Patents

Literature

41results about How to "Less prone to fatigue damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

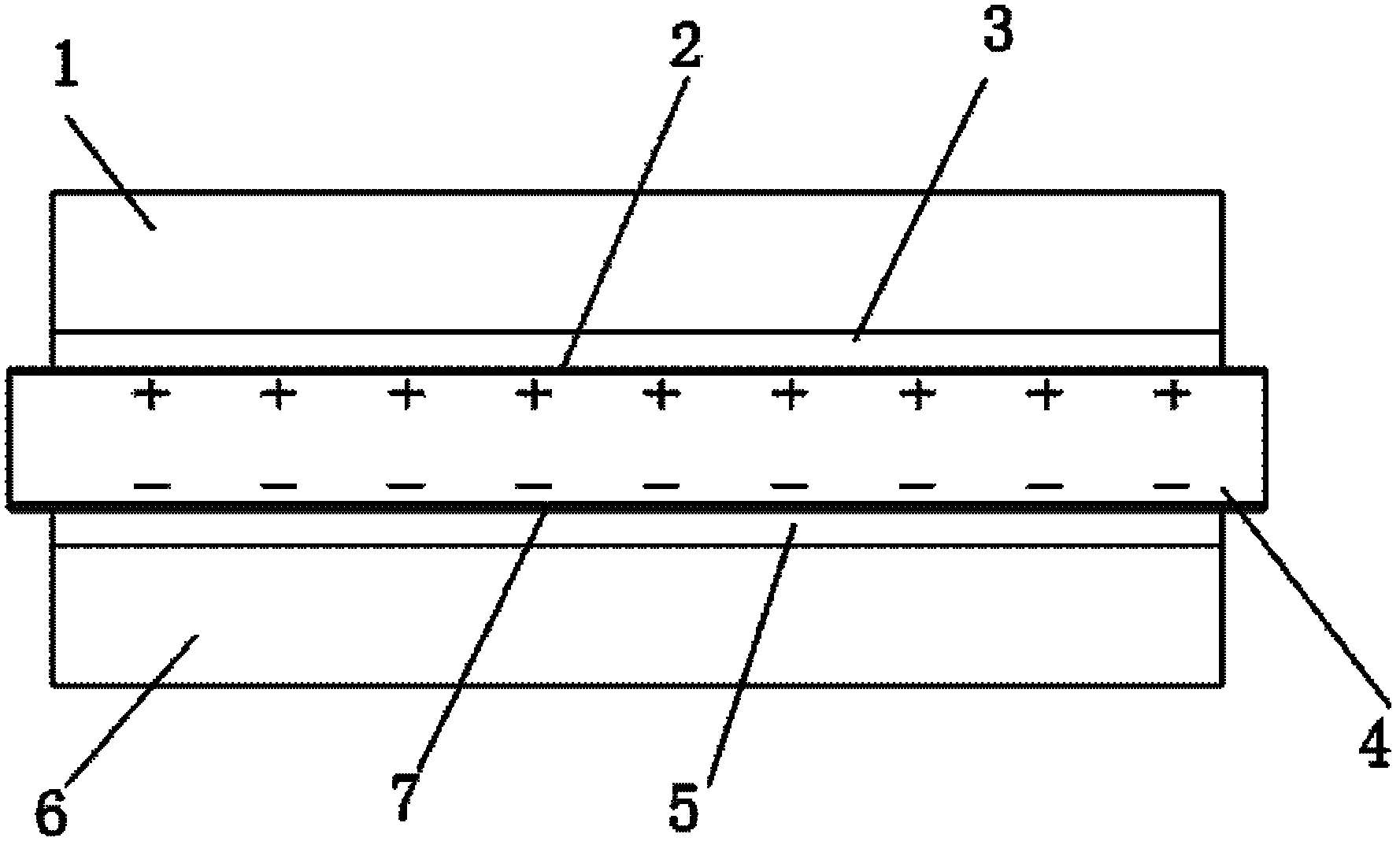

Novel intelligent vibration isolation noise reduction composite structure system and usage method thereof

ActiveCN102413401AReduce noise radiationVibration isolation is effectiveTransducers for subaqueous useFrequency/directions obtaining arrangementsNoise reductionInstrumentation

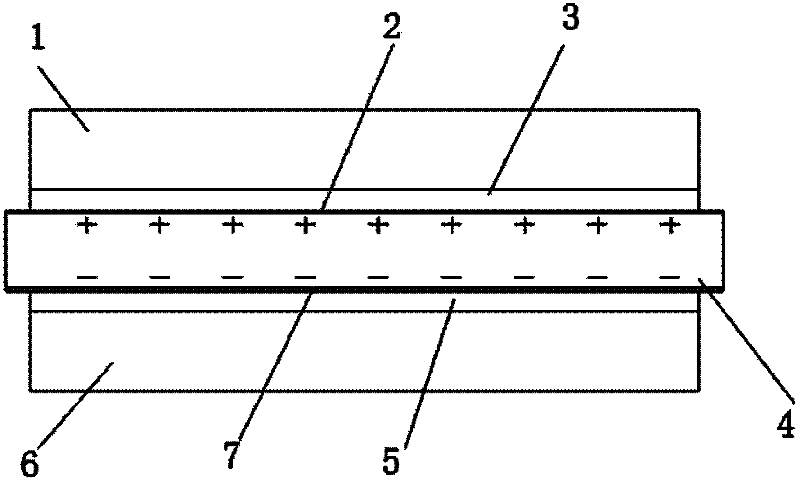

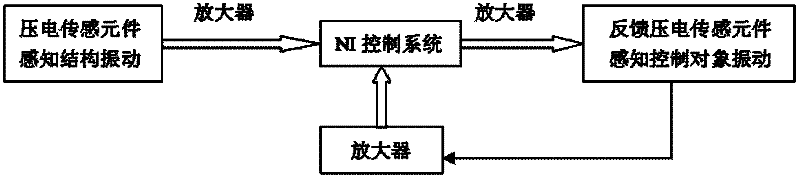

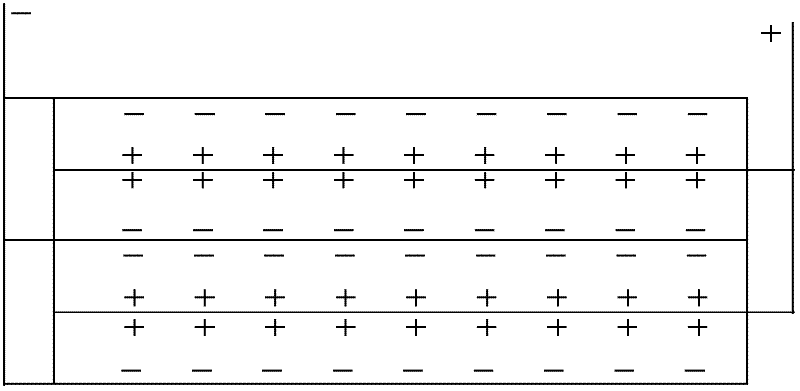

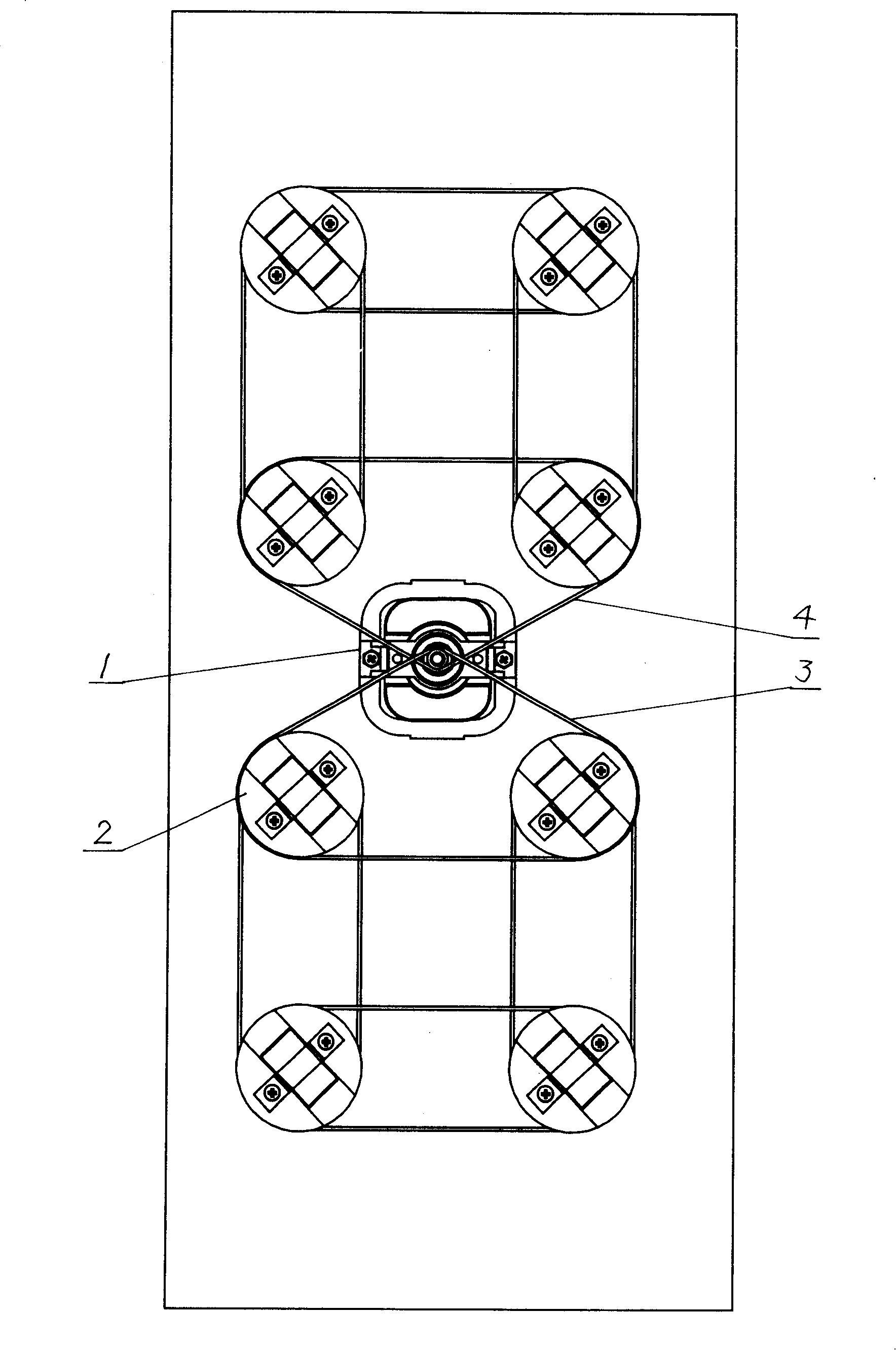

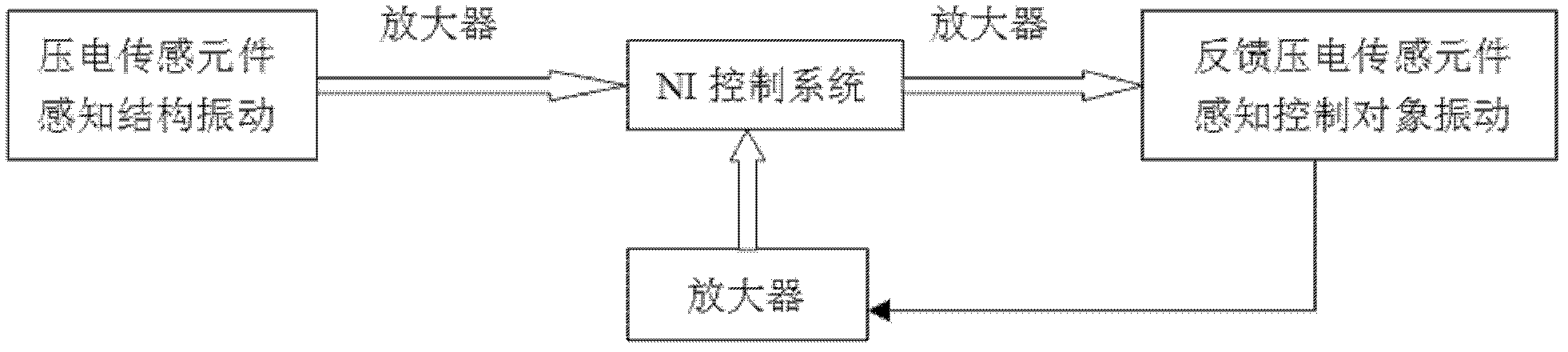

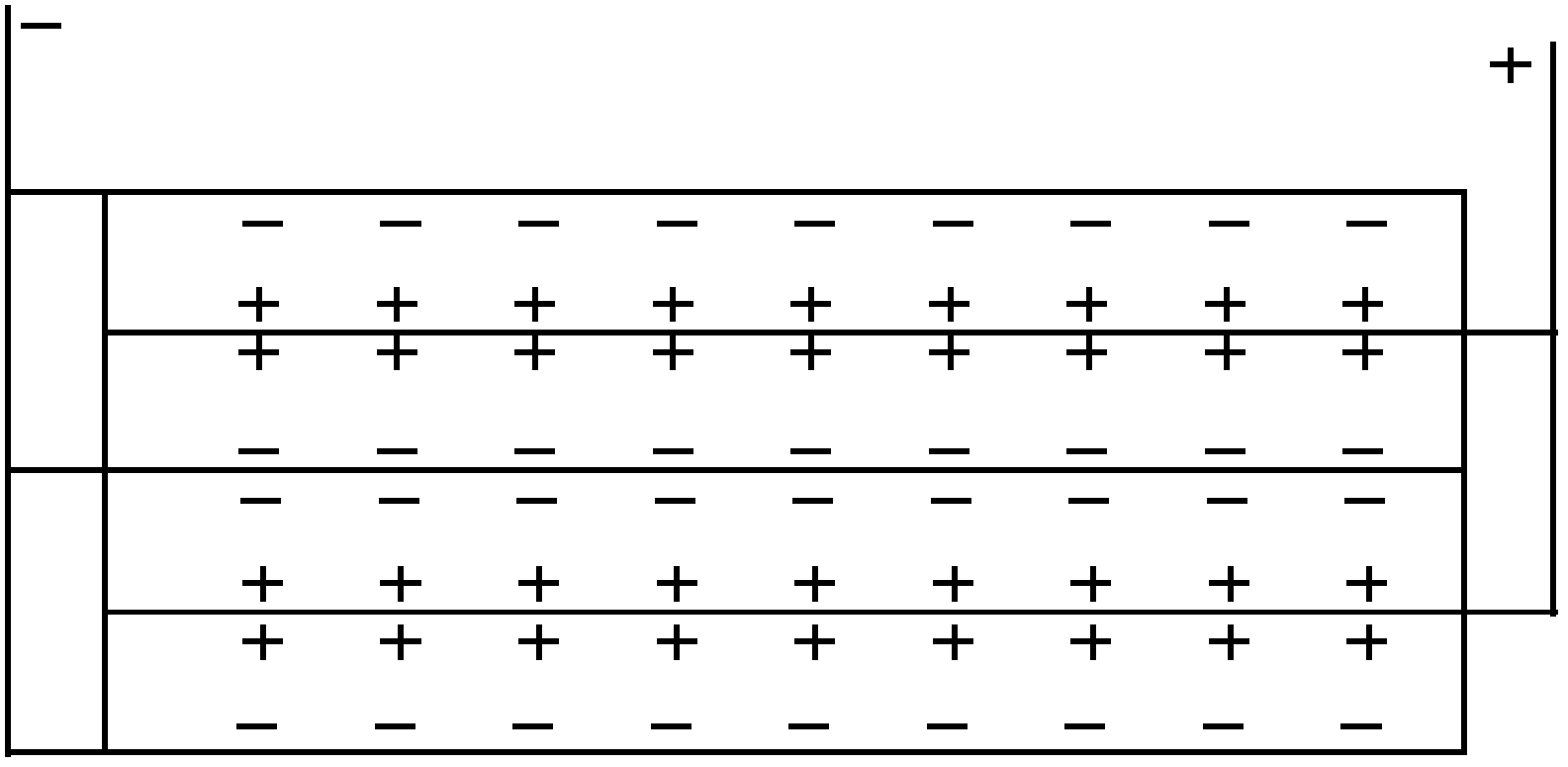

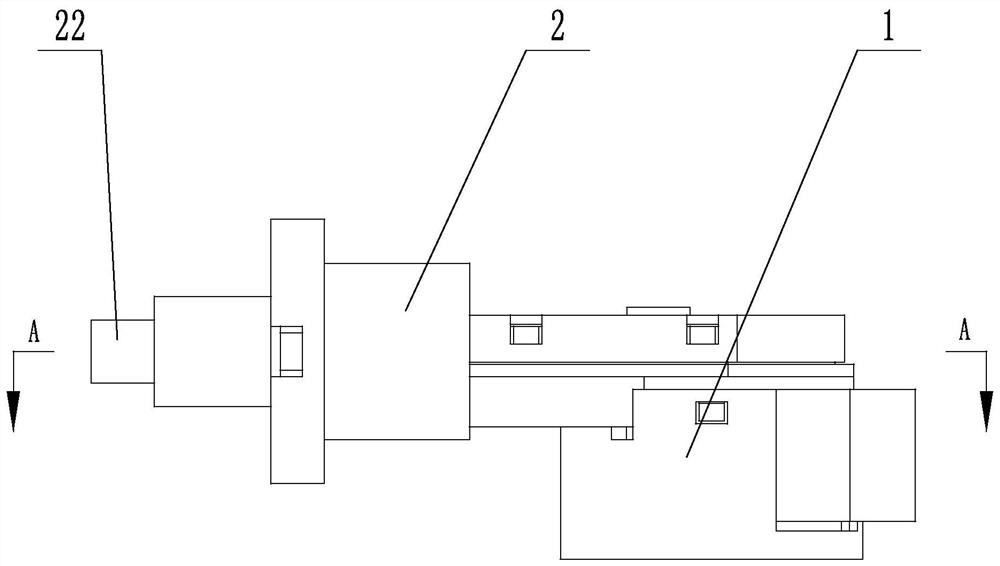

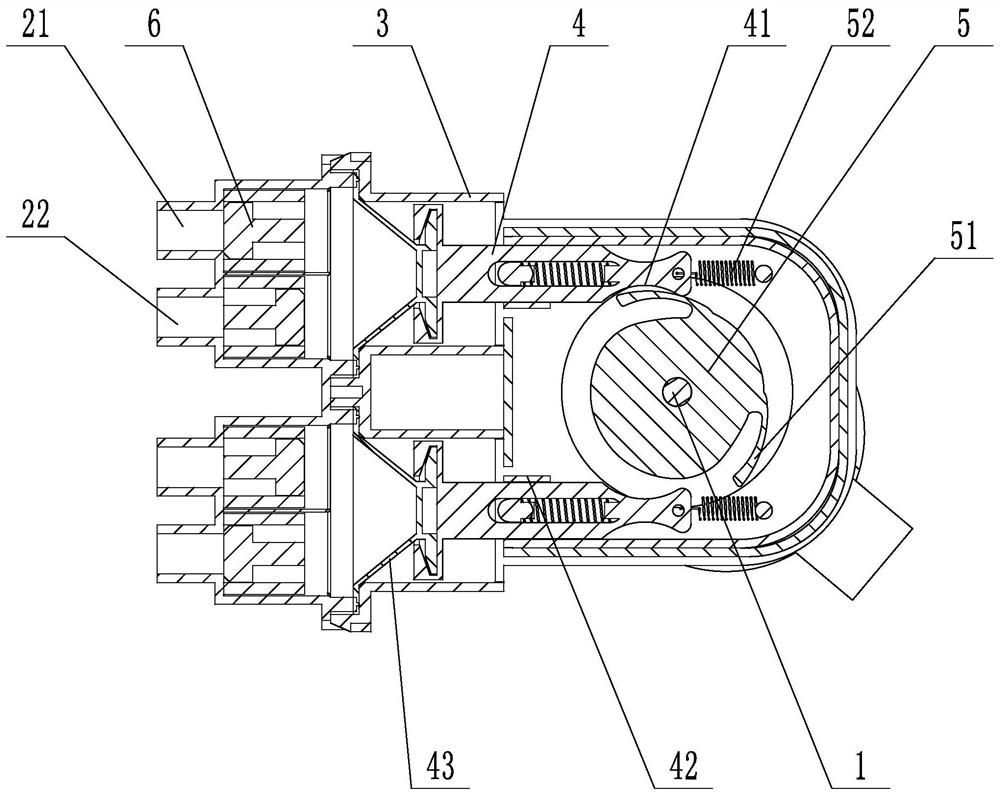

The invention provides a novel intelligent vibration isolation noise reduction composite structure system and a usage method thereof. The system comprises: a feedback piezoelectricity sensing element, an upper insulation transition layer, an upper flexible electrode, an actuator unit, a lower flexible electrode, a lower insulation transition layer and a piezoelectric sensing element. The feedback piezoelectricity sensing element, the actuator unit and the piezoelectric sensing element are connected with a controller through a line. When one sensor perceives external vibration, the controller adds a control voltage to the electrode coated on electroactive polymer surface according to different controlled objects and a control algorithm so that the actuator performs inverse deformation to control vibration transmission. And the other feedback piezoelectricity sensing element is taken as a feedback element which plays a supervision role. A small block which uses the structure is made to firmly stick on a submarine surface. Because of the inverse deformation, the control actuator can control sound radiation of a submarine. By using the system and the method of the invention, vibration isolation and noise abatement in high, middle and low frequency system can be completed. The system and the method can be widely used in the submarine, aerospace, precise instrument equipment vibration isolation field.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Multipath magnetic stirrer for laboratory

InactiveCN101234310AIncreased flex performanceStirring conditions are exactly the sameMixersDrive wheelDifferential pressure

A multi-channel magnetic stirrer for laboratory use is characterized in that a motor drives a plurality of magnetic disks which are provided with driven wheels of the same diameter to rotate, and that the transmission angle between a transmission belt and the contact position with a drive wheel is 90 degrees to 120 degrees, and the motor is a low voltage AC motor. The stirrer is used for measuring the BOD5 value in water by differential pressure method in laboratory. The stirring conditions of the magnetic disks are the same, thus increasing the measuring accuracy and reducing the error. As the flex harass amplitude of the transmission belt is small, the service life can be prolonged, and safety and reliability can be ensured even working in the incubator with condensed water.

Owner:JIANGSU JIANGFEN ELECTROANALYTICAL INSTR

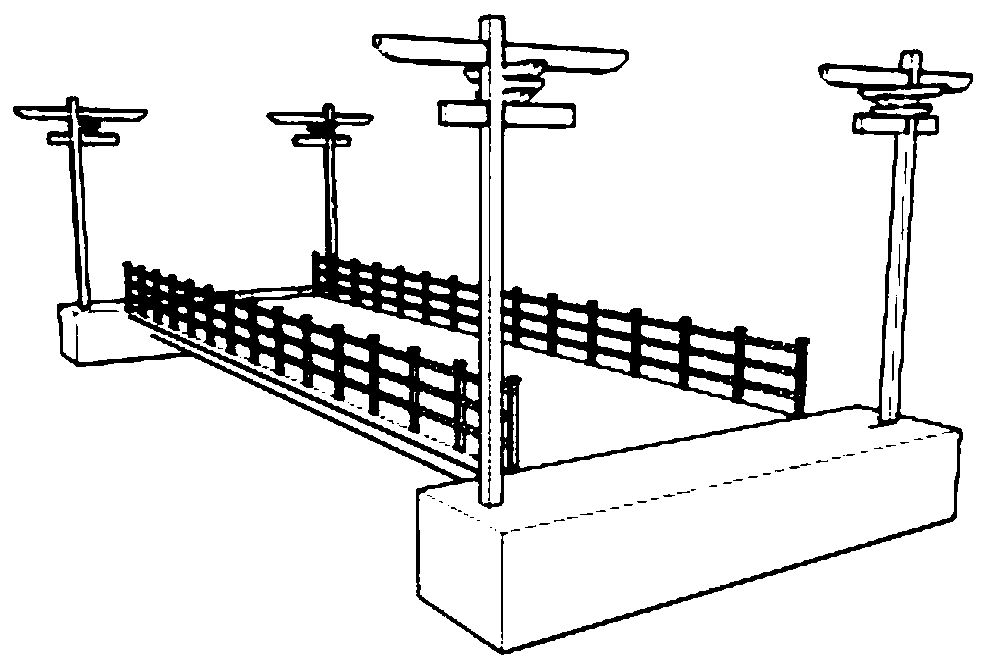

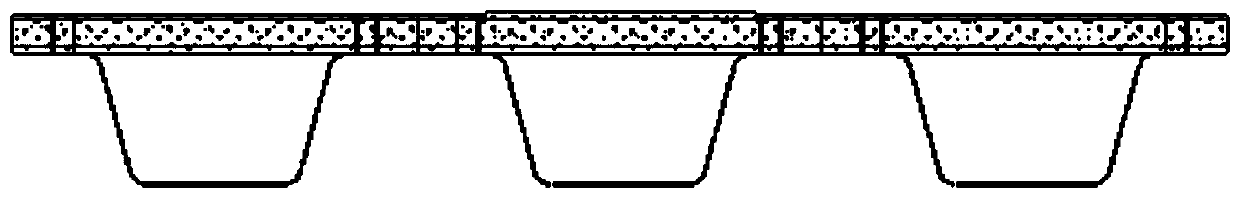

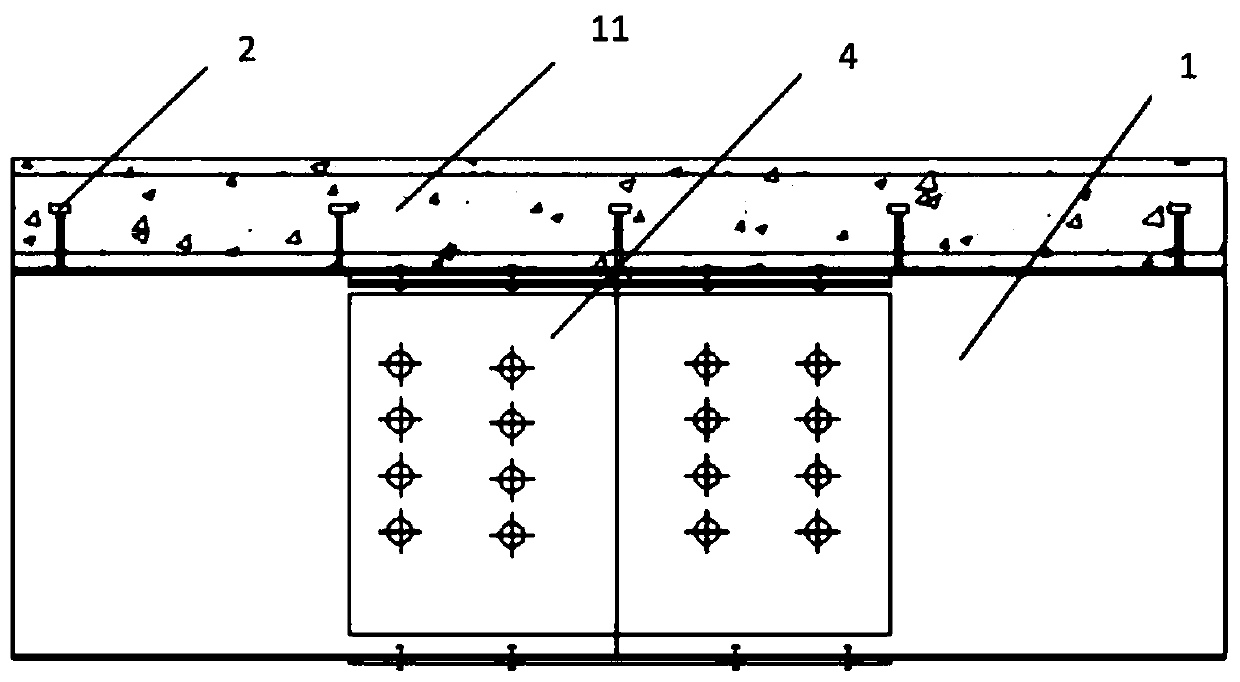

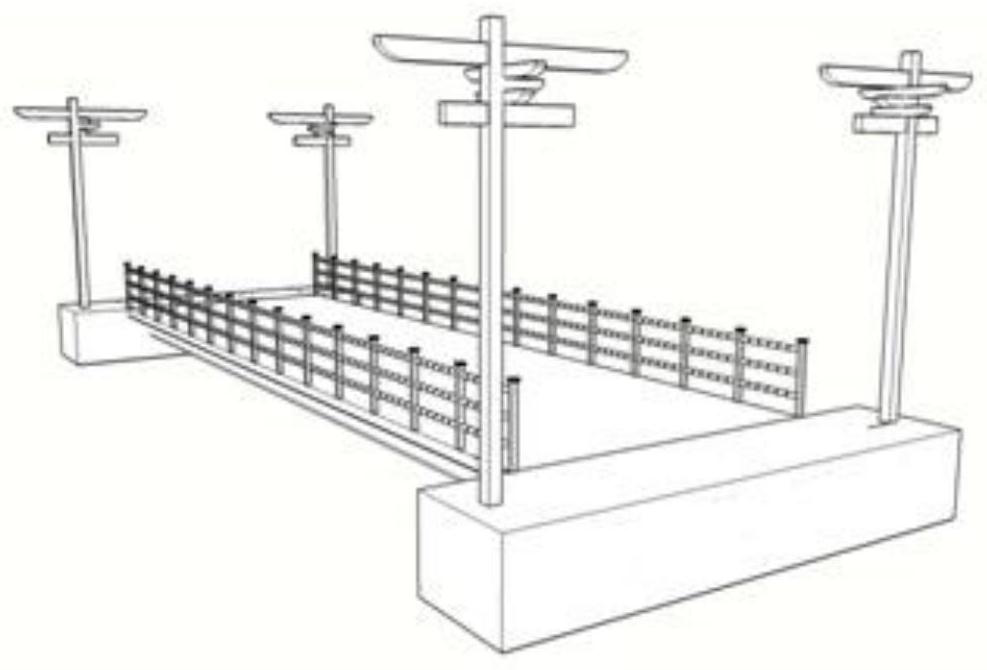

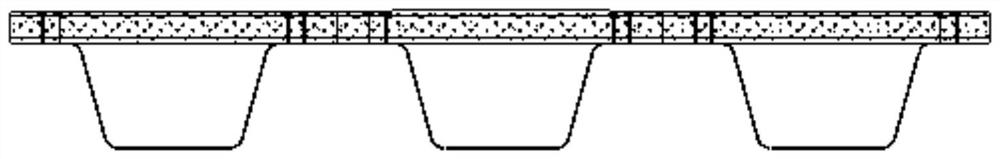

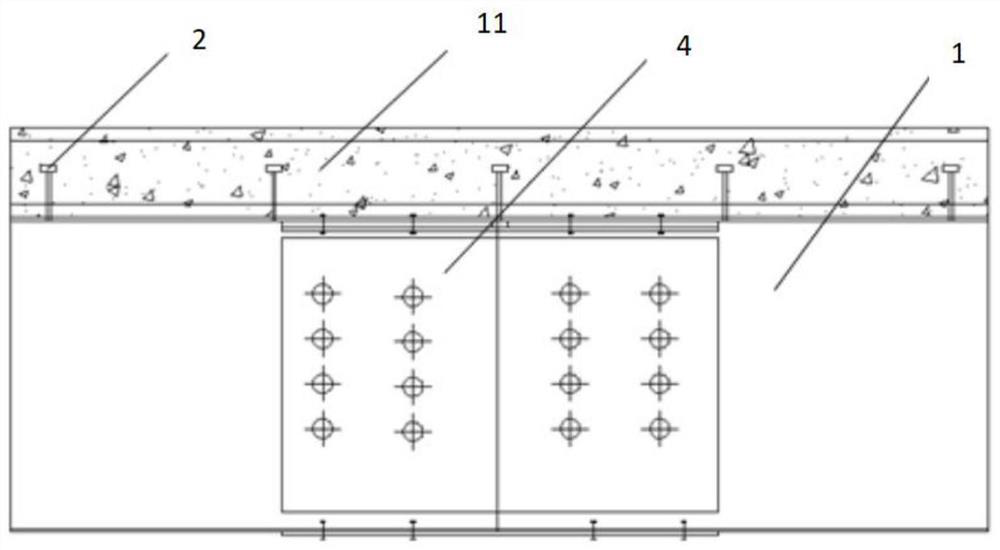

Road cold-bent U-shaped composite beam bridge and construction method thereof

ActiveCN110106772AImprove fatigue performanceLess prone to fatigueBridge structural detailsBridge materialsWelding residual stressAsphalt

The invention discloses a road cold-bent U-shaped composite beam bridge and a construction method thereof. The road cold-bent U-shaped composite beam bridge is structurally characterized in that a plurality of U-shaped steel plates are spliced into a bridge body steel structure; and concrete pouring areas are arranged on the U-shaped steel plates, an asphalt layer is laid on concrete, a gantry isarranged at the bridge head, and guardrails and lamp posts are arranged on the two sides of the bridge. Compared with the prior art, the U-shaped steel plates are formed in a cold-bending mode and donot need to be welded, and thus the welding quality problem and welding residual stress are avoided; steel beam segments spliced in a factory are transported to a site, and then the concrete is pouredto form the bridge; the steel beam segments replace construction formworks, the construction technology is optimized, the construction quality is improved, and the construction period is shortened; and the bearing capacity of cold-bent U-shaped composite beams is three times that of equal-span hollow slab beams, the concrete cracking disease can be reduced, and bridge durability is improved.

Owner:HOHAI UNIV

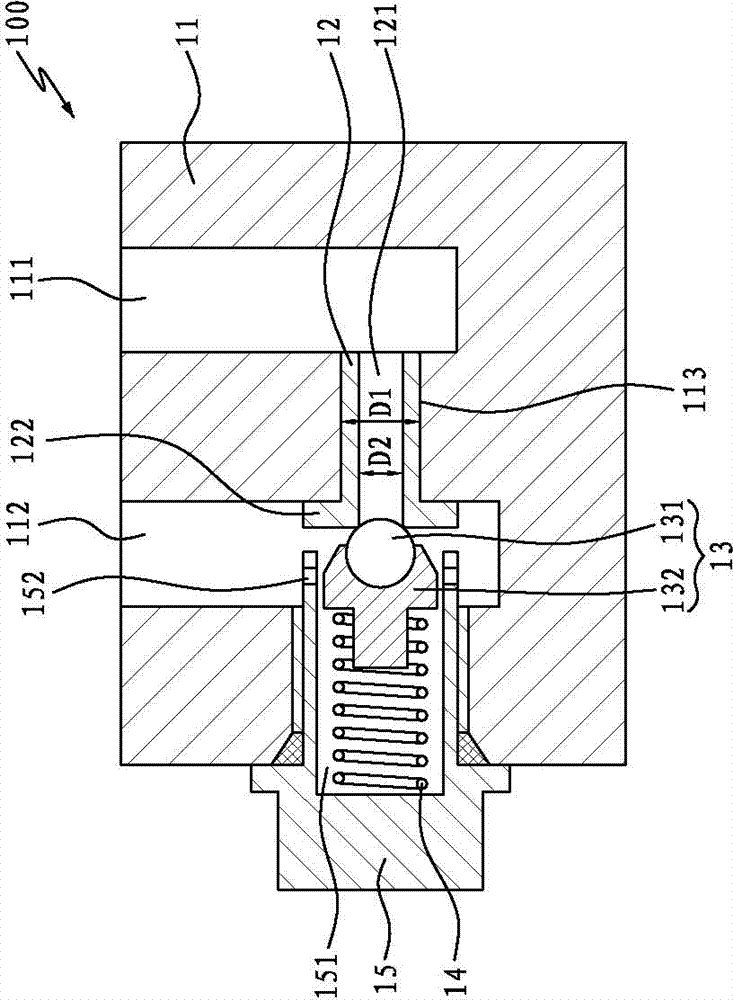

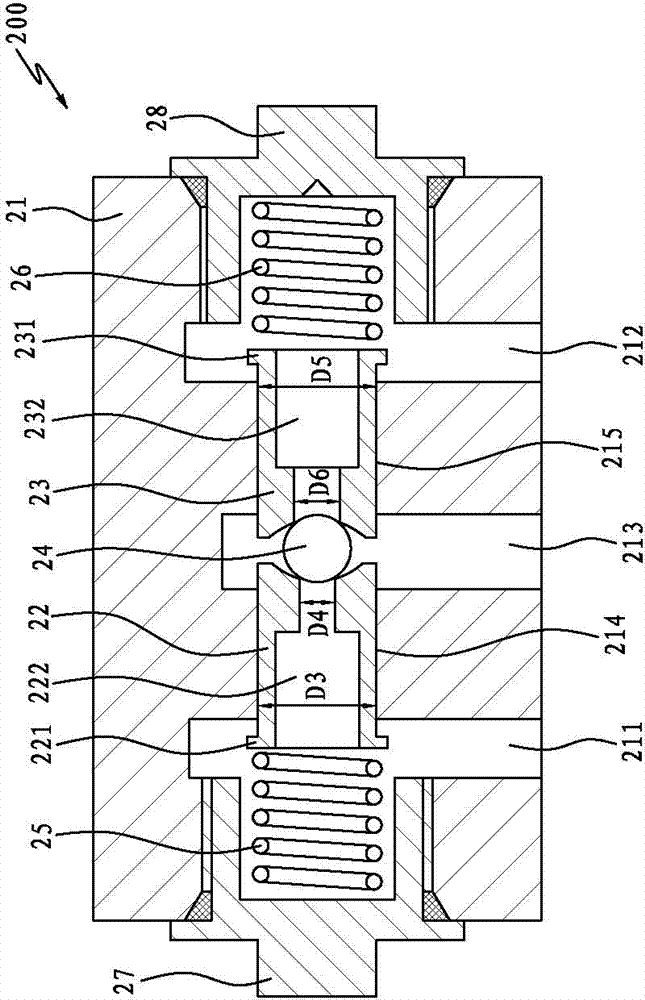

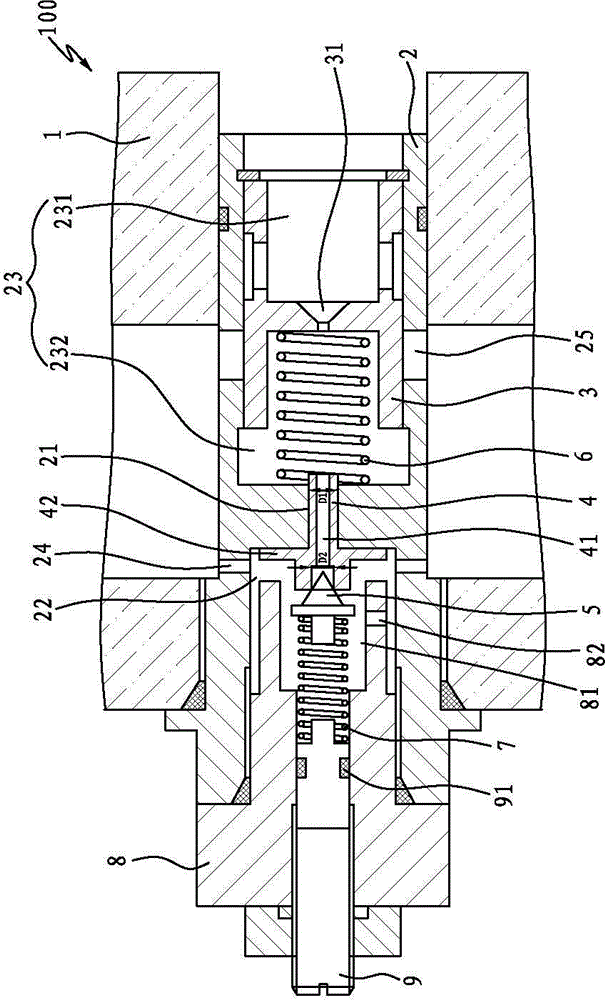

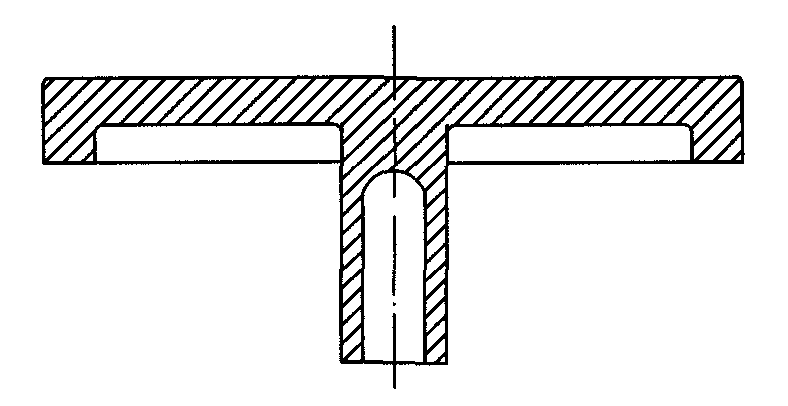

Overload valve

ActiveCN102734249AImprove reliabilityExtended service lifeServomotor componentsFatigue damageEngineering

The invention discloses an overload valve, which comprises a valve body, a valve seat, a valve core and a spring, wherein an oil inlet cavity, an oil return cavity and a valve seat hole are arranged on the valve body; the valve seat is movably sleeved inside the valve seat hole and has a first moving stroke; the valve seat comprises an oil inlet hole communicated with the oil inlet cavity and the oil return cavity; and the spring props against the valve core and can drive the valve core to prop against the valve seat so as to block the oil inlet hole; the valve core has a second moving stroke, and the length of the second moving stroke is greater than that of the first moving stroke. Compared with the prior art, the overload valve is simple in structure, small in spring compression and not easy to generate fatigue damage; the impact of the valve core on the valve seat is relatively small when the overload valve is closed; abrasion of the valve core and the valve seat are greatly reduced, and the reliability and the service life of the overload valve can be greatly improved.

Owner:浙江高宇液压机电有限公司

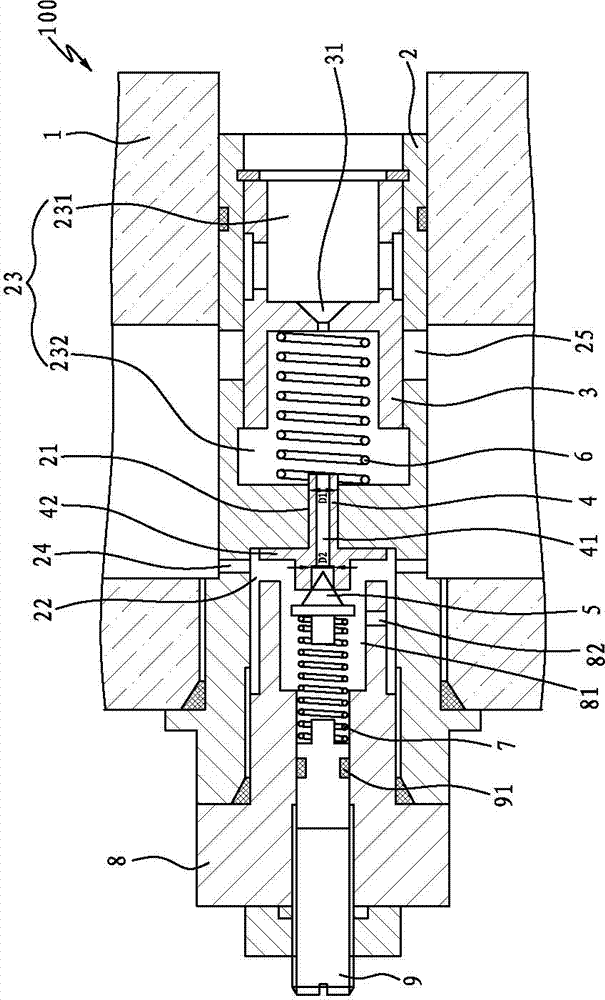

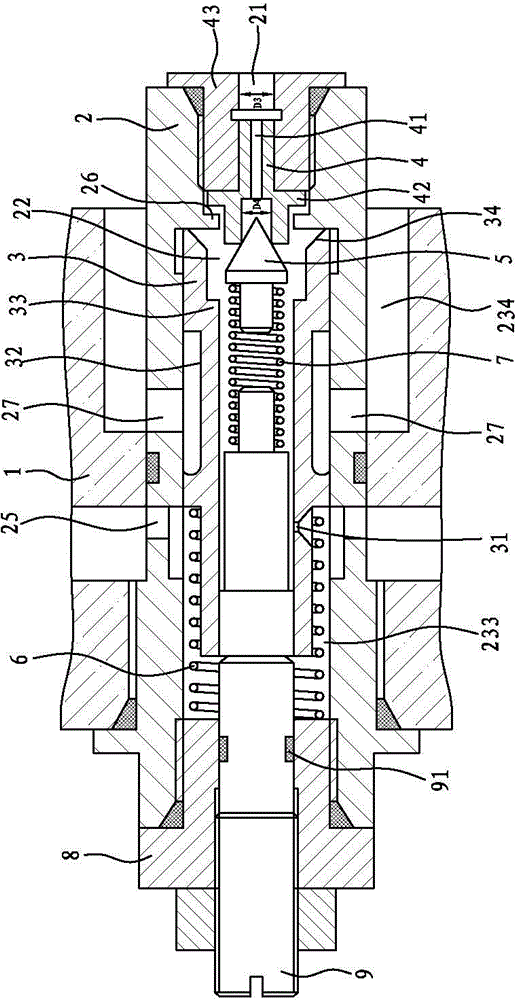

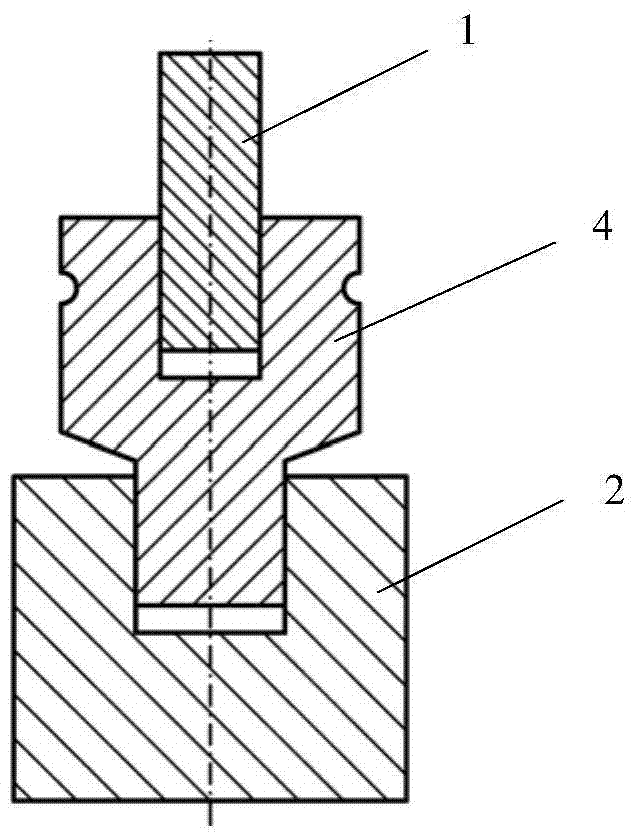

Overflow valve

ActiveCN102734248AImprove use reliabilityExtended service lifeServomotor componentsEngineeringMotion range

The invention discloses an overflow valve comprising a valve body, a main valve seat, a main valve core, a pilot valve seat, a pilot valve core, a main valve spring, a pilot valve spring, a pilot valve seat installation hole and a pilot valve seat limit part, wherein the main valve seat is fixedly sleeved in the valve body, and the pilot valve seat is movably sleeved in the pilot valve seat installation hole and is provided with a pilot valve oil inlet; and the pilot valve seat limit part is used for limiting the motion range of the pilot valve seat, so that the motion stroke of the pilot valve seat is shorter than that of the pilot valve core. Compared with the prior art, with the adoption of the overflow valve, abrasion of the pilot valve core and the pilot valve seat is small, and the pre-pressure of the pilot valve spring is small, so that the using reliability of the overflow valve can be greatly improved, and the service life of the overflow valve can be greatly prolonged.

Owner:浙江高宇液压机电有限公司

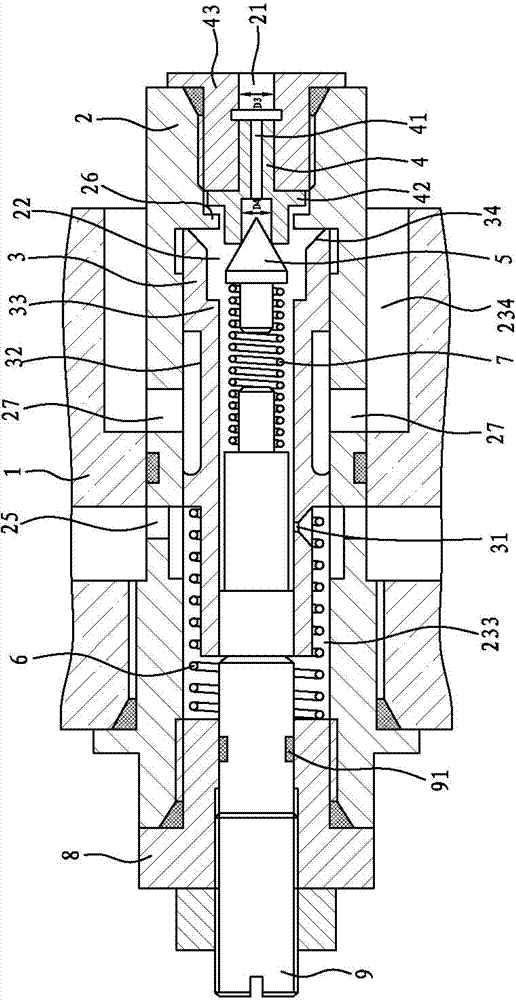

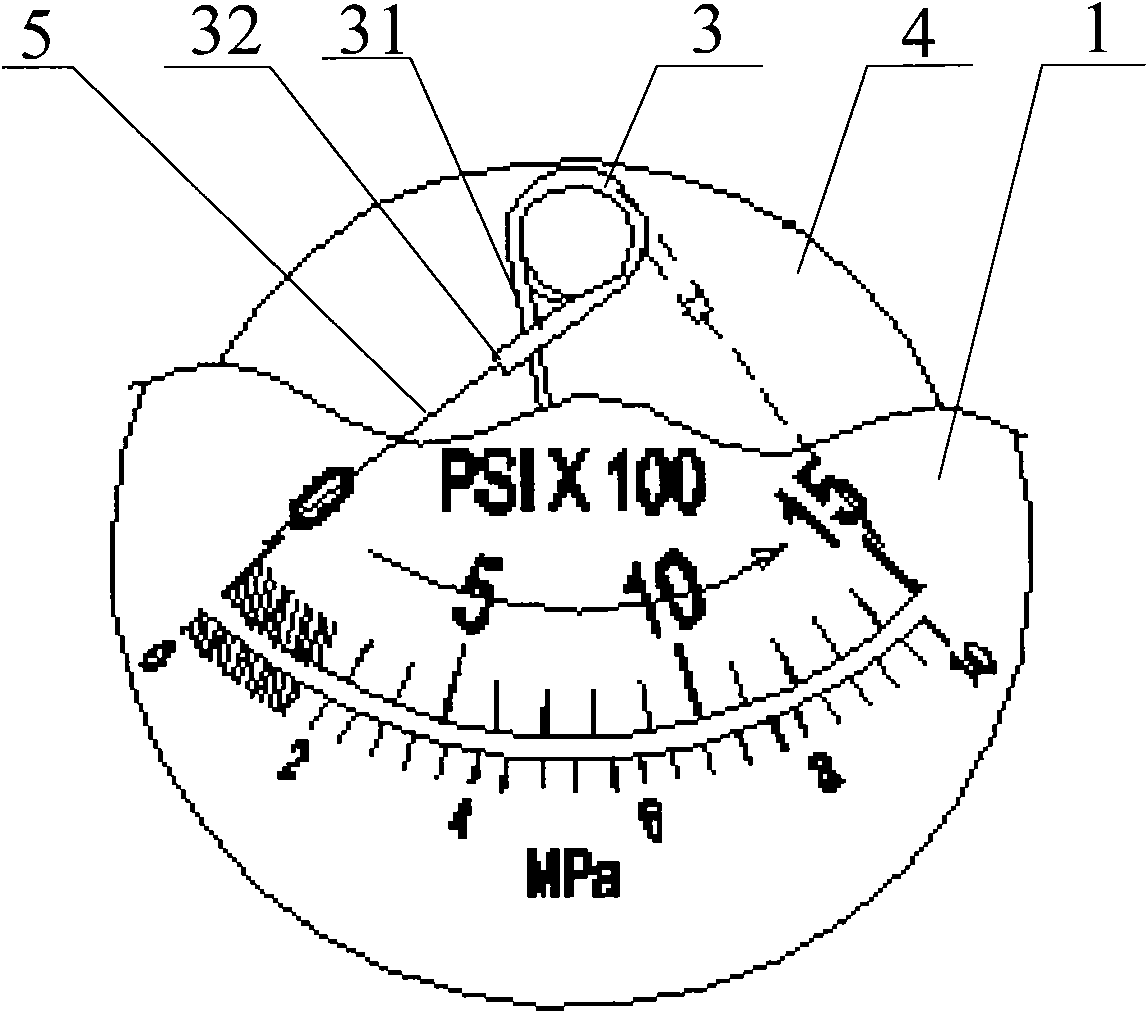

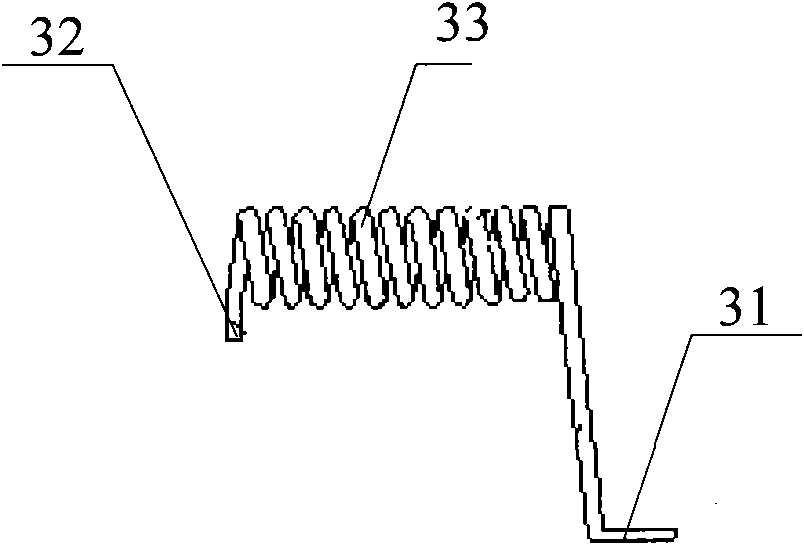

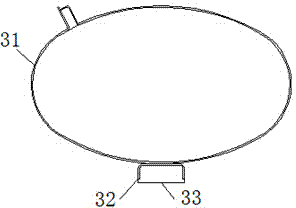

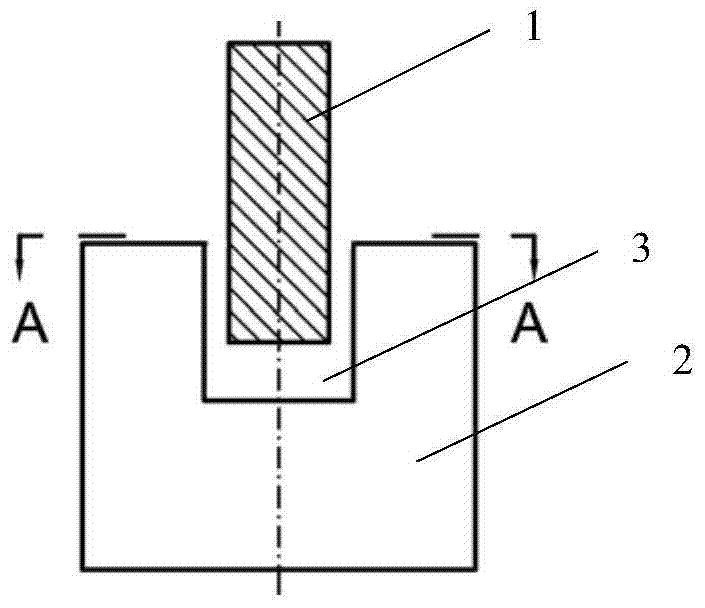

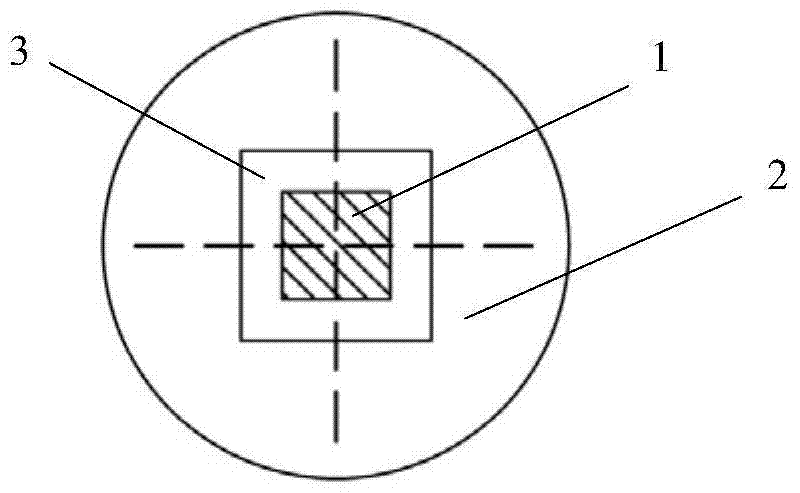

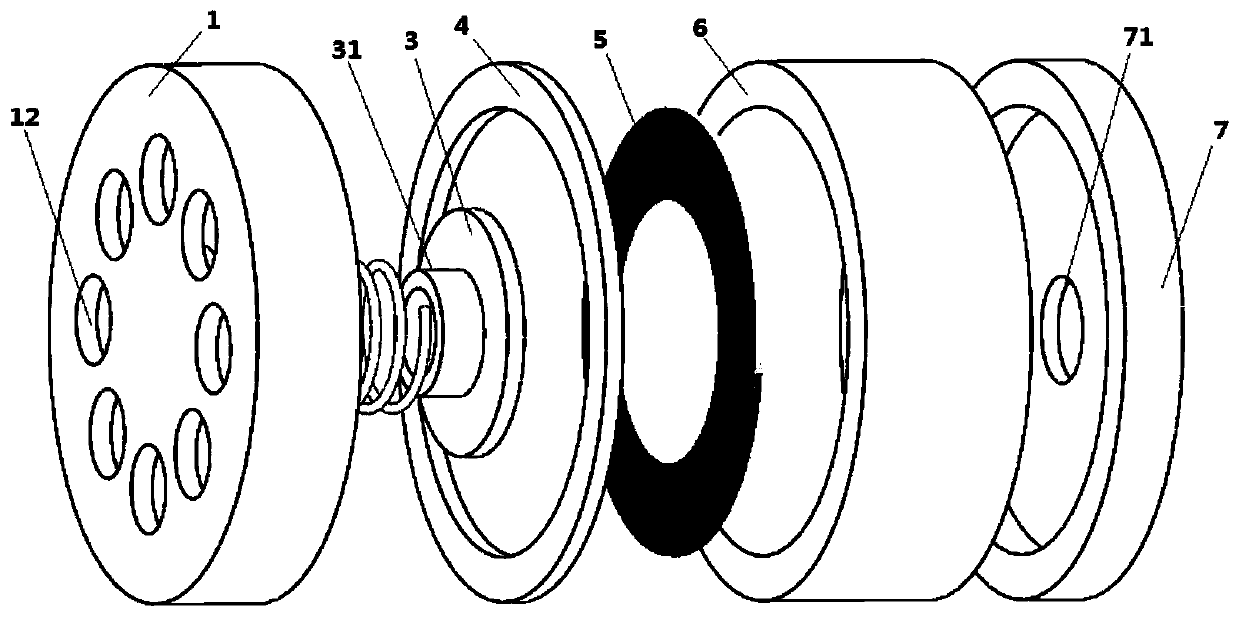

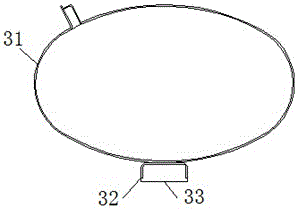

Pressure gauge

InactiveCN101839784AImprove bearing strengthLess prone to fatigue damageFluid pressure measurement using elastically-deformable gaugesResonanceEngineering

The invention discloses a pressure gage, comprising a gauge plate (1), a gauge needle (5), a ventilation chassis joint (4) and a screw type spring tube (3), wherein the first end (31) of the screw type spring tube is fixed at the ventilation opening of the ventilation chassis joint (4), and the second end (32) penetrates the gauge plate (1) to be connected with the gauge needle (5). In the embodiment of the invention, the screw type spring tube is adopted for the elastic element of the pressure gauge, which virtually aims to disperse pressure displacement to a plurality of circles of helical surfaces. Compared with a traditional Bourden tube, the screw type spring tube can bear higher pressure under same displacement, thereby the bearing strength of the elastic element in the pressure gauge is improved. In addition, the gauge needle in the pressure gauge is a free end so that the pressure gauge can counteract impact generated by vibration through the swing of the gauge needle and avoid generating resonance with a vibration source, and the vibration resisting performance of the pressure gauge is improved.

Owner:BEIJING BRIGHTY INSTR +1

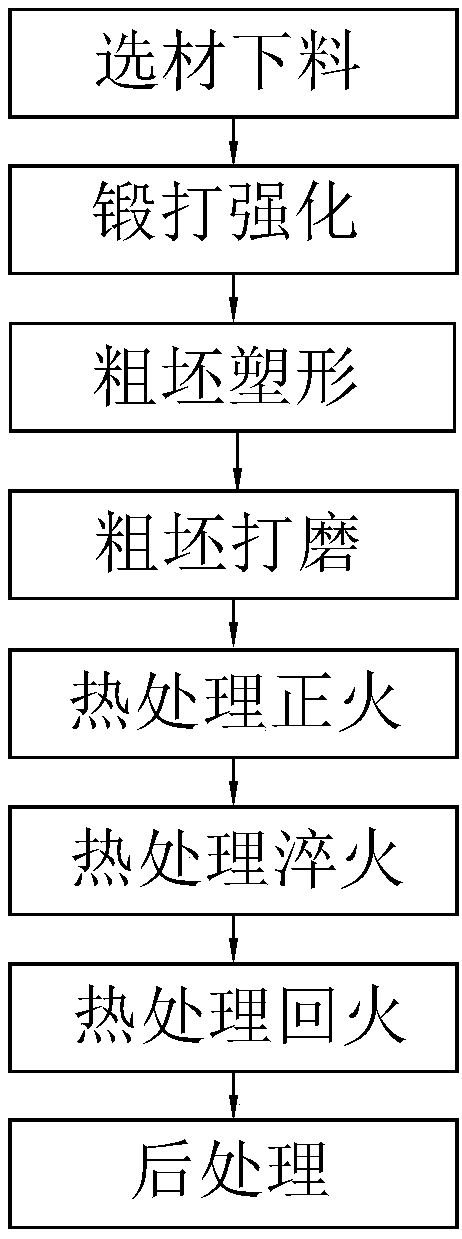

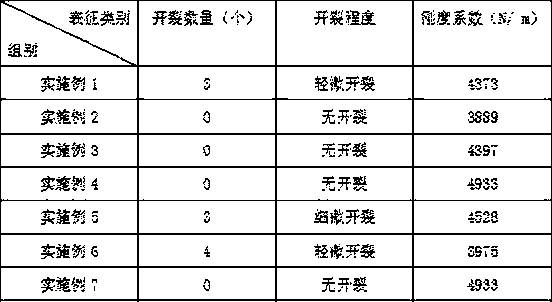

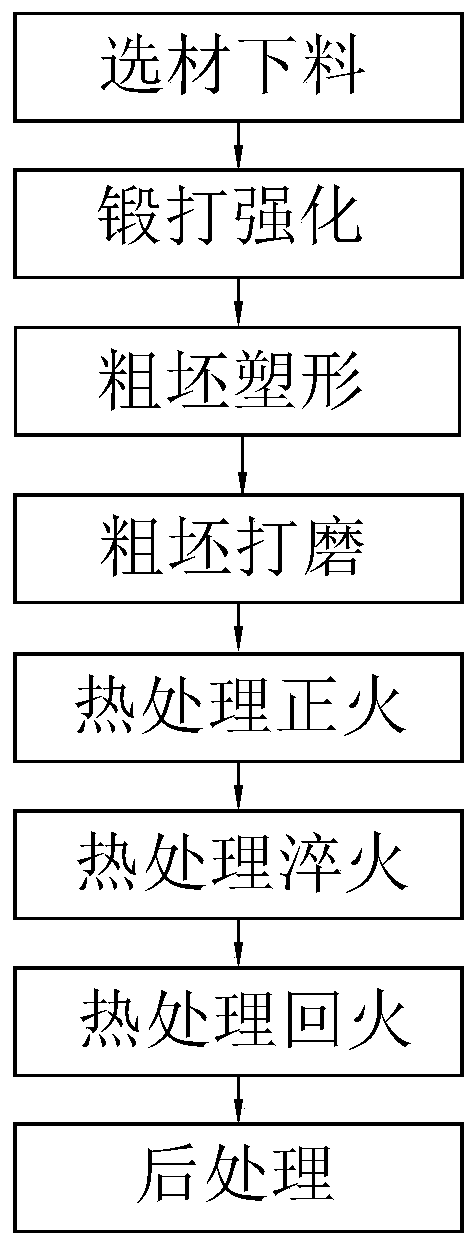

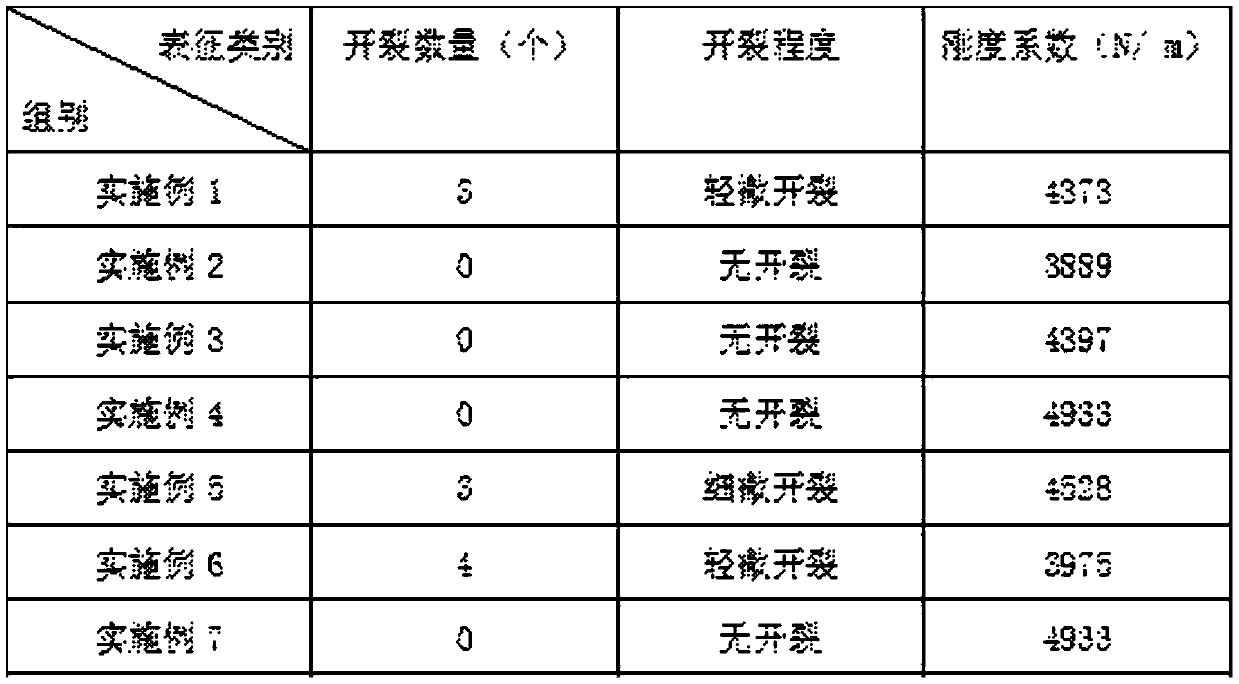

Production process of ball pin

ActiveCN109483177AAvoid crackingHigh surface hardnessFurnace typesPivotal connectionsStress concentrationFatigue damage

The invention discloses a production process of a ball pin, and relates to machining technologies. The production process of the ball pin is used for solving the problem that a common ball pin is prone to breakage. The production process comprises the following steps that (1) material selection and blanking are carried out; (2) forging and strengthening are carried out, and specifically a metal raw material in the step (1) is heated to 700-750 DEG C and then undergoes hot forging; (3) rough blank shaping is carried out, and specifically the forged metal is heated to 850-890 DEG C again, and then undergoes rolling shaping by using a die; (4) rough blank grinding is carried out; (5) heat treatment is carried out; and (6) post-processing is carried out. The production process of the ball pinhas the following advantages and effects that the ball pin formed through hot forging and rolling is not prone to crack due to the technological problem in the manufacturing process, then the ball pinis not prone to breakage due to stress concentration at the cracking position in the using process, moreover, the ball pin has relatively high surface hardness while the toughness of the core part isreserved by adopting the forming mode, then the fatigue damage is not prone to occurrence in the using process of the ball pin, and then the breakage is further not prone to occurrence.

Owner:ZHEJIANG TONGSHI AUTO PARTS

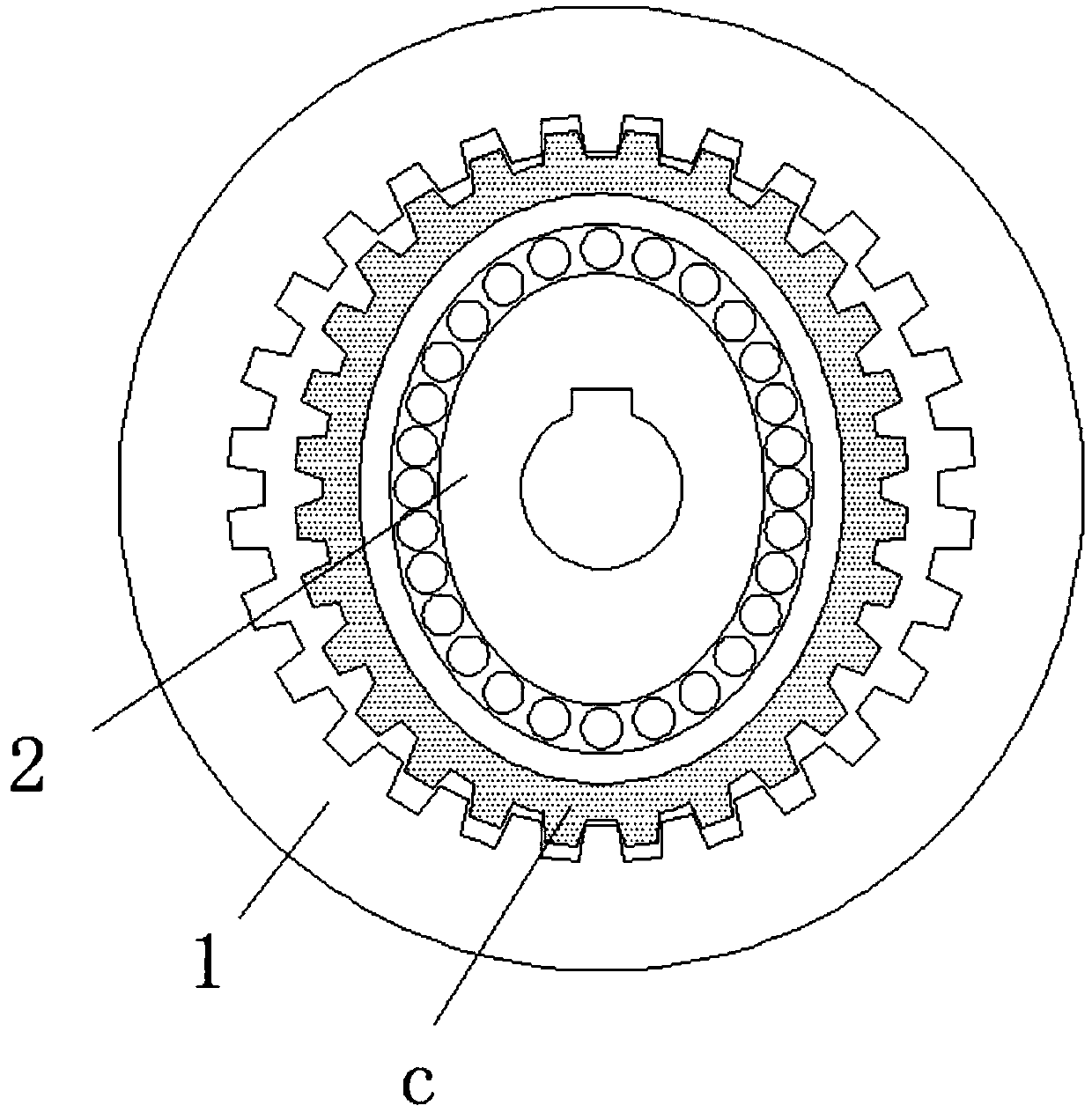

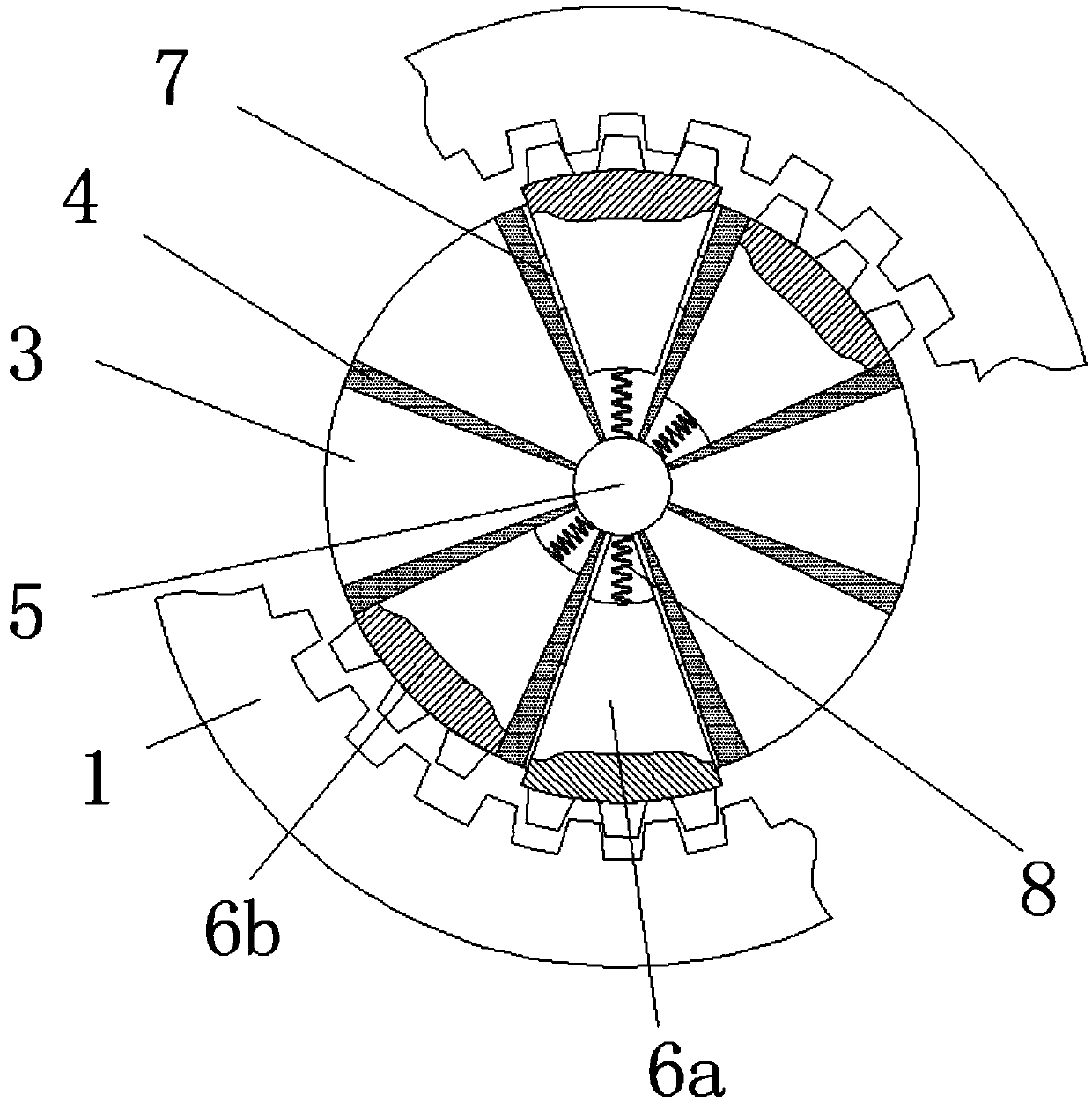

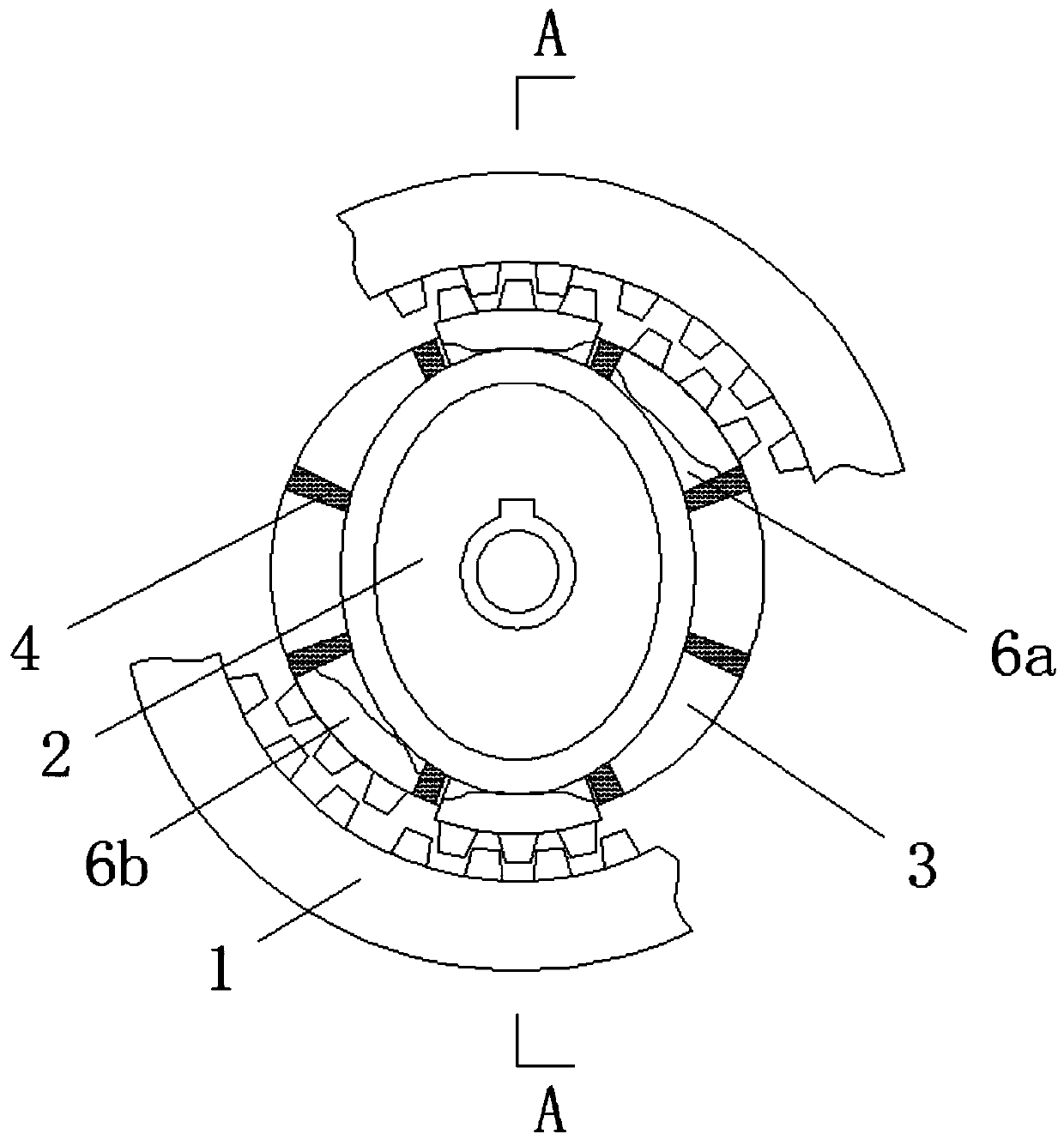

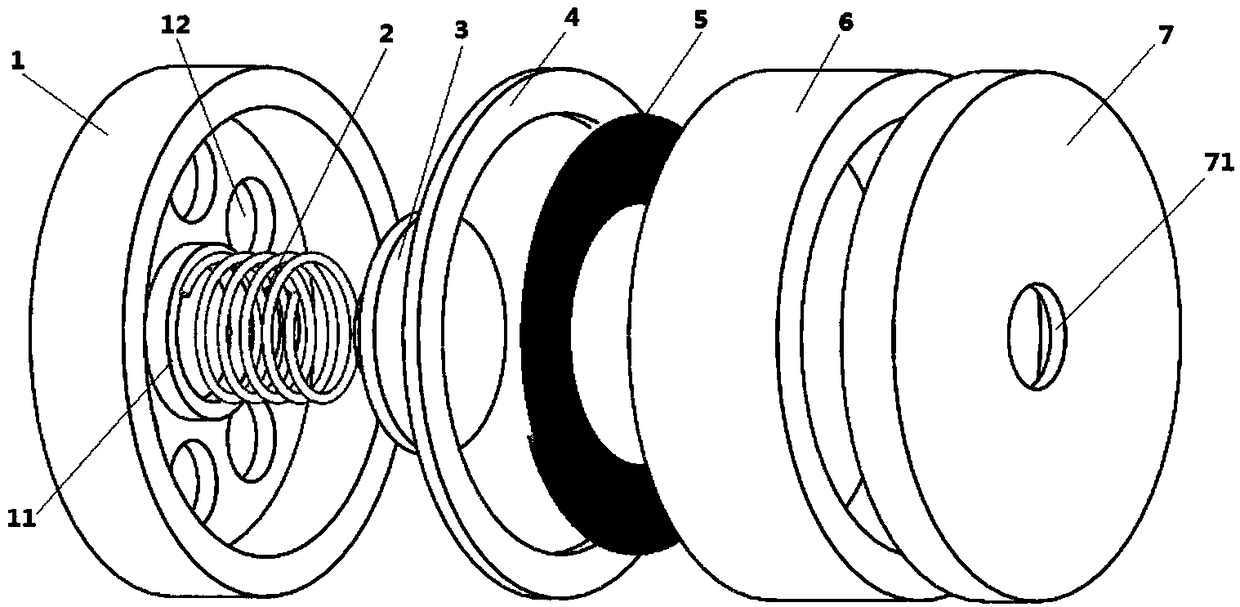

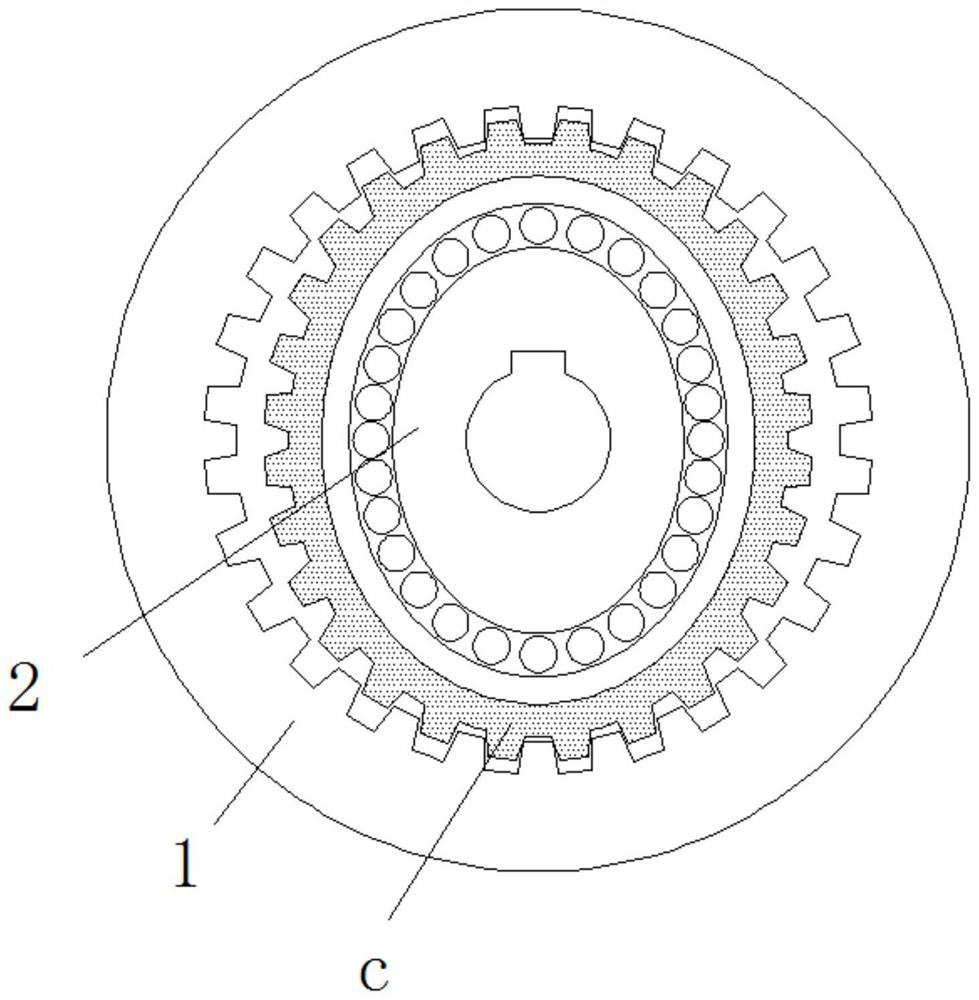

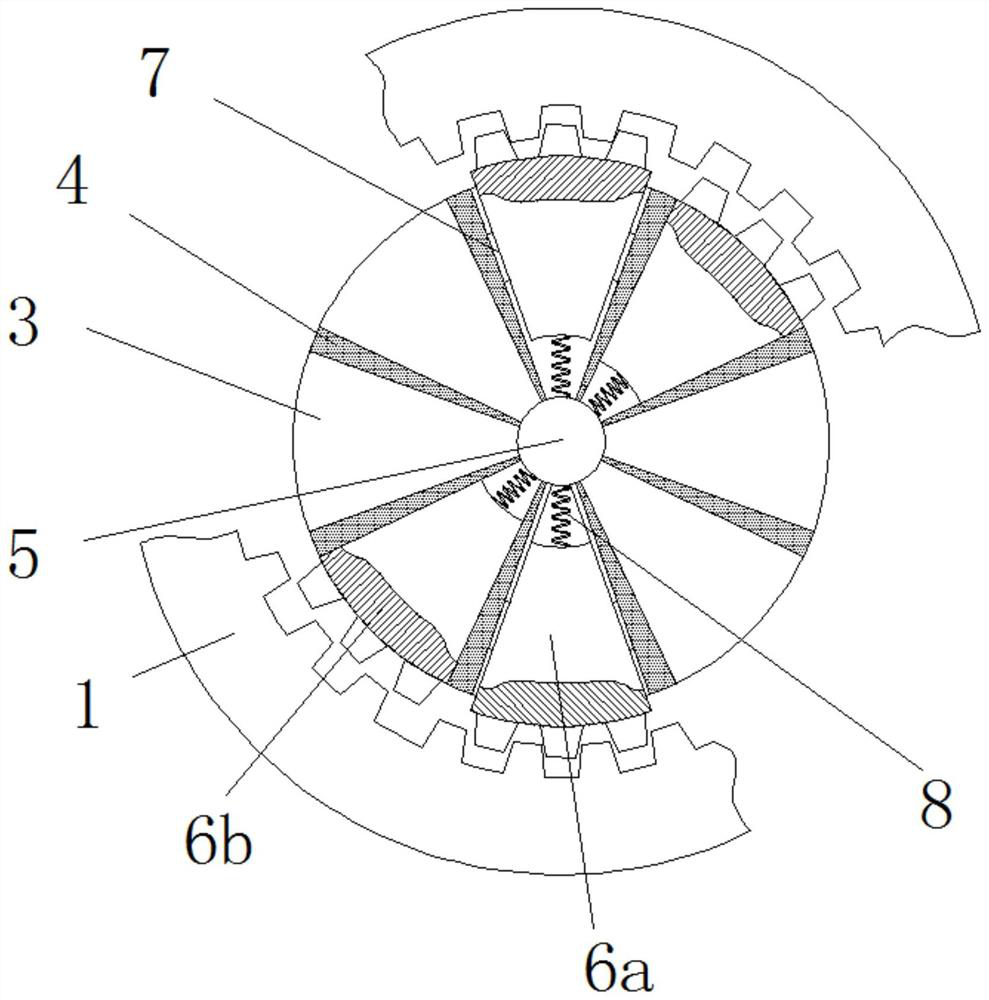

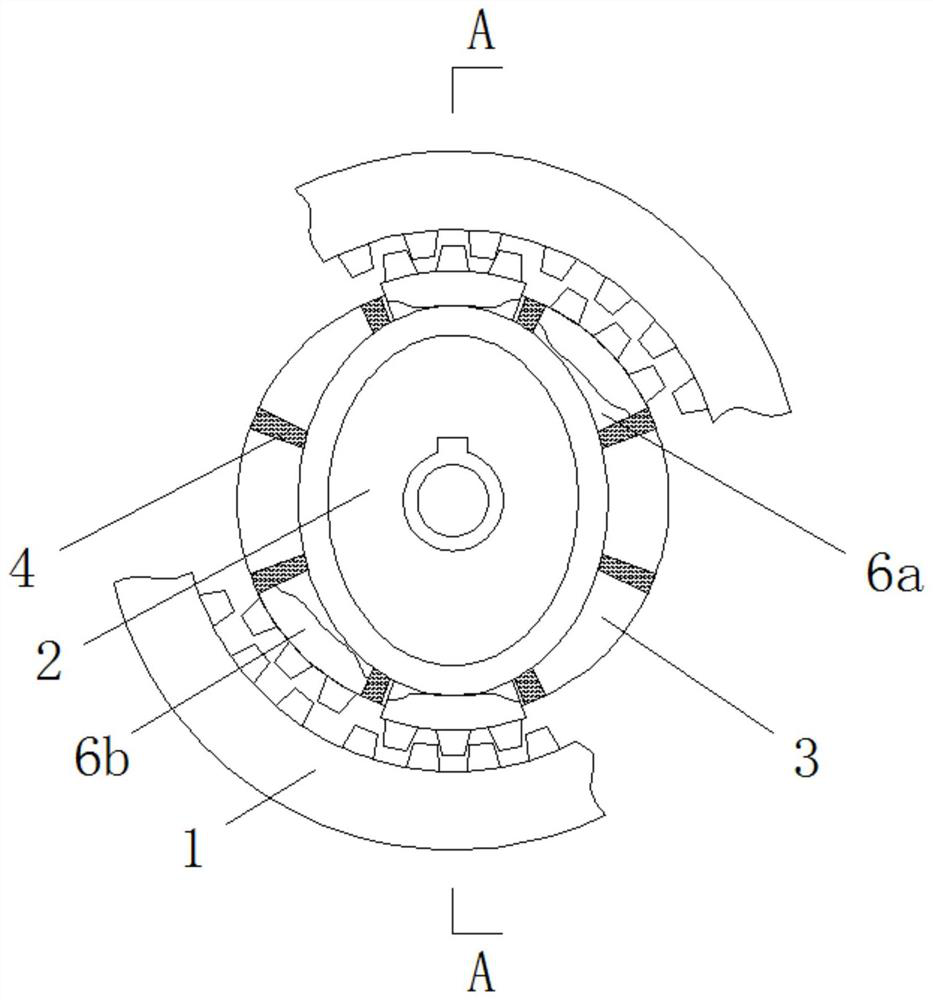

Improved structure of flexible wheel of harmonic reducer

ActiveCN109578547AAvoid the problem of repeated deformation and vulnerabilityLess prone to fatigue damageGearingGearing detailsFatigue damagePull force

The invention relates to the technical field of high-precision reducers, and discloses an improved structure of a flexible wheel of a harmonic reducer. The improved structure comprises a rigid wheel and a wave generator; an output disk is movably sleeved with one end of an inner cavity of the rigid wheel; and eight separating strips are arranged on the front side of the output disk, are distributed on the front side of the output disk in a ring array manner and are in sector shapes. According to the improved structure, the traditional flexible wheel is improved to comprise the output disk, theseparating strips and flexible mechanisms, through cooperation with the restoring tension force effect of reset tension springs, the flexible mechanisms are pushed out of the output disk sequentiallyby the aid of the long-axis part of the wave generator, and teeth outside rigid arc plates mesh with inner teeth of the rigid wheel, so that the speed reduction effect equivalent that of flexible wheels in the prior art is realized; compared with the prior art, the improved structure has the advantages that repeated deformation of the flexible wheel is changed into reciprocating sliding of the flexible mechanisms, deformation of the flexible wheel is changed into deformation of the reset tension springs, thus the problem that the flexible wheel is prone to damage due to repeated deformation is avoided, and meanwhile, the reset tension springs are not prone to fatigue damage and are cheap to replace.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

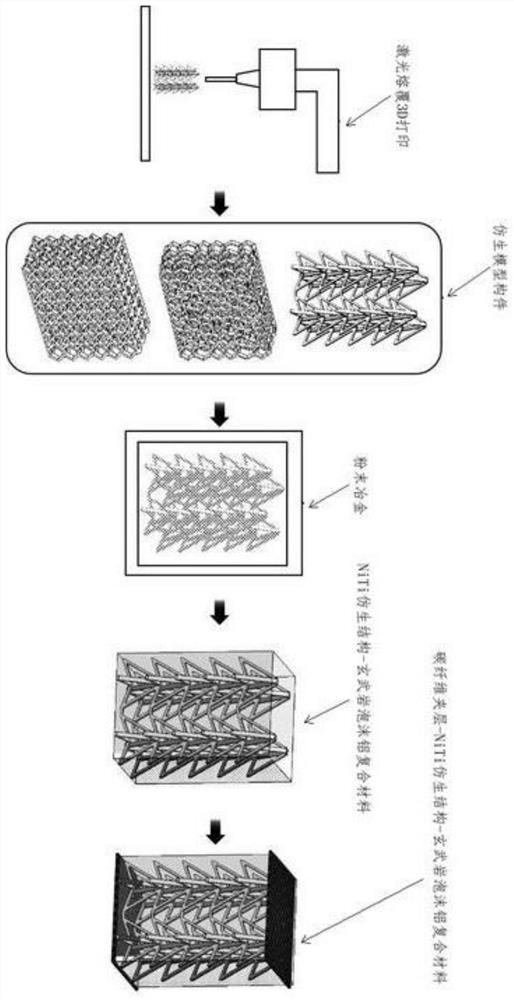

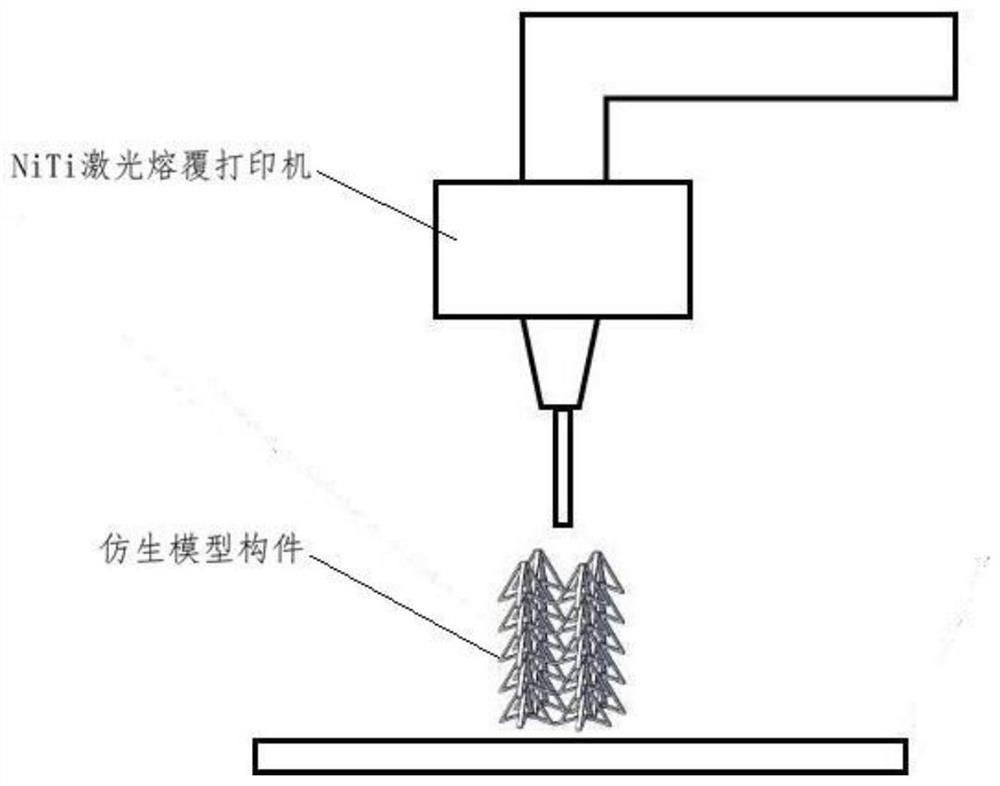

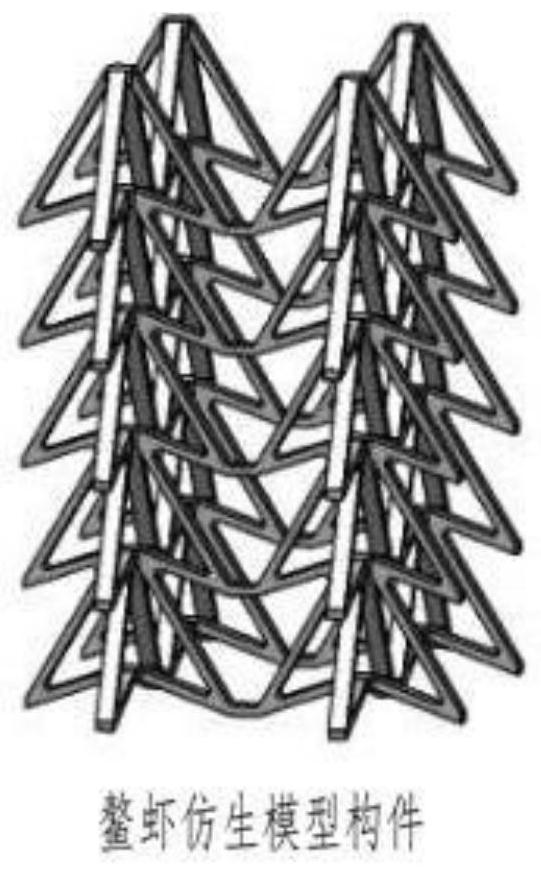

Preparation method of impact-resistant self-recovery bionic composite material

InactiveCN113290244AGuaranteed stabilityBig impactAdditive manufacturing apparatusCarbon fibersShape-memory alloy

The invention discloses a preparation method of an impact-resistant self-recovery bionic composite material, and relates to the technical field of composite materials, a memory alloy NiTi bionic structure is adopted as a composite material matrix, and NiTi shape memory alloy has high elasticity and a shape memory effect, so that the impact-resistant energy-absorbing effect of a composite interlayer material can be enhanced. The excellent functional characteristics of a bionic structure are integrated, the morphological characteristics of a bionic matrix model can be replaced according to requirements, through the use of the NiTi shape memory alloy, the structure can recover the original morphology of the structure under the control of an intelligent temperature control system after the structure is subjected to excessive impact energy and has plastic deformation, and the subsequent recycling of the structure is facilitated. Foamed aluminum and basalt fibers are mixed to prepare a carbon fiber interlayer-NiTi bionic structure-basalt foamed aluminum composite material sandwich plate, and the overall mass is reduced.

Owner:JILIN UNIV

Overflow valve

ActiveCN102734248BImprove use reliabilityExtended service lifeServomotor componentsEngineeringMotion range

Owner:浙江高宇液压机电有限公司

Rim and spoke integral steel wheel manufacturing method

InactiveCN111745106AReduce manufacturing costIncrease profitMetal-working apparatusWheelsHeating furnacePipe

The invention discloses a rim and spoke integral steel wheel manufacturing method. The method comprises the following steps that a steel pipe of a corresponding material is selected according to the size of a blank, or a plate is coiled and then welded into the steel pipe or a whole block of steel is forged into the steel pipe; the steel pipe is heated in a heating furnace to an initial forging temperature, a roll-in head penetrates into the open end of a rim expected, the roll-in head is used for gradual inward rolling-in according to the size of the rim until the right end of a workpiece, during the process, a groove bottom of the rim and a rim body are formed through rolling-in, and during a subsequent rolling-in process, when a temperature of the workpiece is lower than a final forgingtemperature, the workpiece is re-heated to the initial forging temperature; the roll-in head is used for internally rolling-in on the outer circular surface of the workpiece to form a lock ring groove, when the roll-in head reaches the right end of the workpiece, a right end material of the workpiece is gradually inwards bent, closed and folded to form a spoke of a wheel by means of profiling andthe roll-in head at the right end of the workpiece, a central hole of the spoke is formed through closing in the center of the spoke, and finish rolling, shaping, and machining on a central hole, a bolt hole, an air hole and a valve core hole are conducted.

Owner:江西久久车轮制造有限公司

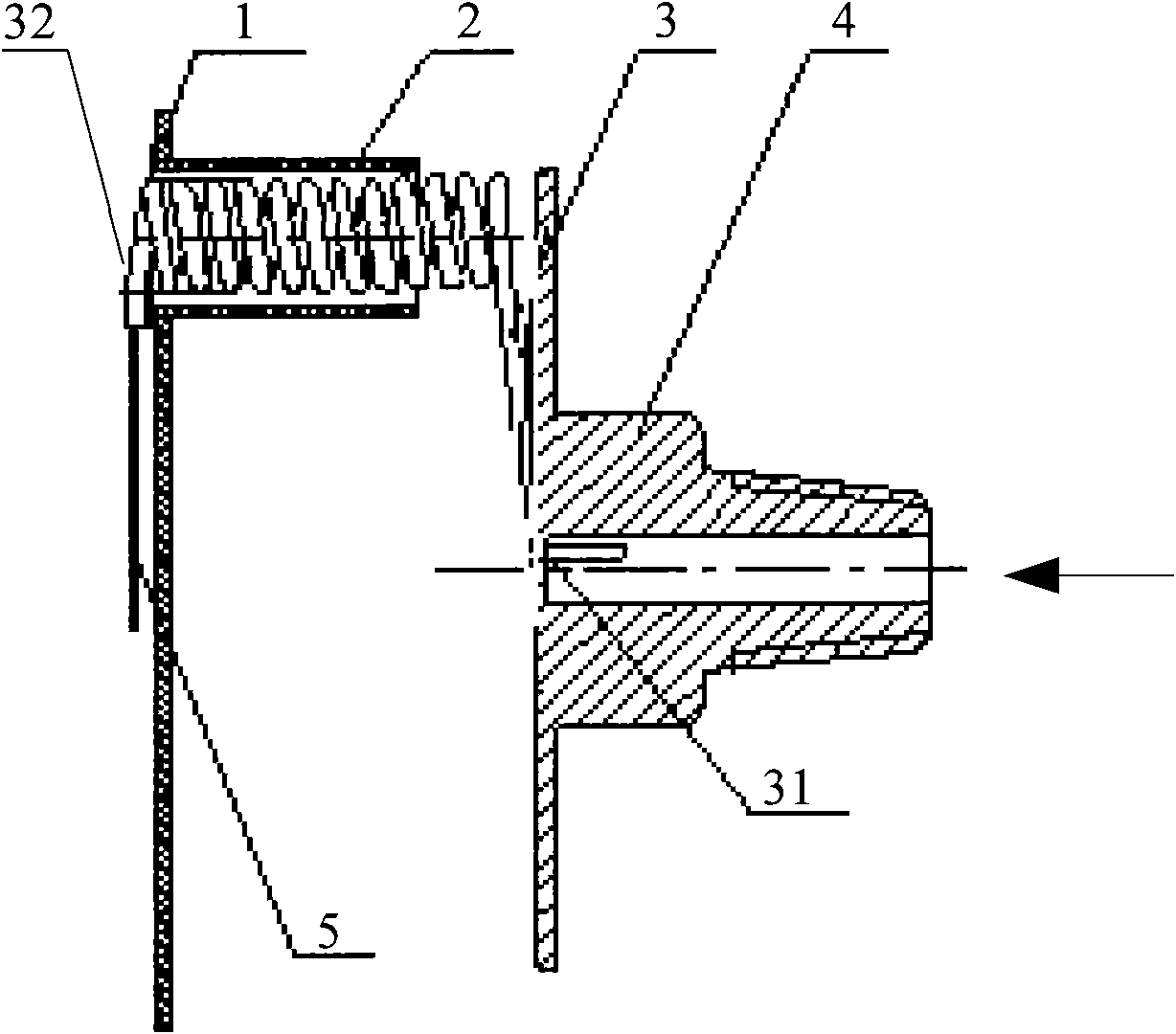

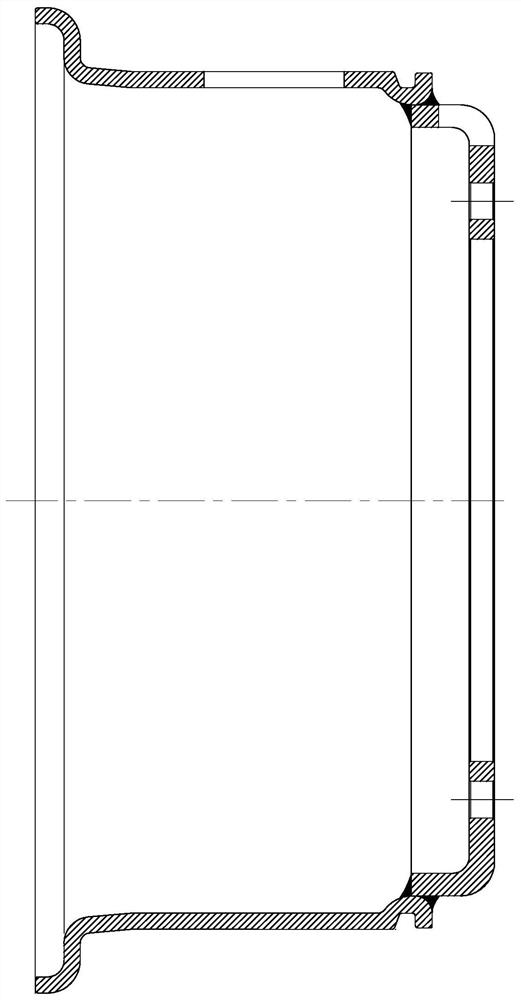

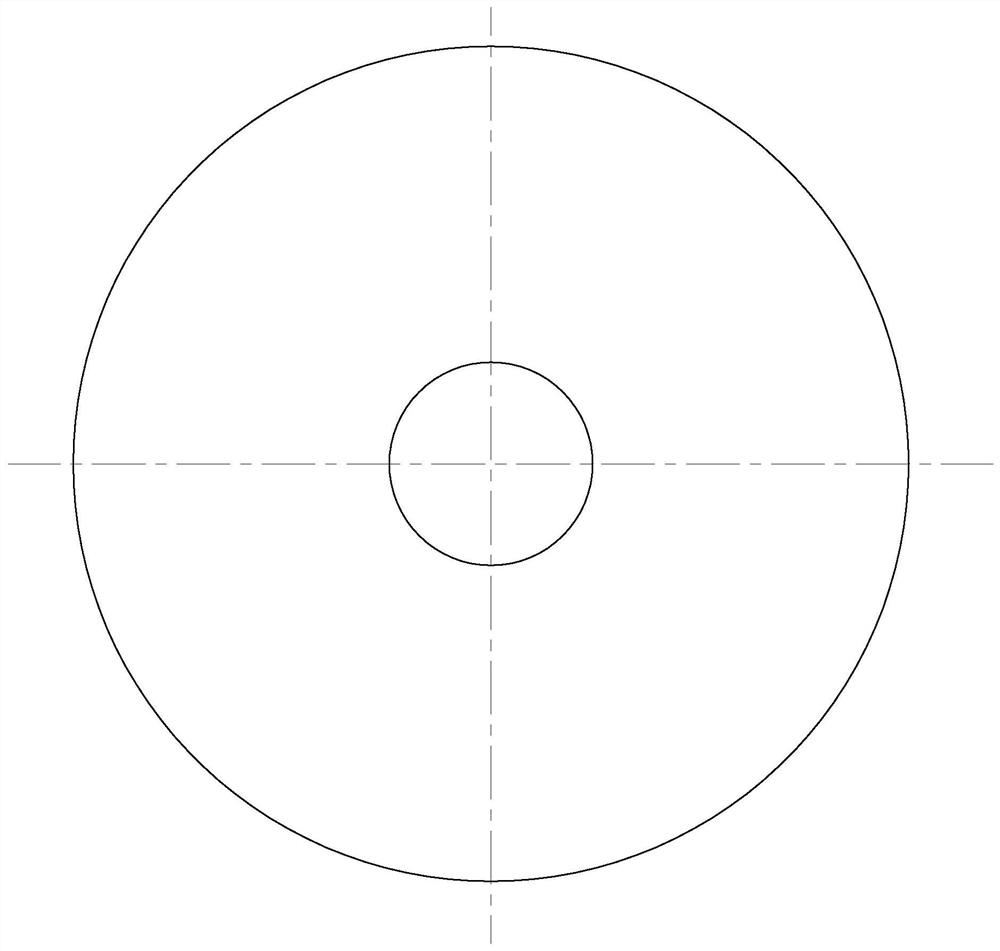

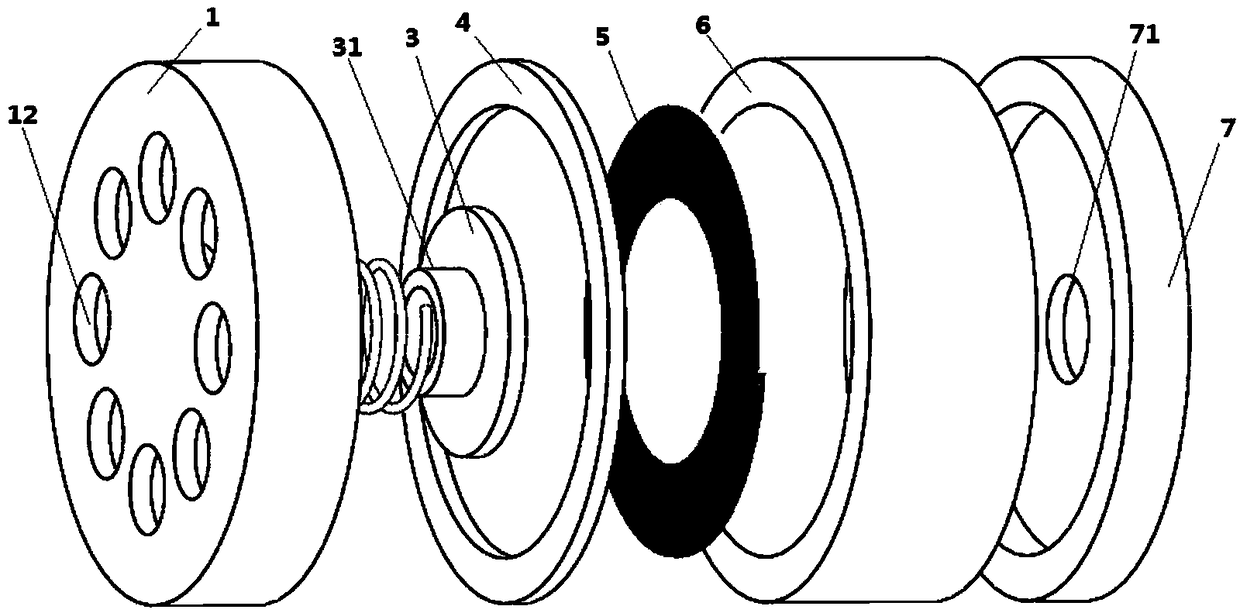

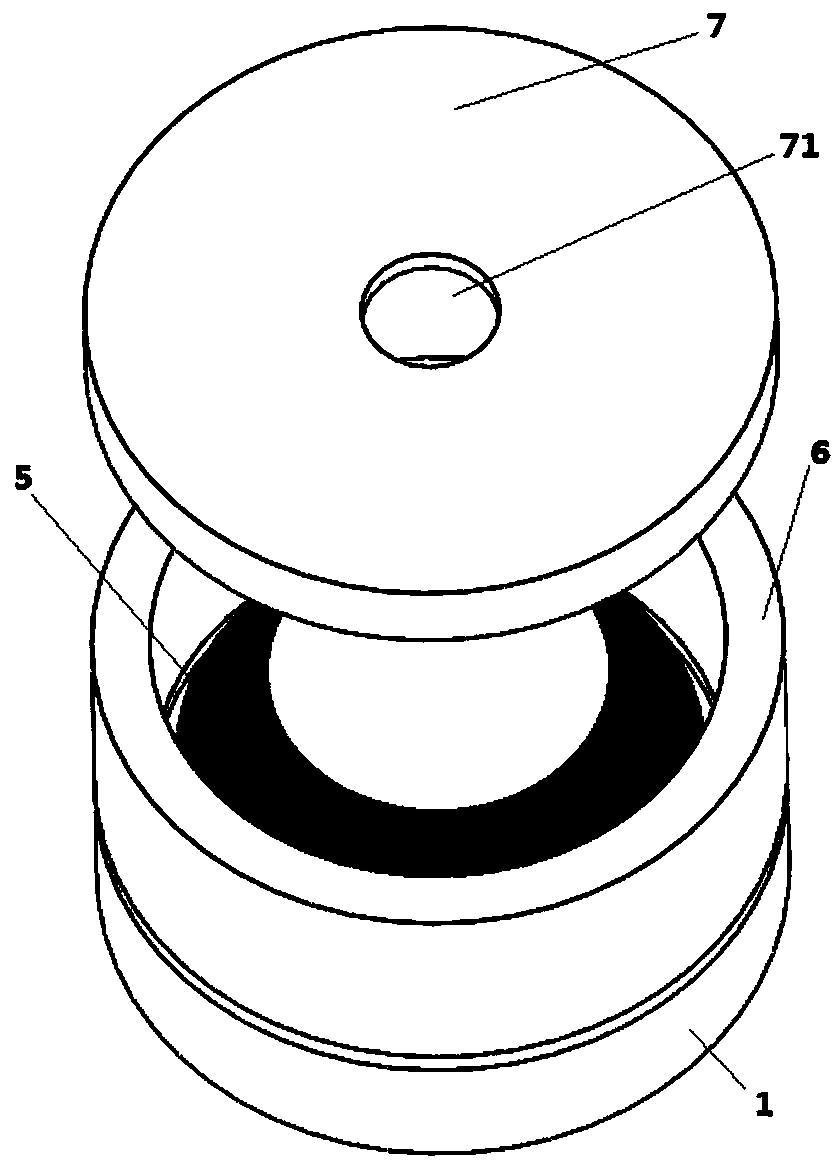

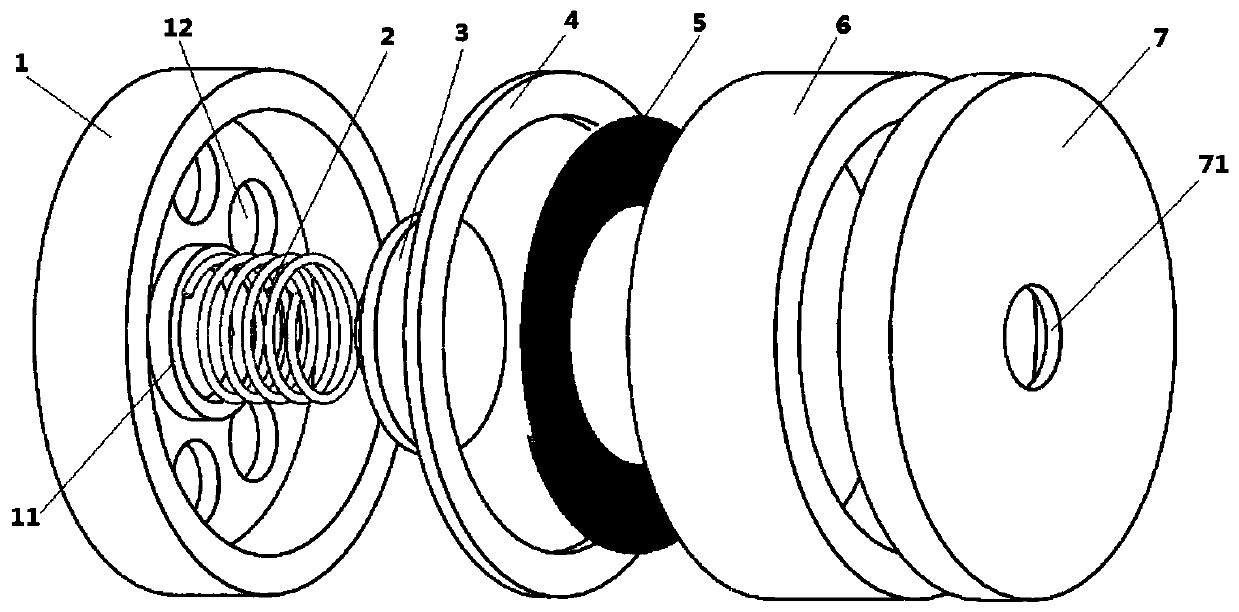

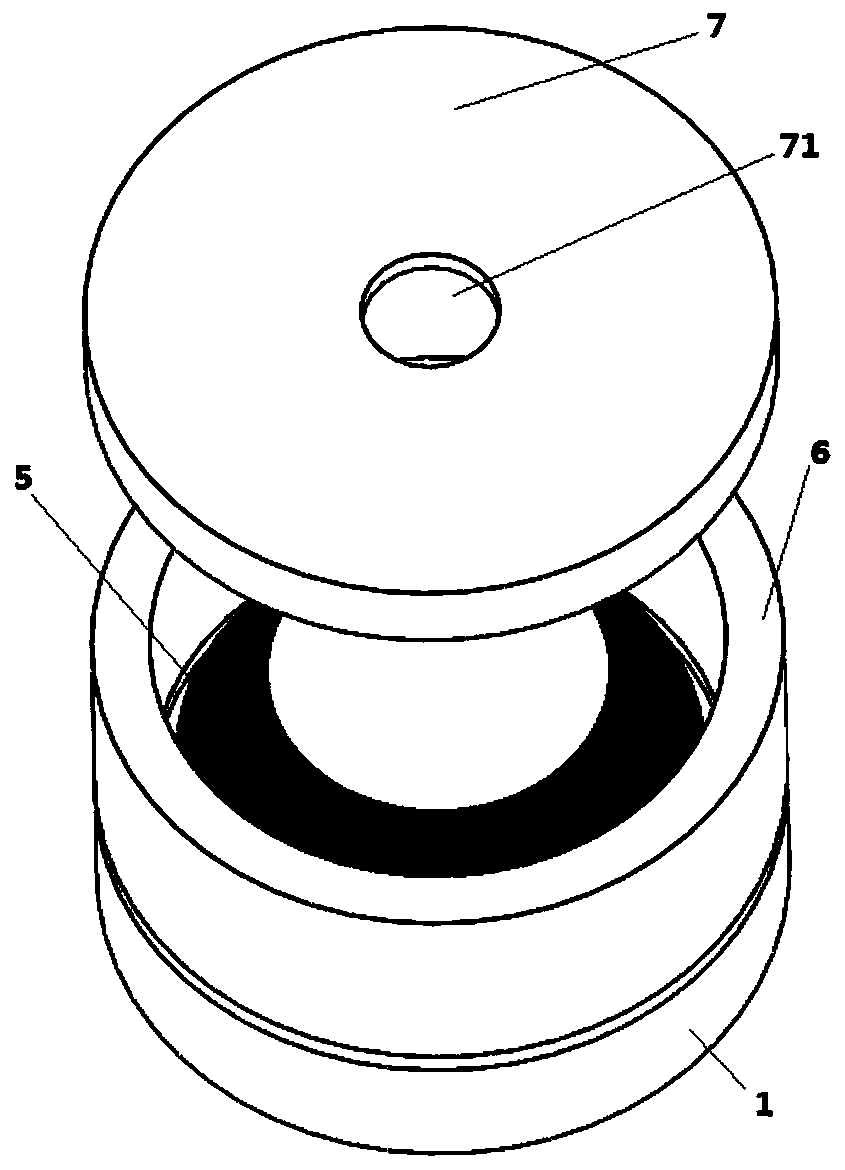

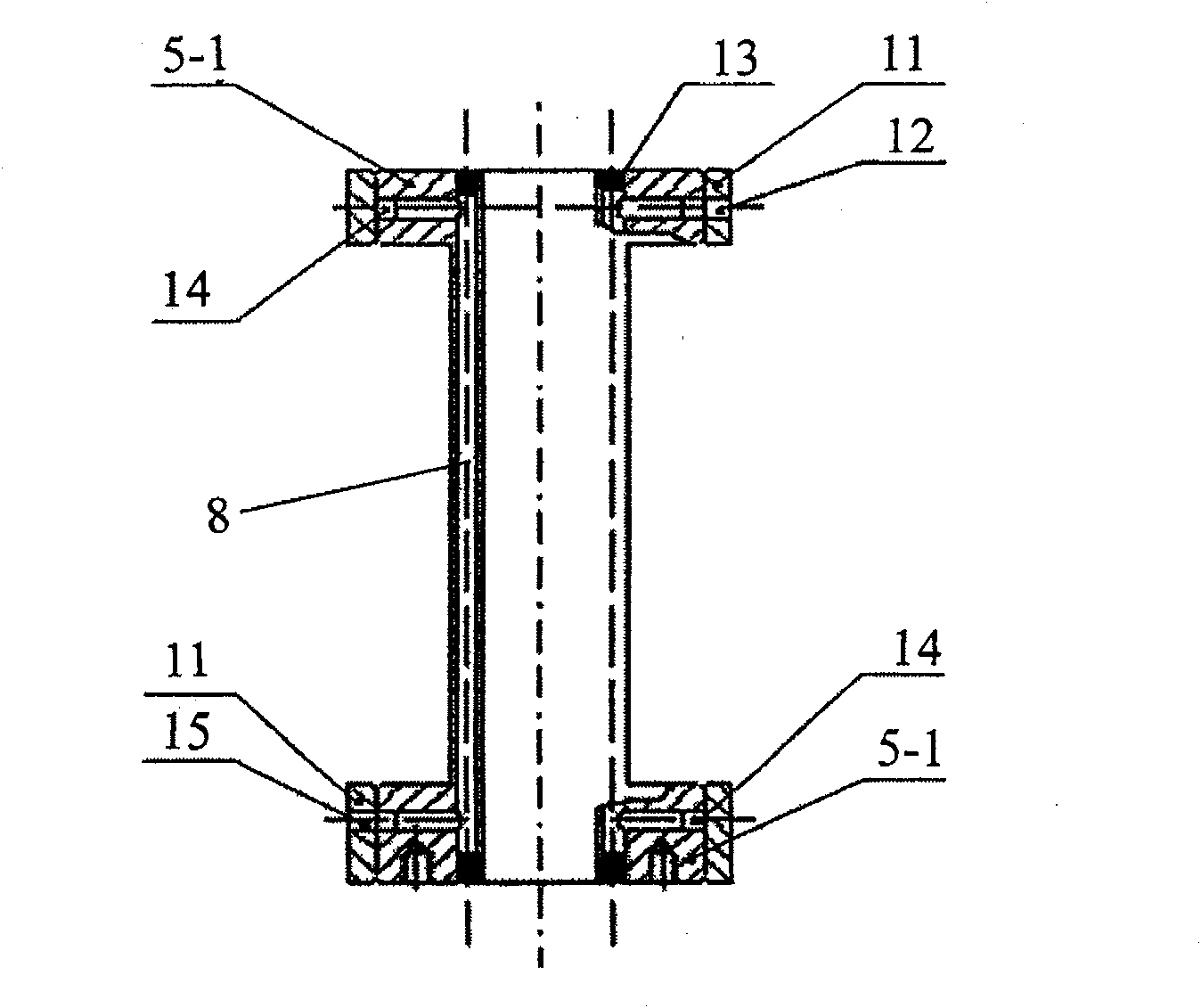

Synthetic jet driver based on dielectric elastomer driving and manufacturing method thereof

ActiveCN109261473ASimple structureEasy to controlMechanical vibrations separationElastic componentEngineering

The invention discloses a synthetic jet driver based on dielectric elastomer driving. The driver includes a front cavity, an elastic component, a dielectric elastomer film, an intermedium ring and a rear cavity. The front cavity and the rear cavity are hollow shells with one end open and the other end closed, and the intermedium ring is a hollow shell with the two ends open; the closed end of therear cavity is provided with a through hole, the open end of the rear cavity is closely connected with the first open end of the intermedium ring, and the second open end of the intermedium ring is connected with the open end of the front cavity. The second open end of the intermedium ring is provided with a dielectric elastomer film, a first inner cavity is formed between dielectric elastomer film and the front cavity, and a second cavity is formed between the dielectric elastomer film, the intermedium ring and the rear cavity; the elastic component is arranged between the front cavity and the dielectric elastomer film. The synthetic jet driver has very simple overall structure and motion control, very high jet speed and ultra low weight, and has great potential application value in the fields of fluid active control, aerospace exploration engineering and the like.

Owner:XI AN JIAOTONG UNIV

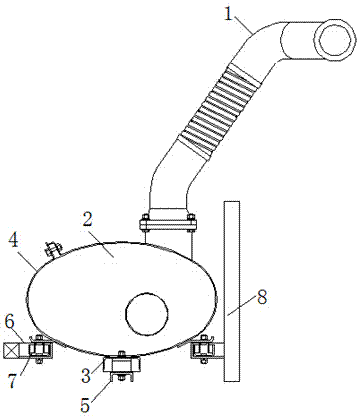

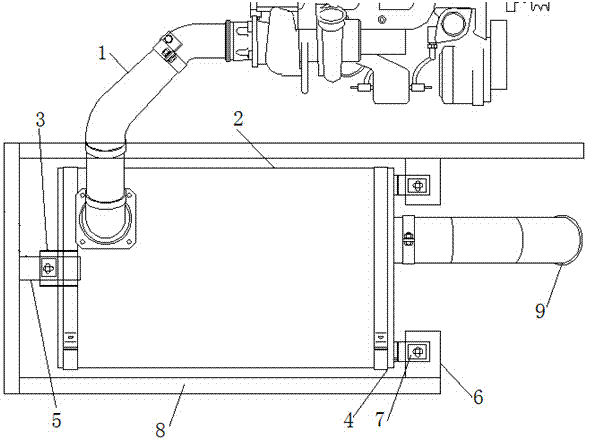

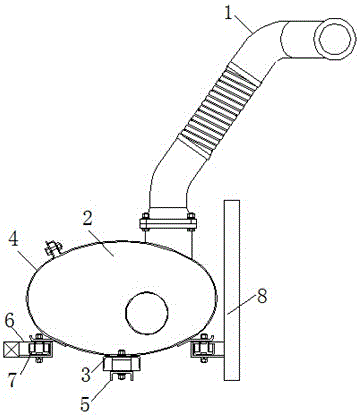

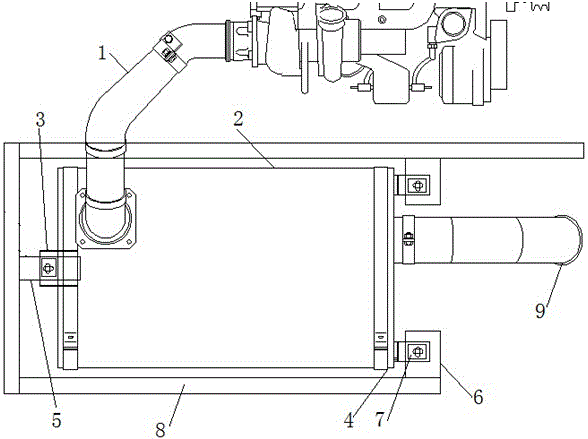

Exhaust suspension device for passenger car

The invention relates to an exhaust suspension device for a passenger car. The exhaust suspension device comprises a single-supporting-point hoop, a double-supporting-point hoop, a first suspension bracket, a second suspension bracket and a third suspension bracket, wherein the single-supporting-point hoop comprises a first hoop and a first bracket arranged at the bottom of the first hoop; a first rubber pad is arranged between the first bracket and the first suspension bracket; a first heat insulating plate for insulating heat of the rubber pad is arranged on the first bracket; the double-supporting-point hoop comprises a second hoop, and a second bracket and a third bracket which are symmetrically arranged on both sides of the bottom of the second hoop; a second rubber pad is arranged between the second bracket and the second suspension bracket; a third rubber pad is arranged between the third bracket and the third suspension bracket; second heat insulating plates for insulating heat of the rubber pads are arranged above the second suspension bracket and the third suspension bracket. The exhaust suspension device has the characteristics of high structural strength, high durability, prevention of fatigue damage, and the like.

Owner:ANHUI ANKAI AUTOMOBILE

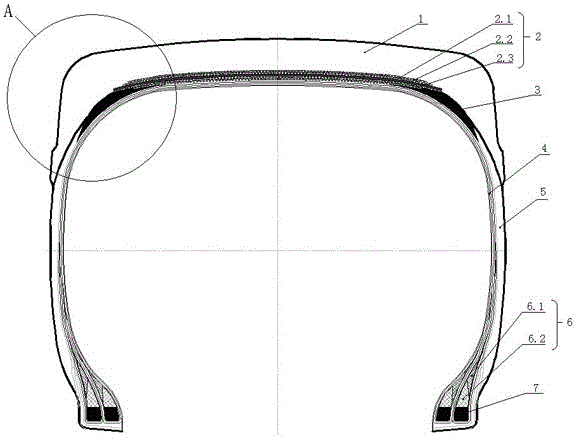

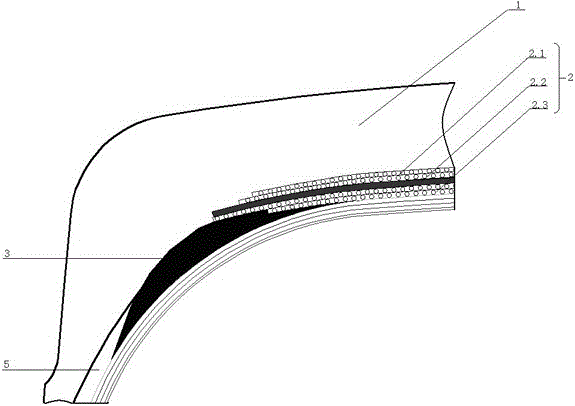

Multi-mining-type high-saturability steel wire-chinlon composite body OTR radial tire

InactiveCN105730150ALarge amount of sinkingReduce the anglePneumatic tyre reinforcementsTire beadMechanical engineering

The invention discloses a multi-mining-type high-saturability steel wire-chinlon composite body OTR radial tire. The multi-mining-type high-saturability steel wire-chinlon composite body OTR radial tire comprises a crown, a tire shoulder, a belted layer, tire body cord fabric, sidewall rubber and a tire bead. Shoulder pad compound is arranged at the joint part of the belted layer and the tire shoulder. Rubber cores and steel wire rings are arranged on the tire bead part. The belted layer comprises a steel wire cord fabric layer I, an insulating rubber plate and a steel wire cord fabric layer II. The insulating rubber plate is located between the steel wire cord fabric layer I and the steel wire cord fabric layer II. The rubber cores are formed by splicing upper triangular rubber core bodies and lower triangular rubber core bodies. The abrasion resistance of the OTR radial tire is about 20% higher than that of bias OTR tires, the oil saving performance of the OTR radial tire is about 13% higher than that of the bias OTR tires, the comprehensive service life of the OTR radial tire is about 50% longer than that of the bias OTR tires, and the OTR radial tire has high cost performance.

Owner:XUZHOU XUGONG TIRES

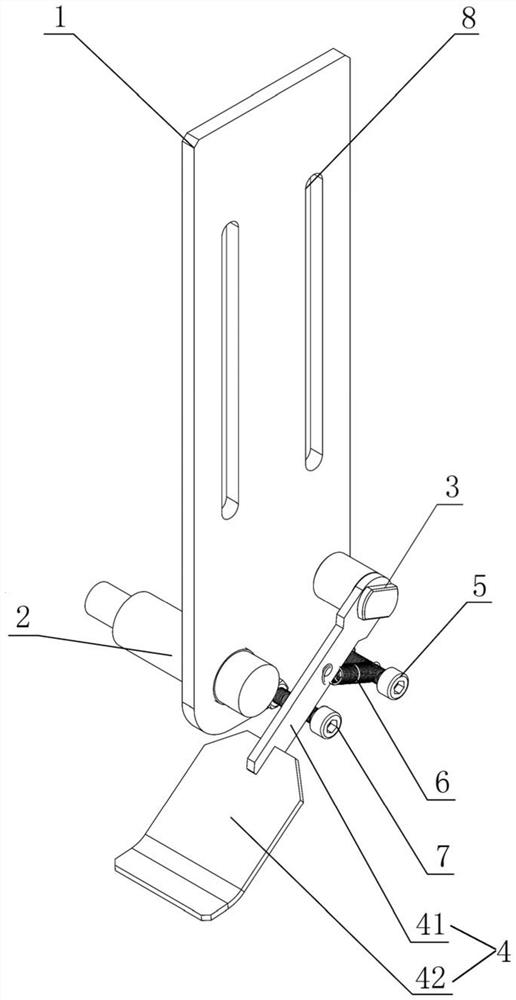

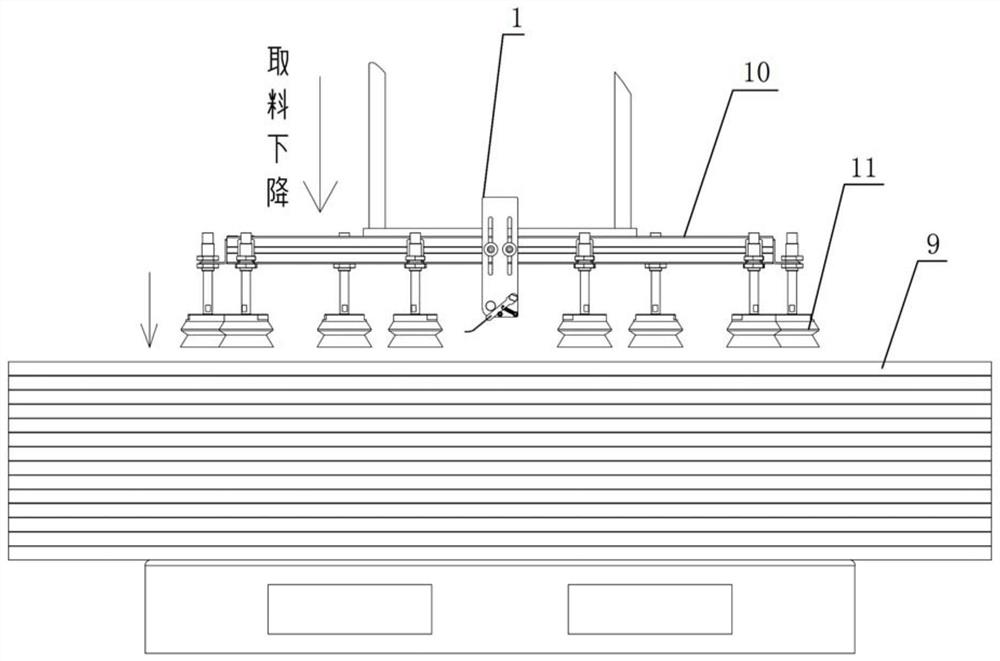

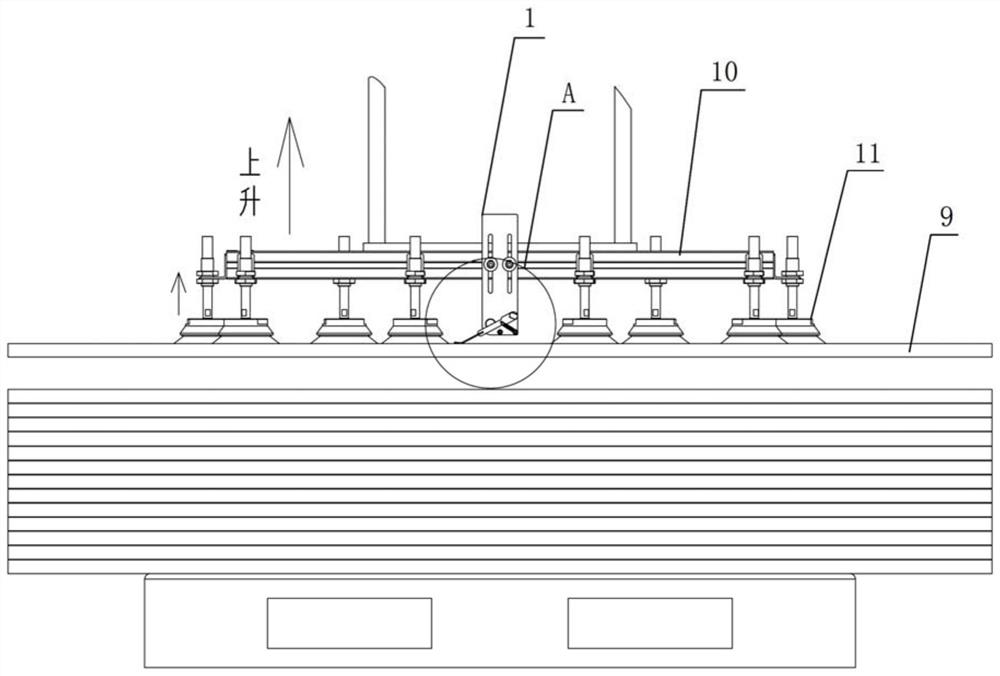

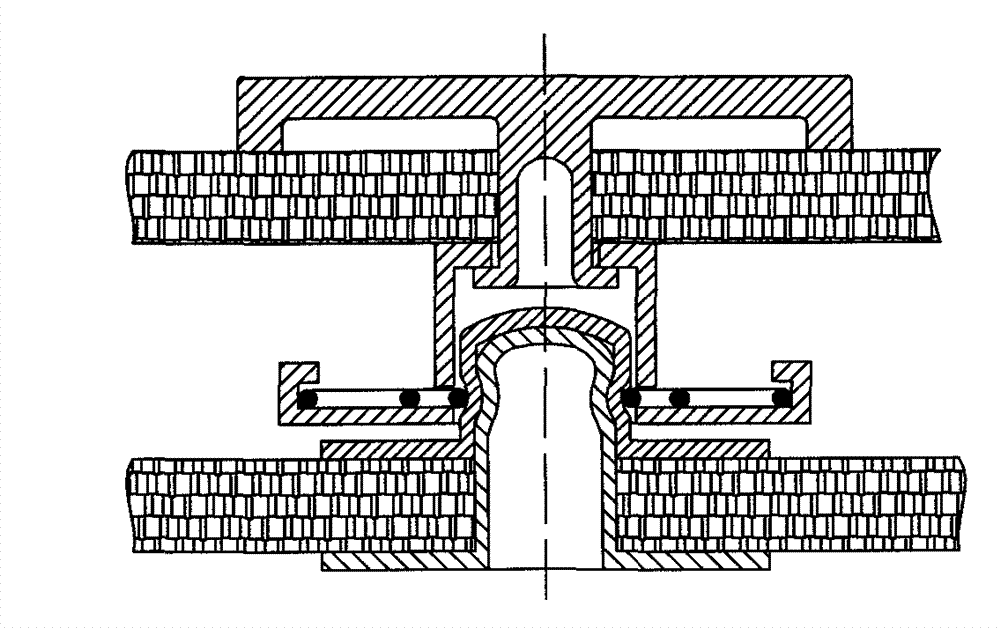

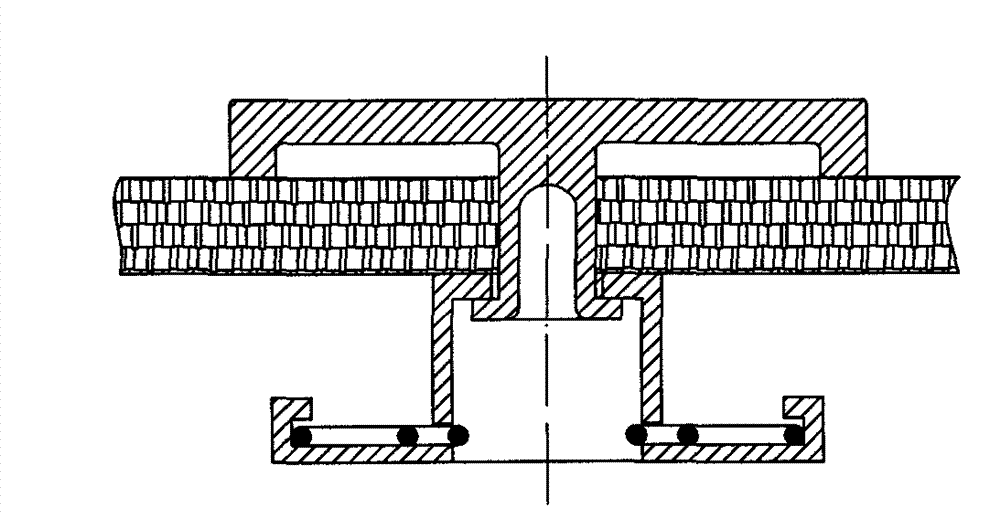

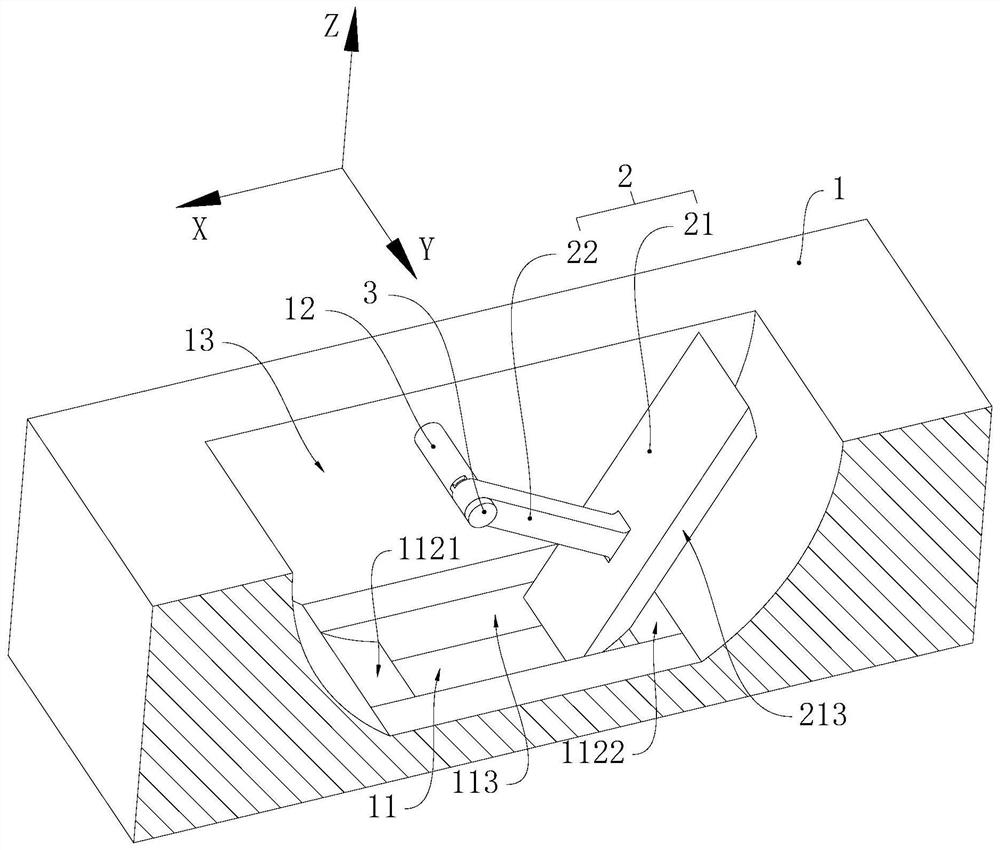

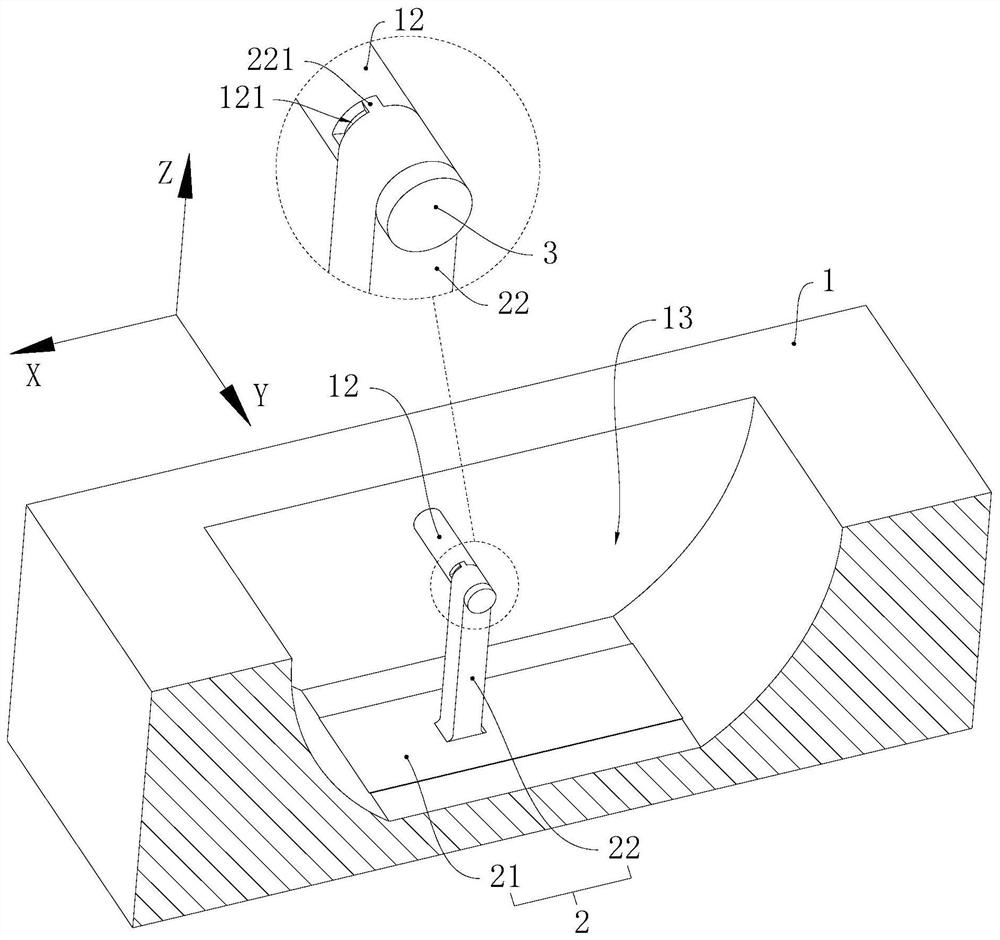

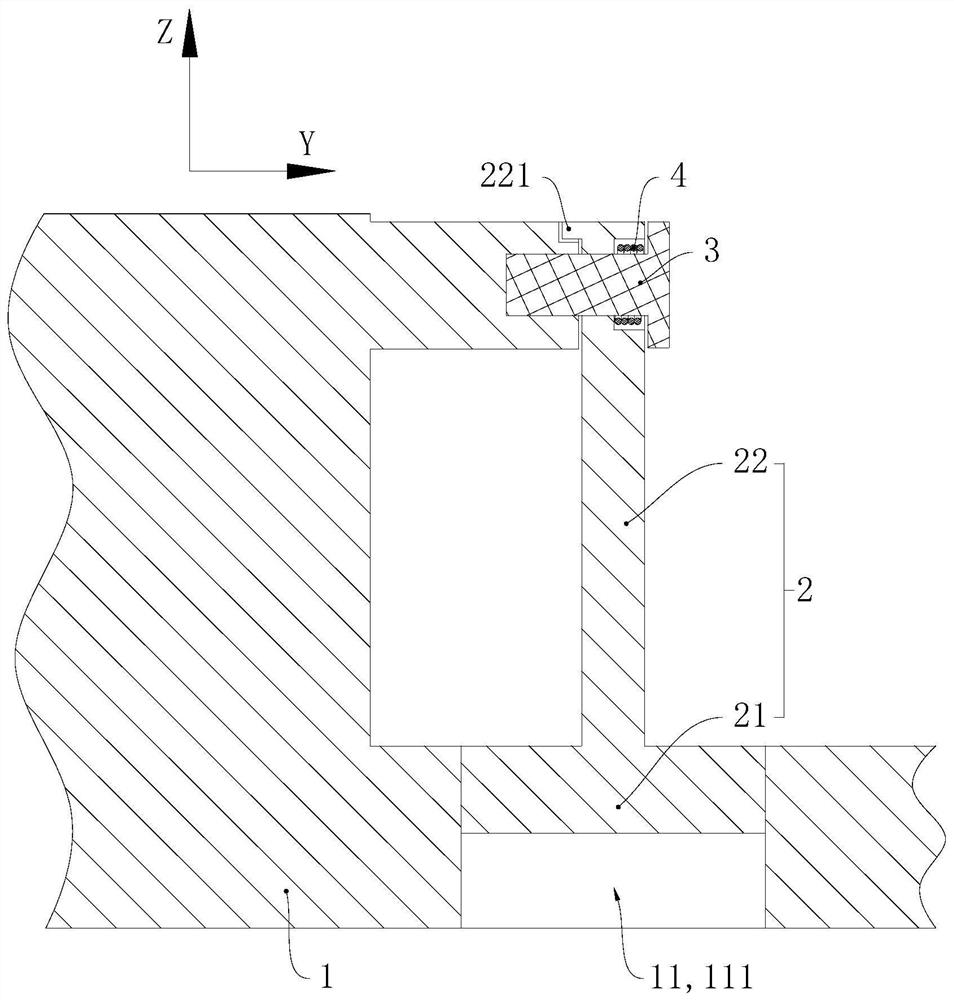

Anti-fatigue manipulator reclaiming detection device

PendingCN111805575ALess prone to fatigue damageReduce maintenance costsManipulatorFatigue damageClassical mechanics

The invention relates to an anti-fatigue manipulator reclaiming detection device. The device comprises a mounting plate, an induction switch, a swing shaft, a swing piece, a fixed rod, an elastic piece and a positioning rod, wherein the induction switch, the swing shaft, the fixed rod and the positioning rod are all arranged on the mounting plate, the fixed rod and the positioning rod are both located below the swing shaft, one end of the swing piece is rotatably connected to the swing shaft, the other end of the swing piece is lapped on the positioning rod, the middle part of the swing pieceis connected to the fixed rod through the elastic piece, and the induction switch is located above the swing piece. The anti-fatigue manipulator reclaiming detection device provided by the invention has the characteristics of not being easy to fatigue damage, low maintenance cost, high responsiveness and high reliability, and more accurate positioning.

Owner:广东联塑安防科技有限公司

Snap fastener of spring surface with round snap spring

InactiveCN103040200AExtended service lifeLess prone to fatigue damageSnap fastenersPress-button fastenersFatigue damageEngineering

The invention discloses a snap fastener of a spring surface with a round snap spring. The snap fastener of the spring surface with the round snap spring has a simple structure and reliable connection, is easy to achieve production automation and is composed of female fasteners and male fasteners which are respectively riveted with fabric and can be fastened and released with each other, wherein the female fasteners are formed by riveting the fabric with the spring surface with orifices provided with elastic snap springs. The snap fastener of the spring surface with the round snap spring is characterized in that the elastic snap spring is an round opening snap spring with the size of an inner hole smaller than the external diameter of the head of the male fastener; a ring sink pit is arranged on the orifice of the spring surface, the round opening snap spring is arranged in the ring sink pit, the end face of the orifice of the spring surface is fixed with a block piece which can prevent the round opening snap spring from coming off from the sink pit. By almost snapping the male fastener all around, the connection between the female fastener and the male fastener is very reliable. Besides, an elastic round snap spring with the structure has a long service life and is difficult to lead to a fatigue damage, thereby being more applicable to large-scale automatic production.

Owner:嘉善雄真金属钮扣厂(普通合伙)

Adapter for transferring torque between square and square bore shafts

ActiveCN104948596BFlexible fillingEfficient fillingYielding couplingWork measurementFatigue damageControl theory

The invention discloses an adapter piece for transmitting torque between a square shaft and a square hole shaft, which belongs to the technical field of measurement and the field of mechanical assembly accessories. The adapter for transmitting torque between a square shaft and a square hole shaft according to the present invention includes a square cylinder, the inner and outer radial surfaces of the square cylinder are adapted to the square shaft and the square hole respectively, and the square cylinder is a split type , which is composed of two symmetrical right-angle gaskets. Under the torsion state, the two right-angle gaskets open to the surroundings and fit with the inner wall of the square hole; the upper ends of the right-angle gaskets are respectively provided with mounting pieces. The mounting tabs are perpendicular to the right-angle spacers. The adapter of the present invention can be tightly attached to the inner wall of the square hole when in use, is only subjected to pressure, transmits torque through force without being subjected to torque, is not damaged by torsion, and is not easily damaged by fatigue. The adapter of the present invention can be automatically centered when it is twisted, so that the rotation centerlines of the two right-angled gaskets coincide with the axes of the square shaft and the square hole.

Owner:刘军

A highway cold-formed U-shaped composite girder bridge and its construction method

ActiveCN110106772BImprove fatigue performanceLess prone to fatigueBridge structural detailsBridge materialsWelding residual stressArchitectural engineering

The invention discloses a highway cold-formed U-shaped composite girder bridge and a construction method thereof. Structurally, a plurality of U-shaped steel plates are spliced into a bridge main steel structure; the U-shaped steel plate is a concrete pouring area, an asphalt layer is laid on the concrete, and the bridge head is arranged Gate frame, guardrails and lamp posts on both sides of the bridge. Compared with the prior art, the U-shaped steel plate of the present invention does not require welding for cold-bending forming, which avoids welding quality problems and welding residual stress; the spliced steel girder segments in the factory are transported to the site, and then concrete is poured to form a bridge. The steel beam segments replace the construction formwork, optimize the construction process, improve the construction quality and shorten the construction period. The flexural bearing capacity of the cold-formed U-shaped composite beam is three times that of the hollow slab beam with the same span, and it can reduce concrete cracking diseases and enhance the durability of the bridge.

Owner:HOHAI UNIV

A synthetic jet driver driven by a dielectric elastomer and its manufacturing method

ActiveCN109261473BSimple structureEasy to controlMechanical vibrations separationJet flowEngineering

The invention discloses a synthetic jet driver based on dielectric elastomer driving. The driver includes a front cavity, an elastic component, a dielectric elastomer film, an intermedium ring and a rear cavity. The front cavity and the rear cavity are hollow shells with one end open and the other end closed, and the intermedium ring is a hollow shell with the two ends open; the closed end of therear cavity is provided with a through hole, the open end of the rear cavity is closely connected with the first open end of the intermedium ring, and the second open end of the intermedium ring is connected with the open end of the front cavity. The second open end of the intermedium ring is provided with a dielectric elastomer film, a first inner cavity is formed between dielectric elastomer film and the front cavity, and a second cavity is formed between the dielectric elastomer film, the intermedium ring and the rear cavity; the elastic component is arranged between the front cavity and the dielectric elastomer film. The synthetic jet driver has very simple overall structure and motion control, very high jet speed and ultra low weight, and has great potential application value in the fields of fluid active control, aerospace exploration engineering and the like.

Owner:XI AN JIAOTONG UNIV

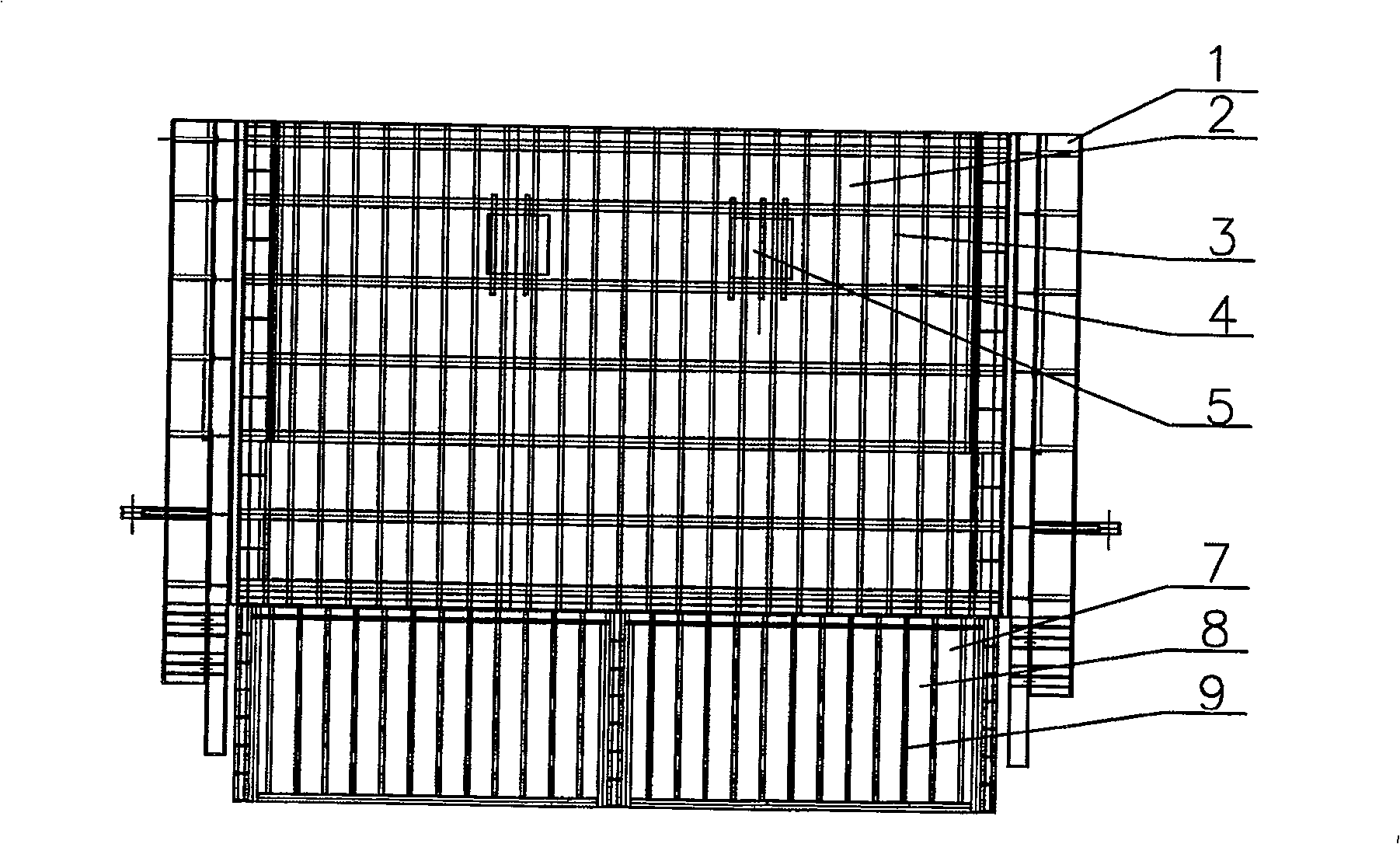

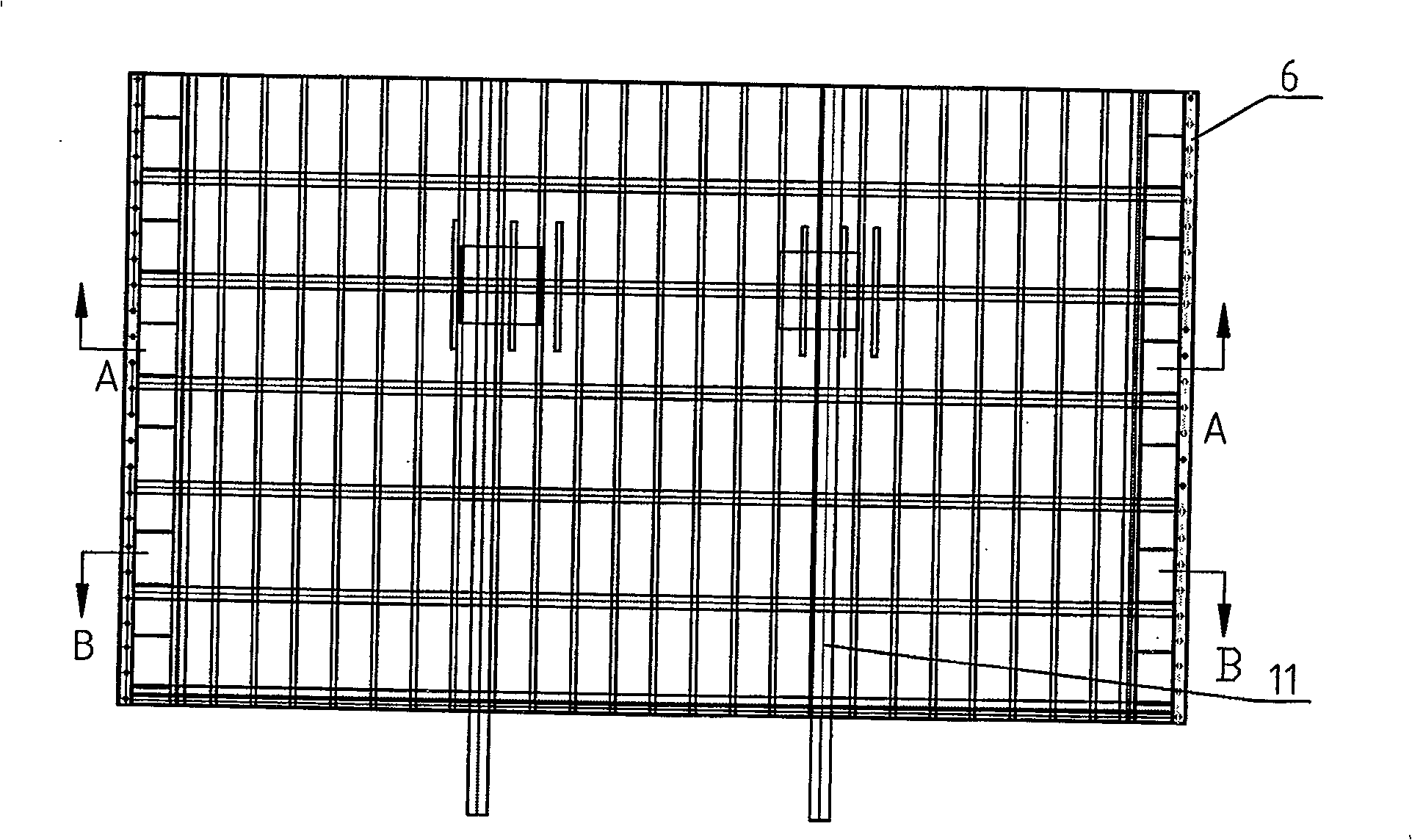

Steel boxed cofferdam and recovery method thereof

ActiveCN100535264CGuaranteed watertightnessCompact structureCaissonsBulkheads/pilesRecovery methodSheet steel

The invention relates to a steel box cofferdam and a recovery method thereof, in particular to a steel box cofferdam used in the construction of deep foundations, long-span bridge caps and upsetting columns and a recovery method thereof. The steel caisson of the present invention includes an upper section and a bottom section, between which are bolted with water-tight angle steel flanges; There are horizontal ribs, and the upper panel is bolted with water-tight angle steel flanges; the bottom section includes the bottom panel made of steel plate, the bottom panel is evenly distributed with vertical ribs horizontally, and the bottom panel is detachable and fastened connect. The invention has the advantages of traditional caissons and steel plate cofferdams, can be reused, has low cost, less soil excavation, less impact on adjacent buildings, deep buried caisson foundation, good stability, and greater support load, the water-stop effect is good.

Owner:SHANDONG LUQIAO GROUP

An improved structure of a harmonic reducer flex wheel

ActiveCN109578547BAvoid the problem of repeated deformation and vulnerabilityLess prone to fatigue damageGearingGearing detailsFatigue damageCompliant mechanism

The invention relates to the technical field of high-precision reducers, and discloses an improved structure of a flexible wheel of a harmonic reducer. The improved structure comprises a rigid wheel and a wave generator; an output disk is movably sleeved with one end of an inner cavity of the rigid wheel; and eight separating strips are arranged on the front side of the output disk, are distributed on the front side of the output disk in a ring array manner and are in sector shapes. According to the improved structure, the traditional flexible wheel is improved to comprise the output disk, theseparating strips and flexible mechanisms, through cooperation with the restoring tension force effect of reset tension springs, the flexible mechanisms are pushed out of the output disk sequentiallyby the aid of the long-axis part of the wave generator, and teeth outside rigid arc plates mesh with inner teeth of the rigid wheel, so that the speed reduction effect equivalent that of flexible wheels in the prior art is realized; compared with the prior art, the improved structure has the advantages that repeated deformation of the flexible wheel is changed into reciprocating sliding of the flexible mechanisms, deformation of the flexible wheel is changed into deformation of the reset tension springs, thus the problem that the flexible wheel is prone to damage due to repeated deformation is avoided, and meanwhile, the reset tension springs are not prone to fatigue damage and are cheap to replace.

Owner:XINYI XIYI ADVANCED MATERIALS RES INST OF IND TECH CO LTD

Discharge valve assembly, compressor and air conditioner

ActiveCN112212039BLess prone to fatigue damageReduce running noiseCheck valvesValve members for absorbing fluid energyExhaust valveImpact

The invention relates to the field of compressors, and provides an exhaust valve assembly, a compressor and an air conditioner. The exhaust valve assembly includes a base body and a movable body, and the base body is provided with an exhaust hole penetrating along the first direction; the movable body is rotatably connected to the base body, and the axis of rotation of the movable body relative to the base body is the first axis, and the first axis is along the first axis. Two directions, the second direction intersects with the first direction; the movable body and the base body are provided with a limit fit structure at the rotational connection, the limit fit structure includes a first limit part and a second limit part, and the first limit part is fixed On the base, the second limiting part is fixed on the movable body; the first limiting part and the second limiting part are distributed along the circumferential direction of the first axis; the second limiting part abuts against the first limiting part , the movable body blocks the vent holes and projects along the first direction, and the projected areas of the vent holes on both sides of the first axis are different in size. The movable body is not easy to be fatigued and damaged due to collision and impact, and it is beneficial to reduce the running noise of the exhaust valve assembly.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

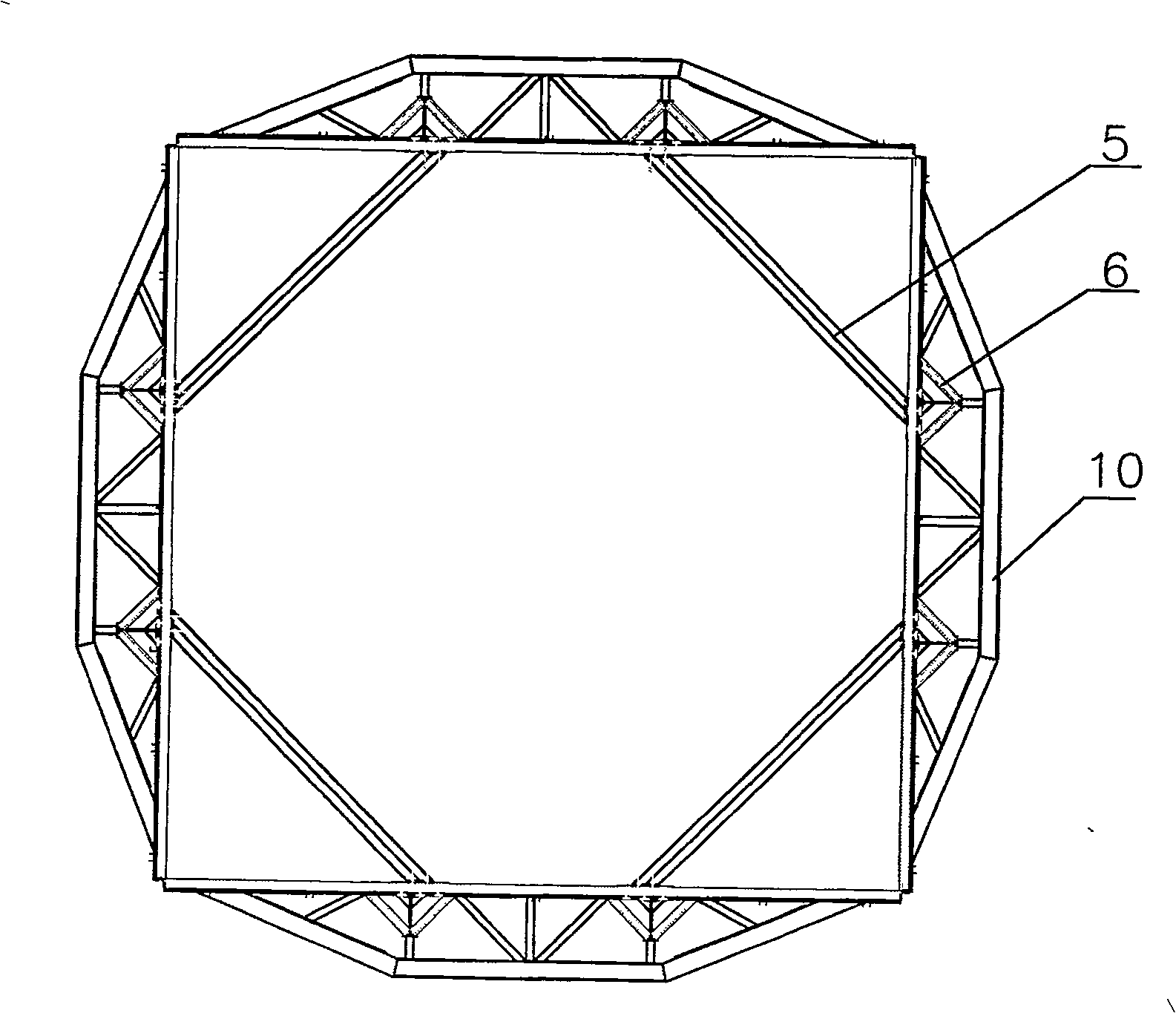

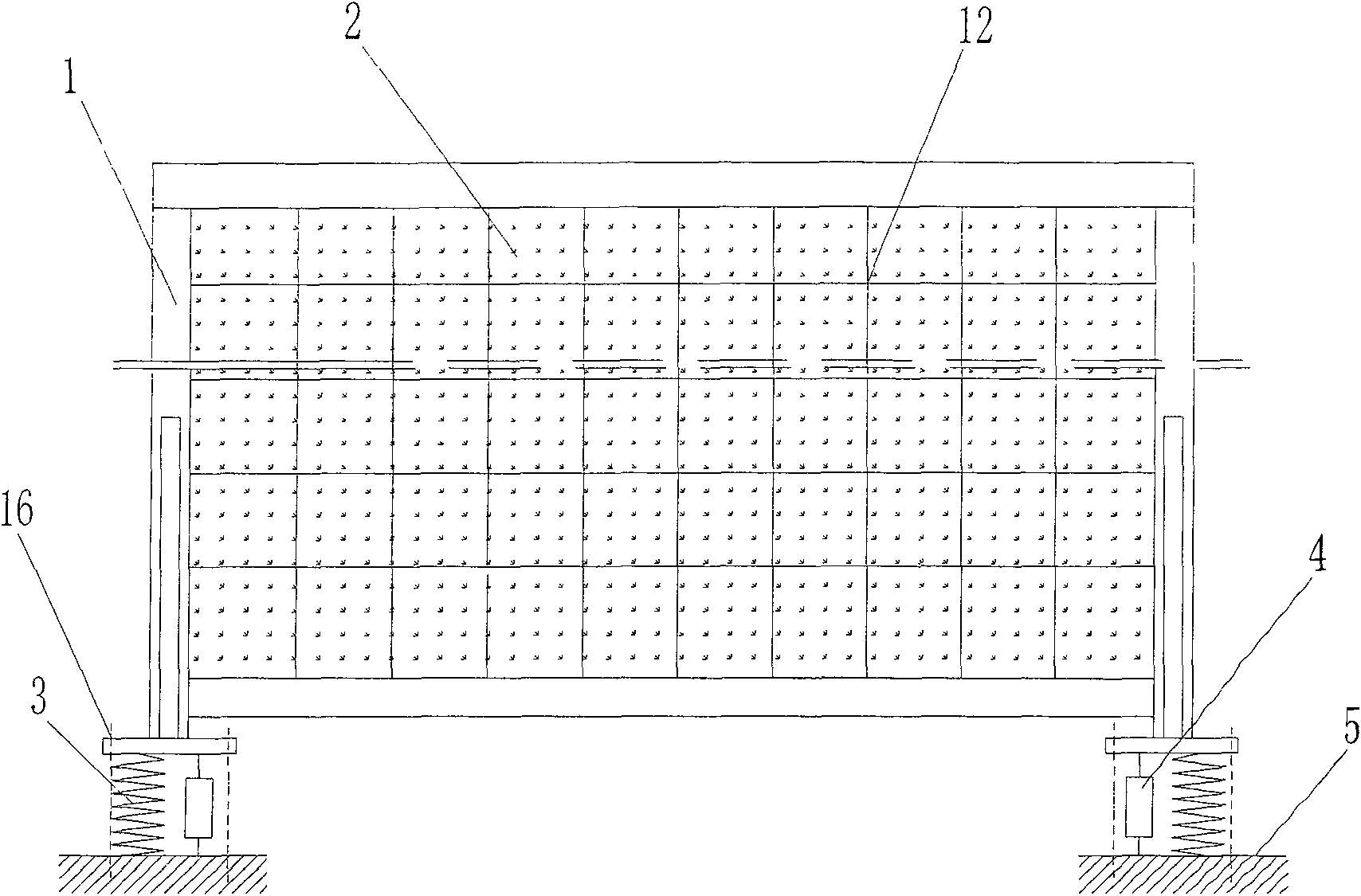

Sound absorbing and insulating barrier

ActiveCN100575610CReduced number of fatigue stress cyclesReduce the excitation forceNoise reduction constructionEngineering

The invention relates to a shield besides road to adsorb noise, which comprises a sound adsorption shield and a support frame, wherein the shield plate and the support frame or / and support frame and the base are connected via flexible element or / and damping element, the flexible element and the damping element can be serially, parallel or integrally connected. The invention can improve sound adsorption ability and protect the base, with long service life, less increase on the load of road, and high safety or the like.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH

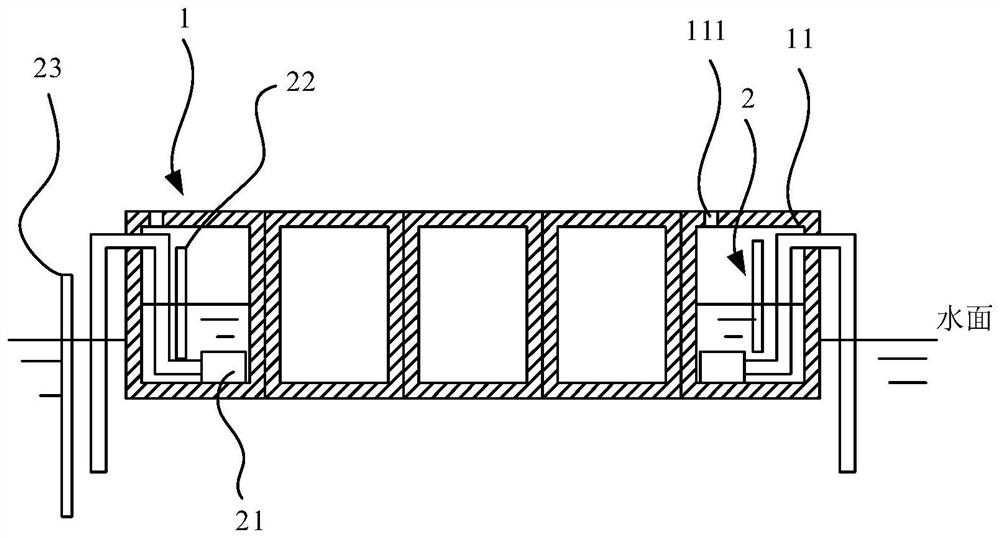

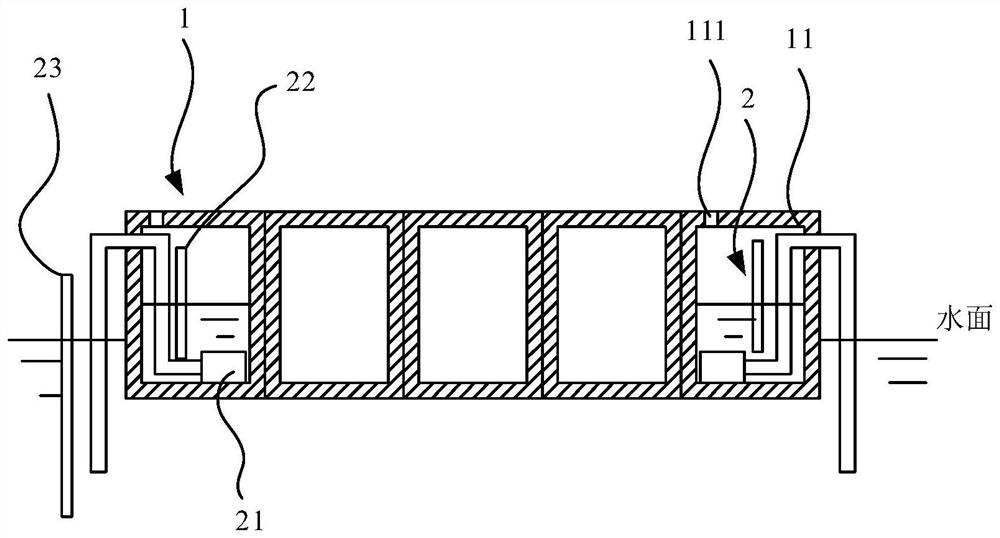

A kind of pontoon and its using method, pontoon bridge

ActiveCN111608067BConducive to long-term safe operationStable forceBridge structural detailsFloating bridgesFatigue damagePontoon bridge

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

A production process of a ball stud

ActiveCN109483177BAvoid crackingHigh surface hardnessFurnace typesPivotal connectionsFatigue damageStress concentration

The invention discloses a production process of a ball pin, and relates to machining technologies. The production process of the ball pin is used for solving the problem that a common ball pin is prone to breakage. The production process comprises the following steps that (1) material selection and blanking are carried out; (2) forging and strengthening are carried out, and specifically a metal raw material in the step (1) is heated to 700-750 DEG C and then undergoes hot forging; (3) rough blank shaping is carried out, and specifically the forged metal is heated to 850-890 DEG C again, and then undergoes rolling shaping by using a die; (4) rough blank grinding is carried out; (5) heat treatment is carried out; and (6) post-processing is carried out. The production process of the ball pinhas the following advantages and effects that the ball pin formed through hot forging and rolling is not prone to crack due to the technological problem in the manufacturing process, then the ball pinis not prone to breakage due to stress concentration at the cracking position in the using process, moreover, the ball pin has relatively high surface hardness while the toughness of the core part isreserved by adopting the forming mode, then the fatigue damage is not prone to occurrence in the using process of the ball pin, and then the breakage is further not prone to occurrence.

Owner:ZHEJIANG TONGSHI AUTO PARTS

Exhaust suspension device for passenger car

The invention relates to an exhaust suspension device for a passenger car. The exhaust suspension device comprises a single-supporting-point hoop, a double-supporting-point hoop, a first suspension bracket, a second suspension bracket and a third suspension bracket, wherein the single-supporting-point hoop comprises a first hoop and a first bracket arranged at the bottom of the first hoop; a first rubber pad is arranged between the first bracket and the first suspension bracket; a first heat insulating plate for insulating heat of the rubber pad is arranged on the first bracket; the double-supporting-point hoop comprises a second hoop, and a second bracket and a third bracket which are symmetrically arranged on both sides of the bottom of the second hoop; a second rubber pad is arranged between the second bracket and the second suspension bracket; a third rubber pad is arranged between the third bracket and the third suspension bracket; second heat insulating plates for insulating heat of the rubber pads are arranged above the second suspension bracket and the third suspension bracket. The exhaust suspension device has the characteristics of high structural strength, high durability, prevention of fatigue damage, and the like.

Owner:ANHUI ANKAI AUTOMOBILE

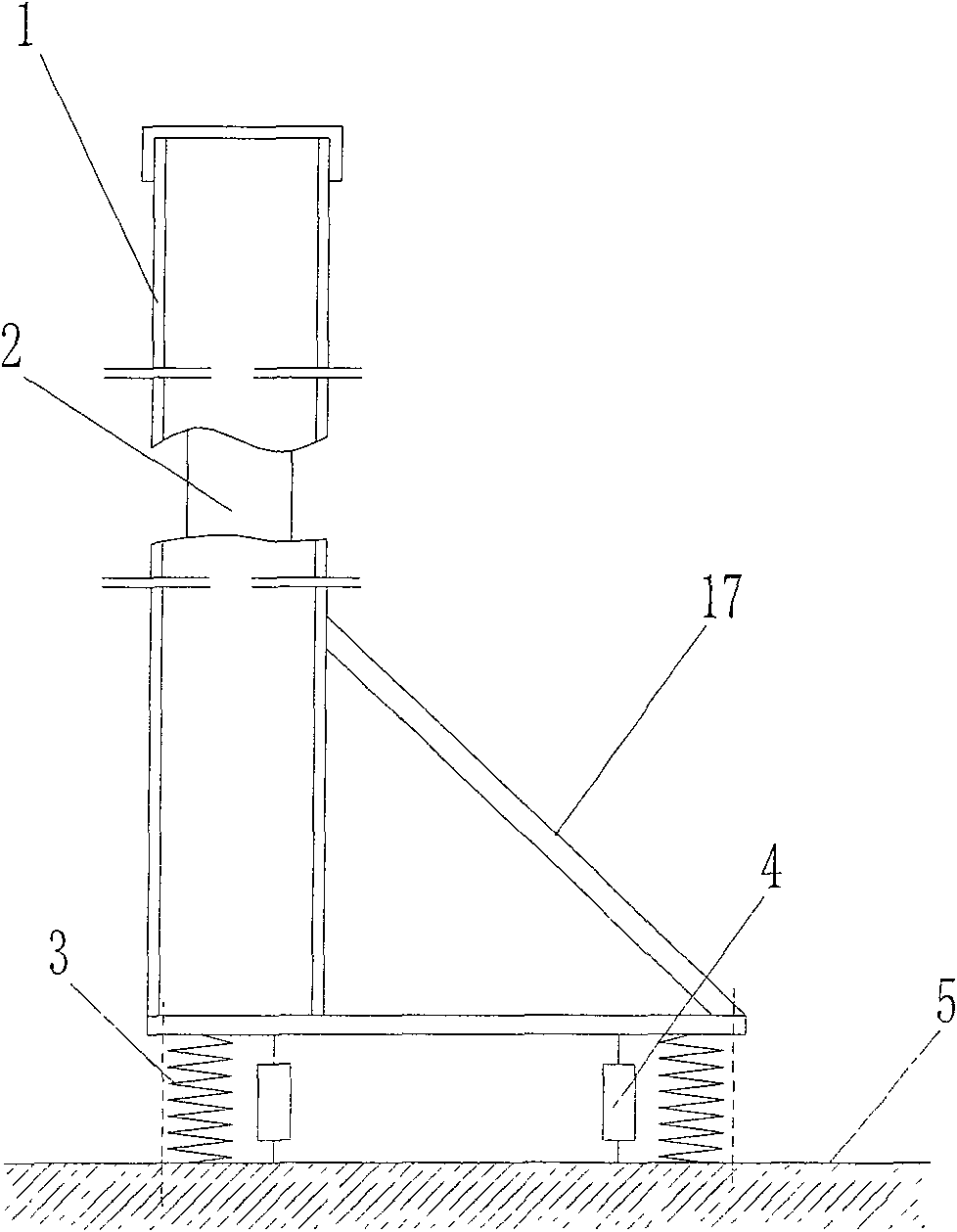

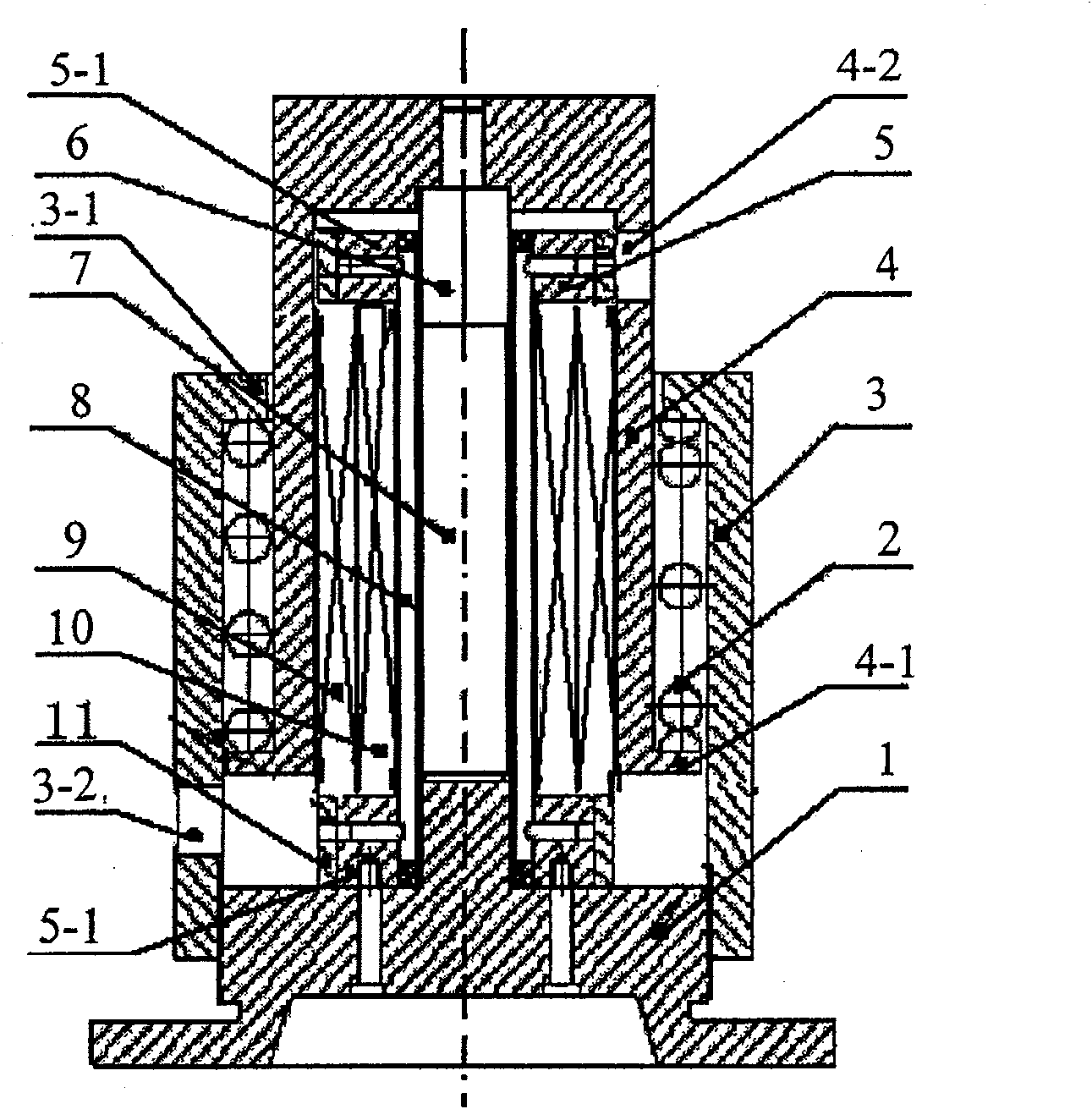

Excitation device

InactiveCN100548511CSimple structureImprove cooling effectMechanical vibrations separationFatigue damageBobbin

The vibration excitation device disclosed by the present invention includes a base, a coil skeleton, an AC coil, a DC coil, an inner sleeve, a spring and an outer sleeve from the inside to the outside of the coaxial line device, and the center hole of the coil skeleton is placed on the positioning boss of the base and fastened to the base, a giant magnetostrictive rod and a positioning block are built in the center hole of the coil frame, one end of the positioning block is in contact with the giant magnetostrictive rod, and the other end is placed in the center positioning concave hole of the inner sleeve . When working, the workpiece is fixed on the base of the excitation device or the bottom surface of the inner sleeve, and the giant magnetostrictive rod is in the mixed magnetic field generated by the AC coil and the DC coil. The telescopic rod produces telescopic deformation along the axial direction, and pushes the positioning block and the inner sleeve to reciprocate and vibrate at high frequency along the axial direction. The vibration excitation device of the present invention has simple structure and good heat dissipation, and high-frequency vibration can be conveniently realized by changing the frequency of the AC power supply, and the vibration frequency can reach 1000-3000 Hz, which can effectively prevent fatigue damage of workpieces.

Owner:ZHEJIANG UNIV

Novel intelligent vibration isolation noise reduction composite structure system and usage method thereof

ActiveCN102413401BReduce noise radiationVibration isolation is effectiveTransducers for subaqueous useFrequency/directions obtaining arrangementsEngineeringNoise reduction

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

A detergent dispenser

ActiveCN110777515BEasy to addThe direction of force is single and stableOther washing machinesTextiles and paperLaundry washing machineGear pump

Owner:HANGZHOU GOLDCOSMOS ELECTRONICS +1

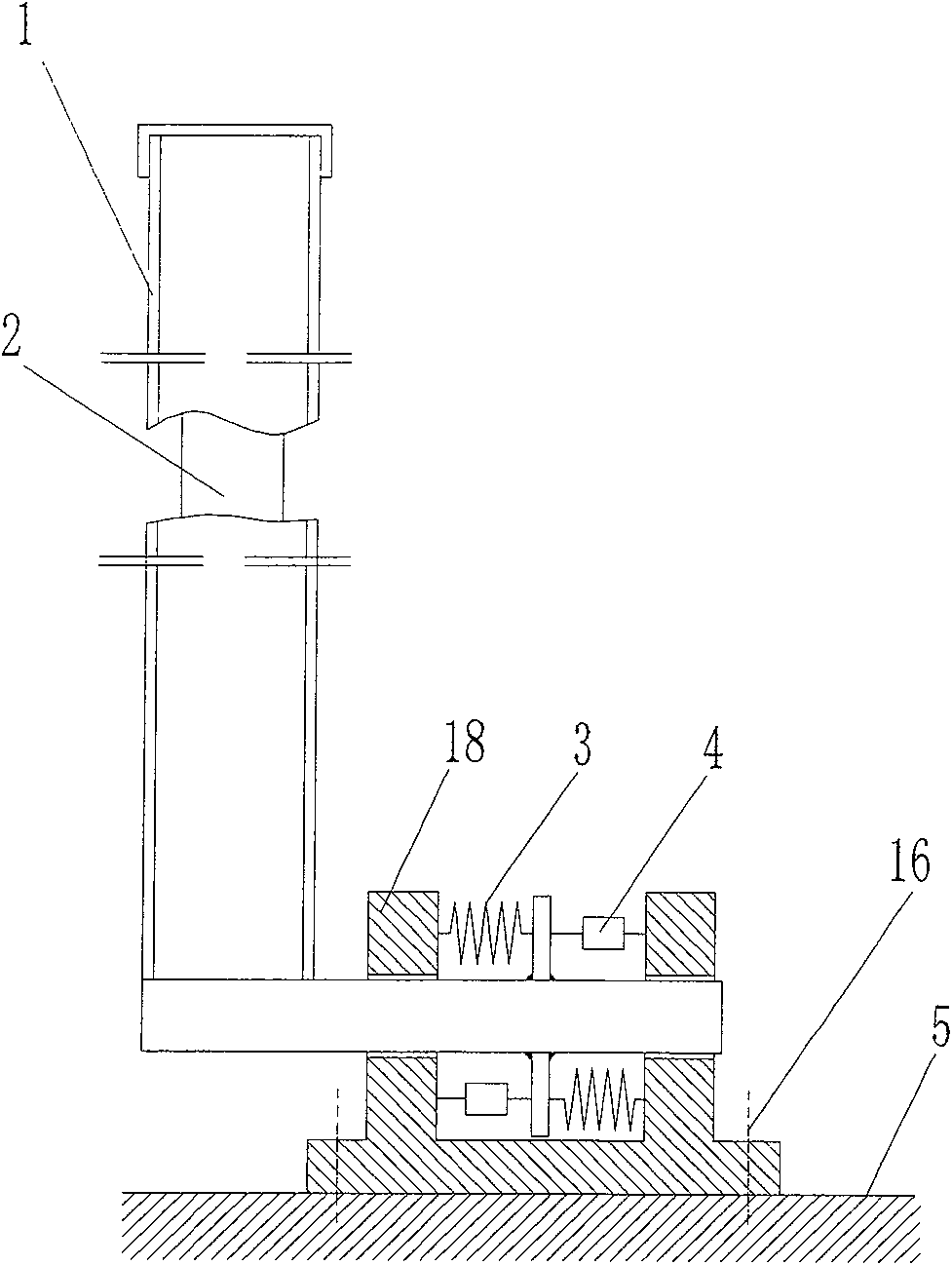

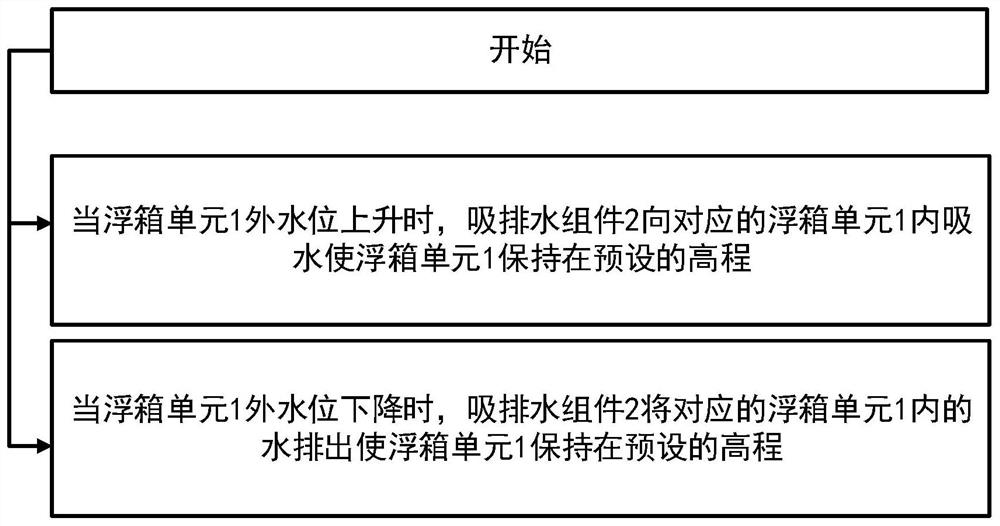

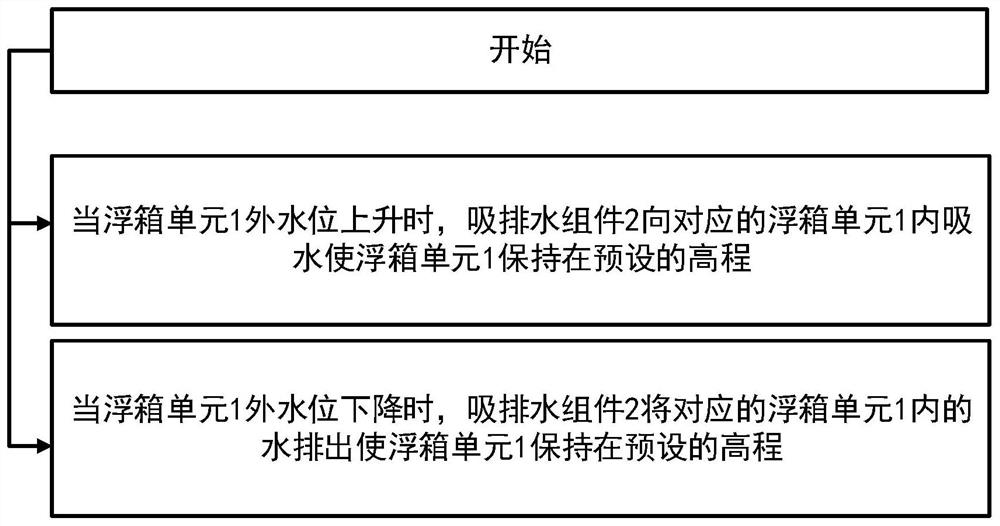

Buoyancy tank, using method thereof and floating bridge

ActiveCN111608067AConducive to long-term safe operationStable forceBridge structural detailsFloating bridgesFatigue damagePontoon bridge

The invention discloses a buoyancy tank, a using method thereof and a floating bridge, which relate to the technical field of floating bridges. The buoyancy tank comprises a plurality of buoyancy tankunits movably connected along a bridge, a water suction and drainage assembly is arranged in each buoyancy tank unit in a matched mode, and the water suction and drainage assemblies are configured inthe mode that when the water level outside the buoyancy tank units rises, the water suction and drainage assemblies suck water into the corresponding buoyancy tank units so that the buoyancy tank units can be kept at a preset elevation, and when the water level outside the buoyancy tank units descends, the water suction and drainage assemblies drain water in the corresponding buoyancy tank unitsso that the buoyancy tank units can be kept at the preset elevation. The mooring device and the telescopic device which are connected with the buoyancy tank can be stressed stably, fatigue damage is not prone to occurring, and long-term safe operation of the floating bridge is facilitated.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com