tile panel

A ceramic tile and panel technology, which is applied in shaft lining, tunnel lining, underground chamber, etc., can solve problems such as poor moisture status, achieve the effect of reducing expansion deformation and preventing infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

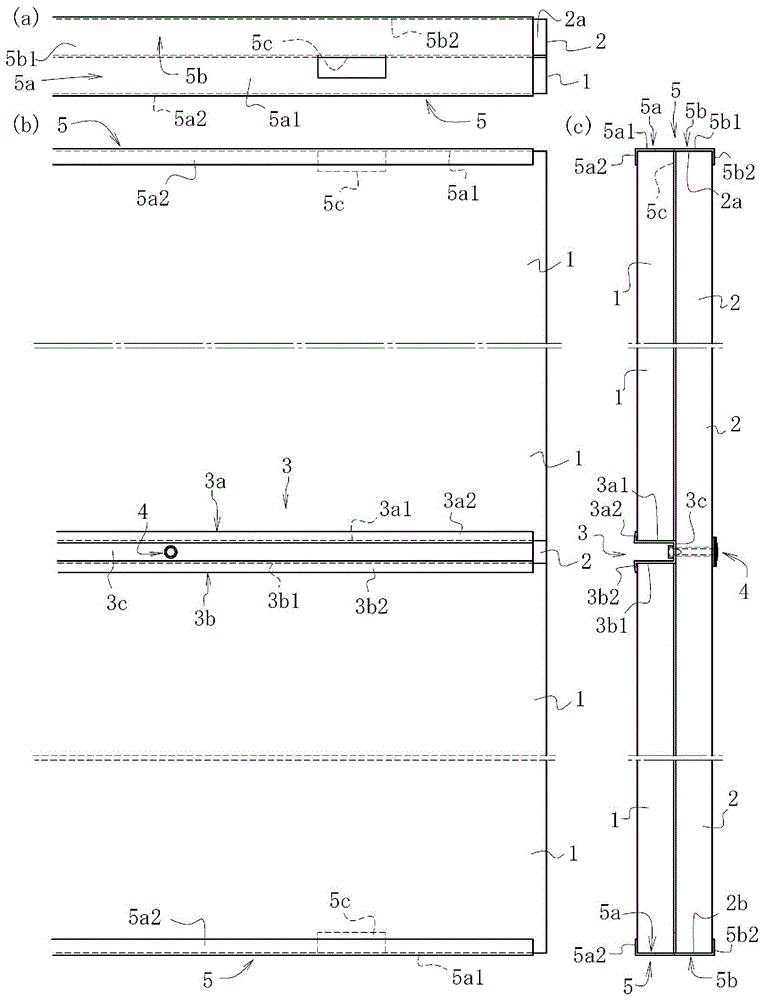

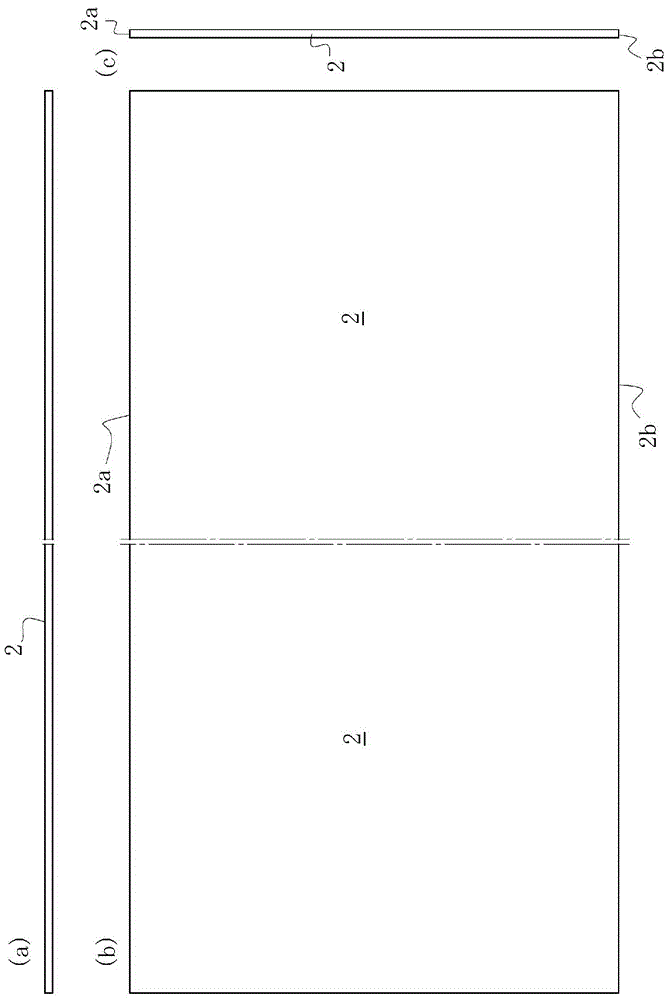

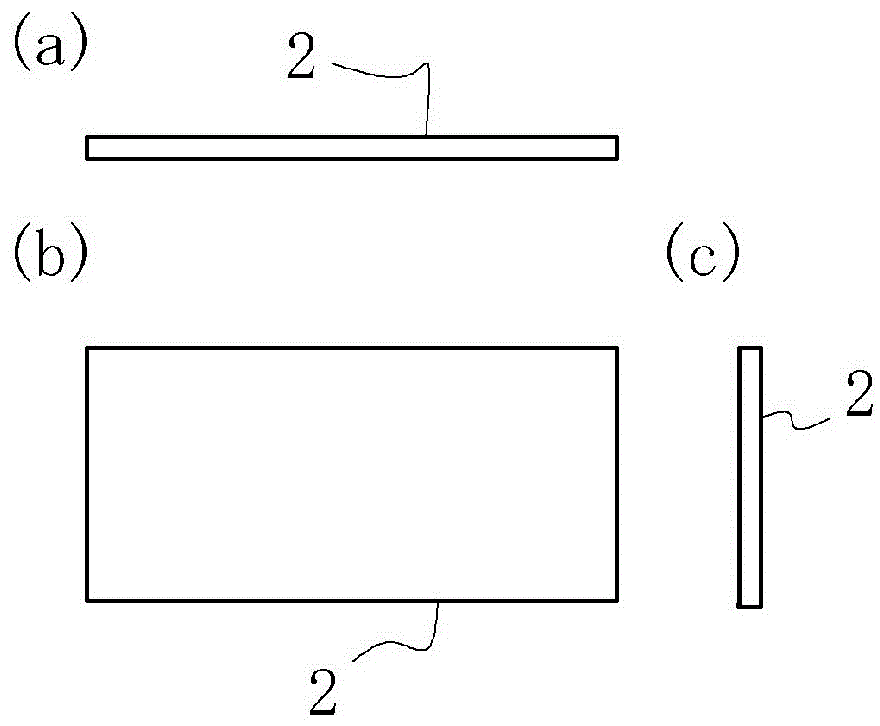

[0084] The ceramic tile panel of this embodiment 1 resembles figure 1 (a)~(c) and figure 2 As shown in (a) to (c), it is composed of a member including a cement board (substrate) 2, and a plurality of ceramic tiles are arranged vertically and laterally on the front surface of the cement board (substrate) 2 1, 1..., the plurality of tiles 1, 1... are arranged vertically and horizontally in front of the cement board 2; the middle buckle metal part 3, the middle buckle metal part 3 has a bottom edge buckle piece 3a and a top The edge buckle piece 3b and the installation piece 3c, the bottom edge buckle piece 3a is arranged in the seam of a plurality of ceramic tiles 1, 1... adjacent up and down, and the bottom of the plurality of tiles 1, 1... Edge, the top edge buckle piece 3b buckles the top edges of a plurality of ceramic tiles 1, 1... directly below, the mounting piece 3c is located between the bottom edge buckle piece 3a and the top edge buckle piece 3b; rivets Part (fixe...

Embodiment 2)

[0109] The ceramic tile panel of present embodiment 2 resembles Figure 7 (a)~ Figure 7 (c) and Figure 8 As shown in (a)-(c), it is the example which added some deformation|transformation to Example 1. The ceramic tile panel of embodiment 2 is made of ceramic tile 11, cement board 2, middle buckle metal part 13, rivet part 4 and upper and lower part buckle metal parts 15 as shown in this figure, and it is the same as the tile 1 of embodiment 1. , The difference between the cement board 2, the middle buckle metal part 3, the rivet part 4 and the upper and lower buckle metal parts 5 lies in a part of the corresponding parts of the middle buckle metal part 13 and the upper and lower buckle metal parts 15. The other aspects are the same. Hereinafter, it demonstrates centering on a different point.

[0110] The difference between above-mentioned ceramic tile 11 and the ceramic tile 1 of embodiment 1 is that Figure 10 (d)~ Figure 10 As shown in (f), the upper and lower edg...

Embodiment 3)

[0125] The ceramic tile panel of present embodiment 3 resembles Figure 11 (a)~ Figure 11 (c) and Figure 12 As shown in (a) to 12(c), it is an example in which some modifications are added to the first embodiment.

[0126]The ceramic tile panel of embodiment 3 is made of ceramic tile 21, cement board 2, middle buckle metal part 23, rivet part 4 and upper and lower part buckle metal parts 25 as shown in this figure, and it is the same as the tile 1 of embodiment 1. , The difference between the cement board 2, the middle buckle metal part 3, the rivet part 4 and the upper and lower buckle metal parts 5 lies in the ceramic tile 21, a part of the corresponding parts of the middle buckle metal part 23 and the upper and lower buckle metal parts 25. The other aspects are the same. Hereinafter, it demonstrates centering on a different point.

[0127] The difference between the above-mentioned ceramic tile 21 and the ceramic tile 1 of Embodiment 1 is that the front side corners o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com