Preparation method of impact-resistant self-recovery bionic composite material

A biomimetic composite material and composite material technology are applied in the field of preparation of self-recovery biomimetic composite materials, which can solve the problems of difficulty in restoring the original shape, poor material recycling rate, insufficient impact resistance of materials, etc. Good performance and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

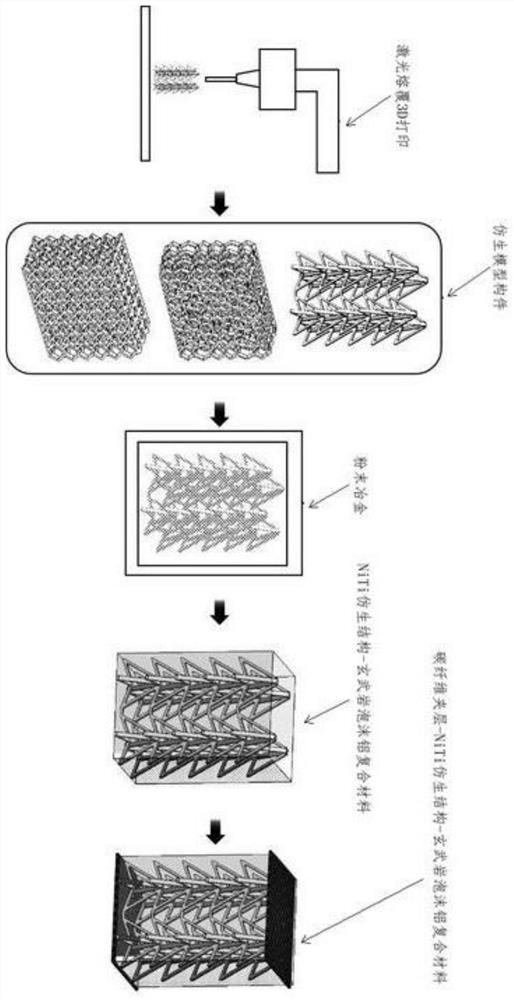

[0060] A kind of preparation method of the impact-resistant self-restoring biomimetic composite material of the present invention, comprises:

[0061] Include the following steps:

[0062] Step 1. Prepare bionic model

[0063] With Ni 50.8 Ti 49.2 Powder is the printing material for 3D printing of bionic models;

[0064] Step two,

[0065] 2a) Preparation of aluminum-basalt composite powder

[0066] Mix aluminum powder and basalt fiber powder evenly according to the mass ratio of 5:1, ball mill, wash, and dry to obtain aluminum-basalt composite powder particles;

[0067] 2b) Preparation of composite enveloping blowing agent

[0068] When the nickel sulfate solution is heated to 80°C, add foaming agent powder and keep stirring, when stirring until the pH range is between 6-8, perform electroless plating, and dry at 100-120°C to obtain a composite package network foaming agent;

[0069] Foaming agent powder is TiH 2 Powder or ZrH 2 or CaCO 3 ;

[0070] 2c) Mixed powd...

Embodiment 1

[0096] The printing parameters of the printer device are:

[0097]

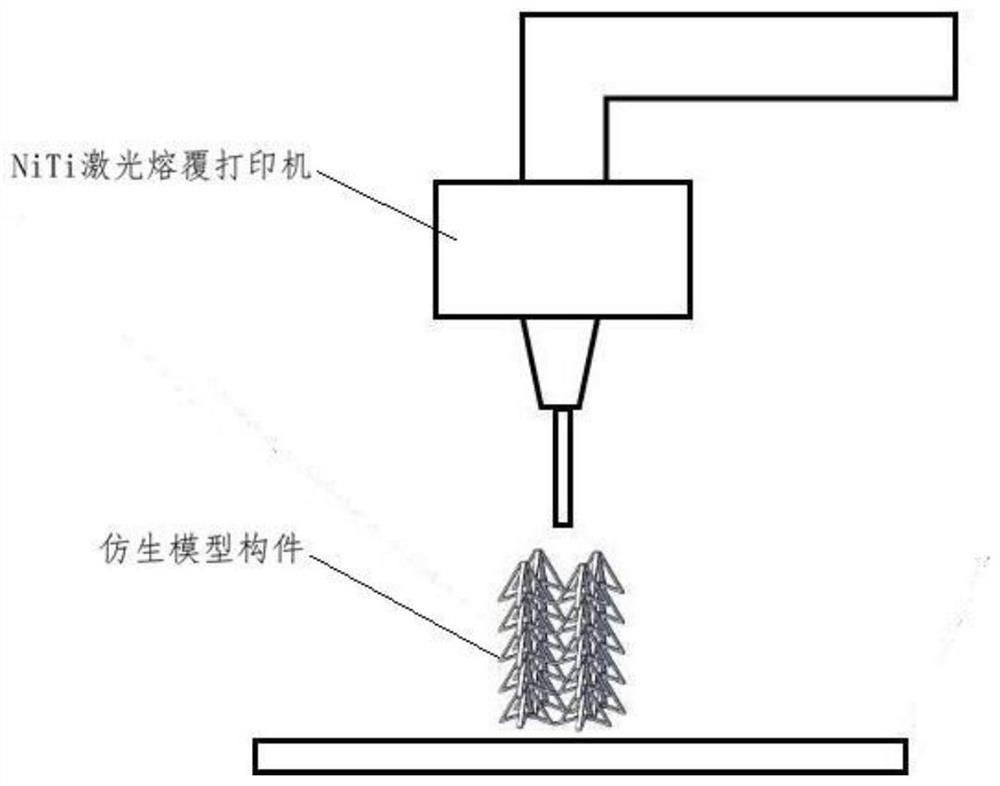

[0098] 3D printing bionic model: BLT-S210 printer performs NiTi powder with a particle size of 15-53 μm 50.8 Ti 49.2 Model laser cladding and printing to manufacture a chiral bionic model, put the model into the mold and glue it to the middle of the bottom of the mold;

[0099] Preparation of aluminum-basalt composite powder: Mix aluminum powder and basalt fiber powder with a mixing mass ratio of 5:1, and use a high-energy ball mill to ball mill and mix the mixed powder to form composite aluminum cladding powder;

[0100] Then, the powder particles are cleaned with alcohol, and dried to obtain aluminum-basalt composite powder particles;

[0101] Preparation of composite enveloping foaming agent: In order to improve the quality of foam molding, nickel sulfate solution (NiSO 4 ·6H 2 0) When the temperature reaches 80°C, pour the foaming agent TiH2 powder into the solution and keep stirring. During this p...

Embodiment 2

[0109] The printing parameters of the printer equipment are the same as those in Embodiment 1:

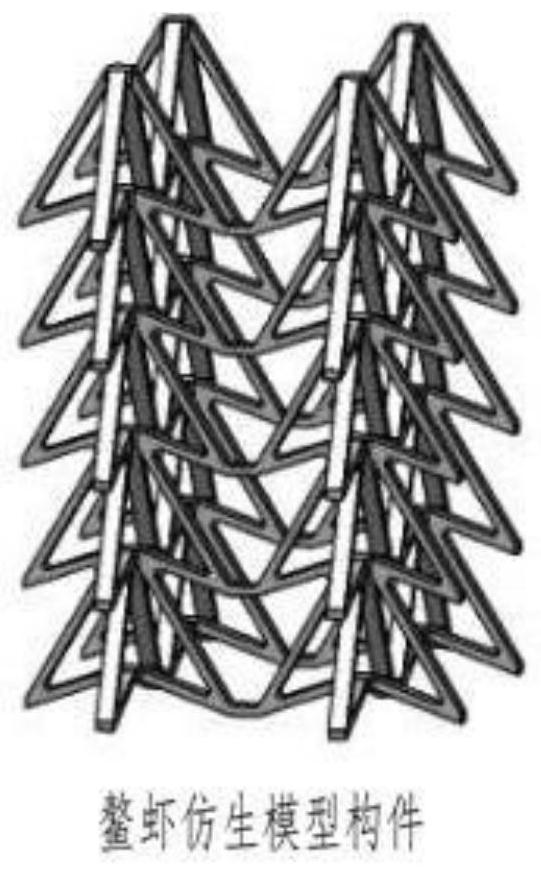

[0110] 3D printing bionic model: BLT-S210 printer performs NiTi powder with a particle size of 15-53 μm 50.8 Ti 49.2 Model laser cladding and printing to manufacture the crayfish bionic model, put the model into the mold and glue it to the middle of the bottom of the mold;

[0111] Preparation of aluminum-basalt composite powder: Mix aluminum powder and basalt fiber powder with a mixing mass ratio of 5:1, and use a high-energy ball mill to ball mill and mix the mixed powder to form composite aluminum cladding powder;

[0112] Then, the powder particles are cleaned with alcohol, and dried to obtain aluminum-basalt composite powder particles;

[0113] Preparation of composite enveloping foaming agent: In order to improve the quality of foam molding, nickel sulfate solution (NiSO 4 ·6H 2 0) When the temperature reaches 80°C, pour the foaming agent TiH2 powder into the solution and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com