Miscellaneous wood vacuum modified composite wooden door and its processing method

A processing method and vacuum technology, applied in wood processing equipment, door leaves, manufacturing tools, etc., can solve the problems of inability to process special-shaped wooden doors, non-environmental protection, etc., and achieve the effects of saving materials, reducing pollution, and reducing expansion and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

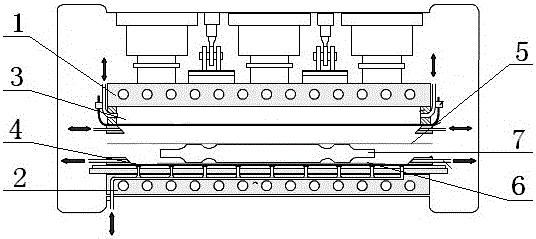

Image

Examples

Embodiment 2

[0036] This embodiment adopts the same vacuum air cushion film press as in Embodiment 1, and the processing method of the vacuum modified composite wooden door of miscellaneous wood is as follows:

[0037] (1) Make a wooden door base plate. The wooden door base plate used in this embodiment is a miscellaneous wood base plate, including pine wood and MDF.

[0038] (2) Place two rubber films between the upper film air cushion and the lower film air cushion of the double-sided film air cushion press, and place the wooden door substrate between the two rubber films to form the workpiece to be pressed;

[0039] (3) Lift the lower platen so that the upper surface of the workpiece to be pressed is bonded to the upper film air cushion, and the workpiece to be pressed is heated to 95°C for 40s;

[0040] (4) Compress the air in the upper air cushion and the lower air cushion of the double-sided film air cushion press, and the air pump pressure is 0.5Mpa for 500s; at the same time, vacuu...

Embodiment 3

[0044] This embodiment adopts the same vacuum air cushion film press as in Embodiment 1, and the processing method of the vacuum modified composite wooden door of miscellaneous wood is as follows:

[0045] (1) Making a wooden door base plate. The wooden door base plate used in this embodiment is a miscellaneous wood base plate, specifically, a miscellaneous wood base plate combined with waste materials after construction formwork is used and a density board. (2) Place two rubber films between the upper film air cushion and the lower film air cushion of the double-sided film air cushion press, and place the wooden door substrate between the two rubber films to form the workpiece to be pressed;

[0046] (3) Lift the lower platen to make the upper surface of the workpiece to be pressed fit with the upper film air cushion, and heat the workpiece to be pressed to 110°C for 20s;

[0047] (4) Compress the air in the upper air cushion and the lower air cushion of the double-sided film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com