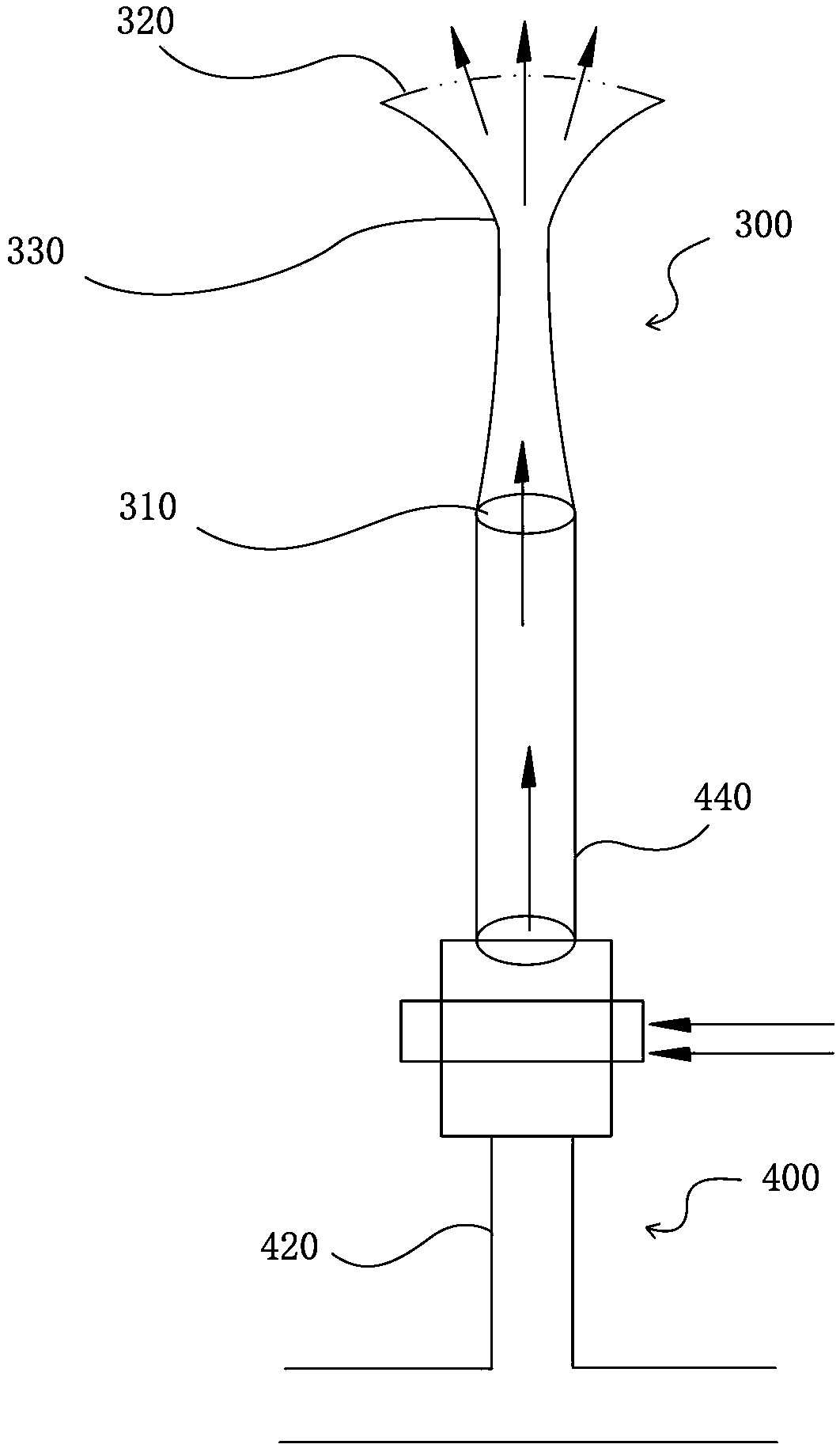

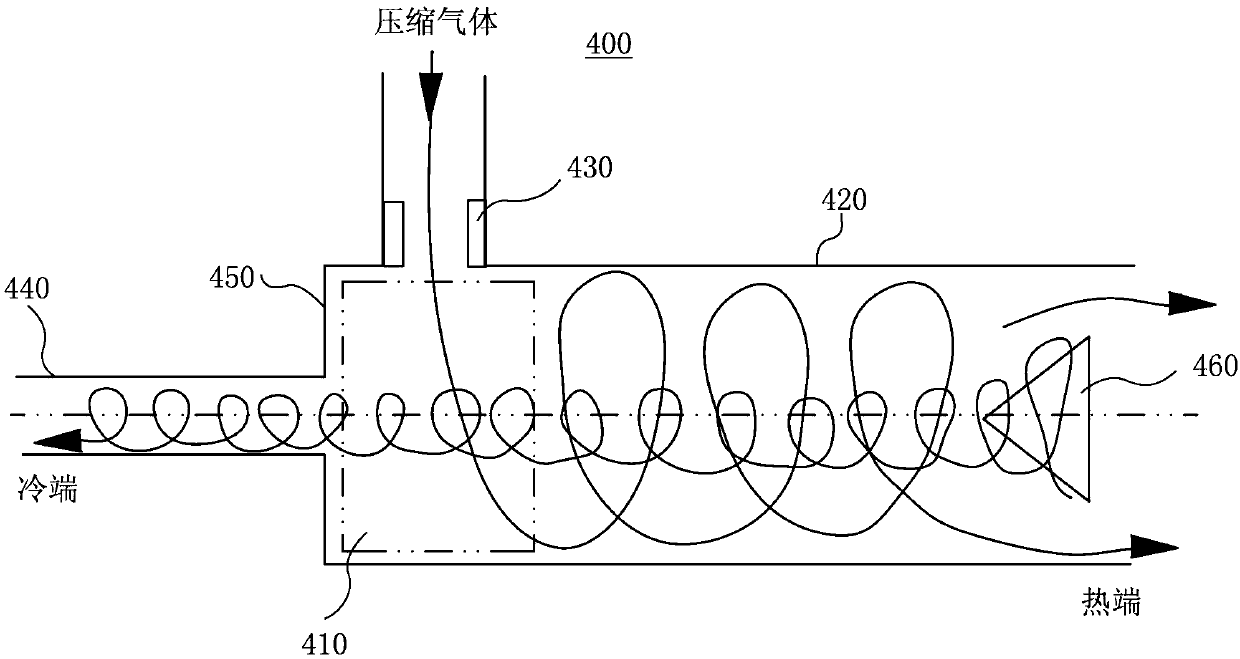

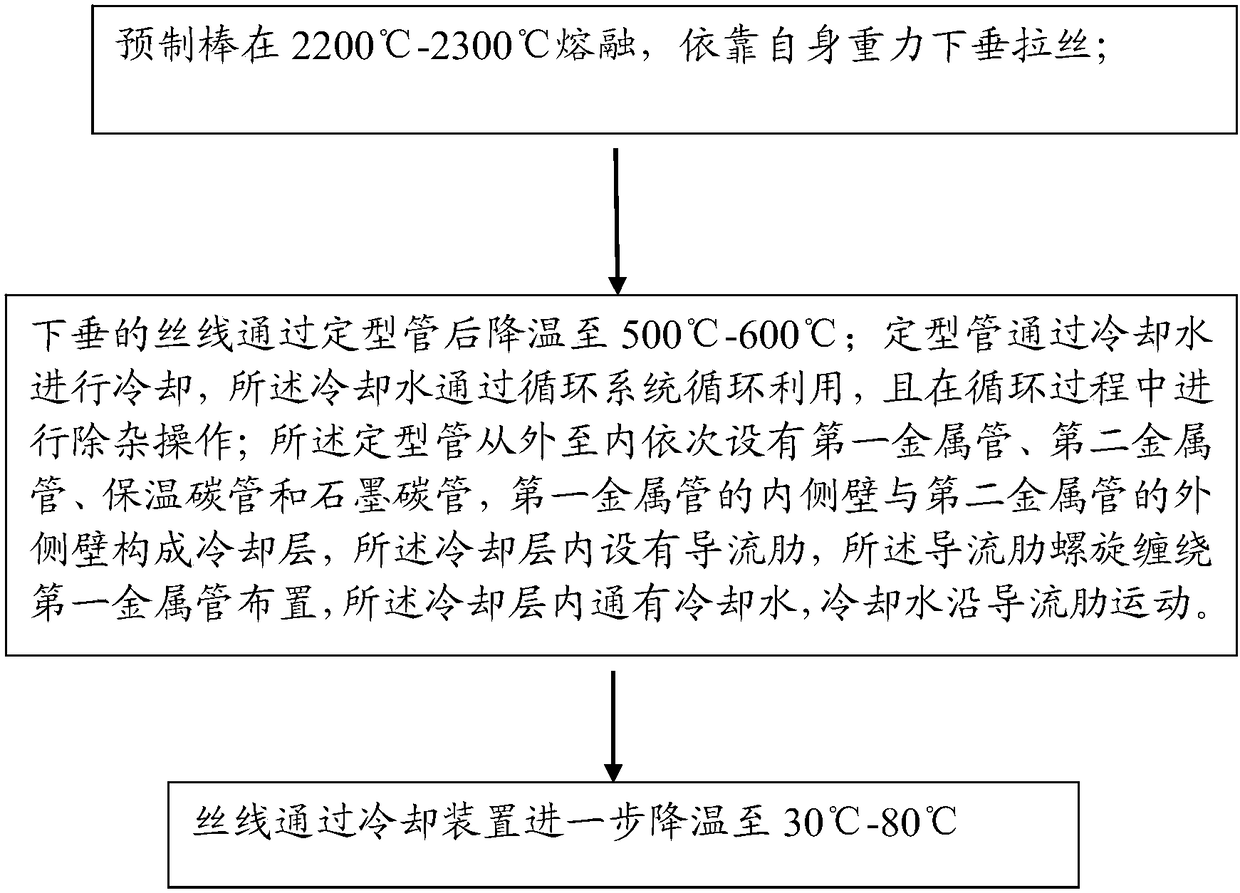

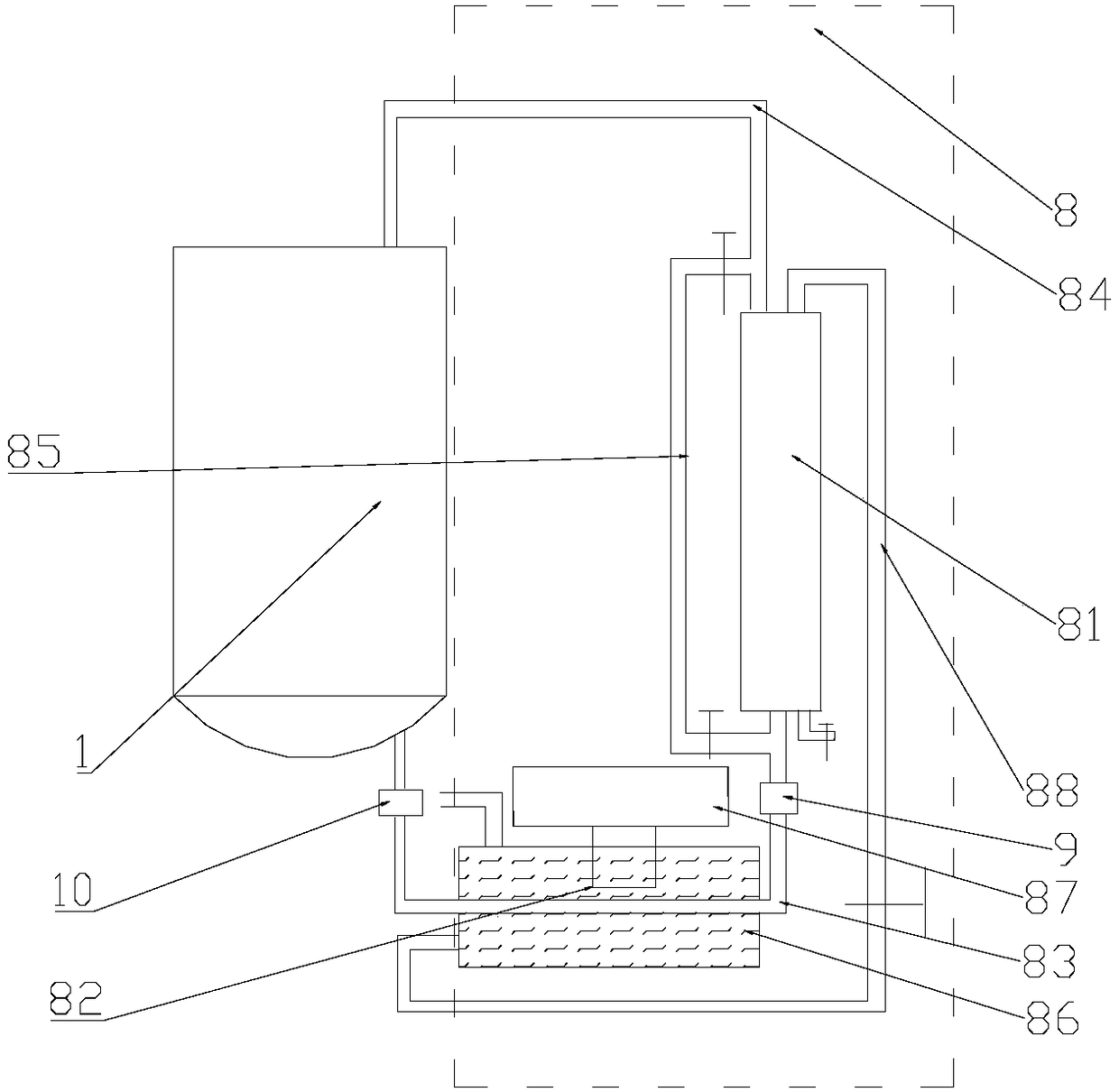

Fiber drawing process

ActiveCN105859122BExtended maintenance cycleExtended service lifeGlass making apparatusScale removal and water softeningYarnCooling effect

Owner:HANGZHOU FUTONG COMM TECH CO LTD

Electrodes and Batteries

ActiveCN112701246BSmall expansion deformationImprove flatnessFinal product manufactureSecondary cellsEngineeringBattery cell

The present application provides an electrode sheet and a battery, the electrode sheet includes a current collector, the current collector includes a first surface and a second surface opposite to each other, at least one of the first surface and the second surface An active material layer is provided, and the side of the active material layer away from the current collector is provided with a protruding point layer, and the thickness of the protruding point layer is from the first end of the current collector to the second end of the current collector. The two ends are decreasing, the first end of the current collector and the second end of the current collector are two opposite ends of the current collector. The embodiment of the present application can solve the problem that the winding electrode sheet has a small expansion space, which makes the cell easily deformed during the cycle and the battery cell has a low liquid storage capacity.

Owner:ZHUHAI COSMX BATTERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com