Novel intelligent vibration isolation noise reduction composite structure system and usage method thereof

A composite structure and intelligent technology, which is applied to transducers and frequency/directional characteristic devices used underwater, can solve the problems of inability to achieve precise vibration control of mechanical structures, low piezoelectric constants, and small strains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

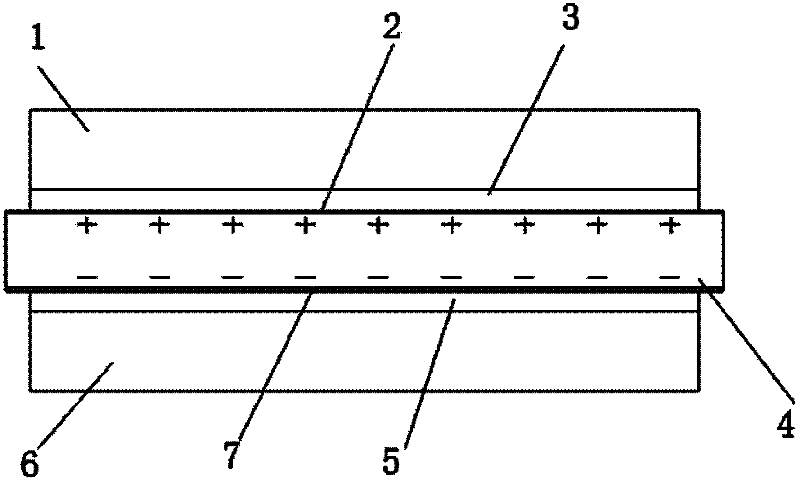

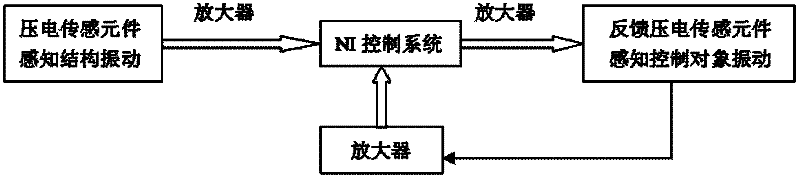

[0024] Such as Figure 1-3 As shown, a new type of intelligent vibration isolation and noise reduction composite structure system includes feedback piezoelectric sensor element 1, upper insulating transition layer 3, upper flexible electrode 2, actuator unit 4, and lower flexible electrode 7 arranged in sequence from top to bottom , the lower insulating transition layer 5 and the piezoelectric sensor element 6, the feedback piezoelectric sensor element 1, the actuator unit 4 and the piezoelectric sensor element 6 are all connected to the controller through lines.

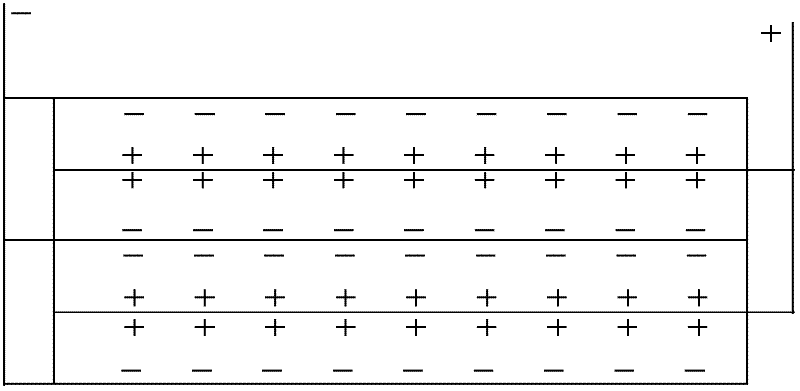

[0025] The actuator unit includes an electric field type electroactive polymer element 4 composed of several layers of electroactive polymer piezoelectric films connected in series. The upper and lower surfaces of the electric field type electroactive polymer element are respectively connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com