A synthetic jet driver driven by a dielectric elastomer and its manufacturing method

A technology of dielectric elastomer and synthetic jet, applied in the direction of fluid using vibration, can solve the problems of small output displacement of the vibration part and low speed of synthetic jet, and achieve the effect of simple structure and control, not easy to fatigue damage and large deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, which are explanations of the present invention rather than limitations.

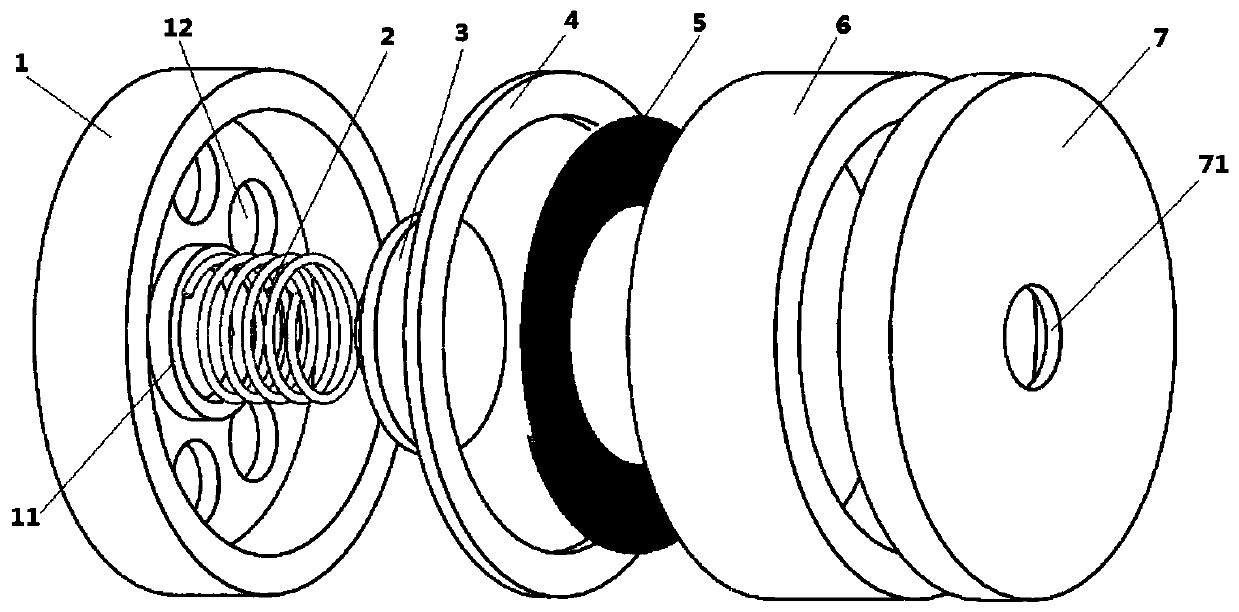

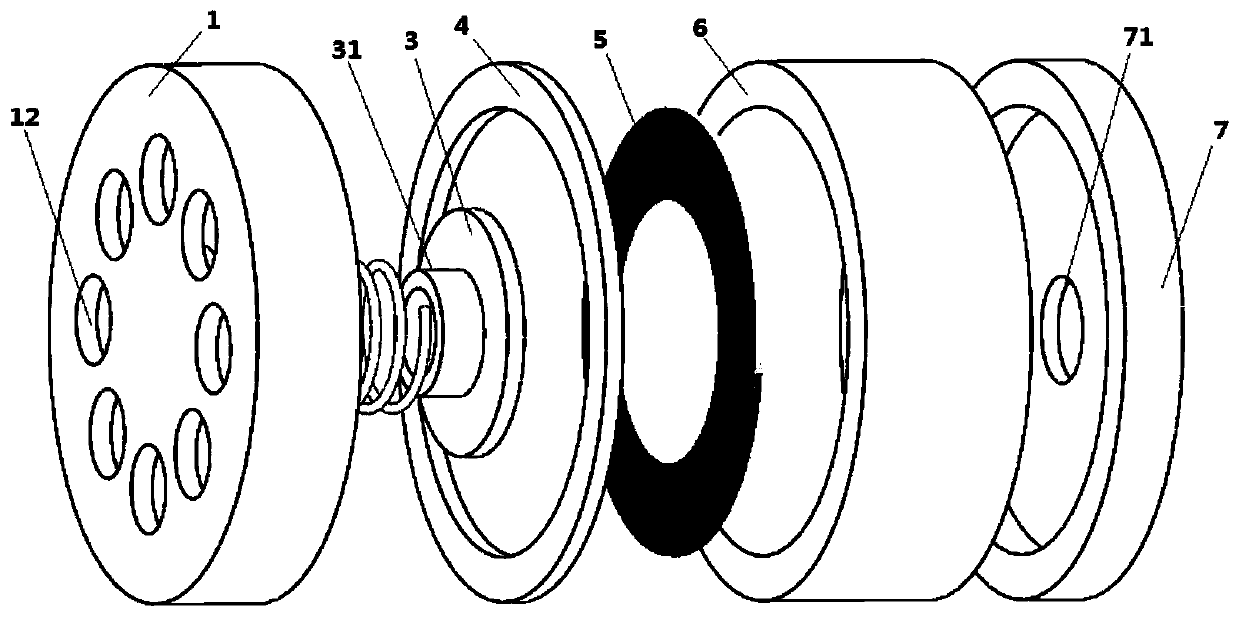

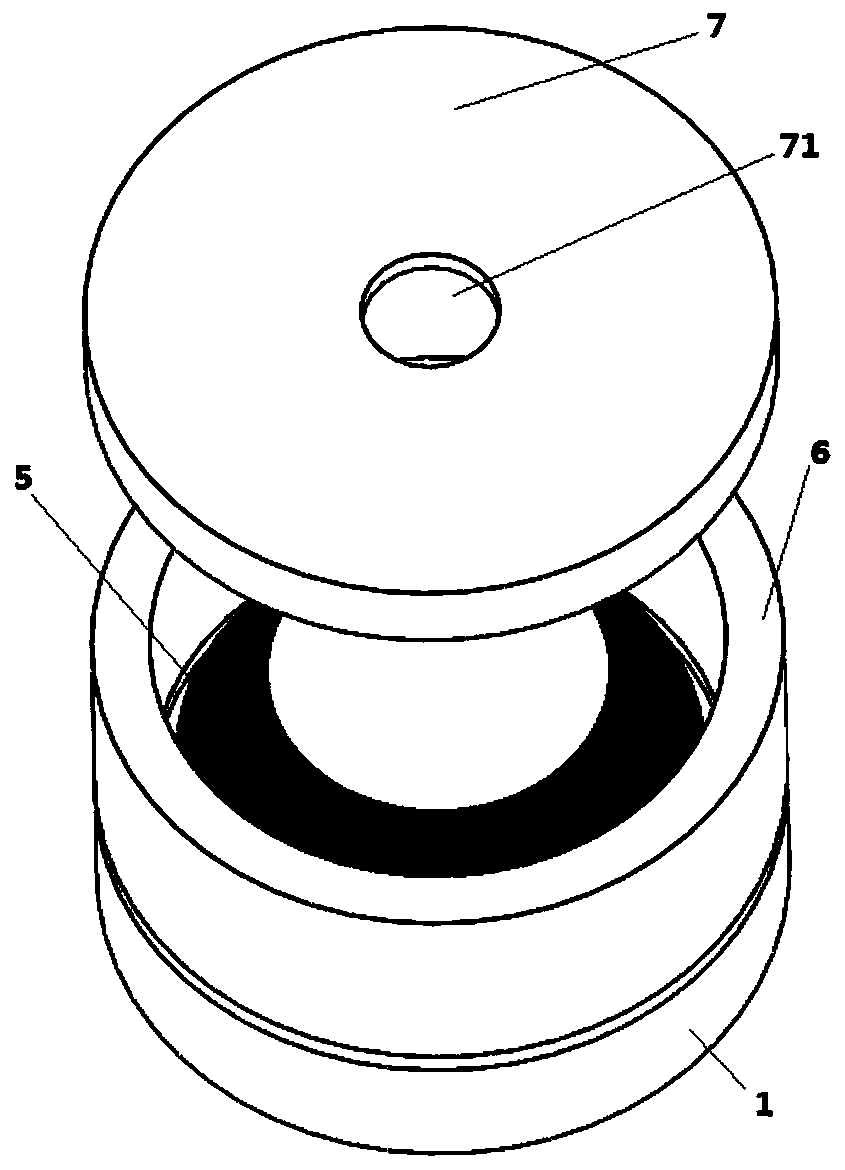

[0030] see Figure 1-2 , The present invention is a synthetic jet driver driven by a dielectric elastomer, including a front cavity 1, a spring 2, a connecting plate 3, a gasket 4, a dielectric elastic film 5, an intermediate ring 6, and a rear cavity 7.

[0031] The front cavity 1 and the rear cavity 7 are hollow cylinders with one end open and one end closed, and the middle ring 6 is a hollow cylinder with two ends open; the openings on both sides of the middle ring 6 are the first open end and the second open end respectively. The open end of the rear cavity 7 is closely connected with the second open end of the middle ring 6, and the first open end of the middle ring 6 is connected with the open end of the front cavity 1; the first open end of the front cavity 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com