Multi-mining-type high-saturability steel wire-chinlon composite body OTR radial tire

A radial tire and composite material technology, which is applied in the field of tire processing, can solve the problems that the bias tire is difficult to adapt to the complex market environment, the price of radial tires is high, and the market utilization rate is low. Excellent fuel-saving performance, not easy to be damaged by fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

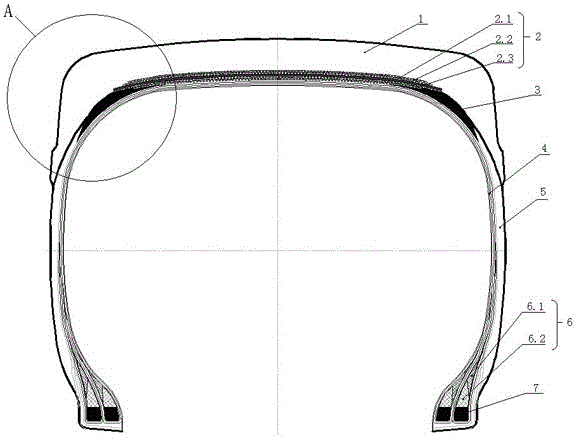

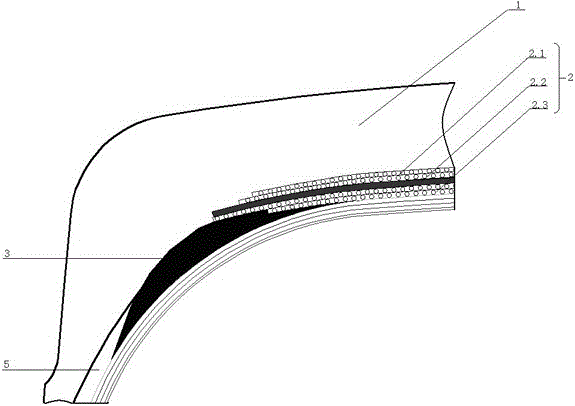

[0025] Such as figure 1 , figure 2 As shown, a multi-station type, high-saturation steel wire-nylon composite material body engineering radial tire, including a crown 1, a tire shoulder, a belt layer 2, a carcass cord 4, a sidewall rubber 5, and a bead. The joint between the belt layer 2 and the tire shoulder is provided with a shoulder pad rubber 3, and a rubber core 6 and a steel traveler 7 are provided at the bead. Layer I 2.3; the isolation film 2.2 is located between the steel ply II 2.1 and the steel ply I 2.3; the rubber core 6 is composed of an upper apex 6.1 and a lower apex 6.2.

[0026] The sum of the steel cord layers of the steel cord layer II2.1 and the steel cord layer I2.3 is 2-6 layers; the included angle between the steel cord cord and the direction of the cross-section contour line is 60°-78°; The adjacent steel cords are stacked alternately to form a multi-layer network structure.

[0027] The carcass cord 4 is 4-10 layers of nylon cords; the angle bet...

Embodiment 2

[0035] Taking 23.5R25L3 steel wire-nylon composite body engineering tire as an example, the present invention will be further described in detail:

[0036] Such as figure 1 As shown, a multi-station type, high-saturation steel wire-nylon composite material body engineering radial tire, including a crown 1, a tire shoulder, a belt layer 2, a carcass cord 4, a sidewall rubber 5, and a bead. The joint between the belt layer 2 and the tire shoulder is provided with a shoulder pad rubber 3, and a rubber core 6 and a steel traveler 7 are provided at the bead. Layer I 2.3; the isolation film 2.2 is located between the steel ply II 2.1 and the steel ply I 2.3; the rubber core 6 is composed of an upper apex 6.1 and a lower apex 6.2.

[0037] The sum of the steel cord layers of the steel cord layer II2.1 and the steel cord layer I2.3 is 4 layers; the width of each layer is: the first layer is 360mm; the second layer is 440mm; the third layer is 380mm; the fourth layer is 400mm ;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com